Abstract

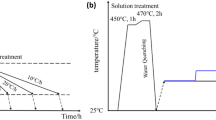

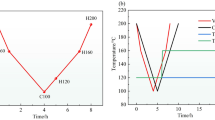

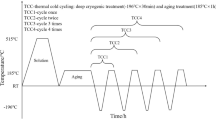

The study optimizes the corrosion resistance of an Al–Zn–Mg–Cu alloy by changing the sequence of cold-rolling (CR) and artificial ageing (AR) processes. The samples are artificially aged at 150 ºC for 45 min and subsequently cold-rolled by the cumulative deformation of 10%, 20%, 30%, and 36%, which are denoted as CR + AR samples. In comparison, the CR + AR samples are cold-rolled by a cumulative 30% reduction in thickness and then aged at 150 ºC for various periods from 1 min to 8 h. The hardness of AR + CR samples increases from 158.7 to 213.4 HV with the increasing cumulative CR passes. But in the CR + AR group, it increases from 166.2 to 228.3 HV for 30-min ageing and decreases slightly with the ageing time. η phase precipitates during artificial ageing are the dominant strengthening factor. The improved corrosion resistance in CR + AR samples is mainly attributed to the formation of discontinuous grain-boundary precipitates that obstruct the anodic corrosion pathway. The optimal corrosion resistance is achieved by 30% cold rolling and ageing at 150 ºC for 8 h. This sample owns the highest impedance (ǀZǀ = 985.0 Ω cm2) and the most positive corrosion potential (Ecorr = −0.748 V).

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.References

Williams JC, Edgar AS (2003) Progress in structural materials for aerospace systems. Acta Mater 51:5775–5799. https://doi.org/10.1016/j.actamat.2003.08.023

Tang J, Wang J, Teng J, Zeng RC (2021) Effect of Zn content on the dynamic softening of Al–Zn–Mg–Cu alloys during hot compression deformation. Vacuum 184:109941. https://doi.org/10.1016/j.vacuum.2020.109941

Zou Y, Wu XD, Tang SB, Zhu QQ, Song H, Cao LF (2020) Co-precipitation of T’ and η’ phase in Al–Zn–Mg–Cu alloys. Mater Charact 169:110610. https://doi.org/10.1016/j.matchar.2020.110610

Mei L, Chen XP, Wang C, Xie J, Liu Q (2021) Good combination of strength and corrosion resistance in an Al-Cu-Mg alloy processed by a short-cycled thermomechanical treatment. Mater Charact 181:111469. https://doi.org/10.1016/j.matchar.2021.111469

Zuo JR, Hou LG, Shi JT, Cui H, Zhuang LZ, Zhang JS (2017) Enhanced plasticity and corrosion resistance of high strength Al–Zn–Mg–Cu alloy processed by an improved thermomechanical processing. J Alloys Compd 716:220–230. https://doi.org/10.1016/j.jallcom.2017.05.047

Guo C, Zhang HT, Li SS, Chen RX, Nan YF, Li L, Wang P, Li BM et al (2021) Evolution of microstructure, mechanical properties and corrosion behavior of Al–4Mg–2Zn–0.3Ag (wt%) alloy processed by T6 or thermomechanical treatment. Corro Sci 188:109551. https://doi.org/10.1016/j.corsci.2021.109551

Zou Y, Cao LF, Wu XD, Wang YC, Sun X, Song H, Couper MJ (2020) Effect of ageing temperature on microstructure, mechanical property and corrosion behavior of aluminum alloy 7085. J Alloys Compd 823:153792. https://doi.org/10.1016/j.jallcom.2020.153792

Wang YC, Liu MW, Xiao WL, Zhao WT, Ma CL (2020) Effects of multi-stage aging treatments on the precipitation behavior and properties of 7136 aluminum alloy. J Alloys Compd 814:152256. https://doi.org/10.1016/j.jallcom.2019.152256

Wang YC, Cao LF, Wu XD, Tong X, Liao B, Huang GJ, Wang ZA (2020) Effect of retrogression treatments on microstructure, hardness and corrosion behaviors of aluminum alloy 7085. J Alloys Compd 814:152264. https://doi.org/10.1016/j.jallcom.2019.152264

Sun XY, Zhang B, Lin HQ, Zhou Y, Sun L, Wang JQ, Han EH, Ke W (2013) Correlations between stress corrosion cracking susceptibility and grain boundary microstructures for an Al–Zn–Mg alloy. Corros Sci 77:103–112. https://doi.org/10.1016/j.corsci.2013.07.032

