Abstract

Oromucosal film preparations have gained popularity in pharmaceutical research and development. Therefore, oral films have been integrated into the monograph “oromucosal preparations” of the European Pharmacopeia in 2012. Regulatory authorities explicitly demand dissolution studies for films, but neither refer to suitable methods nor established specifications. Test methods described in the literature are often limited to immediate release formulations or not applicable to investigate the drug release of films with prolonged release profiles considering the different stages of gastrointestinal transit. The aims of this study were to develop a dissolution test method, which is suitable to investigate the drug release of film preparations with immediate as well as modified release profiles and to explore the potential of the test setup considering some physiological characteristics. Therefore, a conventional flow-through cell was equipped with in-house built sample holders. Three-dimensional printing technology was used for prototyping one of the sample holders. Four different types of films were investigated, such as ODFs with immediate (ODFIR) and prolonged release (ODFPR) characteristics as well as a double-layer film (ODFDL), produced with a water-insoluble shielding layer. Anhydrous theophylline was used as a model drug for all film types. Introducing special fixtures for oral films to a conventional flow-through cell enables successful determination of the drug release behavior of oral film preparations with immediate as well as modified release properties. Investigating ODFDL, the application of film sample holders with backing plates such as film sample holder with backing plate (FHB) and 3D printed film sample holder (FH3D) showed prolonged release profiles with 14.6 ± 1.30% theophylline dissolved within 2 h for FHB compared to 92.9 ± 3.33% for the film sample holder without backing plate (FH). This indicates their suitability to examine the integrity of the shielding layer. The application of the backing plate further decreased the drug release of ODFPR < 315 to 61.0 ± 1.69% dissolved theophylline within 2 h using FHB compared to 82.3 ± 0.74% using FH, due to a reduced ODF surface exposed to the dissolution medium. The potential of the dissolution test setup to consider physiological conditions of the human gastrointestinal transit was investigated by applying different flow rates and media compositions to simulate conditions within the oral cavity, stomach, and intestine. For the application of a low flow rate of 1 ml/min, comparable to the salivary flow within the oral cavity, decreased theophylline release was observed, while similar release profiles were obtained for flow rates between 2 and 8 ml/min. Substantial impact on the theophylline release was exerted by varying the composition of the dissolution medium. Since the drug release from ODFPR is controlled by diffusion through a water-insoluble matrix, ion species and concentration strongly affect the release behavior. In the future, IVIVC studies have to be performed to explore, whether obtained data can be used to predict drug release behavior of ODFs during the human gastrointestinal transit.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

INTRODUCTION

Oromucosal film preparations have gained popularity in pharmaceutical research and development as an alternative dosage form in local and systemic oral drug delivery. According to the literature, oromucosal film preparations can be divided into orodispersible films (ODFs), mucoadhesive buccal films (MBFs), and oromucosal patches (ORPs), depending on their disintegration behavior and residence time in the oral cavity (1).

Until now, oromucosal film preparations have not found their way into the United States Pharmacopeia (USP). Merely, ODFs are mentioned by the Food and Drug Administration (FDA) using the term “soluble films” (2). In 2012, oromucosal film preparations have been integrated into the monograph “oromucosal preparations” of the European Pharmacopeia (Ph.Eur.). This monograph differentiates between MBF, listed within the section “mucoadhesive preparations,” and ODF, holding a separate monograph. But, a clear distinction between MBFs and ODFs is not conveniently possible with the given information, since the monograph does not define any limits and specifications concerning critical quality attributes of this dosage forms. Furthermore, ORPs have not yet been included in the Ph.Eur.

In the literature, the disintegration behavior and the residence time in the oral cavity are often used for classification. MBFs and ORPs are characterized by increased adhesion to the oromucosal epithelium and an increased residence time in the oral cavity to obtain a local or a systemic effect via absorption through the oral mucosa (1,3). Usually, the drug release from ORPs and MBFs is prolonged due to the permanent application or slow disintegration of the polymeric matrix. The application of a second film layer is often described to generate multilayer films with different release rates of the layers or to implement a shielding layer, which facilitates unidirectional drug release and thus buccal absorption of the active substance (4,5,6).

In contrast, ODFs are characterized by rapid disintegration in the oral cavity inducing the deglutition of a large proportion of active substance and thus absorption from the gastrointestinal tract (7). Due to the rapid disintegration, immediate release profiles are often obtained for ODFs (8). However, the incorporation of drug-loaded matrix particles produced via hot-melt extrusion enables prolonged release properties for ODFs (9). Although these ODFs rapidly disintegrate within the oral cavity, prolonged drug release can be obtained throughout the gastric and intestinal transit by drug diffusion through the water-insoluble polymeric matrix after swallowing the individual matrix particles.

The Ph.Eur. explicitly demands dissolution studies for all types of oral film preparations, but suitable test methods are not referred within the monograph (3).

Therefore, dissolution test methods for solid dosage forms described in the Ph.Eur. have often been used for drug release studies of oromucosal film preparations such as the application of the basket apparatus (Ph.Eur./USP apparatus 1) (10,11,12,13), paddle apparatus (Ph.Eur./USP apparatus 2) (13,14,15,16,17), and the flow-through cell (Ph.Eur./USP apparatus 4) (10,18). In a comparative study on dissolution test methods for the investigation of nano- and microparticle-loaded films, Sievens-Figueroa et al. (10) observed an improved discriminatory power for the flow-through cell compared to the basket apparatus. Furthermore, they indicated a high dependence of dissolution profiles obtained using the flow-through cell at different sample positions and medium flow rates.

Due to floating and/or adherence of the films to components of the conventional dissolution apparatuses, which may lead to poor reproducibility, modified dissolution test methods are described in the literature. The paddle apparatus (Ph.Eur./USP apparatus 2) was used in combination with a glass plate (4,5,19), a weight (20) or a wire mesh (21,22) acting as sinker for the film samples, which may reduce floating and unintended adherence to surfaces of the dissolution apparatuses. Two-chamber methods were used to separate the acceptor compartment containing a reservoir of dissolution fluid from the donor compartment containing film samples stored in a decreased volume of dissolution medium, which is in a better agreement with in vivo data of physiological fluid volumes (23,24,25). In addition, the saliva composition (20,21), the salivary flow rate (13,26) or the applied force of the tongue (27) were considered to obtain a more biorelevant test setup.

