Abstract

This study investigates the use of novel alcoholic ammoniacal systems for the extraction of Cu, Zn, and Pb from Fe-rich residue materials as an alternative technology to traditional aqueous ammoniacal extraction. To this purpose, methanol- and ethanol-based ammoniacal solutions were prepared with several ammonium salts (ammonium chloride, -acetate, -carbonate, and -sulfate) and tested for their metal extraction potential (i.e., metal solubility and selectivity) in synthetic systems with metal sulfate salts of Cu, Zn, Pb, and Fe. The obtained metal solubility results were interpreted by modeling the conditions of the different alcoholic ammoniacal systems (NH3 concentration, pH), and used to select the most promising extraction systems. Furthermore, the initial alkalinity of these selected ammoniacal systems was adapted with stoichiometric NaOH additions, which proved to be a determining factor for the NH3 concentration and the pH and, thus, also for the metal solubility and selectivity. Finally, in a case study on the extraction of Cu, Zn, and Pb from a roasted sulfidic tailing, the ammonium acetate NaOH methanol solution and the ammonium chloride methanol solution showed promising metal extraction efficiencies for Zn (> 40%) and Cu (> 27%), while a very low Fe concentration in the extraction solution was assured (< 0.3 mM). These results warrant further research to reveal the full potential of non-aqueous ammoniacal metal extraction.

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Ammonia is known to be an effective leaching agent in hydrometallurgical processes. Despite being initially used to selectively extract Cu, ammoniacal leaching has been expanded towards a range of other non-ferrous metals, e.g., Zn, Ni, Co, Ag, and Au [1,2,3,4,5]. The performance of ammoniacal metal extraction systems is determined by the chemistry of ammonia/ammonium in solution. First, ammonia can act as a Brønsted-Lowry base (proton acceptor), with the acid–base conditions of an aqueous solution defining the ammonia speciation, i.e., unionized (ammonia, NH3) or ionized form (ammonium, NH4+), according to the dissociation constant (wpKa = 9.25). Second, ammonia can act as a Lewis base (free-electron-pair donor) and serve as a ligand for a selection of metals, thereby strongly enhancing the solubility of these metals. A few non-ferrous metal cations, such as Cu(II) and Zn(II) can form such soluble metal-ammine complexes, while other metals, such as Fe and Mn, are not capable of forming stable complexes with ammonia [6]. As a result, an ammoniacal solution induces a strong selectivity with respect to metal dissolution from a complex matrix, which is exploited in hydrometallurgical processes [7]. In these processes, ammonium chloride, ammonium carbonate, and ammonium hydroxide are the most common sources of ammonia [8, 9].

Overall, ammoniacal extraction offers several advantages in comparison with other conventional extraction systems (e.g., acid extraction): (i) a high extraction selectivity, which limits matrix dissolution and, thus, the need for elaborate downstream processing, (ii) a non-corrosive character, (iii) reusability of the extraction solution, and (iv) relatively mild reaction conditions [10]. Therefore, ammoniacal aqueous solutions have proven to be performant for the extraction of valuable metals from various materials, such as matte, secondary resources (e.g., converter slags), and end-of-life resources (e.g., electronic waste, spent lithium-ion batteries) [11,12,13,14,15].

So far, only aqueous ammoniacal leaching has been investigated and developed. However, it is hypothesized that also non-aqueous solvents can be suitable for this purpose and might even provide benefits compared to the conventional aqueous systems from the perspective of extraction performance. First, several ammonium salts have been reported to be soluble in alcohols and can, therefore, serve as a source for ammonia for extraction [16,17,18]. Second, the solvation properties of alcohols for metal salts suggest the potential to further enhance the selectivity characteristics of ammoniacal leaching. The solubility of metal salts in pure alcohols is significantly lower in comparison with that in pure water [19], which follows from differences in the dielectric properties of these solvents, and thus, the solvents’ capability to stabilize solutes (i.e., solvation, complex formation) [20]. In recent studies, the benefit of alcoholic solvents (ethanol and octanol) over an aqueous solvent was already demonstrated for HCl metal extraction systems [21, 22], illustrating that a change in solvent can enhance the reactivity of the lixiviant (e.g., chloride) toward specific solid metal phases to improve the extraction efficiency and/or selectivity. For ammoniacal systems, this approach has not been investigated so far. It is expected that metal dissolution in non-aqueous solvents can be strongly dictated by the metal-ammine interaction, even more than in aqueous systems. Hence, this has the potential to limit the dissolution of unwanted metals in extraction processes (e.g., Fe) and increase the metal extraction selectivity compared to aqueous systems. Third, with respect to aqueous leaching, light alcohols can more easily be recovered through distillation, allowing for an easy route to purify and circulate the leaching medium in the process. Finally, the exploration of ammonia/ammonium salt–alcohol combinations as extraction agents will broaden the routes of solvometallurgy to bring forward alternative approaches to conventional hydrometallurgy.

In this study, the potential of alcoholic ammoniacal systems for metal extraction was examined for the first time. Ammonium salts were used as a source of ammonia in the simple alcohols methanol and ethanol, aiming at a fundamental exploration of alcoholic ammoniacal leaching systems. The H-bonding network in these simple alcohols still sufficiently resembles that of water, which is required to allow the dissolution of ammonia [23]. Yet, with the short alkane chains of these alcohols, hydrophobicity is introduced in the leaching system, which could further decrease the solubility of metals not able to form soluble metal-ammine complexes. First, the solubilities of a range of ammonium salts were determined in both alcohols. The speciation of the dissolved compounds, mainly dictated by acid–base equilibrium reactions, is of key importance to understand the metal extraction properties of these new alcoholic ammoniacal solutions. For aqueous systems, the acid–base equilibrium can easily be measured (i.e., pH measurements) or determined via conventional modeling software. For non-aqueous solvents, however, this is much less straightforward. Based on the work by Sager et al., modeling of the different ammoniacal systems was performed to gain insight into the solution speciation of these systems [24]. Second, the solubilities of four common soluble metal phases in processed sulfidic tailings, i.e., Cu, Zn, Pb and Fe sulfate, were determined experimentally in the different alcoholic ammoniacal systems, while also investigating the effect of the initial alkalinity of these systems on the metal solubility. The interpretation of these results was also supported by modeling. Finally, the most promising alcoholic ammoniacal systems were tested for the extraction of valuable metals (Cu, Zn, and Pb) from a sulfidic tailing. High-metal extraction efficiencies from sulfidic tailings are typically obtained with the oxidation of the metal sulfide phases, which can be pursued via either oxidative ammoniacal extraction [25] or, as performed in this study, oxidative microwave-assisted roasting followed by the ammoniacal extraction of more soluble metal phases (e.g., metal sulfates).

