Abstract

India is highly dependent on fossil fuels mainly coal, oil, and gasoline so as to fulfill its energy demands. But, excessive exploitation of fossil fuels, natural resource scarcity, day-by-day enhancement in oil prices, and emission of green house gases, all these conditions leads to the search for a renewable, sustainable source of energy. Bioethanol is a reliable, economical, and readily available resource of renewable energy, which can be used as a fuel for power generation. Rice is the main staple food of India, and rice crops generate a huge amount of rice straw as crop residue in the fields. Unsustainable use of rice straw and open burning of crop in the field produce threat to the environment by producing large amount of greenhouse gas (GHG) emission and also make farmer’s loose a very viable by-product. Rice straw can be used in bioethanol production and bring additional income and sustainable utilization. India is showing great interests toward the use of ethanol for supplementing its energy requirements. Conversion of rice straw into bioethanol not only overcome the nation’s dependency on foreign countries and saves lot of money spent on importing crude oil but also solves global warming issues.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In India, depletion of crude oil reserves, rising demand, the speedy rise in prices of petroleum, as well as the issue of climate change and energy security compels the researchers to search a substitute source of energy, and bioenergy is becoming increasingly relevant as a possible and potential alternative to fossil fuels. Biofuels are liquid or gaseous fuels obtained from biomass resources that can be utilized in place of diesel or petrol for transport, stationary, portable, and other applications. Biofuels are derived from renewable biomass resources and thus promote sustainable development and also supplement conventional energy sources in order to fulfill the energy needs of India. Bioethanol production from sugars, starch, and lignocellulosic materials is an attractive alternative option for fossil fuels. Bioethanol can be easily blended with the gasoline or employed as alcohol in dedicated engines due to its high octane number and higher heat of vaporization [1]. In India, generally, sugarcane molasses is utilized for ethanol production and till now, about 330 distilleries with the annual production capacity of over 4.0 billion liters have been established [2], but only corn-based or sugarcane-based ethanol production cannot replace the current requirement of one trillion gallons of fossil fuel [3]. Moreover, the exploitation of these edible food crops for bioethanol production put up the question of food security, and therefore it cannot be considered as a good alternative for achieving sustainable development. So, there is a need to generate bioethanol from sources that would not put pressure on food crops, and this led to the bioethanol production from inedible potential feed stocks [4].

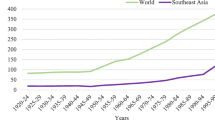

Over the last 25 years since 2000, there is a sharp increase in production of bioethanol world widely, and it has been found that annual production capacity in 2005 and 2006 were about 45 and 49 billion liters, respectively, and total output in 2015 is estimated to reach over 115 billion liters [5]. Previously, Brazil was the largest bioethanol-producing country, but in 2005, the USA became the world’s number one ethanol-producing country. Bioethanol production from non-food crops is of great importance in countries with large populations and growing gasoline consumption such as Brazil, Egypt, China, and India. In India and China, approximately 3.9 billion liters of ethanol can be derived from rice straw and bagasse [6]. Bioethanol generation from lignocellulosic biomass such as rice straws involved a suitable pretreatment method, hydrolysis of the straw to convert the cell walls to simple sugars, conversion of these sugars into ethanol, and lastly distillation. Among the lignocellulosic waste materials in the world, rice straw is one of the abundant, easily available, and inexpensive materials. In India, 23 % of rice straw is either left or burnt in the field and the open burning of rice straw is a threat to atmosphere and climate as it contributes 0.05 % to greenhouse gas (GHG) emissions [7] and thus, it should not be wasted by burning, unless utilizing it for generation of energy.

Characteristics of Rice Straw

Rice straw generally consists of cellulose, hemicelluloses, lignin, silica, and ash content, and its chemical composition depends on varieties and growing season [8]. The general composition of rice straw is cellulose (33–47 %), hemicelluloses (19–27 %), lignin (5–24 %) [9, 10], and silica (18.3 %) [11] (Table 1) [12], and the energy content of rice straw is around 14 MJ per kg at 10 % moisture content. In rice straw, micro fibrils are the basic structural unit which provides mechanical strength to the cell walls and crystalline microfibrills are formed as the cellulose chains are joined together by hydrogen bonds. These are bonded by a gel matrix composed of hemicellulose, lignin, and other carbohydrate polymers to form bio-composites [13–15].