However, test setups described in the literature are often limited to examine immediate release formulations or only applicable to investigate the drug release of oral films with a specific release profile. Furthermore, biorelevant conditions could only partially be considered by these methods. A complete gastrointestinal transit considering the oral cavity as application site, drug liberation within the stomach, and the intestine as absorption site is not feasible to be simulated with existing methods.

In the present study, the flow-through cell apparatus (USP apparatus 4) was used and supplemented by special fixtures for oral films. Customized film sample holders were designed and constructed by means of 3D printing technology to be inserted into a conventional flow-through cell. Four different film formulations with varying release characteristics were produced, such as ODFs with immediate (ODFIR), slightly prolonged (ODFPR < 315), and clearly prolonged (ODFPR500–715) drug release properties as well as a double-layer ODF (ODFDL) consisting of a drug and a shielding layer. Suitability of the test setup to investigate oral films with different release profiles was examined.

Due to the high flexibility of the flow-through cell apparatus adjusting the medium flow rate and changing the dissolution medium even during ongoing experiments, it might be possible to simulate physiological conditions for the entire gastrointestinal transit starting from the oral cavity to the colon. In order to explore the potential for a biorelevant dissolution testing using the flow-through cell apparatus, the impact of different medium compositions, flow rates, and a combination of both on the dissolution profiles was investigated.

The aims of this study were to develop a dissolution test method to reliably determine the release profiles for oral film formulations with different release properties. It should further be investigated whether it is feasible to implement a test setup considering flow rates and media compositions comparable to physiological conditions during the human gastrointestinal transit.

MATERIALS AND METHODS

Materials

The following materials were used for ODF production: anhydrous theophylline (BASF, Ludwigshafen, Germany), anhydrous glycerol (Caesar and Loretz, Hilden, Germany), hypromellose (HPMC, Pharmacoat® 606, Syntapharm, Mülheim, Germany), ethylcellulose (EC, Aqualon® EC N-22, Ashland, Covington, USA), ammonio methacrylate copolymer type B (Eudragit® RS, Evonik, Essen, Germany), silicon dioxide (Aerosil® 200, Evonik, Essen, Germany), absolute ethanol (Honeywell Riedel-de Haën, Seelze, Germany), and distilled water.

For the dissolution studies, buffer solutions considering physiological pH values and electrolyte composition were used and displayed in Table I. Additionally, a phosphate buffer with a pH value of 6.6 (50 mM) according to USP 36 Theophylline extended release capsules was used as a reference. Absolute ethanol and distilled water were used for the assay.

Production of ODFs

All ODFs were produced by solvent casting technique operating the automatic film applicator Coatmaster® 500 (Erichsen, Hemer, Germany) at a speed of 6 mm/s. Before the examination, ODFs were dried for 12 h at room temperature and stored airtight in sealed aluminum sachets. The drug load of an ODF with the size of 20 × 30 mm was 15 mg anhydrous theophylline.

ODFs with Immediate Theophylline Release

ODFs with immediate release properties (ODFIR) were made from anhydrous theophylline (2.1%), glycerol (6%), HPMC (15%), and distilled water (76.9%). They were manufactured applying a gap width of 1200 μm.

Double-Layer ODFs Containing Theophylline Anhydrous

The drug layer was produced applying a gap width of 800 μm and contained anhydrous theophylline (3.13%), glycerol (6%), HPMC (15%), and distilled water (75.87%). After drying, the second layer, representing the water-insoluble shielding layer, was manufactured by mixing EC (16%), glycerol (4%), and ethanol absolute (80%). The shielding layer was cast with a gap width of 400 μm directly on top of the drug layer.

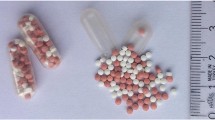

ODFs with Prolonged Theophylline Release (9)

ODFs with prolonged release properties (ODFPR) were manufactured by incorporating theophylline-loaded matrix particles (MPs) produced via hot-melt extrusion into the ODF-forming polymer solution. MPs consisted of anhydrous theophylline (30%), silicon dioxide (0.5%), and Eudragit® RS (69.5%). After preparing the ODF-forming polymer solution, consisting of HPMC (15%), anhydrous glycerol (6%), and distilled water (72.06%), MPs (6.94%) were added and the ODFs were produced with a gap width of 1200 μm. ODFPR < 315 contained MPs with a size of less than 315 μm, characterized by moderately prolonged theophylline release. MPs with a size of 500 up to 715 μm, characterized by strongly prolonged theophylline release, were used for the preparation of ODFPR500–715.

ODF Characterization

Thickness and Weight

A micrometer screw (IP65, Mitutoyo, Neuss, Germany) modified by mounting a plate (6 cm2) at each end of the measurement area was used to determine the film thickness (n = 10). During the measurement, ODFs were clamped in between these two plates and their maximum thickness was determined. The measurement range of the screw is from 0 to 25 mm with an accuracy of 0.001 mm. The mass of ODFs (n = 10) with a size of 6 cm2 was determined using an analytical balance (CP224S, Sartorius, Göttingen, Germany) with a maximum measurement value of 220 g and an accuracy of 0.1 mg.

Disintegration Time

Disintegration time of ODFs (n = 6) was investigated using the automated PharmaTest® disintegration tester (PTZ AUTO EZ, PharmaTest® Apparatebau, Hainburg, Germany) equipped with a film sample holder and weights of 3 g (PT-ODF test basket, PharmaTest® Apparatebau, Hainburg, Germany) in 900 ml distilled water at 37 ± 0.5°C (28).

