Abstract

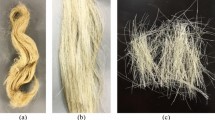

Sisal fiber/polycaprolactone (SF/PCL) composites are a new and exciting development in the field of sustainable materials research. Enhancing the physical strength of these SF/PCL composites has been the primary emphasis of the present study work. The most efficient strategies to increase the chemical treatment process have been identified using methodologies such as Taguchi’s and Grey Relational Analysis (GRA). The injection molding technique was used to make the composites while important variables were changed. Chemical treatments solutions (potassium hydroxide, lithium hydroxide, and potassium acetate), chemical concentration (2%, 4%, and 6% w/v), and treatment duration (3, 6, and 9 h) were the variables for this work. Various SF/PCL composite variations were produced as a result of these adjustments. A number of physical properties were measured to assess the improved composites’ strength, including modulus of elasticity, flexural strength, impact resistance, deformability under bending, elongation under tension, and tensile strength. To examine the examined and treated materials in detail, we employed a scanning electron microscope (SEM). Using GRA and mean plots, the composite’s ideal values were the same. The optimal parameters for X1-Y2-Z2 were determined to enhance the mechanical properties of SF/PCL, which are KOH, 4%, and 4 h. However, the microstructure of the PCL matrix bio-composite strengthened with sisal fiber was affected by a variety of surface treatments.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Data availability

No datasets were generated or analysed during the current study.

Change history

14 September 2024

The original online version of this article was revised: The author name ‘Vikrant Yashwant Ganvir’ was incorrectly written as ‘Vikrant Yashwant Ganvi’. The original article has been corrected.

20 September 2024

A Correction to this paper has been published: https://doi.org/10.1007/s10751-024-02127-1

References

Krishnaiah, P., Ratnam, C.T., Manickam, S.: Improved Mechanical Properties and Theoretical Prediction of Young’s Modulus of Polylactide Composites Reinforced with Sisal Fibers, in Materials Today: Proceedings, pp. 22494–22505. (2018)

Gupta, U.S., et al.: Investigation on effects of fiber loading of mechanical properties of banana/sisal hybrid composite, in Materials Today: Proceedings, pp. 7829–7837. (2021)

Miraoui, I., Jaballi, S., Rabeh, S.: Analysis of long unidirectional sisal fibers reinforced plaster: An experimental investigation, in Materials Today: Proceedings, pp. 152–157. (2021)

Jayaraman, A., Balaji, V., Sowsuriya, S., Bhuvanesh, S., Vasudevan, M.: Upcycling agro-waste fibres for cleaner production of concrete– technical feasibility and environmental considerations, in IOP Conference Series: Earth and Environmental Science, (2023)

Agor, C.D., Mbadike, E.M., Alaneme, G.U.: Evaluation of sisal fiber and aluminum waste concrete blend for sustainable construction using adaptive neuro-fuzzy inference system. Sci. Rep., 13, 1, (2023)

Thangaraj, S., Pradeep, G.M., Dani, M.S.H., Mayakannan, S., Benham, A.: Experimental investigations on tensile and compressive properties of nano alumina and arecanut shell powder reinforced polypropylene hybrid composites. Mater. Today Proc. 68, 2243–2248 (2022)

Bothiraj, T., Boopathi, K., Kalaiselvan, K., Benham, A., Mayakannan, S.: Experimental investigations on mechanical and wear behavior of waste marble dust and coconut fiber reinforced hybrid bio composites. Mater. Today Proc. 68, 2239–2242 (2022)

Rahman, M.M., Sultana, J.: Design and Optimization of Natural Fiber Reinforced Hybrid Composite RVE: A Finite Element Analysis, in International Conference on Engineering, Science and Advanced Technology, ICESAT 2023, pp. 204–209. (2023)

Das, D., Mukhopadhyay, S., Kaur, H.: Optimization of fiber composition in natural fiber-reinforced composites using a simplex lattice design. J. Compos. Mater. 46(26), 3311–3319 (2012)

Aggarwal, L., Sinha, S., Bhatti, M.S., Gupta, V.K.: Mixer design optimization with fractured surface topography of mechanical properties of polymer biocomposites. J. Taiwan. Inst. Chem. Eng. 74, 272–280 (2017)

Mayakannan, S., Raj, J.B., Raja, V.L., Nagaraj, M.: Effectiveness of silicon nanoparticles on the mechanical, wear, and physical characteristics of PALF/sisal fiber–based polymer hybrid nanocomposites. Biomass Convers. Biorefin. 13(14), 13291–13305 (2023)

Satishkumar, P., Mahesh, G., Meenakshi, R., Vijayan, S.N.: Tribological characteristics of powder metallurgy processed Cu-WC/SiC metal matrix composites, in Materials Today: Proceedings, Elsevier Ltd, pp. 459–465. (2020)

Silva, G., Kim, S., Bertolotti, B., Nakamatsu, J., Aguilar, R.: Optimization of a reinforced geopolymer composite using natural fibers and construction wastes. Constr. Build. Mater., 258, (2020)