Bioethanol Production

The presence of a complex structure of lignin and hemicelluloses with cellulose in rice straw produces hindrance in its conversion into bioethanol and makes the process very complicated [4, 16]. The production of ethanol from rice straw includes four major steps, namely pretreatment, hydrolysis, fermentation, and distillation [17], and it is shown in Fig. 1 (http://www.slideshare.net/vanhana/2014-fallsemester-introductiontobiofuels).

Bioethanol generation process (http://www.slideshare.net/vanhana/2014-fallsemester-introductiontobiofuels)

Pretreatment

Rice straw encompasses of a compact packing of cellulose, hemicelluloses, and lignin [18] which causes difficulties in bioethanol production, and thus a pretreatment process is crucial to disrupt lignocellulosic complex, to remove lignin, to reduce cellulose crystallinity, and to increase the porosity of the materials [19–21]. Different types of pretreatment techniques such as physical, chemical, and biological techniques are employed. Grinding and milling, irradiation, steaming, temperature and pressure, etc. are some techniques of physical pretreatment. Several studies had reported that microwave irradiation causes an alteration in the structure of cellulose [22], degradation of lignin and hemicelluloses, and increase the enzymatic susceptibility of lignocellulosic materials [23]. Various kinds of chemical pretreatment method such as lime, acid, steam explosion, sulphur dioxide explosion, ammonia fiber explosion, and ionic liquid have been used for pretreatment of biomass [24]. Chemicals such as alkali, acids, organic acids, peroxides, etc. are generally employed for chemical pretreatment process. In alkali pretreatment, sodium hydroxide (NaOH), potassium hydroxide (KOH), and calcium hydroxide (Ca(OH)2) are frequently applied chemicals. Taherzadeh and Karimi [25] found that sodium hydroxide enhances the internal surface of cellulose, reduces the degree of polymerization and crystallinity, and resulted in disrupting the lignin structure. Different types of pretreatment technologies such as physico-chemical, thermo-chemical, combination of chemical and biological process, etc. are employed during combined pretreatment process. Alkali-assisted photocatalysis efficiently changed the physical and microstructure of rice straw, decreases the lignin content, and thereby enhances the hydrolysis rate [26]. Several scientists had investigated microwave-assisted chemical pretreatment process and found it an effective and efficient pretreatment technique [16, 27]. In biological pretreatment, generally, white-rot fungi which belong to Basidiomycetes class is exploited for this purpose [28]. White-rot fungi produces lignolytic enzymes such as manganese peroxidase (MnP), lignin peroxidase (LiP), and laccase [29, 30], and in the presence of Mn (III) and veratryl alcohol (VA), MnP and LiP are oxidized by H2O2, respectively; the oxidized form of these enzymes causes the oxidation of lignin. Bak et al. found that Dichomitus squalens utilized in biological pretreatment of rice straw increases the enzymatic digestibility of lignocelluloses and promote cellulose hydrolysis [31].

Hydrolysis

During hydrolysis, the carbohydrate polymers present in lignocellulosic materials are converted into simple sugars which are further involved in fermentation [25]. Recently, various methods for the hydrolysis of lignocellulosic materials have been described, and the most commonly applied methods can be classified as chemical hydrolysis which includes dilute and concentrated acid hydrolysis and enzymatic hydrolysis. In hydrolysis, hemicellulose is hydrolyzed to xylose, mannose, acetic acid, galactose, etc. while cellulose and lignin are hydrolyzed to glucose and phenolics, respectively. During chemical hydrolysis, the pretreatment and the hydrolysis may take place in a single step, and lignocellulosic materials are exposed to a chemical for a specific time period at a specific temperature, chemical concentration, substrate concentration, and thus resulted in sugar monomers from cellulose and hemicellulose polymers [32]. In acid hydrolysis, sugars are converted into degradation products such as furfural, hydroxyl furfural, and it can be prevented by using enzymes favoring 100 % selective conversion of cellulose to glucose. Microwave-assisted chemical pretreatment raises the enzymatic saccharification by eradicating lignin and hemicelluloses [33–35]. Enzymatic hydrolysis involves utilization of enzymes for the disruption of cellulose and hemicellulose [36]. There are many structural parameters of the biomass, such as lignin and hemicellulose content, surface area, and cellulose crystallinity that creates a problem in enzymatic hydrolysis of cellulose and hemicellulose [37]. Generally, enzymatic hydrolysis is conducted at low pH conditions (pH 4.8) and at temperature ranges of 318–323 K, and it does not have a corrosion problem that leads to its low utility cost as compared to acid or alkaline hydrolysis [4].