Dissolution

Dissolution Test Setup

An automated flow-through cell apparatus (CE7 smart, Sotax, Aesch, Switzerland) according to USP type 4 was operated in closed-loop by means of a peristaltic pump (Ismatec® IPC, Cole-Parmer, Wertheim, Germany). The flow-through cell was connected to a paddle apparatus (USP type 2, AT7, Sotax) applying a rotational speed of 50 rpm, which was used as a temperature-controlled medium reservoir. UV spectroscopy (Lambda 25/Lambda 40, Perkin Elmer, Waltham, USA) was used to measure the theophylline concentration online in a resolution of 60 s for a total time of 1000 min at λmax of 271 nm. Since each flow-through cell was connected to a separate vessel filled up with preheated and constantly stirred dissolution medium, the risk of an inhomogeneous theophylline concentration in the medium reservoir and thus incorrect UV spectroscopic measurements was minimized. The total fluid volume within the inlet- and outlet tubes was 16.2 ± 0.06 ml. The test setup is schematically represented in Fig. 1.

The flow-through cell apparatus was equipped with six cells of 22.6 mm in diameter. Each cell contained a valve ball of 5 mm in diameter and a bed of 7.6-g glass spheres with a diameter of 1 mm to ensure a laminar medium flow (Fig. 2). The upper part of the cell was separated from the sample chamber using a cellulose nitrate membrane filter with a pore size of 1 μm and a diameter of 25 mm (GE Healthcare UK, Amersham Place, UK) to avoid unsolved sample particles being flushed out. The fluid volume inside the cells sample chamber was reduced from 16.7 ± 0.04 to 14.3 ± 0.06 ml adding the glass spheres.

Sample Holder for Oral Film Preparations

Three different types of the sample holder for oral film preparations were designed and constructed in-house to be used in commercial USP4 flow-through cells with a diameter of 22.6 mm. The use of a film sample holder can prevent floating, sticking together, and adherence of the film to the chamber wall, by keeping the film in a constant position inside the sample chamber during dissolution testing. Furthermore, it allows a homogeneous rinsing of the film by dissolution medium.

Customized Film Sample Holder

The basic structure of the film sample holder (FH) is made of plexiglas and the clamping device to fix the oral films is made of polyvinyl chloride (PVC). A schematic representation is displayed in Fig. 3. The FH has a height of 30 mm and a width of 22.6 mm and fits exactly in the sample chamber of a commercial USP4 flow-through cell. Before dissolution testing, the FH needs to be manually inserted. The mounted clamping device is constructed for oral films with a maximum size of 20 × 30 mm.

Customized Film Sample Holder with Backing Plate

The design of the film sample holder with backing plate (FHB) is similar to the FH. But the FHB is constructed with an additional backing plate, at which one side of the oral film can be attached using adhesive tape. Figure 4 demonstrates a schematic representation of the sample holder. The dissolution medium homogeneously rinses one side of the film, while the other side is protected by the backing plate. This could be used to mimic the adhesion of the film to the oral mucosa. In case of multilayer films produced with a shielding layer to induce unidirectional drug release, the FHB could be utilized to examine the integrity of the shielding layer by fixing the drug layer to the backing plate, while the shielding layer is exposed to the dissolution medium.

3D Printed Film Sample Holder

The 3D printed film sample holder (FH3D) was designed using Inventor® Professional 2016 Software (Autodesk®, San Rafael, USA). The G-code for the 3D printing was generated with the open source software Slic3r (version 1.2.9). The FH3D was 3D printed from commercial PLA-filaments (Prodim, Helmond, The Netherlands) using the 3D printer Prodim XXL Pro (Prodim, Helmond, The Netherlands). A schematic drawing of the FH3D is displayed in Fig. 5. Oral films can easily be inserted into the internal opening and fixed with one side to the FH3D rear panel using adhesive tape and therefore simulating the adherence of the film to the oral mucosa. The external dimensions of the FH3D permit a precise fit into the flow-through cell. Applying the FH3D, the operative volume in the flow-through cell will be further reduced from 14.3 ± 0.06 ml to 3.2 ± 0.02 ml, which is comparable to in vivo data of the human saliva volume and flow rate (29,30,31).

Comparison and Suitability of Film Sample Holders for the Investigation of Different Oral Film Preparations

For the comparative study, the three different types of film sample holders (FH, FHB, FH3D) were evaluated regarding their suitability for dissolution testing of ODFs with varying drug release properties such as ODFIR, ODFPR < 315, ODFPR500–715, and ODFDL. Therefore, the flow-through cell apparatus was operated with a flow rate of 8 ml/min and a medium reservoir of 1000 ml phosphate buffer with a pH value of 6.6, applying the previously mentioned test setup in combination with the film sample holders. In the case of FHB and FH3D, the ODFs were attached by adhesive tape tesa® 51570 (Tesa, Norderstedt, Germany) to the backing plates. ODFDL was fixed to the FH3D by positioning the drug layer to the backing plate, while the shielding layer is exposed to the dissolution medium. All experiments were performed in triplicate under sink conditions.

Investigation of Influencing Variables

The influence of the flow rate and the media composition on the dissolution behavior of ODFPR500–715 was investigated using the flow-through cell method in combination with the FH3D sample holder. ODFsPR500–715 values were attached to the backing plate of FH3D by adhesive tape tesa® 51570. All experiments were performed in triplicate under sink conditions.

Impact of Flow Rate

To investigate the impact of different flow rates on the release behavior, the flow rate was adjusted from 1 ml/min simulating the saliva flow within the oral cavity to 2 and 6 ml/min mimicking physiological flow rates of the intestinal and gastric fluid, respectively. Additionally, a flow rate of 8 ml/min was applied, which is typically used for dissolution testing according to the Ph.Eur. The medium reservoir was filled up with 1000 ml phosphate buffer with a pH value of 6.6 at 37 ± 0.5°C.

Impact of Media Composition and pH Values

Within this study, the use of artificial saliva with a pH value of 7.35, artificial gastric fluid with a pH value of 1.2, and artificial intestine fluid with a pH value of 6.8 as dissolution medium was explored, each with a capacity of 1000 ml within the medium reservoir. For all experiments, the flow rate was kept constant at 8 ml/min.

Implementation of a Dissolution Test Setup Combining Medium Exchange and Flow Rate Adaption

For a dissolution test of ODFPR500–715 combining medium exchange and flow rate adaption during ongoing dissolution tests, the flow-through cell method was used and the FH3D was applied. ODFsPR500–715 values were attached by adhesive tape to the backing plate of the FH3D. The experiment was performed in triplicate under sink conditions.

