Abstract

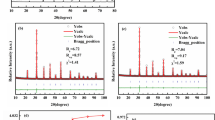

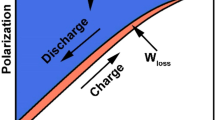

To produce high-performance dielectric capacitors for pulsed power applications, BaTiO3@(MgO–Nb2O5)–xYb2O3 (BT@MNY-x) ceramics were prepared via solid-state reaction route. The BT@MNY ceramics retained tetragonal perovskite structure without other obvious phases. Profound structural tests by Rietveld refinement of XRD patterns verified Yb3+ substituted the Ti4+ sites. In addition, after Yb3+ ions were incorporated into the lattice of barium titanate, the cubic phase of barium titanate was slightly distorted, the lattice constant of the sample gradually increased, and the tetragonality of the sample gradually decreased. With the increase of Yb2O3 content, the porosity and the diffuseness degree (γ) of the ceramics first decreased and then increased, reaching the peak values in the BT@MNY-0.5 sample. In addition, the grain size and dielectric constant of the samples decreased with the increase of Yb2O3 content. As a result, the breakdown voltage of the ceramics and performance metrics such as effective energy storage density first increased and then decreased. The calculated activation energies (Ea = 0.9–1.1 eV) closely resemble those observed for oxygen vacancy conduction activation energy in perovskite systems (around 1 eV), indicating that the conductivity in the BT@MNY ceramics is likely governed by oxygen vacancies. When x = 0.5, environmentally friendly barium titanate-based ceramics with Wrec of 0.82 J/cm3 and η of 44.34% were achieved. This work provides a theoretical basis for high energy storage barium titanate ceramics.

Similar content being viewed by others

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

F. Yan, J. Qian, S. Wang, J. Zhai, Nano Energy (2024). https://doi.org/10.1016/j.nanoen.2024.109394

D. Li, X. Zeng, Z. Li et al., J. Adv. Ceram. 10, 675 (2021). https://doi.org/10.1007/s40145-021-0500-3

C. Hou, W. Huang, W. Zhao, D. Zhang, Y. Yin, X. Li, ACS Appl. Mater. Interfaces. 9, 20484 (2017). https://doi.org/10.1021/acsami.7b02225

Z. Yao, Z. Song, H. Hao et al., Adv. Mater. (2017). https://doi.org/10.1002/adma.201601727

L. Yao, Z. Pan, S. Liu, J. Zhai, H.H. Chen, ACS Appl. Mater. Interfaces. 8, 26343 (2016). https://doi.org/10.1021/acsami.6b09265

H. Zhang, T. Wei, Q. Zhang et al., J. Mater. Chem. C 8, 16648 (2020). https://doi.org/10.1039/d0tc04381h

G. Wang, Z. Lu, Y. Li et al., Chem. Rev. 121, 6124 (2021). https://doi.org/10.1021/acs.chemrev.0c01264

X. Wu, Y. Xu, Y. Hu et al., Nat. Commun. 9, 4573 (2018). https://doi.org/10.1038/s41467-018-06914-7

L. Yang, X. Kong, F. Li et al., Prog. Mater. Sci. 102, 72 (2019). https://doi.org/10.1016/j.pmatsci.2018.12.005

W. Yang, H. Zeng, F. Yan et al., J. Mater. Chem. A 10, 11613 (2022). https://doi.org/10.1039/d2ta02534e

F. Shang, J. Wei, J. Xu et al., ACS Appl. Mater. Interfaces. 14, 53081 (2022). https://doi.org/10.1021/acsami.2c16577

L. Liu, Y. Liu, J. Hao et al., Nano Energy (2023). https://doi.org/10.1016/j.nanoen.2023.108275

B. Luo, X. Wang, E. Tian, H. Song, H. Wang, L. Li, ACS Appl. Mater. Interfaces. 9, 19963 (2017). https://doi.org/10.1021/acsami.7b04175

S.S. Parizi, A. Mellinger, G. Caruntu, ACS Appl. Mater. Interfaces. 6, 17506 (2014). https://doi.org/10.1021/am502547h

Y. Wenbo, Z. Chenghao, X. Yiming et al., J. Eur. Ceram. Soc. 43, 900 (2022). https://doi.org/10.1016/j.jeurceramsoc.2022.11.001