Materials and Methods

Chemicals

The chemicals used in this study include solvents, ammonium salts, metal sulfate salts, and NaOH. The solvents were methanol (CH3OH, water content < 0.1%, VWR), ethanol (CH3CH2OH, water content < 0.1%, VWR), and MilliQ™ water. The ammonium salts included ammonium acetate (NH4CH3COOH, VWR, ≥ 98%), ammonium carbonate ((NH4)2CO3, Aldrich, ≥ 99.9%), ammonium sulfate ((NH4)2SO4, VWR, ≥ 99.0), and ammonium chloride (NH4Cl, Merck, ≥ 99.8%). The metal sulfate salts were copper sulfate (CuSO4.5H2O, VWR, ≥ 99.0%), zinc sulfate (ZnSO4.7H2O, Merck, ≥ 99.0%), lead sulfate (PbSO4, Aldrich, ≥ 98.0%), and iron sulfate (FeSO4.7H2O, VWR, ≥ 99.0%). Finally, also sodium hydroxide (NaOH, Merck, ≥ 97.0%) was used.

Speciation Modeling in Alcoholic and Aqueous Ammoniacal Systems

The behavior of ammonium salts in alcoholic and aqueous ammoniacal systems was modeled, based on the dissolution reactions of the different ammonium salts and the acid–base equilibrium reactions of the dissolved NH4+ and anions (Table 1). The acidic dissociation constants (Ka) of the dissolved NH4+ and anions in methanol and ethanol were determined according to the work by Sager et al. [24]. Using Eq. 1, Ka values for aqueous systems (wKa) were converted to values suitable for a solvent system (sKa), by considering the dielectric constant of water (εw) and of the solvent (εs), the charge of the acid (zA) and its respective base (zB), and the radius of the acid (rA), base (rB), and proton (rH) [24]. Additional parameters were the elementary charge (e), gas constant (R), Avogadro number (N), and temperature (T). The parameters considered for each acid–base reaction are listed in Table S1. Finally, the calculated Ka values for the three studied solvents were used to determine the speciation of acid–base active components as a function of the pH in each system.

Solubility of Ammonium Salts in Alcohols

The solubilities of ammonium acetate, ammonium carbonate, ammonium sulfate, and ammonium chloride were determined in methanol and ethanol at 20 °C, according to the procedure depicted in Fig. 1a. Several dosages of these ammonium salts were added to 5 mL of solvent. Subsequently, the solutions were agitated in a vortex mixer for 15 min. After agitation, the solutions were visually inspected to determine whether the solute was completely dissolved or precipitates/suspended particles were present. Subsequently, the equilibrium conditions of each ammonium salt-alcohol system were derived based on the initial ammonium salt concentration at maximum salt solubility, as well as the relevant dissolution and acid–base reaction equations (Table 1) and the calculated pKa values (Table S2).

A flowchart of the experimental procedure used for the assessment of a the ammonium salt solubility, b the metal sulfate salt solubility in ammoniacal systems, c the metal sulfate salt solubility in alkali-adapted ammoniacal systems, and d the metal leaching from microwave-roasted sulfidic tailings using alcoholic ammoniacal systems

Solubility of Metal Sulfates in Alcoholic and Aqueous Ammoniacal Systems

The solubilities of copper sulfate, zinc sulfate, lead sulfate, and iron sulfate were studied in ammoniacal methanol, ethanol, and water solutions at 20 °C (duplicate treatment), according to the procedure depicted in Fig. 1b. The dosage of ammonium salts in the alcohols was based on their measured maximum solubility in each solvent (Sect. “Solubility of Ammonium Salts in Alcohols”), whereas the dosage in water was done according to literature solubility values (Table 2). Of each ammoniacal solution, 5 mL was mixed with an excess of the metal sulfates in an overhead shaker at 5 rpm for 24 h. Subsequently, the suspensions were filtered (chromafil® RC-45/25 – 0.45 µm) to obtain metal-saturated solutions. The metal-saturated alcoholic solutions were first treated in a DigiPREP digestion system at 60 °C until complete evaporation of the solvent, and the obtained residues dissolved using aqua regia and MilliQ water. Finally, all samples were analyzed by inductive coupled plasma optical emission spectrometry (Perkin Elmer AVIO 500 equipped with a PrepFAST Autodilution System) to determine the metal concentration. From the molar concentrations of Cu, Zn, Pb, and Fe in the different solutions, an apparent separation factor was calculated for Cu, Zn, and Pb (indicated as M) in each leaching system, which was defined as [M]/[Fe].

The Solubility of Metal Sulfates in Alkali-Adapted Ammoniacal Alcoholic Systems

Three ammoniacal systems were selected for further optimization of their metal extraction potential: the ammonium chloride methanol, ammonium acetate methanol, and ammonium acetate ethanol systems. Again, the dosage of ammonium salts in the alcohols was based on their measured maximum solubility in each solvent (Table 2). To 5 mL of each of these ammoniacal solvents, NaOH was added as a fine powder at a molar [OH−]o/[amm] ratio of either 0, 0.3 or 1, with [amm] the total ammonia/ammonium concentration in the specific ammoniacal solvent and [OH−]o the hydroxide concentration prior to equilibration (Fig. 1c). Finally, oversaturated solutions of each metal sulfate were prepared by adding a dose of 1 molmetal/Lsolvent and mixing in an overhead shaker at 5 rpm for 24 h (duplicate treatment). Subsequently, the suspensions were filtered and their metal concentration was determined via ICP-OES. Using the above-mentioned modeling approach, the effect of NaOH on the equilibrium conditions of the ammoniacal solutions, prior to metal addition, was determined.