To simulate conditions of the oral cavity, the flow-through cell apparatus was operated for 3 min in open-loop with artificial saliva (pH 7.35) applying a flow rate of 1 ml/min. For the entire time interval, the whole volume of artificial saliva needed for the test (approximately 3 ml) was collected, weighed, and their theophylline concentration was determined offline.

After 3 min of simulating the conditions of the oral cavity, the dissolution medium within the reservoir was exchanged by 600 ml artificial gastric fluid with a pH value of 1.2 at 37 ± 0.5°C. The flow rate was adapted to 6 ml/min and the flow-through cell apparatus was operated for 120 min in closed-loop to mimic the conditions of the stomach.

To simulate the conditions of the intestine, a second medium change to artificial intestine fluid (600 ml; 37 ± 0.5°C) was performed and the flow rate was adjusted to 2 ml/min in closed-loop. These settings were retained for 880 min.

Determination of the Residual Theophylline Content

The residual theophylline content of both types of ODFPR after dissolution was determined UV photometrically (Lambda 25, Perkin Elmer, Waltham, USA) at λmax of 271 nm by dissolving the remaining MPs in 200 ml ethanol 70% (w:w). All measurements were performed in triplicate.

RESULTS AND DISCUSSION

ODF Characterization

In order to draw conclusions about the relation between ODF properties and dissolution behavior, all produced formulations were characterized regarding their thickness, mass, and disintegration time. The results of ODF characterization are summarized in Table II. In addition to the combined films ODFDL, both adjacent layers (drug and shielding layer) were assessed separately.

Thicknesses and masses are similar for ODFIR and ODFDL. In comparison, thicknesses and masses of ODFPR are increased due to the incorporation of MPs.

Except for ODFDL, all produced ODFs were disintegrated rapidly in less than 60 s. Considering a disintegration time threshold of 30 s defined by the FDA for orodispersible tablets, only one out of four investigated formulations would fulfill the requirement. However, the Ph.Eur. defines a disintegration time limit of 180 s for orodispersible tablets, which would be fulfilled by all formulations, except for ODFDL, which is not intended to be rapidly disintegrated. However, the separated drug layer shows fast disintegration in less than 30 s.

Comparison and Suitability of Film Sample Holders for the Investigation of Different Oral Film Preparations

The new dissolution method based on the USP type 4 flow-through cell apparatus was developed to reliably investigate oral film preparations with different drug release properties. To avoid dosage form–related problems as floating, sticking together, or adhering to the wall of the sample chamber, special film sample holders keeping the film in a constant position inside of the cell, while fully wetting the surfaces, were developed and applied to the flow-through cell method. The obtained dissolution profiles for ODFs with immediate and modified release properties applying the different types of film sample holders are displayed in Fig. 6. Table III additionally presents percentages of the labeled amount of anhydrous theophylline dissolved at defined points in time and the corresponding MDT50% values.

Dissolution profiles of (a) ODFIR, (b) ODFPR < 315, (c) ODFPR500–715, and (d) ODFDL obtained applying the three different types of film sample holders: FH (dark gray), FHB (light gray), and FH3D (black) and 1000 ml phosphate buffer pH 6.6 (37 ± 0.5°C) within the medium reservoir in closed-loop with a flow rate of 8 ml/min and online UV photometrical detection at 271 nm; mean ± sd (n = 3)

ODFs with Immediate Theophylline Release

The dissolution profiles of ODFIR are demonstrated in Fig. 6a. Investigating the drug release behavior of ODFIR applying the three different film sample holders, all obtained dissolution profiles show more than 80% theophylline released in 60 min, which complies with the FDAs definition of immediate release formulations (32). Using FH3D, rapid and complete (t80% < 20 min) theophylline release and low variability is observed. Decreased release rates and increased variability is observed applying FH and FHB. Fixing the ODF to the clamping device of FH and FHB, which inhibits the dissolution medium to homogeneously rinse the ODF, could be the reason for the increased variabilities. Using FHB, the requirements for immediate release dosage forms defined by the FDA are just met with nearly 80% theophylline released in 45 min. The decreased release rate applying FHB could be explained by the backing plate, at which one site of the ODF is adhered to by adhesive tape reducing the contact area between ODF surface and dissolution medium.

ODFs with Prolonged Theophylline Release

In Fig. 6b, the dissolution profiles of ODFPR315 using different sample holders are displayed. As expected, the drug release of ODFPR < 315 is prolonged by up to 23 min (t50% of ODFPR < 315 = 44 min for FHB) compared to ODFIR (t50% of ODFIR = 21 min for FHB). Whereas the application of FH and FH3D show similar dissolution profiles, the drug release prolongation is stronger using FHB. The burst effect is caused by theophylline particles, located at the surface of the MPs, and the release rate are reduced, applying the FHB. This effect is not observed for FH3D, which is also constructed with a backing plate, leading to the assumption that the application of a backing plate is not the sole reason for the drug release prolongation using FHB. The combined use of a backing plate and a clamping device implemented for FHB may lead to a reduction of the contact area between ODF and dissolution medium and an inhibition of dissolution medium constantly rinsing the ODF as well as a facilitated occurrence of air bubbles, which in total might explain the decreased release rate.

The results investigating the drug release of ODFPR500–715 are demonstrated in Fig. 6c. The flow-through cell method is particularly suitable to investigate films with prolonged release properties as demonstrated by the clearly prolonged dissolution curves. Here, the application of a sample holder, keeping the film in a constant position, affects the beginning of the dissolution testing, until the ODFs are disintegrated. Over the entire investigation period, similar dissolution profiles were obtained for ODFPR500–715, independent of the applied sample holder.

Double-Layer ODFs Containing Theophylline Anhydrous

Figure 6d demonstrates dissolution profiles of ODFDL obtained using the different sample holders.

In contrast to the previously investigated ODFs, ODFDL is constructed with a shielding layer, which is usually implemented to reduce dispersion of the drug into the oral cavity and to induce buccal absorption of the drug. To test the integrity of the shielding layer, dissolution test methods considering specific setups have to be used.