Jiang L, Zhang ZH, Fu HD, Huang SY, Zhuang DW, Xie JX (2022) Corrosion behavior and mechanism of Al–Zn–Mg–Cu alloy based on the characterization of the secondary phases. Mater Charact 189:111974. https://doi.org/10.1016/j.matchar.2022.111974

Ren YF, Wan TJ, Xu YS, Zhang K, Zhang MY, Li JH (2024) Effects of stress aging treatment on the microstructure, mechanical properties and electrochemical corrosion behavior of Al–Zn–Mg–Cu alloy. J Alloys Compd 997:174686. https://doi.org/10.1016/j.jallcom.2024.174686

Zhang ZG, Ma XW, Zhang CS, Chu GN, Meng ZJ, Zhao GQ, Chen L (2022) Effect of stress-aging treatment on the mechanical and corrosion properties of Al–Zn–Mg–Cu alloy. Mater Sci Eng 838:142791. https://doi.org/10.1016/j.msea.2022.142791

Adrien J, Maire E, Estevez R, Ehrstrom JC, Warner T (2004) Influence of the thermomechanical treatment on the microplastic behaviour of a wrought Al–Zn–Mg–Cu alloy. Acta Mater 52:1653–1661. https://doi.org/10.1016/j.actamat.2003.12.009

Zhang M, Shuai GL, Wang YQ, Li Z, Zhang DT, Yu HZ, Li L (2022) Corrosion behaviors at different temperature based on the ultrafine-grained structure of Al–Fe alloy. Mater Lett 311:131508. https://doi.org/10.1016/j.matlet.2021.131508

Chen Y, Tang YC, Zhang HA, Hu N, Gao N, Starink MJ (2019) Microstructures and hardness prediction of an ultrafine-grained Al-2024 Alloy. Metals 9:1182. https://doi.org/10.3390/met9111182

Williamson GK, Smallman RE (1956) III. Dislocation densities in some annealed and cold-worked metals from measurements on the X-ray debye-scherrer spectrum. Philos Mag 1:34–46. https://doi.org/10.1080/14786435608238074

Velázquez-Carrillo OA, García-Pastor FA (2021) Thermal stability of microstructure, mechanical properties, formability parameters and crystallographic texture in an Al-7075 alloy processed by accumulative roll bonding. J Mater Res Technol 11:2208–2220. https://doi.org/10.1016/j.jmrt.2021.02.041

Fuster V, Druker AV, Baruj A, Malarría J, Bolmaro R (2015) Characterization of phases in an Fe–Mn–Si–Cr–Ni shape memory alloy processed by different thermomechanical methods. Mater Charact 109:128–137. https://doi.org/10.1016/j.matchar.2015.09.026

Ding LP, Zhao L, Weng YY, Schryvers D, Liu Q, Idrissi H (2021) Atomic-scale investigation of the heterogeneous precipitation in the E (Al18Mg3Cr2) dispersoid of 7075 aluminum alloy. J Alloys Compd 851:156890. https://doi.org/10.1016/j.jallcom.2020.156890

Li XZ, Chen X, Zheng JX, Xu XS, Chen B (2024) Atomic-level characterization of η-twins with non-homogeneous nucleation on the E(Al18Mg3Cr2) phase in 7075 alloy: TEM observations and DFT calculations. J Alloys Compd 976:173148. https://doi.org/10.1016/j.jallcom.2023.173148

Meyrick G, Powell GW (1973) Phase transformations in metals and alloys. Annu Rev Mater Sci 3:327–362. https://doi.org/10.1146/annurev.ms.03.080173.001551

Xiong YD, Robson JD, Yao YC, Zhong XL, Guarracino F, Bendo A, Jin ZL, Hashimoto T et al (2023) Effects of heat treatments on the microstructure and localized corrosion behaviors of AA7075 aluminum alloy. Corros Sci 221:111361. https://doi.org/10.1016/j.corsci.2023.111361

Garner A, Euesden R, Yao YC, Aboura Y, Zhao H, Donoghue J, Curioni M, Gault B et al (2021) Multiscale analysis of grain boundary microstructure in high strength 7xxx Al alloys. Acta Mater 202:190–210. https://doi.org/10.1016/j.actamat.2020.10.021