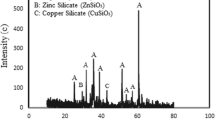

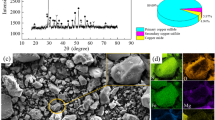

Case Study: Metal Extraction from a Roasted Sulfidic Tailing Using Ammoniacal Methanol Leaching Systems

Alcoholic ammoniacal systems were assessed for metal extraction from a roasted sulfidic tailing (0.4% Cu, 1.1% Zn, 0.4% Pb), according to the procedure as depicted in Fig. 1d. The tailing, originating from the Neves Corvo mine (Portugal), was treated at 500 °C for 60 min in a microwave-assisted roasting process using a PYRO advanced microwave furnace (Milestone) (details roasting procedure and material characterization in Sect. S1). Subsequently, the roasted material was leached in a 0.33 M ammonium chloride methanol solution and in a 4.95 M ammonium acetate methanol solution, both with or without NaOH addition at a ratio of [OH−]o/[amm] equal to 1. Next to these alcoholic ammoniacal treatments, also extractions from roasted tailing in pure water and pure methanol, and from non-roasted tailing in water were performed, obtaining seven different leaching systems in total. The extraction was performed using a liquid/solid ratio of 10 mL g−1 in an overhead shaker at 5 rpm at 20 °C (duplicate treatment), for either 0.5 h, 3 h, or 24 h. After extraction, the leachate was recovered by centrifugation (3000 rpm for 10 min) and filtration, and subsequently analyzed with ICP-OES.

Results and Discussion

Speciation Modeling in Alcoholic Ammoniacal Systems

Calculated pKa values of ammonium and other relevant ions in methanol and ethanol (Table S2), derived from Eq. 1, were used to model the speciation of these ions as a function of the pH, allowing comparison with speciation in an aqueous system (Fig. 2). For all considered compounds, the pKa values increased according to the series water < methanol < ethanol. This means that in the alcoholic systems, more alkaline conditions are required to deprotonate the ions in solution. For the NH4+/NH3 equilibrium, this effect was limited, with a pKa of 9.3 in water and 10.7 in ethanol (Fig. 2a). For the CH3COOH/CH3COO− equilibrium, the solvent has a strong effect on the pKa value, ranging from 4.8 in water to 10.8 in ethanol (Fig. 2b). In the modeled H2SO4 aqueous system, the fully deprotonated SO42− became dominant from a pH of 3.5, while in ethanol, a pH above 10.6 was required (Fig. 2c). In the modeled H2CO3 aqueous system, the fully deprotonated CO32− became dominant from a pH of 10.3, in methanol from a pH of 16.6 (Fig. 2d). In ethanol, no CO32− was present in the established pH range, as a calculated pKa2 value of 20.2 was obtained. Finally, the obtained pKa values for HCl in methanol (−4.3) and ethanol (−2.2) were higher compared to the pKa value of −8.0 in water, yet all pKa values remained negative (Table S2). As a result, Cl− was considered to be a neglectable proton acceptor in all three solvents.

Solubility of Ammonium Salts in Methanol and Ethanol

The solubility of the four tested ammonium salts was by far the highest in water, followed by methanol and ethanol (Table 2). Both in methanol and ethanol, the highest solubility was obtained with ammonium acetate, i.e., 55.0 g/100 mL in methanol and 9.5 g/100 mL in ethanol. Yet, Patnaik reported a much lower ammonium acetate solubility in methanol at 15 °C (7.9 g/100 mL), which presumably is linked to a different methanol purity [18]. Ammonium carbonate showed a reasonable solubility in methanol (5.5 g/100 mL), but a very poor solubility in ethanol with none of the tested dosages dissolving completely. Ammonium chloride was soluble in methanol to some extent (1.8 g/100 mL), but only very limited in ethanol. The determined ammonium chloride solubility range in methanol was slightly below the solubility reported by Seidel et al. (2.76 g/100 mL at 25 °C) [26], and also the solubility range in ethanol was slightly below values reported by Patnaik (0.6 g/100 mL at 19 °C) and Seidel (0.53 g/100 mL at 25 °C) [18, 26]. Finally, ammonium sulfate was very poorly soluble in methanol and was, as a result, not further tested in ethanol.

The solubility of ammonium salts in solvents can be explained by the principles of dissolution thermodynamics. The strength of the cation–anion attraction in the crystal lattice of the salt is quantified by the lattice enthalpy, which is 2153 kJ mol−1 for ammonium carbonate [27], 1766 kJ mol−1 for ammonium sulfate [28], 730 kJ mol−1 for ammonium acetate [29, 30], and 700 kJ mol−1 for ammonium chloride [29, 31]. To achieve solvation of a salt, the solvent must overcome this energy by liberating and stabilizing the salt ions in stronger solvent–ion interactions, e.g., hydrogen bond or ion–dipole interactions. On the one hand, the strength of these interactions is determined by the ability of the solvent to isolate, stabilize, and coordinate ions, which is expressed by the dielectric constant of the solvent. Water has a dielectric constant of 80.20, while this is significantly lower for methanol (33.64) and ethanol (25.16) [32]. On the other hand, the size and charge of the involved ions also influence the interaction strength, as an increasing ion charge and a decreasing ionic radius results in a stronger attraction (Table S1) [33].

The obtained trend in ammonium salt solubility within a single solvent follows from the strength of the cation–anion attraction in the crystal structure of the salt, quantified by the lattice enthalpy, and the charge and radius of the obtained ions. In the ammonium salt solutions, the NH4+-solvent interaction is based on the formation of hydrogen bonds between the oxygen atom of the solvent and the hydrogen of NH4+. The highest ammonium salt solubility was obtained with ammonium acetate, which is in line with the low lattice enthalpy value of this salt and the low charge and radius of an acetate anion. The solubility ranking of the remaining ammonium salts was an interplay of the effects of the salt’s lattice enthalpy, the ionic radius and the ion charge, of which the latter could also be affected by the actual speciation of the dissolved acid–base active ions. Next to this, the results showed that the solubility of ammonium salts across the different solvents followed the trend of the dielectric constants of those solvents, and thus, the solvation capacity of the four tested solvents decreased according to the series water > methanol > ethanol. Due to the poor solubility of ammonium sulfate in the alcohols, this salt was not further investigated as an ammonium source.

Modeling the Equilibrium Conditions of Methanol- and Ethanol-Based Ammonium Salt Solutions

The molar concentration of ammonia/ammonium [amm] (Table 3), the acid–base equilibrium reactions (Table 1), and the calculated Ka values (Table S1) were used to calculate the pH and the NH3 concentration at equilibrium (Table 3). The ratio of the equilibrium NH3 concentration and the initial ammonium concentration derived from the dissolution of the ammonium salt ([NH3]eq/[amm]) was also calculated, with [amm] equal to the sum of [NH4+]eq and [NH3]eq.