Using FH to investigate ODFDL, which was constructed without a backing plate fixing one side of the ODF, an immediate release profile was observed with 82.4 ± 8.78% released theophylline in 45 min. Both sides of ODFDL were exposed to the dissolution medium, impeding FH to test the integrity of shielding layers. FHB was produced with a backing plate. The drug layer of ODFDL was fixed to the backing plate, while the shielding layer was directed to the dissolution medium. Using FHB, the dissolution profile of ODFDL is strongly prolonged following zero-order kinetics for nearly the entire investigation period of 1000 min. Drug release was controlled by diffusion through the shielding layer and also appeared from the uncovered sides of the drug layer. Applying FH3D, which also comprises a backing plate the ODF can be attached to, the beginning of the release profile is similar to the profile, obtained using FHB. But the release rate rapidly increases after a dissolution time of approximately 500 min, indicating that ODFs were detached from the backing plate of FH3D.

In the literature, investigation periods for in vitro dissolution tests of up to 14 h are described for buccal patches and hot-melt extruded oral films (33,34,35,36,37). However, a maximum residence time of 30 min is described for multilayer buccal films, which are available on the market and which are especially designed for a prolonged application period (38,39). To evaluate the results concerning a sufficient investigation period for the dissolution test, the acceptance of a prolonged residence time in the oral cavity should be examined demonstrating a potential restraining factor for the application of oral films. Attaching ODFs to the backing plate of FHB and FH3D using adhesive tape, ODFs have been wetted from one side only, while ODFs are placed onto the tongue and stuck to the upper palate during in vivo application. This induced the ODFs being wetted from both sides, whereby the attached side is only wetted by the thin salivary layer of the oral mucosa. In future experiments, film sample holders lined with (artificial) mucosa instead of adhesive tape should be used to ensure that ODFs are being attached to the backing plate and being wetted from both sides. Test methods described in literature use esophageal porcine mucosa (40) or artificial mucous materials such as gelatin gels or compacted mucin material (41), which could be applied for further dissolution tests considering certain biorelevant test conditions.

Investigation of Influencing Variables

The investigation of influencing variables was performed to assess the impact of different flow rates pH values and fluid compositions on the release behavior. The results are further valuable to explore the potential of the instrumental test setup, simulating physiological conditions during the gastrointestinal transit. The experiments were conducted using ODFPR500–715, since this type of ODF was designed to pass complete gastrointestinal transit. The oral cavity, thereby, represents the application site, while drug liberation and absorption will mainly take place within the stomach and intestine after swallowing the water-insoluble matrix particles of ODFPR500–715. Due to the limitation of the operative volume inside the sample chamber to approximately 3 ml, which is in a better agreement to physiological saliva volumes, FH3D was applied to the test setup.

Impact of Flow Rate

The influence of different flow rates on the release behavior of ODFPR500–715 was investigated operating the flow-through cell equipped with FH3D. The dissolution profiles are displayed in Fig. 7. Percentages of released theophylline at specific points in time and MDT50% values are summarized in Table III.

Dissolution profiles of ODFPR500–715 obtained operating the flow-through cell equipped with the FH3D and 1000 ml phosphate buffer pH 6.6 (37 ± 0.5°C) within the medium reservoir in closed-loop with online UV photometrical detection at 271 nm applying different flow rates of 1, 2, 6, 8, and 16 ml/min; mean ± sd (n = 3)

With decreasing medium flow, the release rate decreases, resulting in increased MDT50% values. This effect was most pronounced adjusting a flow rate of 1 ml/min. Here, the theophylline release was incomplete after 1000 min and the release rate was clearly decreased compared to flow rates of 2 up to 16 ml/min. Applied release rates of 2 up to 16 ml/min only show minor differences within the resulting dissolution profiles, rather than resulting from a decreased burst effect. The burst effect, caused by theophylline particles located at the surface of MPs, slightly decreases with decreasing flow rates. This could be explained by the instrumental setup comprising a relatively high residual volume of dissolution medium within the tubes. At low flow rates, the circulation of dissolution fluid through the tubes facilitates a systematic delay in the theophylline concentration detection. Furthermore, mixing of dissolution medium within the tubes could further affect the detected drug release. A certain tube volume is necessary to operate flow-through methods, which has to be considered evaluating the drug release behavior especially at low flow rates.

Impact of Media Composition and pH Values

In Fig. 8 dissolution profiles and in Table III, the percentages of dissolved theophylline at specific points in time as well as MDT50% values of ODFPR500–715 investigated using different dissolution fluids are compared. The different dissolution media used for the experiments showed pH values in the range of relevant physiological fluids. The composition represents a simplified model of the complex physiological fluid composition and only considers ion species and strengths.

Dissolution profiles of ODFPR500–715 obtained operating the flow-through cell equipped with the FH3D in closed-loop applying a flow rates of 8 ml/min with online UV photometrical detection at 271 nm and 1000 ml of different dissolution media (artificial saliva, artificial gastric fluid, and artificial intestine fluid; 37 ± 0.5°C) within the medium reservoir; mean ± sd (n = 3)

Dissolution behavior is mainly controlled by drug diffusion through the MPs consisting of the cationic acrylic copolymer Eudragit® RS. The permeability of Eudragit® RS sis a function of the anionic species contained in the dissolution medium by chloride ion exchange (42,43,44). As consequence, the anionic species used for the buffer solution influences the drug release behavior.

In artificial saliva (25 mM) with a pH value of 7.35 theophylline release is slightly accelerated with a MDT50% value of 39.0 min compared to MDT50% value of 48.3 min for dissolution studies in artificial intestine fluid (50 mM) with a pH value of 6.8. Both buffer solutions contain phosphate ions as anionic buffer species but in different molar concentrations, which could cause the slight differences in the dissolution profiles.

In artificial gastric fluid (pH 1.2), theophylline release is prolonged with a MDT50% value of 102.9 min. Due to chloride ions within the artificial gastric fluid, the permeability and thus drug release are decreased compared to the drug release in artificial saliva and intestine fluid. These fluids contain phosphate ions as anionic buffer species, which clearly increase the permeability of the Eudragit® RS matrix.