S. Li, P. Ge, H. Tang et al., ACS Appl. Energy Mater. 5, 12174 (2022). https://doi.org/10.1021/acsaem.2c01679

W. Huang, Y. Chen, X. Li, G. Wang, J. Xia, X. Dong, Chem. Eng. J. (2022). https://doi.org/10.1016/j.cej.2022.135523

A.A. Instan, S.P. Pavunny, M.K. Bhattarai, R.S. Katiyar, Appl. Phys. Lett. (2017). https://doi.org/10.1063/1.4986238

Z.B. Shen, X.H. Wang, D.S. Song, L.T. Li, Adv. Appl. Ceram. 115, 435 (2016). https://doi.org/10.1080/17436753.2016.1181814

J.B. Lim, S. Zhang, T.R. Shrout, Electron. Mater. Lett. 7, 71 (2011). https://doi.org/10.1007/s13391-011-0311-8

W. Liu, J. Gao, Y. Zhao, S. Li, J. Alloy. Compd. (2020). https://doi.org/10.1016/j.jallcom.2020.155938

D.W. Hahn, Y.H. Han, Jpn. J. Appl. Phys. (2009). https://doi.org/10.1143/jjap.48.111406

X.H. Ren, D.Y. Gui, Materials (2021). https://doi.org/10.3390/ma14226802

R. Waser, Ferroelectrics. 133, 109 (1992). https://doi.org/10.1080/00150199208217984

C. Sidar, M.N. Tripathi, P.K. Bajpai, Comput. Condens. Matter. 11, 27 (2017). https://doi.org/10.1016/j.cocom.2017.03.005

G.-W. Yan, M.-G. Ma, C.-B. Li et al., J. Alloy. Compd. (2021). https://doi.org/10.1016/j.jallcom.2020.158021

R. Stumpe, D. Wagner, D Bäuerle, Phys. Status Solidi A 75, 143 (1983). https://doi.org/10.1002/pssa.2210750116

M. Wei, J. Zhang, K. Wu, H. Chen, C. Yang, Adv. Appl. Ceram. 116, 439 (2017). https://doi.org/10.1080/17436753.2017.1352109

G. Ge, K. Huang, S. Wu et al., Energy Storage Mater. 35, 114 (2021). https://doi.org/10.1016/j.ensm.2020.11.006

C. Zhu, X. Wang, Q. Zhao, Z. Cai, Z. Cen, L. Li, J. Eur. Ceram. Soc. 39, 1142 (2019). https://doi.org/10.1016/j.jeurceramsoc.2018.11.034

Z. Song, H. Liu, S. Zhang et al., J. Eur. Ceram. Soc. 34, 1209 (2014). https://doi.org/10.1016/j.jeurceramsoc.2013.11.039

P. Guan, Y. Zhang, J. Yang, M. Zheng, Ceram. Int. 49, 11796 (2023). https://doi.org/10.1016/j.ceramint.2022.12.024

B. Liu, X. Wang, R. Zhang, L. Li, J. Am. Ceram. Soc. 100, 3599 (2017). https://doi.org/10.1111/jace.14802

Z. Shen, X. Wang, B. Luo, L. Li, J. Mater. Chem. A 3, 18146 (2015). https://doi.org/10.1039/c5ta03614c

M. Wei, J. Zhang, K. Wu, H. Chen, C. Yang, Ceram. Int. 43, 9593 (2017). https://doi.org/10.1016/j.ceramint.2017.03.139

X. Yi, C. Ji, G. Chen et al., Phys. Status Solidi A (2019). https://doi.org/10.1002/pssa.201900721

X. Dong, H. Chen, M. Wei, K. Wu, J. Zhang, J. Alloy. Compd. 744, 721 (2018). https://doi.org/10.1016/j.jallcom.2018.01.276

Acknowledgements

This work is supported by the Shanghai Institute of Ceramics, Chinese Academy of Sciences.

Author information

Authors and Affiliations

Contributions

Yang Gao: data curation, writing—original draft preparation. Tianyi Xie: conceptualization, methodology, software, writing—reviewing and editing. Huaizhi Wang: data curation, visualization, investigation, software. Junjie Yang: software, validation. Huixing Lin: supervision.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that there are no conflicts of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Gao, Y., Xie, T., Wang, H. et al. Effect of Yb2O3 doping on energy storage and dielectric properties of barium titanate based ceramics. J Mater Sci: Mater Electron 35, 1719 (2024). https://doi.org/10.1007/s10854-024-13470-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-024-13470-y