Fermentation and Distillation

Rice straw can be converted into ethanol either by simultaneous saccharification and fermentation (SSF) or by separate enzymatic hydrolysis and fermentation (SHF). Ethanol production depends on several factors such as sugar recovery percent, sugar type (pentose or hexose), and inhibitors production [38]. Sacchamyces cerevisiae is majorly used by industries for fermenting bioethanol in industrial processes as this is very robust and well suited to the fermentation of lignocellulosic hydrolysates. S. cerevisiae and the bacterium Zymomonas mobilis are the most common microorganisms exploited for ethanol production [39] because they help in obtaining high ethanol yields (90–97 % of theoretical). After enzymatic hydrolysis and fermentation are conducted, a distillation of ethanol occurred, and it is dehydrated for obtaining 99.5 % of purity. Lignin, unreacted carbohydrates, and other organics generate steam and electricity after undergoing combustion process in a boiler.

Need of Ethanol Generation From Rice Straw

In India, recent studies have reported that the present molasses-based ethanol production is not economically suitable for the commercial blending of ethanol in petrol. The study has revealed that if the government is aiming to bring 10 % ethanol blending effectively by the year 2016–2017, as planned in the National Biofuel Policy, approximately 736.5 million tons of sugarcane with area coverage of 10.5 million ha would be needed [2]. Ten percent blending target is achieved only if the production and area under sugarcane are increased more than the doubled from the current situation. As the sugarcane crop consumed a large quantity of water about 20,000–30,000 m3/ha/crop, therefore, it would not be a sustainable solution to extend the sugarcane area beyond a certain limit [2]. Moreover, cyclical nature of sugarcane production and its usage in pharmaceutical and food industry also creates a big hurdle in ethanol generation (Table 2) [40]. All these circumstances strengthen the researchers to look out an alternative for the production of ethanol and lignocellulosic substances such as rice straw is the best available option. Rice straw is present in large quantities and after an appropriate pretreatment can be easily fermented to produce ethanol, which can be utilized either as a motor fuel in pure form or as a blending component in gasoline. Otherwise, farmers burnt these straws openly for clearing the field that led to the air pollution and emission of greenhouse gases [41]. On-site development of ethanol plant from straws provides fuel for feedstock transport, plant operations, product transport, and in several other purposes that will make the agriculture system sustainable and self-sufficient. So, in an urge to shift toward the greener source of energy, production of ethanol from rice straw is a better option.

Conclusion

In India, as the energy consumption rate, the demand of coal and petroleum, dependence on foreign countries for oil imports so as to fulfill the energy demands, depletion of fossil fuels reserves, global warming, and other climate change issues raised day by day, promotion of renewable energy resources has a significant importance. Exploitation of agri-residues for power generation is a green initiative to provide electricity and thermal energy. Bioethanol generation from rice straw emits fewer amounts of GHG and also lignin, unreacted carbohydrates, and other organics obtained during the process is used for steam and electricity generation. Therefore, use of rice straw for bioethanol generation helps in becoming more energy independent and also provides employment and direct economic benefit to local communities. Therefore, it can be concluded that utilization of rice straw for bioethanol generation is a sustainable, renewable, reliable, and pollution-free process.

References

Hahn-Hagerdal B, Karhumaa K, Fonseca C, Spencer-Martins I, Gorwa-Grauslund M. Towards industrial pentose-fermenting yeast strains. Appl Microbiol Biotechnol. 2007;74:937–53.

Raju SS, Parappurathu S, Chand R, Joshi PK, Kumar P, Msangi S. Biofuels in India: Potential, Policy and Emerging Paradigms. Policy paper. NCAP. 2012.

Bell JL, Attfield PV. Breakthrough in yeast for making bio-ethanol from lignocellulosic. Sydney: Microbiogen Pty LTD, Mac quarie University Campus; 2006.