Implementation of a Dissolution Test Setup Combining Medium Exchange and Flow Rate Adaption

The flow-through cell method in combination with the FH3D was developed to investigate the dissolution behavior of ODFs with immediate as well as modified release properties. For dissolution testing combining medium exchange and flow rate adaption for ODFs with prolonged drug release, the oral cavity representing the application site as well as liberation and absorption within stomach and intestine should be imitated. Due to its ability of easily changing the dissolution medium and adjusting the flow rates during ongoing experiments, the flow-through cell method could be used for dissolution testing considering physiological conditions. The dissolution profile of ODFPR500–715 investigated performing two media exchanges and adaptations of flow rates within the dissolution process is displayed in Fig. 9.

Dissolution profile of ODFPR500–715 analyzed using a dissolution test setup combining medium exchange and flow rate adaption: flow-through cell equipped with FH3D in artificial saliva for 3 min in open-loop at 1 ml/min, in artificial gastric fluid (37 ± 0.5°C) for 120 min in closed-loop (600 ml artificial gastric fluid within the medium reservoir) at 6 ml/min and in artificial intestine fluid (37 ± 0.5°C) for 880 min in closed-loop (600 ml artificial intestine fluid within the medium reservoir) at 2 ml/min; offline (open-loop) and online (closed-loop) detection at 271 nm; mean ± sd (n = 3)

To simulate conditions of the oral cavity, the flow-through cell apparatus was operated for 3 min, which complies with the residence time of ODFs in the oral cavity considering a rapid disintegration of ODFPR500–715 (27.0 ± 5.6 s), a stimulated deglutition frequency of 3.5 to 5.3 swallows in 2 min and a swallowed saliva volume of 0.96 to 1.19 ml (45,46). In vitro, salivary flow rates of 0.3 to 1.4 ml were observed (47,48,49). Thus, the flow rate to simulate salivary flow was adjusted to 1 ml/min. As dissolution medium, a preheated (37 ± 0.5°C) phosphate buffer solution with a pH value of 7.35 and an ion concentration of 25 mM similar to human saliva was used (27). FH3D was used to reduce the operative volume within the sample chamber to approximately 3 ml, which is comparable to in vivo data of the human stimulated saliva volume (29,30,31). Furthermore, ODFs were attached to the backing plate of FH3D to mimic the adhesion to the oral mucosa after ODF application in the oral cavity. Applying the described test setup, a maximum theophylline release of 1.3 ± 0.7% was observed for ODFPR500–715 within 3 min.

However, the flow-through cell method, used to mimic conditions of the oral cavity, could further be improved. Due to the relatively high residual tube volume, which causes a delay in drug release detection especially at low flow rates, the flow-through cell method is inappropriate to investigate ODFs showing fast and high drug release within the first 3 min. Thus, an UV fiber optical probe could be installed directly above the membrane filter at the upper part of the flow-through cell to monitor the drug release inline without time delay. Furthermore, to mimic adhesion of ODFs in the oral cavity and to ensure that ODFs are being wetted from both sides, (artificial) mucosa could be used to line the backing plate of FH3D, at which the ODFs were attached during dissolution testing.

To mimic gastric conditions, the dissolution medium was changed to an artificial gastric fluid with a pH value of 1.2 considering a physiological concentration of sodium chloride and the flow rate was adjusted to 6 ml/min, which is comparable to in vitro data (50,51). The gastric transit time was found to be in a wide range depending on the size, shape, and consistency of the swallowed dosage form (50,52). Therefore, an investigation time of 120 min was assumed according to the gastric transit time recommended by the Ph.Eur. In the beginning, accelerated drug release of approximately 25% released theophylline in less than 30 min was observed due to increased solubility of theophylline at low pH values and an increased medium flow. At the end of the investigation period, approximately 28% theophylline was released, indicating a clearly decreased rate controlled by diffusion through the Eudragit® RS matrix.

After a second medium change, conditions of the intestine were simulated by using artificial intestine fluid with a pH value of 6.8 as dissolution medium and applying a flow rate of 2 ml/min (53,54). Theophylline release was almost linear and clearly prolonged over the entire investigation period. Furthermore, drug release was not completed within the investigation period of 1000 min. These effects are caused by a decreased flow rate applied for dissolution testing simulating the small intestine and a drug release mechanism, which is completely controlled by the diffusion of theophylline through the Eudragit® RS matrix. Theophylline particles located at the MPs surface causing the burst effect were already dissolved.

CONCLUSION

Within this study, a dissolution test method has been provided which allows successful investigation of oral film preparations with immediate as well as modified release properties.

Therefore, a commercial USP type 4 flow-through cell was equipped with three different types of in-house built film sample holders keeping the film in a constant position inside of the cell. The application of film sample holders constructed with a backing plate such as FHB and FH3D led to decreased release rates for ODFDL, indicating their suitability to examine the integrity of the shielding layer, which is used to facilitate unidirectional drug release. The application of FHB further decreased the drug release of ODFIR and ODFPR < 315 compared to FH. This is due to a reduced ODF surface exposed to the dissolution medium, which is better compared to their in vivo application, since one site of the ODF should be attached to the oral mucosa. The potential of the dissolution test setup to consider physiological conditions of the human gastrointestinal transit was investigated by applying different flow rates and media compositions to simulate conditions within the oral cavity, stomach, and intestine. Drug release studies were performed using FH3D, since the application of FH3D reduces the operative volume inside the sample chamber to approximately 3 ml, which is in a better agreement to physiological saliva volumes. The application of a low flow rate of 1 ml/min, comparable to the salivary flow within the oral cavity, showed decreased theophylline release, while similar release profiles were obtained for flow rates between 2 and 8 ml/min. This information is of high interest for the development of oral films intending buccal absorption of the drug, since a reduced amount of drug dissolved in the oral cavity could be directly correlated to decreased oromucosal absorption. However, the acceptance of ODF could be improved, since a reduced amount of drug dissolved in the oral cavity also reduces the taste of the drug. Substantial impact on the theophylline release was exerted by varying the composition of the dissolution medium. Since the drug release from ODFPR is controlled by diffusion through a water-insoluble matrix, ion species and concentration strongly affect the release behavior. In the future, in vivo studies need to be performed to explore, whether the obtained dissolution profiles are comparable to in vivo data to predict drug release behavior of ODFs during the human gastrointestinal transit. Dissolution testing under consideration of physiological conditions offers an analytical instrument to further evaluate dissolution-related issues in the field of pharmaceutical research and development such as assessment of drug permeation and taste.