Peng XY, Li Y, Xu GF, Huang JW, Yin ZM (2018) Effect of precipitate state on mechanical properties, corrosion behavior, and microstructures of Al–Zn–Mg–Cu Alloy. Met Mater Int 24:1046–1057. https://doi.org/10.1007/s12540-018-0057-z

Moghanni-Bavil-Olyaei H, Arjomandi J, Hosseini M (2017) Effects of gallium and lead on the electrochemical behavior of Al–Mg–Sn–Ga–Pb as anode of high rate discharge battery. J Alloys Compd 695:2637–2644. https://doi.org/10.1016/j.jallcom.2016.11.176

McCafferty E (2005) Validation of corrosion rates measured by the Tafel extrapolation method. Corros Sci 47:3202–3215. https://doi.org/10.1016/j.corsci.2005.05.046

Fu J, Cui K (2022) Effect of Mn content on the microstructure and corrosion resistance of Al–Cu–Mg–Mn alloys. J Alloys Compd 896:162903. https://doi.org/10.1016/j.jallcom.2021.162903

Brunner JG, Birbilis N, Ralston KD, Virtanen S (2012) Impact of ultrafine-grained microstructure on the corrosion of aluminium alloy AA2024. Corros Sci 57:209–214. https://doi.org/10.1016/j.corsci.2011.12.016

Feng L, Pan QL, Wei LL, Huang ZQ, Liu ZM (2015) Through-thickness inhomogeneity of localized corrosion in 7050–T7451 Al alloy thick plate. J Cent South Univ 22:2423–2434. https://doi.org/10.1007/s11771-015-2769-2

Laxman Mani Kanta P, Srivastava PC, Venkateswarlu K, Paswan S, Mahato B, Das G, Sivaprasad K, Gopala Krishna K (2017) Corrosion behavior of ultrafine-grained AA2024 aluminum alloy produced by cryorolling. Int J Miner Metall Mater 24:1293–1305. https://doi.org/10.1007/s12613-017-1522-2

Bonora PL, Andrei M, Eliezer A, Gutman EM (2002) Corrosion behaviour of stressed magnesium alloys. Corros Sci 44:729–749. https://doi.org/10.1016/S0010-938X(01)00101-9

Guo C, Wang H, Guo YQ, Chen YF, Ke YJ, Zhang HT, Liu XG, Nagaumi H (2024) Regulating corrosion resistance of Al–4.5Mg–2.0Zn–0.3Ag alloy via non-isothermal ageing combined with cold rolling. Corros Sci 229:111878. https://doi.org/10.1016/j.corsci.2024.111878

Dos Santos SL, Antunes RA, Santos SF (2015) Influence of injection temperature and pressure on the microstructure, mechanical and corrosion properties of a AlSiCu alloy processed by HPDC. Mater Des 88:1071–1081. https://doi.org/10.1016/j.matdes.2015.09.095

Li JF, Jia ZQ, Li CX, Birbilis N, Cai C (2009) Exfoliation corrosion of 7150 Al alloy with various tempers and its electrochemical impedance spectroscopy in EXCO solution. Mater Corros 60:407–414. https://doi.org/10.1002/maco.200805102

Moreira AH, Benedetti AV, Sumodjo PTA, Garrido JA, Cabot PL (2002) Electrochemical behaviour of heat-treated Al–Zn–Mg alloys in chloride solutions containing sulphate. Electrochim Acta 47:2823–2831. https://doi.org/10.1016/S0013-4686(02)00169-X

Liu Y, Wang Z, Ke W (2014) Study on influence of native oxide and corrosion products on atmospheric corrosion of pure Al. Corros Sci 80:169–176. https://doi.org/10.1016/j.corsci.2013.11.027

Xiong HQ, Zhou YX, Kong CL, Yu HL (2022) Effect of retrogression treatment with different heating rates on microstructure, strength and corrosion behaviors of 7050 alloy. Materials Charact 186:111819. https://doi.org/10.1016/j.matchar.2022.111819

Tao JQ, Xiang L, Zhang YP et al (2022) Corrosion behavior and mechanical performance of 7085 aluminum alloy in a humid and hot marine atmosphere. Materials 15:7503. https://doi.org/10.3390/ma15217503

Zhao GY, Wen QH, Fang M, Xiao Z (2024) Effects of high temperature pre-precipitation on mechanical and corrosion behavior of an Al–Zn–Mg–Cu alloy. J Alloy Compd 983:173738. https://doi.org/10.1016/j.jallcom.2024.173738