The modeling showed that the equilibrium pH increased according to the series water < methanol < ethanol. Although [amm] decreased from water to methanol and ethanol system according to the solubility results (Table 3), the [NH3]eq/[amm] ratio increased. For ammonium acetate, this ratio increased from 1% in water to 14% in methanol and 52% in ethanol, which resulted in an NH3 equilibrium concentration of 0.68 M in methanol, 0.58 M in ethanol, and 0.05 M in water. The remarkably high [NH3]eq/[amm] ratio in ethanol was related to the contribution of CH3COO− as a significant proton acceptor at an equilibrium pH of 10.7 (Fig. 2). In the case of ammonium chloride, Cl− did not act as a proton acceptor, resulting in relatively low equilibrium pH values and low [NH3]eq/[amm] ratios for the three solvents. Finally, for ammonium carbonate in water and methanol, comparable equilibrium pH values were obtained. Since the ammonium carbonate solubility in water was much higher compared to that in methanol, this also resulted in a higher equilibrium concentration of NH3 in water. It can be concluded that, via this modeling approach, it was possible to conceptualize the equilibrium conditions of the different alcoholic ammoniacal systems. The NH3 concentration in the solution, which is a determining factor for the formation of metal-ammine complexes, depended both on the amount of dissolved ammonium salt and the presence of proton-accepting anions (CH3COO−, CO32−).

Metal Sulfate Solubility in Alcoholic and Aqueous Ammoniacal Systems

The solubility of copper sulfate, zinc sulfate, lead sulfate, and iron sulfate was studied in methanol, ethanol, and water systems containing ammonium chloride, ammonium carbonate, or ammonium acetate (Fig. 3). The modeled conditions (NH3 concentration, anion concentration, and pH) of the initial ammoniacal solutions (Table 3) and the colors of the obtained metal solutions (Fig. S1) were used for the interpretation of the metal solubility results.

The Cu, Zn, Pb, and Fe concentration in a methanol, ethanol, or water-based solution, containing either ammonium chloride, ammonium carbonate, ammonium acetate, or no ammonium salt. These ammonium salts were added at their maximum solubility (Table 2). Error bars represent the standard deviation (n = 2)

Pure Solvent Systems

In general, metal solubility decreased according to the series of water > methanol > ethanol (Fig. 3), as explained by a decreasing dielectric constant of this series. In water, metal cations are stabilized by complexation with H2O ligands, e.g., Cu(H2O)62+ or Zn(H2O)62+. The light-blue color of the obtained Cu solution supported the presence of the Cu(H2O)62+ complex (Fig. S1) [34]. A similar metal dissolution mechanism likely takes place in alcohols. In the case of methanol and ethanol, metal (M) complexes such as M(CH3OH)62+ and M(CH3CH2OH)62+ could stabilize dissolved metal cations (M2+), which for Cu also resulted in light-blue alcoholic solutions (Fig. S1). The light-yellow-colored aqueous Fe solution and the orange-colored methanol Fe solution suggested that Fe in both cases was present as a Fe(III) complex (Fe(H2O)63+ or Fe(CH3OH)63+, respectively), rather than as a Fe(II) complex Fe(H2O)62+ with a typical pale green color. After the dissolution of FeSO4, Fe2+ has, thus, been oxidized during the experiment. Finally, it should be noted that the obtained Pb concentration in pure water was significantly lower compared to the Cu, Zn, and Fe concentrations, which was the result of the poor solubility of PbSO4. Also in the alcoholic systems, this trend was present.

Ammonium Chloride Systems

In an aqueous system, ammonium chloride decreased the Cu, Zn, and Fe solubility, whereas it increased the Pb solubility (Fig. 3). These trends were attributed to the presence of Cl−, rather than that of NH3, since the modeling indicated a very low NH3 concentration (Table 3). Dissolved Cl− formed complexes with the dissolving metals and, for Cu, this was illustrated by the green-colored solution (Fig. S1). Pauling et al. reported that the Cu-Cl complex CuCl42− has a pale yellow–brown color and, therefore, the green-colored Cu solution related to a mixed dissolved Cu speciation of CuCl42− and Cu(H2O)62+ complexes [35]. Likely, also dissolved Zn (e.g., ZnCl+) and Fe (e.g., FeCl2+) were present as a complex with Cl− [36, 37]. The decreased Cu, Zn, and Fe dissolution in the presence of ammonium chloride, however, was linked to the formation of metal hydroxide/chloride precipitates at the modeled initial pH of 4.3, as derived from M-Cl-H2O Pourbaix diagrams: CuCl2.3Cu(OH)2 precipitates in the pH range from -2 to 6.5 [38], Zn(OH)1.6Cl0.4 precipitates in the pH range from 2.5 to 8 [39], and Fe2O3 precipitates in the pH range from 3 to 10.5 [37]. Finally, the increased Pb concentration in this medium was attributed to the formation of soluble of Pb-Cl complexes, which are dominant species in a pH range from 0 to 7.5 [40].

In the alcoholic systems, the addition of ammonium chloride resulted in a very different trend compared to the aqueous system. The increased solubility of Cu, Zn, and Fe was the result of the near absence of OH− in the alcoholic systems: the presence of OH− was required in the formation of the aforementioned metal hydroxide/chloride precipitates. As a result, stable M-Cl complexes could enhance the solubility of Cu, Zn, and Fe in the tested alcohols relative to the situation in the pure alcohols.

Ammonium Carbonate Systems

In an aqueous system, the addition of ammonium carbonate resulted for Zn and Fe in a significant reduction of their solubility, whereas the Cu and Pb solubility were slightly enhanced (Fig. 3). The aqueous ammonium carbonate solution had a modeled initial pH of 9.2 and a high NH3 concentration of 5.3 M (Table 3). For Cu and Zn, complexation with NH3 to the formation of soluble metal-ammine complexes is dominant in the pH range of 8 to 11, while moving outside this range implies the formation of Cu(OH)2 and Zn(OH)2 precipitates [41, 42]. It is expected that, in the non-buffered environment of the Cu and Zn solutions, Cu and Zn precipitation was likely to occur and to compete with the formation of metal-ammine species. For Zn, this decreased the solubility relative to the situation in pure water, while for Cu, the complexation capacity of NH3 dictated the Cu speciation and increased Cu solubility. Both Pb and Fe were not able to form stable ammine complexes. Therefore, the positive effect of ammonium carbonate on the solubility of Pb was likely a pH effect, resulting in the formation of soluble Pb(OH)42−. Finally, the limited solubility of Fe was the result of the presence of CO32−, causing the Fe precipitation in the form of Fe-carbonates.

