Abstract

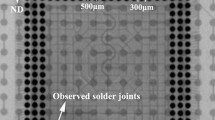

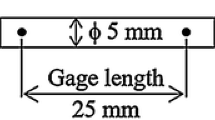

Crack propagation has been observed on the bulk solder area of the reworked fine-pitch ball grid array component with the solder joint type SAC305 (Sn97.18 Ag2.0 Cu0.75 Ni0.07) post 550 cycles thermal cycling test (TCT). Four variables were analyzed; control sample PT0, rework sample RT0, and two samples being exposed to the TCT at 550 cycles: sample without rework PT550 and sample with rework RT550. Nondestructive and destructive tests such as 3D X-ray, dye and pull test, cross-section, optical inspection, field emission scanning electron microscopy, and energy dispersive X-ray analysis (EDX) have been complemented with strain-energy density simulation results to further understand the symptoms. EDX analysis results show that up to 12.04 percent, by weight (wt%) gold content is present in the intermetallic compound particles along the crack propagation area in the bulk solder joint’s area due to the undissolved gold. Strain-energy density up to 3.04 Pa to the solder joints causing thermal fatigue crack as observed in the 3D X-ray, dye and pull test, and cross-section sample.

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from Western Digital®, but restrictions apply to the availability of these data, which were used under license for the current study, and so are not publicly available. Data are, however, available from the authors upon reasonable request and with permission of Western Digital.

References

C.E. Ho, C.W. Fan, W.Z. Hsieh, Surf. Coat. Technol. 259, 244–251 (2014). https://doi.org/10.1016/j.surfcoat.2014.04.027

J. Pan, J. Silk, M. Powers, P. Hyland, IEEE Trans. Compon. Packag. Manuf. Technol. 1, 1662–1669 (2011). https://doi.org/10.1109/TCPMT.2011.2160398

A.A. Ismail, M. Abu Bakar, A.A. Ehsan, Z.E. Zolkefli, Jurnal Teknologi 84, 1–8 (2022). https://doi.org/10.11113/jurnalteknologi.v84.19321

J.H. Du, Z. Raz, 5th international conference on control, automation and robotics (ICCAR). IEEE, pp. 776–781, 2019. https://doi.org/10.1109/ICCAR.2019.8813504

A. Otáhal, I. Szendiuch, J. Electr. Eng. 69, 305–310 (2018). https://doi.org/10.2478/jee-2018-0043

J. Wang, S. Xue, P. Zhang, P. Zhai, Y. Tao, J. Mater. Sci. Mater. Electron. 30, 9065–9086 (2019). https://doi.org/10.1007/s10854-019-01333-w

A.A. Ismail, M.A. Bakar, A.A. Ehsan, A. Jalar, E. Basiron, F.C. Ani, IEEE 39th international electronics. manufacturing technology conference (IEMT), pp. 1–4, 2022. https://doi.org/10.1109/IEMT55343.2022.9969477

A.A. Ismail, M.A. Bakar, A.A. Ehsan, A. Jalar, J. Burke, Z.E. Zolkefli, E. Basiron, Sci. Rep. 12, 15118 (2022). https://doi.org/10.1038/s41598-022-19436-6

A. Jalar, M.A. Bakar, R. Ismail, Metall. Mater. Trans. A 51, 1221–1228 (2020). https://doi.org/10.1007/s11661-019-05614-1

X. Liu, J. Shang, J. Hao, A. Hu, L. Gao, M. Li, 8th international conference on electronic packaging technology (ICEPT), pp. 984–987, 2017. https://doi.org/10.1109/ICEPT.2017.8046608

S. Zhang, H. Zhao, H. Xu, X. Fu, Microelectron. Reliab. 120, 114094 (2021). https://doi.org/10.1016/j.microrel.2021.114094

I.S. Aisha, A. Ourdjini, M.A.A. Hanim, O.S. Azlina, Int. J. Comput. Appl. 52, 244–250 (2015). https://doi.org/10.1504/ijcat.2015.073590

J.H. Lau, J. Electron. Packag. 143, 020803 (2020). https://doi.org/10.1115/1.4048037

M.S. Chang, M.A.A. Mohd Salleh, D.S.C. Halin, F. Somidin, H. Yasuda, K. Nogita, J. Mater. Res. Technol. (2023). https://doi.org/10.1016/j.jmrt.2023.09.139

H. Ji, J. Wang, M. Li, Microelectron. Reliab. 66, 134–142 (2016). https://doi.org/10.1016/j.microrel.2016.10.003

J. Xu, M. Wu, J. Pu, S. Xue, Adv. Mater. Sci. Eng. (2020). https://doi.org/10.1155/2020/4969647

B. Yu, Y. Gao, Chips 1, 191–209 (2022). https://doi.org/10.3390/chips1030013

K. Sinha, C. Glancey, H. Takiar, Y.C. Ong, L. Pan, IEEE 22nd electronics packaging technology conference (EPTC), pp. 330–334, 2020. https://doi.org/10.1109/eptc50525.2020.9315056

A.A. Ismail, M. Abu Bakar, A.A. Ehsan, A. Jalar, E. Basiron, F.C. Ani, IEEE Trans. Compon. Packag. Manuf. Technol. 12, 1492–1501 (2022). https://doi.org/10.1109/TCPMT.2022.3198406

J. Wang, S. Xue, J. Wang, P. Zhang, Y. Tao, Z. Wang, J. Mater. Sci. Mater. Electron. 31, 5731–5737 (2020). https://doi.org/10.1007/s10854-020-03141-z

Y.W. Sui, R. Sun, J.Q. Qi, Y.Z. He, F.X. Wei, Q.K. Meng, Z. Sun, Rare Met. 42, 1043–1049 (2017). https://doi.org/10.1007/s12598-017-0968-8

Acknowledgements

The authors would like to acknowledge the financial support provided by Western Digital® via SanDisk Storage Malaysia Sdn. Bhd. through a research grant (RR-2020-004) and collaboration with the Universiti Kebangsaan Malaysia.

Funding

This work was funded by Western Digital® via SanDisk Storage Malaysia Sdn. Bhd., RR-2020-004, Azman Jalar.

Author information

Authors and Affiliations

Contributions

A.I and Z.Z performed rework sample preparation, temperature measurements, 3D X-ray, cross-section samples, dye and pull test, FE-SEM, and EDX analysis. A.I performed the strain-energy density simulation analysis. Data validation and general recommendations were provided by E.B, F.C.A., and A.I. The first draft of the manuscript was written by A.I, and all authors commented on previous versions of the manuscript. Supervision, writing, review, editing, and funding acquisition were performed by M.A, A.J, and F.C.A. All authors read and approved the final manuscript. All authors contributed to the study's conception and design.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Ethical approval

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ismail, A.A., Abu Bakar, M., Jalar, A. et al. Undissolved gold in fine-pitch BGA solder joint under thermal cycling test. J Mater Sci: Mater Electron 35, 866 (2024). https://doi.org/10.1007/s10854-024-12595-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-024-12595-4