References

Preis M, Woertz C, Kleinebudde P, Breitkreutz J. Oromucosal film preparations: classification and characterization methods. Expert Opin Drug Deliv. 2013;10(9):1303–17.

FDA. Data standards of structured product labeling 2012 Available from: http://www.fda.gov/ForIndustry/DataStandards/StructuredProductLabeling/ucm162038. Accessed 03 July 2018.

Pharmacopoeia E. Oromucosal preparations. Strasbourg, France: European Directorate for the Quality of Medicines (EDQM) 2016.

Preis M, Woertz C, Schneider K, Kukawka J, Broscheit J, Roewer N, et al. Design and evaluation of bilayered buccal film preparations for local administration of lidocaine hydrochloride. Eur J Pharm Biopharm. 2014;86(3):552–61.

Shidhaye SS. Mucoadhesive bilayered patches for administration of sumatriptan succinate. AAPS PharmSciTech. 2008;9(3):909.

Puratchikody A, Prasanth VV, Mathew ST, Kumar BA. Development and characterization of mucoadhesive patches of salbutamol sulfate for unidirectional buccal drug delivery. Acta Pharma. 2011;61(2):157–70.

Hoffmann E, Breitenbach A, Breitkreutz J. Advances in orodispersible films for drug delivery. Expert Opin Drug Deliv. 2011;8(3):299–316.

Krampe R, Visser JC, Frijlink HW, Breitkreutz J, Woerdenbag HJ, Preis M. Oromucosal film preparations: points to consider for patient centricity and manufacturing processes. Expert Opin Drug Deliv. 2016;13(4):493–506.

Speer I, Preis M, Breitkreutz J. Prolonged drug release properties for orodispersible films by combining hot-melt extrusion and solvent casting methods. Eur J Pharm Biopharm. 2018;129:66–73.

Sievens-Figueroa L, Pandya N, Bhakay A, Keyvan G, Michniak-Kohn B, Bilgili E, et al. Using USP I and USP IV for discriminating dissolution rates of Nano- and microparticle-loaded pharmaceutical strip-films. AAPS PharmSciTech. 2012;13(4):1473–82.

Low AQJ, Parmentier J, Khong Y, Chai CCE, Tun T, Berania J, et al. Effect of type and ratio of solubilising polymer on characteristics of hot-melt extruded orodispersible films. Int J Pharm. 2013;455(1–2):138–47.

El-Mahrouk GM, El-Gazayerly ON, Aboelwafa AA, Taha MS. Chitosan lactate wafer as a platform for the buccal delivery of tizanidine HCl: in vitro and in vivo performance. Int J Pharm. 2014;467(1):100–12.

Adrover A. In vitro dissolution testing of oral thin films: a comparison between USP 1, USP 2 apparatuses and a new millifluidic flow-through device. Chem Eng Res Des. 2015;95:173.

Shen B-d, Shen C-y, Yuan X-d, Bai J-x, Lv Q-y, Xu H, et al. Development and characterization of an orodispersible film containing drug nanoparticles. Eur J Pharm Biopharm. 2013;85(3, Part B):1348–56.

Shimoda H, Taniguchi K, Nishimura M, Matsuura K, Tsukioka T, Yamashita H, et al. Preparation of a fast dissolving oral thin film containing dexamethasone: a possible application to antiemesis during cancer chemotherapy. Eur J Pharm Biopharm. 2009;73(3):361–5.

Garsuch V, Breitkreutz J. Novel analytical methods for the characterization of oral wafers. Eur J Pharm Biopharm. 2009;73(1):195–201.

Cilurzo F, Cupone I, Minghetti P, Selmin F, Montanari L. Fast dissolving films made of maltodextrins. Eur J Pharm Biopharm. 2008;70(3):895–900.

Sievens-Figueroa L, Bhakay A, Jerez-Rozo JI, Pandya N, Romañach RJ, Michniak-Kohn B, et al. Preparation and characterization of hydroxypropyl methyl cellulose films containing stable BCS class II drug nanoparticles for pharmaceutical applications. Int J Pharm. 2012;423(2):496–508.

Furtado S, Bharath S, Basavaraj BV, Abraham S, Deveswaran R, Madhavan V. Development of chitosan based bioadhesive bilayered patches of metoprolol tartarate. Development. 2010;4(3):032.

Okamoto H, Taguchi H, Iida K, Danjo K. Development of polymer film dosage forms of lidocaine for buccal administration: I. penetration rate and release rate. J Control Release. 2001;77(3):253–60.

Mashru RC. Development and evaluation of fast-dissolving film of salbutamol sulphate. Drug Dev Ind Pharm. 2005;31(1):25.

Juliano C, Cossu M, Pigozzi P, Rassu G, Giunchedi P. Preparation, in vitro characterization and preliminary in vivo evaluation of buccal polymeric films containing chlorhexidine. AAPS PharmSciTech. 2008;9(4):1153–8.

Li C, Bhatt PP, Johnston TP. In vitro release and permeation of oxytocin from a mucoadhesive buccal patch. Pharm Dev Technol. 1996;1(4):357–64.

Park D-M, Song Y-K, Jee J-P, Kim HT, Kim C-K. Development of chitosan-based ondansetron buccal delivery system for the treatment of emesis. Drug Dev Ind Pharm. 2012;38(9):1077–83.

del Consuelo ID, Falson F, Guy RH, Jacques Y. Ex vivo evaluation of bioadhesive films for buccal delivery of fentanyl. J Control Release. 2007;122(2):135–40.

Xia Y. A new method for evaluating the dissolution of orodispersible films. Pharm Dev Technol. 2015;20(3):375.