Sun Y, Cheng J. Hydrolysis of lignocellulosic materials for ethanol production: a review. Bioresour Technol. 2002;83:1–11.

Talebnia F, Karakashev D, Angelidaki I. Production of bioethanol from wheat straw: an overview on pretreatment, hydrolysis and fermentation. Bioresour Technol. 2010;101:4744–53.

Yano S, Sawayama S, Inoue H, Fujimoto S, Minowa T, Imou K, et al. Ethanol production potential from rice straw and bagasse in China, India, and ASEAN countries. Taiyo Enerugi. 2009;35(6):39–44.

Gadde B, Menke C, Wassmann R. Rice straw as a renewable energy source in India, Thailand, and the Philippines: overall potential and limitations for energy contribution and greenhouse gas mitigation. Biomass Bioener. 2009;33(11):1532–46.

Shen H, Sh Ni DB, Sundstol F. Studies on untreated and urea-treated rice straw from three cultivation seasons: a. Physical and chemical measurements in straw and straw fractions. Anim Feed Sci Tech. 1998;73:243–61.

Garrote G, Dominguez H, Parajo JC. Autohydrolysis of corncob: study of non-isothermal operation for xylo-oligosaccharide production. J Food Eng. 2002;52:211–8.

Saha BC. Hemicellulose bioconversion. Ind Microbiol Biotechnol. 2003;30:279–91.

Hessien MM, Rashad MM, Zaky RR, Abdel-Aal EA, El-Barawy KA. Controlling the synthesis conditions for silica nanosphere from semi-burned rice straw. Mater Sci Eng B-Adv. 2009;162(1):14–21.

Jenkins BM, Baxter LL, Miles Jr TR, Miles TR. Combustion properties of biomass, fuel process. Technol. 1998;54:17–46.

Atanu B, Badal CS, John WL, Shogren RL, Willett JL. Process for obtaining cellulose acetate from agricultural by-products. Carbohydr Polym. 2006;64:134–7.

Wiiiam JO, Justin S, Syed HI, Gregory MG, Mara EG, Jean FR. Application of cellulose microfibrils in polymer nanocomposites. J Polym Environ. 2005;13:301–6.

Xu Z, Wang QH, Jiang Z, Yang XX, Ji YZ. Enzymatic hydrolysis of pretreated soybean straw. Biomass Bioenergy. 2007;31:162–7.

Zhu S, Wu Y, Yu Z, Liao J, Zhang Y. Pretreatment by microwave/alkali of rice straw and its enzymatic hydrolysis. Process Biochem. 2005;40:3082–6.

Chittibabu S, Ravoof SA, Pratheepa K, Supassri T. Enhancing enzymatic hydrolysis of rice straw using microwave assisted nitric acid pretreatment. Int J Med and Biosci. 2012;1(3):13–7.

Himmel ME, Ding SY, Johnson DK, Adney WS, Nimlos MR, Brady JW, Foust TD. Biomass recalcitrance engineering plants and enzymes for biofuels production. Sci;315:804-807

Karimi K, Emtiazi G, Tahcrzadeh MJ. Ethanol production from dilute acid pretreated rice straw by simultaneous saccharification and fermentation with Mucor indicus, Rhizopus oryzae and Saccharomyces cerevisiae. Enzyme Microb Technol. 2006;40:138–44.

Mosier N, Wyman CE, Dale BE, Elander RT, Lee YY, Holtzapple M, et al. Features of promising technologies for pretreatment of ligno-cellulosic biomass. Bioresour Technol. 2005;96:673–86.

Kumar P, Barrett DM, Delwiche MJ, Stroeve P. Methods for pretreatment of lignocellulosic biomass for efficient hydrolysis and biofuel production. Ind and Chem Eng Res. 2009;48(8):3713–29.

Xiong J, Ye J, Liang WZ, Fan PM. Influence of microwave on the ultra structure of cellulose. J South Chin Univ Technol. 2000;28(3):84–9.

Azuma J, Tanaka F, Koshijima T. Enhancement of enzymatic susceptibility of lignocellulosic wastes by microwave irradiation. J Ferment Technol. 1984;62:377–84.