The solubility of metals in ammonium carbonate ethanol solutions was omitted, given the low solubility of ammonium carbonate in this system. With ammonium carbonate in methanol, however, the modeling indicated relatively high concentrations of NH3, i.e., 0.68 M. Consequently, NH3 could form soluble complexes with Cu and Zn, and the dark-blue color of the obtained Cu solution also confirmed the presence of the Cu-NH3 complex [35]. However, the potential benefit of NH3 complexation for the solubility of Cu and Zn was reduced due to the presence of HCO3− and CO32−, which could result in the formation of insoluble metal carbonate precipitates [18]. As opposed to the effect in the aqueous system, ammonium carbonate slightly decreased the Pb solubility in methanol, likely because the low OH− concentration limited the formation of soluble Pb complexes such as Pb(OH)42−. Finally, the limited Fe solubility in ammonium carbonate methanol systems was in line with the results obtained with ammonium carbonate aqueous systems.

Ammonium Acetate Systems

The presence of ammonium acetate in water decreased the Cu, Zn, and Fe solubility, whereas the Pb solubility drastically increased (Fig. 3). The modeled initial conditions of the ammonium acetate aqueous solution showed an NH3 concentration of 0.05 M, a CH3COO− concentration of 0.05 M, and a pH of 7.0. The speciation of Cu in the aqueous ammonium acetate solution was perceived as a mixture of Cu-CH3COO− and Cu-NH3 complexes, the latter resulting in a dark-blue color (Fig. S1). Yet, due to a relatively low initial pH (Table 3), the contribution of Cu-NH3 complex formation was limited while the formation of Cu(OH)2 precipitation was promoted [42]. A comparable mechanism likely explains the limited Zn solubility, since the pH of the Zn solution was also outside the pH range for stable Zn-NH3 complexes [41]. Next to this, the Pb solubility increased as a result of the formation of soluble Pb-CH3COO− complexes. Finally, the obtained Fe ammonium acetate solution was dark brown of color, which indicated the presence of Fe(III)-CH3COO− complexes (Fig. 2) [43]. Nevertheless, also a lower Fe solubility was obtained in the presence of ammonium acetate as a result of the precipitation of Fe-oxyhydroxides.

The addition of ammonium acetate to alcoholic systems resulted for all four tested metals in a higher solubility compared to the pure alcohol solvents, which can be linked to the complexation of metals with CH3COO− and/or NH3. In the case of Cu and Zn, metal-ammine complexes were formed, with the presence of Cu-NH3 complexes supported by the dark-blue color of the Cu solutions. Next to that, CH3COO− could form soluble complexes with all four metals [18] and, in the case of Fe, this resulted in red/brown-colored solutions (Fig. S1) [43].

The Selectivity of Metal Solubility in Alcoholic Ammoniacal Systems

Two main aspects need to be considered to identify the most performant alcoholic ammoniacal extraction system: on the one hand, a high Cu, Zn, and Pb solubility is required (i.e., molar concentration) while, on the other hand, also a high leaching selectivity with respect to Fe is needed (i.e., apparent separation factor). Both aspects are assessed in Fig. 4. Here, it can be concluded that (i) ammonium acetate in methanol, (ii) ammonium acetate in ethanol, and (iii) ammonium chloride in methanol were overall the most promising alcoholic media for a high and selective dissolution of Cu, Zn, and Pb. However, it was hypothesized that the performance of these extraction systems could be improved by increasing their initial alkalinity (addition of a strong base) and, thus, increasing the initial concentration of metal-complexing NH3 and CH3COO− ligands.

The Effect of Alkalinity on Alcoholic Ammoniacal Leaching Systems

Modeling the Effect of Initial Alkalinity of Alcoholic Ammoniacal Systems

The effect of alkalinity in three selected alcoholic ammoniacal systems (ammonium chloride–methanol, ammonium acetate–ethanol, and ammonium acetate–methanol) was determined by modeling the addition of OH− at [OH−]o/[amm] ratios of 0, 0.3 and 1 (Table 4). Furthermore, modeling was based on the dissolution reactions of the ammonium salts (Table 2), the acid–base equilibrium reactions of the involved ions (pKa values in each solvent in Table S2) and the neutralization reaction of NH4+ with OH−:

The modeling indicated that an increased [OH−]o/[amm] ratio enhanced the deprotonation of NH4+ and CH3COOH (Fig. 5, Table 4) and that a nearly full deprotonation of both compounds was obtained at [OH−]o/[amm] equal to 1. The highest deprotonation of NH4+ as a result of NaOH addition was obtained in the ammonium chloride methanol solution, for which the NH3 concentration evolved from 4.8 0.10–6 to 0.33 M and the pH from 5.3 to 14.7. As expected, Cl speciation was not affected by NaOH addition. Concerning the ammonium acetate alcoholic solutions, a [OH−]o/[amm] ratio of both 0 and 0.3 resulted in higher NH4+ deprotonation in ethanol compared to in methanol, while at a [OH−]o/[amm] ratio of 1, NH4+ and CH3COOH were fully deprotonated in both alcohols. In conclusion, a higher initial alkalinity enhanced the metal complexation potential.

Metal Dissolution

The dissolution of copper, zinc, lead, and iron sulfate was examined in a 0.33 M ammonium chloride methanol solution, a 1.11 M ammonium acetate ethanol solution, and a 4.95 M ammonium acetate methanol solution, to which NaOH was added at [OH−]o/[amm] ratios of 0, 0.3, or 1. For the ammonium chloride methanol system, the dissolution of all studied metals decreased with NaOH addition (Fig. 6a). This effect was very pronounced for Fe, for which the concentration decreased from 0.28 M to 10–3.6 M, and a clear solution was obtained at the [OH−]o/[amm] ratio of 1 (Fig. S1). With the [OH−]o/[amm] ratio increasing from 0 to 1, the modeled NH3 concentration increased from 10–5.32 M to 0.33 M (Table 4), while the color of Cu-containing solutions turned from green to dark blue as a result of a more pronounced Cu-NH3 and a diminished Cu-Cl complex formation (Fig. S1). Therefore, upon increasing alkalinity, the formation of M-NH3 complexes was favored, but at the same time, insoluble metal hydroxides precipitated.