Krampe R, Sieber D, Pein-Hackelbusch M, Breitkreutz J. A new biorelevant dissolution method for orodispersible films. Eur J Pharm Biopharm. 2016;98(Supplement C):20–5.

Beilke D, Preis M. Zerfallsprüfung von Schmelzfilmen. TechnoPharm. 2014;4(Nr. 6):334–7.

Shannon TL. Parotid fluid flow rate as related to whole saliva volume. Arch Oral Biol. 1962;7(3):391–4.

Watanabe S, Ohnishi M, Imai K, Kawano E, Igarashi S. Estimation of the total saliva volume produced per day in five-year-old children. Arch Oral Biol. 1995;40(8):781–2.

Humphrey SP, Williamson RT. A review of saliva: normal composition, flow, and function. J Prosthet Dent. 85(2):162–9.

Shah V, Lesko L, Fan J, Fleischer N, Handerson J, Malinowski H, et al. FDA guidance for industry: dissolution testing of immediate release solid oral dosage forms. Dissolution Technol. 1997;4:15–22.

Repka MA, Gutta K, Prodduturi S, Munjal M, Stodghill SP. Characterization of cellulosic hot-melt extruded films containing lidocaine. Eur J Pharm Biopharm. 2005;59(1):189–96.

Perioli L, Ambrogi V, Angelici F, Ricci M, Giovagnoli S, Capuccella M, et al. Development of mucoadhesive patches for buccal administration of ibuprofen. J Control Release. 2004;99(1):73–82.

Wong C, Yuen K, Peh K. Formulation and evaluation of controlled release Eudragit buccal patches. Int J Pharm. 1999;178(1):11–22.

Parodi B, Russo E, Caviglioli G, Cafaggi S, Bignardi G. Development and characterization of a buccoadhesive dosage form of oxycodone hydrochloride. Drug Dev Ind Pharm. 1996;22(5):445–50.

Abruzzo A, Bigucci F, Cerchiara T, Cruciani F, Vitali B, Luppi B. Mucoadhesive chitosan/gelatin films for buccal delivery of propranolol hydrochloride. Carbohydr Polym. 2012;87(1):581–8.

Pharmaceuticals M. Onsolis (fentanyl buccal soluble film): US prescribing information 2011 2011. 2018. Available from: http://www.accessdata.fda.gov/drugsatfda_docs/label/2009/022266s000lbl.pdf. Accessed 24 May 2018.

Garnock-Jones KP. Fentanyl buccal soluble film: a review in breakthrough cancer pain. Clin Drug Investig. 2016;36(5):413–9.

Kockisch S, Rees GD, Young SA, Tsibouklis J, Smart JD. A direct-staining method to evaluate the mucoadhesion of polymers from aqueous dispersion. J Control Release. 2001;77(1):1–6.

Lindert S. Entwicklung und Charakterisierung filmförmiger Zubereitungen zur oromukosalen Anwendung von Peptiden. Düsseldorf: Heinrich-Heine Universität; 2016.

Wagner KG, McGinity JW. Influence of chloride ion exchange on the permeability and drug release of Eudragit RS 30 D films. J Control Release. 2002;82(2):385–97.

Bodmeier R, Guo X, Sarabia RE, Skultety PF. The influence of buffer species and strength on diltiazem HC1 release from beads coated with the aqueous cationic polymer dispersions, Eudragit RS, RL 30D. Pharm Res. 1996;13(1):52–6.

Knop K. Influence of buffer solution composition on drug release from pellets coated with neutral and quaternary acrylic polymers and on swelling of free polymer films. Eur J Pharm Sci. 1996;4(5):293–300.

Lagerlof F, Dawes C. The volume of saliva in the mouth before and after swallowing. J Dent Res. 1984;63(5):618–21.

Wu KP, Ke J-Y, Chung C-Y, Chen C-L, Hwang T-L, Chou M-Y, et al. Relationship between unstimulated salivary flow rate and saliva composition of healthy children in Taiwan. Chang Gung Med J. 2008;31(3):281–6.

Ono K, Morimoto Y, Inoue H, Masuda W, Tanaka T, Inenaga K. Relationship of the unstimulated whole saliva flow rate and salivary gland size estimated by magnetic resonance image in healthy young humans. Arch Oral Biol. 2006;51(4):345–9.

Gutman D, Ben-Aryeh H. The influence of age on salivary content and rate of flow. Int J Oral Surg. 1974;3(5):314–7.

Kong F, Singh R. Disintegration of solid foods in human stomach. J Food Sci. 2008;73(5).

Vertzoni M, Dressman J, Butler J, Hempenstall J, Reppas C. Simulation of fasting gastric conditions and its importance for the in vivo dissolution of lipophilic compounds. Eur J Pharm Biopharm. 2005;60(3):413–7.

Davis S, Hardy J, Fara J. Transit of pharmaceutical dosage forms through the small intestine. Gut. 1986;27(8):886–92.

Mudie DM, Amidon GL, Amidon GE. Physiological parameters for Oral delivery and in vitro testing. Mol Pharm. 2010;7(5):1388–405.

Kerlin P, Zinsmeister A, Phillips S. Relationship of motility to flow of contents in the human small intestine. Gastroenterology. 1982;82(4):701–6.

Brady S, Wesling M, Donzelli J, Kaszuba S. Swallowing frequency: impact of accumulated oropharyngeal secretion levels and gustatory stimulation. Ear Nose Throat J. 2016;95(2):E7–10.

Acknowledgements

We gratefully acknowledge Prof. Dr. N. Roewer and Dr. J. Broscheit (Sapiotec GmbH) for their support. We also thank S. Niese and S. Stich (Heinrich Heine University) for their help constructing the film sample holders. For the donation of excipients, we would like to thank Ashland, Evonik, and Shin-Etsu Chemical.

Author information

Authors and Affiliations

Corresponding author

Additional information

Guest Editor: Sandra Klein

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Speer, I., Preis, M. & Breitkreutz, J. Novel Dissolution Method for Oral Film Preparations with Modified Release Properties. AAPS PharmSciTech 20, 7 (2019). https://doi.org/10.1208/s12249-018-1255-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1208/s12249-018-1255-1