Feng JQ, Wang YB, Tao FX, Li YK, He KZ, Xu ZB, Tang HQ, Wang ZD (2024) Effect of tensile cracks on the corrosion protection properties of anodic oxide films on 5083 Al alloy. J Alloys Compd 997:174950. https://doi.org/10.1016/j.jallcom.2024.174950

Tian RZ, Wang ZT (2000) Aluminum Alloy and Its Processing Manual. Central South University Press, Changsha

Rao YQ, Wang Q, Oka D, Ramachandran CS (2020) On the PEO treatment of cold sprayed 7075 aluminum alloy and its effects on mechanical, corrosion and dry sliding wear performances thereof. Surf Coat Technol 383:125271. https://doi.org/10.1016/j.surfcoat.2019.125271

Zhang Z, Deng YL, Ye LY, Wu WB, Wang FQ, Jiang KD, Guo XB (2020) Influence of aging treatments on the strength and localized corrosion resistance of aged Al–Zn–Mg–Cu alloy. J Alloys Compd 846:156223. https://doi.org/10.1016/j.jallcom.2020.156223

Shao P, Xiao H, Liu K, Chen X, Hou MY, Zhang QB, Qiao C, Huang S (2024) Influence of annealing temperature on the mechanical properties and corrosion behavior of Ti–5.5Al–2.0Zr–1.5Sn–0.5Mo–1.5Nb alloy. Arabian J Chem 17:105790. https://doi.org/10.1016/j.arabjc.2024.105790

Akiyama E, Zhang ZG, Watanabe Y, Tsuzaki K (2008) Effects of severe plastic deformation on the corrosion behavior of aluminum alloys. J Solid State Electrochem 13:277–282. https://doi.org/10.1007/s10008-007-0496-9

Liu YR, Pan QL, Li H, Huang ZQ, Ye J, Li MJ (2019) Revealing the evolution of microstructure, mechanical property and corrosion behavior of 7A46 aluminum alloy with different ageing treatment. J Alloys Compd 792:32–45. https://doi.org/10.1016/j.jallcom.2019.03.324

Lin Y, Lu CG, Wei CY, Zheng ZQ (2018) Effect of aging treatment on microstructures, tensile properties and intergranular corrosion behavior of Al-Cu-Li alloy. Materials Charact 141:163–168. https://doi.org/10.1016/j.matchar.2018.04.04

Wang KX, Yin DF, Zhao YC, Atrens A, Zhao MC (2020) Microstructural evolution upon heat treatments and its effect on corrosion in Al–Zn–Mg alloys containing Sc and Zr. J Mater Res Technol 9:5077–5089. https://doi.org/10.1016/j.jmrt.2020.03.025

Wang YC, Yin LT, Jin Y, Pan JS, Leygraf C (2017) Numerical simulation of micro-galvanic corrosion in Al alloys: steric hindrance effect of corrosion product. J Electrochem Soc 164:1035–1043. https://doi.org/10.1149/2.0871714jes

Li CY, Fan XL, Cui LY, Zeng RC (2020) Corrosion resistance and electrical conductivity of a nano ATO-doped MAO/methyltrimethoxysilane composite coating on magnesium alloy AZ31. Corros Sci 168:108570. https://doi.org/10.1016/j.corsci.2020.108570

Zhang HT, Guo C, Li SS, Li BM, Nagaumi H (2022) Influence of cold pre-deformation on the microstructure, mechanical properties and corrosion resistance of Zn-bearing 5xxx aluminum alloy. J Mater Res Technol 16:1202–1212. https://doi.org/10.1016/j.jmrt.2021.12.080

Acknowledgements

This research has been funded by National Natural Science Foundation of China (No. 51601162) and Natural Science Foundation of Fujian Province, China (No. 2021J011208).

Author information

Authors and Affiliations

Contributions

Jiafan Chen was involved in the investigation and writing—original draft. Xu Yuan contributed to the investigation and writing—review and editing. Zhenghao Gong assisted in the investigation, methodology, and data curation. Ying Chen contributed to the conceptualization, supervision, and funding acquisition. Juan Zuo and Jingjing Sun were involved in the investigation. Bilan Lin contributed to the writing—review and editing. Houan Zhang contributed to the resources and project administration.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Handling Editor: Nima Haghdadi.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chen, J., Yuan, X., Gong, Z. et al. Optimizing corrosion behaviours of an Al–Zn–Mg–Cu alloy through cold rolling and artificial ageing. J Mater Sci (2024). https://doi.org/10.1007/s10853-024-10155-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10853-024-10155-z