The Cu, Zn, Pb, or Fe concentration in a 0.33 M ammonium chloride methanol (a), a 1.11 M ammonium acetate ethanol (b), and a 4.95 M ammonium acetate methanol solution (c), presenting for each of these systems the effect of NaOH addition at different [OH−]o/[amm] molar ratios. Error bars represent the standard deviation (n = 2)

For the ammonium acetate ethanol solution, NaOH addition generally reduced the dissolution of the target metals, whereas the Fe solubility was strongly increased (Fig. 6b). The modeling indicated that the NH3 and CH3COO− concentrations at a [OH−]o/[amm] ratio of 0 were around 0.50 M, whereas at a [OH−]o/[amm] ratio of 1, these concentrations were both 1.11 M. The increase in the CH3COO− concentration, favoring Fe-acetate complex formation, strongly enhanced the Fe solubility to finally obtain dark-brown-colored Fe solutions (Fig. S1). However, this increase of the CH3COO− concentration did not have the same positive effect on Pb solubility, which was likely compromised by Pb-hydroxide precipitation. Finally, the increased NH3 concentration with NaOH addition did not enhance the dissolution of Cu and Zn, which was likely also linked to Cu-hydroxide and Zn-hydroxide precipitation due to high initial alkalinity.

For the ammonium acetate ethanol solution, increased alkalinity enhanced the Cu and Zn solubility, while it decreased the Fe and Pb solubility (Fig. 6c). Modeling showed that changing the [OH−]o/[amm] ratio from 0 to 1 strongly increased the NH3 concertation from 0.68 M to 4.95 M, while the already high CH3COO− concentration was affected to a much lesser extent. The Cu dissolution was facilitated via enhanced formation of soluble Cu-NH3 complexes, as confirmed by the obtained dark-blue-colored Cu solutions (Fig. S1). Enhanced Zn-NH3 complex formation also benefitted the Zn solubility. Finally, NaOH addition enhanced the formation of insoluble hydroxide precipitates for Fe and Pb, as the benefit of additional CH3COOH deprotonation remained limited.

It can be concluded that increasing the initial alkalinity of an alcoholic ammoniacal solution does not always improve the potential for target metal extraction, either in terms of absolute target metal solubility or leaching selectivity over Fe. Yet, these solubility tests with synthetic metal salts were able to identify alcoholic ammoniacal solutions promising for further testing in a leaching experiment with mineral residues containing Cu, Zn, Pb, and Fe phases. First, the ammonium chloride methanol solution remained of interest because (i) the relative high Cu and Zn solubility obtained in the absence of NaOH, and (ii) the very low Fe solubility in the presence of NaOH at [OH−]o/[amm] equal to, which furthermore suggested a selective Zn dissolution. Second, the ammonium acetate methanol solution was promising only in the presence of NaOH at [OH−]o/[amm] equal to 1, obtaining a high Cu and Zn solubility of 0.7 M while diminishing the Fe dissolution.

Metal Leaching from Microwave-Roasted Sulfidic Tailings Using Alcoholic Ammoniacal Systems

The potential of ammoniacal-methanol systems was demonstrated with the metal extraction from roasted sulfidic tailing, using ammonium acetate and ammonium chloride methanol solutions, with or without a stoichiometric NaOH addition at [OH−]o/[amm] of 1 (Fig. 7). As reference treatments, also unroasted tailing and roasted tailing were treated in water (Fig. S3), next to roasted tailing in methanol (Fig. 7). Consistent with earlier studies on the roasting of sulfidic tailings and aqueous extraction, the metal extraction from unroasted tailing in water was very limited, with extraction efficiencies < 5% and metal concentrations < 0.8 mM [44]. Roasting of the sulfidic tailing caused the thermal oxidation of poorly soluble sulfide minerals, which strongly increased target metal extraction in water, reaching 33% Cu extraction (2.2 mM Cu) and 47% Zn extraction (8.4 mM Zn) after 0.5 h. However, also a high Fe concentration of 1.2 mM was obtained in this system.

a The extraction efficiencies and the metal concentrations obtained in methanol-based extraction solutions with microwave-roasted tailings, presented as a function of the extraction time. b Pictures of the corresponding solutions obtained after 24 h extraction (duplicate treatment). Error bars represent the standard deviation (n = 2)

For the ammoniacal-methanol systems, the obtained metal extraction mostly confirmed the metal solubility trends from the previous section (Fig. 7). In the absence of ammonium salts, methanol was a poor solvent for all four metals, with only Zn reaching a noticeable extraction of 17%. On the contrary, highest metal extraction values in the tested methanol systems were obtained in the presence of ammonium acetate: the presence of NH3 allowed metal-ammine complex formation with Cu (blue color) and Zn, while acetate likely formed complexes with all four investigated metals, including Fe (yellow color) originating from Fe2O3. As a result, a green-colored solution was obtained after 24 h extraction (Fig. 7b), containing 1.8 mM Fe. This obtained Fe concentration in tailing leachate was significantly lower than that in the solubility experiment with FeSO4. This was explained by difference in the initial Fe speciation of both experiments, i.e., pure FeSO4 (pKsp of 2.2 in water) in the solubility experiment and the poorly soluble Fe2O3 phase (pKsp of 42.2 in water) of the roasted sulfidic tailing in the tailing leaching experiment (Fig. S4) [45, 46]. It should be noted that also a high Pb extraction of 60% was obtained with this ammonium acetate solution. The addition of NaOH with ammonium acetate strongly decreased the Fe and Pb extraction, which was consistent with results from the synthetic ammonium acetate system (Fig. 6c). The Fe concentration only reached 0.07 mM after 24 h, while the extraction efficiency of Cu and Zn remained comparable to that of the ammonium acetate system without NaOH. This resulted in a blue-colored extraction solution (Fig. 7b).

For the ammonium chloride methanol solution, good extraction efficiencies for Zn (40%) and Cu (27%) were obtained, while the Pb and Fe extraction remained limited. Especially the low Fe concentration in this system after 24 h (0.3 mM) was remarkable, following the high Fe solubility obtained earlier in the same system (Fig. 6). This was explained by the fact that the ammonium chloride methanol solution allowed a reasonably good solvation of the soluble FeSO4 form, yet the Fe-Cl interaction was, in comparison with an interaction with, e.g., acetate, not strong enough to dissolve Fe from the poorly soluble Fe2O3 phase. The obtained solution had a light-yellow color (Fig. 7b), which was attributed to the presence of Cu-Cl complexes. Finally, also in the ammonium chloride methanol solution with NaOH addition, the Pb and Fe extraction remained low. The modeling of the ammonium chloride system indicated that the NaOH addition strongly increased the NH3 concentration (Fig. 5a). Consequently, Cu-NH3 complexes could be formed, which was confirmed by the blue color of the obtained solution (Fig. 7a). Notwithstanding the presence of ammonia, the Cu extraction slightly decreased in comparison with the ammonium chloride system without NaOH addition, while the Zn extraction dropped significantly. Both these trends were also in line with the results obtained from the synthetic metal systems (Fig. 6a).

