Abstract

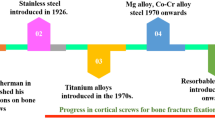

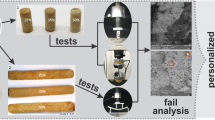

The drawbacks associated with metallic implants, like stress shielding and revision surgery, can be avoided using bioabsorbable implants. Hence, in this work, biocomposites made of different compositions of polylactic acid (PLA), nanohydroxyapatite (nHap), and modified chitosan (MCS) were prepared. The prepared biocomposite was subjected to X-ray diffraction, surface morphology, differential scanning calorimetry, contact angle analysis, thermogravimetric, Fourier transform infrared spectroscopy, and mechanical characterisation. The field emission scanning electron microscopy with energy-dispersive X-ray spectroscopy analysis demonstrated that the drawback of non-uniform distribution associated with chitosan (CS) had been overcome with the MCS. The maximum degradation temperature obtained with the biocomposite developed in the present investigation was higher (389 °C) than with neat PLA and PLA with chitosan. Thus, the interaction of nHAp with MCS and PLA made the fabricated biocomposites superior in terms of thermal stability. The contact angle study showed an enhancement in the surface wettability property, suggesting that the prepared biocomposites are suitable for cell adhesion. The study found PLA/nHAp/MCS composite to have better modulus and elongation as compared to PLA and PLA/nHAp. Also, the characterisation of the materials showcased better physiochemical properties with PLA/nHAp/MCS biocomposite. Moreover, the DSC results confirmed that no phase separation has occurred in the formed biocomposites. Thus, the developed biocomposites have the potential to be an alternative biodegradable implant material, especially for fabricating bone screws and plates to be used as non-load bearing internal fixation devices.

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.References

Bioresorbable Polymers Market Size Will Attain USD 2939.7 Million by 2028 growing at 13.4% CAGR - Exclusive report by zion market research global bioresorbable (Resorbable) Polymers Market Size, Share, Trends Analysis Report.

Bioresorbable Polymers Market Size, Share & Trends Analysis Report By Product (PLA, Proteins, Polyglycolic Acid), By application (drug delivery, orthopedics), By Region (Asia Pacific, North America), And Segment Forecasts, 2022–2030

Subbiah T, Bhat GS, Tock RW, Parameswaran S, Ramkumar SS (2005) Electrospinning of nanofibers. J Appl Polym Sci 96(2):557–569

Onche II, Osagie OE, Inuhu S (2011) Removal of orthopaedic implants:indications, outcome and economic implications. J West Afr Coll Surg 1(1):101–112

Nag P, Chanda S (2021) Biomechanical design prognosis of two extramedullary fixation devices for subtrochanteric femur fracture: a finite element study. Med Biol Eng Comput Springer 59:271–285. https://doi.org/10.1007/s11517-020-02306-6

Nag P, Borgohain B, Ahmed KA et al (2022) The influence of static load and sideways impact fall on extramedullary bone plates used to treat intertrochanteric femoral fracture: a preclinical strength assessment. Ann Biomed Eng 50(12):1923–1940. https://doi.org/10.1007/s10439-022-03013-z

Yetkin H, Senköylü A, Cila E (2000) Biodegradable implants in orthopaedics and traumatology. Turk J Med Sci 30(1):297–301

Suzuki S, Ikada Y (2012) Bioabsorbable polymers. Biomater Surg Oper 13:19–38

Bhasney SM, Patwa R, Kumar A, Katiyar V (2017) Plasticizing effect of coconut oil on morphological, mechanical, thermal, rheological, barrier, and optical properties of poly (lactic acid): A promising candidate for food packaging. J Appl Polym Sci 134(41):1–12

Russias J, Saiz E, Nalla RK, Gryn K, Ritchie RO, Tomsia AP (2006) Fabrication and mechanical properties of PLA/HA composites: a study of in vitro degradation. Mater Sci Eng C 26(8):1289–1295

Kontakis GM, Pagkalos JE, Tosounidis TI, Melissas J, Katonis P (2007) Bioabsorbable materials in orthopaedics. Acta Orthop Belg 73(2):159–169

Tripathi N, Katiyar V (2016) PLA/functionalized-gum arabic based bionanocomposite films for high gas barrier applications. J Appl Polym Sci 133(21):1–8

Shan L, Shuhao Q, He M, Zhou D, Qin Q, Wang H (2020) Current applications of poly (lactic acid) composites in tissue engineering and drug delivery. Compos Part B Eng 199:108238

Gross KA, Komarovska L, Viksna A (2013) Efficient zinc incorporation in hydroxyapatite through crystallization of an amorphous phase could extend the properties of zinc apatites. J Aust Ceram Soc 49(2):129–135