Behera S, Arora R, Nandhagopal N, Kumar S. Importance of chemical pretreatment for bioconversion of lignocellulosic biomass. Renew Sust Energ Rev. 2014;36:91–106.

Taherzadeh M, Karimi K. Pretreatment of lignocellulosic wastes to improve ethanol and biogas production: a review. Int J Mol Sci. 2008;9:1621–51.

Kun N, Peng C, Xu Z, Wen-Song T. Enhanced enzymatic hydrolysis of rice straw pretreated by alkali assisted with photocatalysis technology. J Chem Technol Biotechnol. 2009;84:1240–5.

Curreli N, Agelli M, Pisu B, Rescigno A, Sanjust E, Rinaldi A. Complete and efficient enzymatic hydrolysis of pretreated wheat straw. Process Biochem. 2002;37:937–41.

Taniguchi M, Suzuki H, Watanabe D, Sakai K, Hoshino K, Tanaka T. Evaluation of pretreatment with pleurutus ostreatus for enzymatic hydrolysis of rice straw. J Biosci Bioeng. 2005;100:637–43.

Tien M, Kirk TK. Lignin degrading enzyme from the hymenomycete phanerocete chryososporium Burds. Sci. 1983;221:661–3.

Perie FH, Gold MH. Manganese recognition of manganese peroxidase expesstion and lignin degradation by the white rot fungus Dichomitus squalens. Appl Environ Microbiol. 1991;57(8):2240–5.

Bak JS, Kim MD, Choi I-G, Kim KH. Biological pretreatment of rice by fermenting with Dichomitus squalens. New Biotechnol. 2010;27(4):424–34.

Taherzadeh MJ, Karimi K. Acid-based hydrolysis processes for ethanol from lignocellulosic materials: a review. BioResour. 2007;34:472–99.

Singh R, Tiwari S, Srivastava M, Shukla A. Performance study of combined microwave and acid pretreatment method for enhancing enzymatic digestibility of rice straw for bioethanol production. Plant Knowl J. 2013;2(4):157–62. http://www.sciencej.com/singh_2_4_2013_157_162.pdf.

Singh R, Tiwari S, Srivastava M, Shukla A. Microwave assisted alkali pretreatment of rice straw. J Energ. 2014. http://www.hindawi.com/journal/jen/2014/483813.pdf.

Singh R, Tiwari S, Srivastava M, Shukla A. Experimental study on the performance of microwave assisted Hydrogen peroxide (H2O2) pretreatment of rice straw. Agric Eng Int: CIGR J. 2014b;16(1):173-181. www.cigrjournal.org/index.php/E journal/article/view/2633

Pike PW, Sengupta D, Hertwig TA. Integrating biomass feedstocks into chemical production complexes using new and existing processes. Baton Rouge: Minerals Processing Research Institute, Louisiana State University; 2008.

Pan X, Gilkes N, Saddler JN. Effect of acetyl groups on enzymatic hydrolysis of cellulosic substrates. Holzforschung. 2006;60:398–401.

Singh R, Shukla A, Tiwari S, Srivastava M. A review on delignification of lignocellulosic biomass for enhancement of ethanol production potential. Renew and Sustain Energ Reviews. 2014;32:713–28.

Claassen PAM, Lopez Contreras AM, Sijtsma L, Weusthuis RA, Van Lier JB, Van Niel EWJ, et al. Utilization of biomass for the supply of energy carriers. Appl Microbiol Biotechnol. 1999;52:741–55.

Planning Commission, Government of India, Report of the Committee on Development of Biofuel. 2003. http://planningcommission.nic.in/reports/genrep/cmtt_bio.pdf.

Gupta PK, Sahai S, Singh N, Dixit CK, Singh DP, Sharma C, et al. Residue burning in rice-wheat cropping system: causes and implications. Current Sci. 2004;87(12):1713–7.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Human and Animal Rights and Informed Consent

This article does not contain any studies with human or animal subjects performed by any of the authors.

Additional information

This article is part of the Topical Collection on Regional Renewable Energy

Rights and permissions

About this article

Cite this article

Singh, R., Srivastava, M. Regional Renewable Energy India: Bioethanol From Rice Straw. Curr Sustainable Renewable Energy Rep 3, 53–57 (2016). https://doi.org/10.1007/s40518-016-0057-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40518-016-0057-x