In this case study, both the ammonium acetate methanol solution with stoichiometric NaOH and the ammonium chloride methanol solution without NaOH addition were identified as the most promising systems for selective extraction of the target metals from roasted sulfidic tailing. Yet, it should be noted that this result likely depends on the content and the speciation of the four investigated metals in this specific residue material. Consequently, to further explore alcoholic ammoniacal extraction for other tailings or other Fe-rich residue materials, it remains important to continue gaining knowledge on the solubility of a variety of common metal phases in alcohols, e.g., metal oxides or dehydrated metal salts.

Conclusion

This study described the design of alcoholic ammoniacal systems for the selective extraction of valuable metals (Cu, Zn, Pb) from Fe-rich residue materials, e.g., roasted sulfidic tailings. As these leaching systems are novel, basic insights and knowledge needed to be gained to understand and subsequently optimize such systems.

-

The ammonium salt solubilities in methanol and ethanol were highest for ammonium acetate, followed by ammonium carbonate and ammonium chloride. The leachability of Cu, Zn, Pb, and Fe sulfate salts in the ammonium acetate methanol/ethanol systems and ammonium chloride methanol system were promising in terms of metal concentration and target metal selectivity, compared to the corresponding aqueous systems. Increasing the initial alkalinity of the alcoholic ammoniacal systems by NaOH addition strongly increased the concentration of metal ligands (NH3, acetate) but did not always result in higher target metal solubility/selectivity.

-

A model of the initial equilibrium conditions of saturated ammonium salt solutions was developed to calculate the speciation of NH3/NH +4 and anions.

-

The ammonium acetate methanol and the ammonium chloride methanol systems were selected to be tested on a roasted sulfidic tailing material with the aim to selectively extract Cu, Zn, and Pb in respect to Fe. Both solutions showed promising metal extraction efficiencies for Zn (> 40%) and Cu (> 27%), while a very low Fe concentration in the extraction solution was maintained (< 0.3 mM).

References

Meng X, Han KN (1996) Principles and applications of ammonia leaching of metals - a review. Miner Process Extr Metall Rev 16:23–61. https://doi.org/10.1080/08827509608914128

Gargul K, Boryczko B (2015) Removal of zinc from dusts and sludges from basic oxygen furnaces in the process of ammoniacal leaching. Arch Civ Mech Eng 15:179–187. https://doi.org/10.1016/j.acme.2014.08.004

Niinae M, Komatsu N, Nakahiro Y et al (1996) Preferential leaching of cobalt, nickel and copper from cobalt-rich ferromanganese crusts with ammoniacal solutions using ammonium thiosulfate and ammonium sulfite as reducing agents. Hydrometallurgy 40:111–121

Katsiapi A, Tsakiridis PE, Oustadakis P, Agatzini-Leonardou S (2010) Cobalt recovery from mixed Co-Mn hydroxide precipitates by ammonia-ammonium carbonate leaching. Miner Eng 23:643–651. https://doi.org/10.1016/j.mineng.2010.03.006

Zipperian D, Raghavan S, Wilson JP (1988) Gold and silver extraction by ammoniacal thiosulfate leaching from a rhyolite ore. Hydrometallurgy 19:361–375. https://doi.org/10.1016/0304-386X(88)90041-2

Parhi PK, Panigrahi S, Sarangi K, Nathsarma KC (2008) Separation of cobalt and nickel from ammoniacal sulphate solution using Cyanex 272. Sep Purif Technol 59:310–317. https://doi.org/10.1016/j.seppur.2007.07.026

Knaislová A, Vu HN, Dvořák P (2018) Microwave and ultrasound effect on ammoniacal leaching of deep-sea nodules. Minerals 8:1–16. https://doi.org/10.3390/min8080351

Xu Y, Li J, Liu L (2016) Current status and future perspective of recycling copper by hydrometallurgy from waste printed circuit boards. Procedia Environ Sci 31:162–170. https://doi.org/10.1016/j.proenv.2016.02.022

Lu BCY, Graydon WF (1955) Rates of copper dissolution in aqueous ammonium hydroxide solutions. J Am Chem Soc 77:6136–6139. https://doi.org/10.1021/ja01628a012

Reilly IG, Scott DS (1977) The leaching of a chalcopyrite concentrate in ammonia. Can J Chem Eng 55:527–533. https://doi.org/10.1002/cjce.5450550508

Ku H, Jung Y, Jo M et al (2016) Recycling of spent lithium-ion battery cathode materials by ammoniacal leaching. J Hazard Mater 313:138–146. https://doi.org/10.1016/j.jhazmat.2016.03.062

Park KH, Mohapatra D, Reddy BR, Nam CW (2007) A study on the oxidative ammonia/ammonium sulphate leaching of a complex (Cu-Ni-Co-Fe) matte. Hydrometallurgy 86:164–171. https://doi.org/10.1016/j.hydromet.2006.11.012

Rudnik E, Pierzynka M, Handzlik P (2016) Ammoniacal leaching and recovery of copper from alloyed low-grade e-waste. J Mater Cycles Waste Manag 18:318–328. https://doi.org/10.1007/s10163-014-0335-x

Aracena A, Valencia A, Jerez O (2020) Ammoniacal system mechanisms for leaching copper from converter slag. Metals (Basel). https://doi.org/10.3390/met10060712

Williamson AJ, Verbruggen F, Chavez Rico VS et al (2021) Selective leaching of copper and zinc from primary ores and secondary mineral residues using biogenic ammonia. J Hazard Mater 403:123842. https://doi.org/10.1016/j.jhazmat.2020.123842

Schäfer D, Xia J, Vogt M et al (2007) Experimental investigation of the solubility of ammonia in methanol. J Chem Eng Data 52:1653–1659. https://doi.org/10.1021/je700033y

Huang LJ, Xue WL, Zeng ZX (2011) The solubility of ammonia in ethanol between 277.35 K and 328.15 K. Fluid Phase Equilib 303:80–84. https://doi.org/10.1016/j.fluid.2011.01.006

Patnaik P (2003) Handbook of inorganic chemicals. McGraw-Hill, New York

Lide DR (2006) CRC handbook of chemistry and physics, 87th edn. CRC Press, Boca Raton, FL

Maclennan A, Hu Y (2017) Investigation of solvation effects on iron(II) and iron(III) salt solutions by X-ray absorption spectroscopy. Can J Chem 95:1170–1177. https://doi.org/10.1139/cjc-2017-0141