Binay B, Kumar R (2019) Plasma treated and untreated thermoplastic biopolymers/biocomposites in tissue engineering and biodegradable implants. Mater Biomed Eng 15:339–369

Liu S, Yan H, Fang Z, Wang H (2014) Effect of graphene nanosheets on morphology, thermal stability and flame retardancy of epoxy resin. Compos Sci Technol 90:40–47

Buzarovska A, Sorina D, Leona C, Marieta C (2018) Porous poly (L-lactic acid) nanocomposite scaffolds with functionalized TiO2 nanoparticles: Properties, cytocompatibility and drug release capability. J Mater Sci 53(16):11151–11166

Wendel M, Sommarin Y, Heine Gard D (1998) Bone matrix proteins: isolation and characterization of a novel cell-binding keratan sulfate proteoglycan (osteoadherin) from bovine bone. J Cell Biol 141(3):839–847

Shepherd JH, Shepherd DV, Best SM (2012) Substituted hydroxyapatites for bone repair. J Mater Sci Mater Med 23(10):2335–2347

Felfel RM, Ahmed I, Parsons AJ, Rudd CD (2013) Bioresorbable screws reinforced with phosphate glass fibre: manufacturing and mechanical property characterisation. J Mech Behav Biomed Mater 17:76–88

Singh M, Pal AK, Bhasney SM, Bhagabati P, Katiyar V (2018) Effect of dicumyl peroxide on a poly (lactic acid) (PikkLA)/poly (butylene succinate) (PBS)/functionalized chitosan-based nanobiocomposite for packaging: A reactive extrusion study. ACS Omega 3(10):13298–13312

Cheung RCF, Ng TB, Wong JH, Chan WY (2015) Chitosan: an update on potential biomedical and pharmaceutical applications. Mar Drugs 13(8):5156–5186

Kumar MN, Muzzarelli RA, Muzzarelli C, Sashiwa H, Domb AJ (2004) Chitosan chemistry and pharmaceutical perspectives. Chem Rev 104:6017–6084

Pal AK, Katiyar V (2016) Nanoamphiphilic chitosan dispersed poly (lactic acid) bionanocomposite films with improved thermal, mechanical, and gas barrier properties. Biomacromol 17(8):2603–2618

Zhang H, Mao X, Du Z, Jiang W, Han X, Zhao D, Han D, Li Q (2016) Three dimensional printed macroporous polylactic acid/hydroxyapatite composite scaffolds for promoting bone formation in a critical-size rat calvarial defect model. Sci Technol Adv Mater 17(1):136–148

Tu C, Chen J, Huang C, Xiao Y, Tang X, Li H, Ma Y, Yan J, Li W, Wu H, Liu C (2020) Effects of electromagnetic fields treatment on rat critical-sized calvarial defects with a 3D-printed composite scaffold. Stem Cell Res Ther 11:1–4

Liu S, Qin S, He M, Zhou D, Qin Q, Wang H (2020) Comp B Eng 199:108238

Sun F, Wang T, Yang Y (2022) Hydroxyapatite composite scaffold for bone regeneration via rapid prototyping technique: a review. Rapid Prototyp J 28(3):585–605

Jia Z, Ma H, Liu J, Yan X, Liu T, Cheng YY, Li X, Wu S, Zhang J, Song K (2023) Preparation and characterization of polylactic acid/nano hydroxyapatite/nano hydroxyapatite/human acellular amniotic membrane (PLA/nHAp/HAAM) hybrid scaffold for bone tissue defect repair. Materials 16(5):1937

Bikiaris ND, Koumentakou I, Samiotaki C, Meimaroglou D, Varytimidou D, Karatza A, Kalantzis Z, Roussou M, Bikiaris RD, Papageorgiou GZ (2023) Recent advances in the investigation of poly(lactic acid) (PLA) nanocomposites: incorporation of various nanofillers and their properties and applications. Polymers 15(5):1196

Prasad A, Bhasney SM, Prasannavenkadesan V, Sankar MR, Katiyar V (2023) Nano-hydroxyapatite reinforced polylactic acid bioabsorbable cancellous screws for bone fracture fixations. J Appl Polym Sci 140(43):e54577

Prasad A, Bhasney SM, Prasannavenkadesan V, Sankar MR, Katiyar V (2023) Polylactic acid reinforced with nano-hydroxyapatite bioabsorbable cortical screws for bone fracture treatment. J Polym Res 30(5):177

Prasad A, Bhasney SM, Sankar MR, Katiyar V (2017) Fish scale derived hydroxyapatite reinforced poly (lactic acid) polymeric bio-films: possibilities for sealing/locking the internal fixation devices. Mater Today 4(2):1340–1349