Girgin I, Erkal F (1993) Dissolution characteristics of scheelite in HClC2H5OHH2O and HClC2H5OH solutions. Hydrometallurgy 34:221–229. https://doi.org/10.1016/0304-386X(93)90036-D

Kopkova EK, Shchelokova EA, Gromov PB (2015) Processing of titanomagnetite concentrate with a hydrochloric extract of n-octanol. Hydrometallurgy 156:21–27. https://doi.org/10.1016/j.hydromet.2015.05.007

Choi S, Parameswaran S, Choi JH (2020) Understanding alcohol aggregates and the water hydrogen bond network towards miscibility in alcohol solutions: graph theoretical analysis. Phys. Chem. Chem. Phys. 22:17181–17195

Sager EE, Robinson RA, Bates RG (1964) Medium effects on the dissociation of weak acids in methanol-water solvents. J Res Natl Bur Stand Sect A, Phys Chem 68:305

Feng D, Van Deventer JSJ (2002) Leaching behaviour of sulphides in ammoniacal thiosulphate systems. Hydrometallurgy 63:189–200. https://doi.org/10.1016/S0304-386X(01)00225-0

Seidell A (1940) Solubilities of inorganic and metal organic compounds, 3d ed., v. 1. D van Nostrard, New York

House JE Jr (1980) Decomposition of ammonium carbonate and ammonium bicarbonate and proton affinities of the anions. Inorg Nucl Chem Lett 16:185–187

Petruševski VM, Monković M, Šoptrajanov B (2007) Demonstrations as a tool for ironing-out preconceptions: 1. On the reactions of alkali metal sulfates with concentrated sulfuric acid. Chem Educ 12:71–74

Smith DW (1977) Ionic hydration enthalpies. J Chem Educ 54:540. https://doi.org/10.1021/ed054p540

Trompette JL, Arurault L, Fontorbes S, Massot L (2010) Influence of the anion specificity on the electrochemical corrosion of anodized aluminum substrates. Electrochim Acta 55:2901–2910. https://doi.org/10.1016/j.electacta.2009.12.063

Parker VB (1965) Thermal properties of aqueous uni-univalent electrolytes. US Government Printing Office, Washington, DC

Gregory AP, Clarke RN (2005) Traceable measurements of the static permittivity of dielectric reference liquids over the temperature range 5–50 C. Meas Sci Technol 16:1506

Atkins P, Overton T (2010) Shriver and Atkins’ inorganic chemistry. Oxford University Press, USA

Ogden MI, Beer PD (2011) Water & O-donor ligands. Encycl Inorg Bioinorg Chem. https://doi.org/10.1002/9781119951438.eibc0238

Pauling L (1988) General chemistry. Courier Corporation

Irish DE, Mccarroll B, Young TF (1963) Raman study of zinc chloride solutions. J Chem Phys 39:3436–3444. https://doi.org/10.1063/1.1734212

Kesavan S, Mozhi TA, Wilde BE (1989) Potential-pH diagrams for the Fe-Cl-H2O system at 25 to 150°C. Corrosion 45:213–215

Macleod I, North N (1980) 350 years of marine corrosion in Western Australia. Corros Aust 5:11–15

Vazquez-Arenas J, Sosa-Rodriguez F, Lazaro I, Cruz R (2012) Thermodynamic and electrochemistry analysis of the zinc electrodeposition in NH4Cl–NH3 electrolytes on Ti, glassy carbon and 316L stainless steel. Electrochim Acta 79:109–116. https://doi.org/10.1016/j.electacta.2012.06.091

Powell KJ, Brown PL, Byrne RH et al (2009) Chemical speciation of environmentally significant metals with inorganic ligands. Part 4: the Pb2+ OH-, Cl-, and systems (IUPAC Technical Report). Pure Appl Chem 12:2425–2476

Moghaddam J, Sarraf-Mamoory R, Yamini Y, Abdollahy M (2005) Determination of the optimum conditions for the leaching of nonsulfide zinc ores (high-SiO2) in ammonium carbonate media. Ind Eng Chem Res 44:8952–8958

Radmehr V, Koleini SMJ, Khalesi MR, Mohammadi MRT (2013) Ammonia Leaching: a new approach of copper industry in hydrometallurgical processes. J Inst Eng Ser D 94:95–104

Perrin DD (1959) Spectrophotometric determination of iron as ferric acetate complex. Anal Chem 31:1181–1182

Everaert M, Lemmens V, Atia TA, Spooren J (2020) Sulfidic mine tailings and marl waste rock as compatible resources in a microwave-assisted roasting process. J Clean Prod 274:1–28. https://doi.org/10.1016/j.jclepro.2020.122628

Bjerrum J, Sillén LG, Schwarzenbach GK, Berecki-Biedermann C (1958) Stability constants of metal-ion complexes, with solubility products of inorganic substances 2: inorganic ligands, 2nd edn. Chemical Society, London

Marion GM, Catling DC, Kargel JS (2003) Modeling aqueous ferrous iron chemistry at low temperatures with application to Mars. Geochim Cosmochim Acta 67:4251–4266. https://doi.org/10.1016/S0016-7037(03)00372-7

Capello C, Fischer U, Hungerbühler K (2007) What is a green solvent? a comprehensive framework for the environmental assessment of solvents. Green Chem 9:927–993. https://doi.org/10.1039/b617536h

Prat D, Wells A, Hayler J et al (2015) CHEM21 selection guide of classical- and less classical-solvents. Green Chem 18:288–296. https://doi.org/10.1039/c5gc01008j

Acknowledgements

The authors would like to thank Wendy Wouters for the microwave-assisted roasting and the extraction experiment with the roasted tailing, Myrjam Mertens for the XRD analysis, Raymond Kemps for the SEM-EDX analysis, and Warre Van Dun for the assistance with the ICP-OES measurements. Nor Kamariah is thankful for the funding from the European Union’s EU Framework Program for Research and Innovation Horizon 2020 under Grant Agreement No 812580 (MSCA-ETN SULTAN). This publication reflects only the authors' view, exempting the Commission from any liability.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no confict of interest.

Additional information

The contributing editor for this article was Atsushi Shibayama.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Everaert, M., Guerrero, F., Kamariah, N. et al. Fundamental Insights in Alcoholic Ammoniacal Systems for Selective Solvometallurgical Extraction of Cu, Zn, and Pb from Tailings. J. Sustain. Metall. 7, 1537–1551 (2021). https://doi.org/10.1007/s40831-021-00382-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40831-021-00382-y