Tripathi N, Katiyar V (2016) PLA/functionalized-gum arabic based bio nanocomposite films for high gas barrier applications. J Appl Polym Sci 133(21):1–8

Backes EH, Pires LDN, Costa LC, Passador FR, Pessan LA (2019) Analysis of the degradation during melt processing of PLA/Biosilicate® composites. J Compos Sci 3(2):52. https://doi.org/10.3390/jcs3020052

Ambrosio-Martín J, Fabra MJ, López-Rubio A, Gorrasi G, Sorrentino A, Lagaron JM (2016) Assessment of ball milling as a compounding technique to develop nanocomposites of poly(3-hydroxybutyrate-co-3-hydroxyvalerate) and bacterial cellulose nanowhiskers. J Polym Environ 24:241–254. https://doi.org/10.1007/s10924-016-0767-6

Torres-Hernández YG, Ortega-Díaz GM, Téllez-Jurado L, Castrejón-Jiménez NS, Altamirano-Torres A, García-Pérez BE, Balmori-Ramírez H (2018) Biological compatibility of a polylactic acid composite reinforced with natural chitosan obtained from shrimp waste. Materials 11:1465. https://doi.org/10.3390/ma11081465

Mohamad SNK, Ramli I, Abdullah LC, Mohamed NH, Islam MS, Ibrahim NA, Ishak NS (2021) Evaluation on structural properties and performances of graphene oxide incorporated into chitosan/poly-lactic acid composites: CS/PLA versus CS/PLA-GO. Polym Basel 13(11):1839. https://doi.org/10.3390/polym13111839.PMID:34199389;PMCID:PMC8199591

Injorhor P, Trongsatitkul T, Wittayakun J, Ruksakulpiwat C, Ruksakulpiwat Y (2022) Nano-hydroxyapatite from white seabass scales as a bio-filler in polylactic acid biocomposite: preparation and characterization. Polym Basel 14(19):4158. https://doi.org/10.3390/polym14194158

Correlo VM, Boesel LF, Bhattacharya M, Mano JF, Neves NM, Reis RL (2005) Properties of melt processed chitosan and aliphatic polyester blends. Mat Sci Eng A Struct 403:57–68

Râpă M, Miteluţ AC, Tănase EE, Grosu E, Popescu P, Popa ME, Rosnes JT, Sivertsvik M, Darie-Niţă RN, Vasile C (2016) Influence of chitosan on mechanical, thermal, barrier and antimicrobialproperties of PLA-biocomposites for food packaging. Compos Part B Eng 102:112–121

Liu S, Zheng Y, Liu R, Tian C (2020) Preparation and characterization of a novel polylactic acid/hydroxyapatite composite scaffold with biomimetic micro-nanofibrous porous structure. J Mater Sci Mater Med 31:1–11. https://doi.org/10.1007/s10856-020-06415-4

Veljović D, Jančić-Hajneman R, Balać I, Jokić B, Putić S, Petrović R, Janaćković D (2011) The effect of the shape and size of the pores on the mechanical properties of porous HAP-based bioceramics. Ceram Int 37(2):471–479

Gupta A, Prasad A, Mulchandani N, Shah M, Sankar MR, Kumar S, Katiyar V (2017) Multifunctional nanohydroxyapatite-promoted toughened high-molecular-weight stereocomplex poly (lactic acid)-based bionanocomposite for both 3D-printed orthopedic implants and high-temperature engineering applications. ACS Omega 2(7):4039–4052

Acknowledgements

The authors would like to thank the experimental and instrumental facility provided by the Centre for Sustainable Polymers and CIF at IIT Guwahati, India. The first author acknowledges the contribution of SERB-FICCI and ORTHOTECH, India, towards the fellowship received under the Prime Minister’s Fellowship for Doctoral Research. The authors would like to acknowledge Dr. Gourhari Chakraborty and Dr. Siddharth M. Bhasney for their insightful suggestions.

Author information

Authors and Affiliations

Contributions

D.B. contributed to conceptualisation, experimentation, data analysis, manuscript writing—first draft, and manuscript writing—review draft. V.P. contributed to data analysis and manuscript writing—review draft. V.K. contributed to data validation, conceptualisation, and supervision.

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare no conflict of interest.

Additional information

Handling Editor: Stephen Eichhorn.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Bose, D., Prasannavenkadesan, V. & Katiyar, V. Tailored material for bioresorbable internal fixation devices: a novel approach using nanohydroxyapatite and chitosan in polylactic acid. J Mater Sci 59, 215–227 (2024). https://doi.org/10.1007/s10853-023-09110-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-023-09110-1