Patil, S., Bhaskar, R., Xavier, J.R., Raja, R.: Experimental evaluation and statistical modeling of sustainable sisal fiber-reinforced fly ash-based lateritic concrete using response surface methodology. J. Building Eng., 84, (2024)

Patil, S., Bhaskar, R., Xavier, J.R.: Optimization of rheological and mechanical properties of sustainable lateritic self-compacting concrete containing sisal fiber using response surface methodology. J. Building Eng., 84, (2024)

Velumani, S., Navaneethakrishnan, P., Jayabal, S., Robinson Smart, D.S.: Optimization of mechanical properties of non-woven short sisal fibre-reinforced vinyl ester composite using factorial design and GAmethod. Bull. Mater. Sci. 36(4), 575–583 (2013)

Navaneethakrishnan, S., Athijayamani, A.: Taguchi method for optimization of fabrication parameters with mechanical properties in sisal fibre–vinyl ester composites. Australian J. Mech. Eng. 15(2), 74–83 (2017)

Ragunath, S., et al.: Multiobjective Optimization of Mechanical Properties on Sisal-Glass Fiber-Reinforced Hybrid Composites Using Response Surface Methodology and LINGO Analysis, Advances in Materials Science and Engineering, vol. 2021. (2021)

Veeranjaneyulu, I., et al.: Friction and wear optimization of SiC/graphite reinforced AZ31 hybrid composite using Taguchi method. Int. J. Interact. Des. Manuf. 18(3), 1373–1386 (2024)

Satishkumar, P., Infant Jegan Rakesh, A.J., Meenakshi, R., Saravana Murthi, C.: Characterization, mechanical and wear properties of Al6061/Sicp/fly ashp composites by stir casting technique, in Materials Today: Proceedings, Elsevier Ltd, pp. 2687–2694. (2020)

Satishkumar, P., Gokila Krishnan, G., Seenivasan, S., Rajarathnam, P.: A study on tribological evaluation of hybrid aluminium metal matrix for thermal application, in Materials Today: Proceedings, Elsevier Ltd, pp. 1097–1104. (2021)

Srividya, K., et al.: Design and analysis of wear parameters for epoxy based composite using RSM-box behnken optimization tool. Int. J. Interact. Des. Manuf., (2023)

Lakshmipathi, A.R., et al.: Shear strength, wear, thermal conductivity, and hydrophobicity behavior of fox millet husk biosilica and Amaranthus dubius stem fiber–reinforced epoxy composite: A concept of biomass conversion. Biomass Convers. Biorefin, (2023)

Natrayan, L., Surakasi, R., Paramasivam, P., Dhanasekaran, S., Kaliappan, S., Patil, P.P.: Statistical experiment analysis of wear and mechanical behaviour of abaca/sisal fiber-based hybrid composites under liquid nitrogen environment. Front. Mater., 10, (2023)

Venkatesh, R.P., Ramanathan, K., Rama Krishnan, S.: Tensile properties of NFRP hybrid composite: Modeling and optimization. Int. J. Soft Comput. 9(4), 260–266 (2014)

Sun, Z.-Y., Han, H.-S., Dai, G.-C.: Mechanical properties of injection-molded natural fiber-reinforced polypropylene composites: Formulation and compounding processes. J. Reinf. Plast. Compos. 29(5), 637–650 (2010)

Lv, H., et al.: Electrospun PCL-based polyurethane/HA microfibers as drug carrier of dexamethasone with enhanced biodegradability and shape memory performances. Colloid Polym. Sci. 298(1), 103–111 (2020)

Xu, Y., Liu, B., Zou, L., Sun, C., Li, W.: Preparation and characterization of PLLA/chitosan-graft-poly (ε-caprolactone) (CS-g-PCL) composite fibrous mats: The microstructure, performance and proliferation assessment. Int. J. Biol. Macromol. 162, 320–332 (2020)

Behera, S., Gautam, R.K., Mohan, S.: The effect of eco-friendly chemical treatment on sisal fiber and its epoxy composites: Thermal, mechanical, tribological and morphological properties. Cellulose. 29(17), 9055–9072 (2022)

Cavalcanti, D.K.K., Banea, M.D., Neto, J.S.S., Lima, R.A.A., L. F. M. da Silva, and, Carbas, R.J.C.: Mechanical characterization of intralaminar natural fibre-reinforced hybrid composites, Compos B Eng, vol. 175, (2019)

Girimurugan, R., Shilaja, C., Mayakannan, S., Rajesh, S., Aravinth, B.: Experimental investigations on flexural and compressive properties of epoxy resin matrix sugarcane fiber and tamarind seed powder reinforced bio-composites. Mater. Today Proc. 66, 822–828 (2022)

Murugan, G., Loganathan, G.B., Sivaraman, G., Shilaja, C., Mayakannan, S.: Compressive behavior of tamarind shell powder and fine granite particles reinforced epoxy matrix based hybrid bio-composites. ECS Trans. 107(1), 7111 (2022)

Jayaraman, R., Girimurugan, R., Suresh, V., Shilaja, C., Mayakannan, S.: Improvement on tensile properties of epoxy resin matrix sugarcane fiber and tamarind seed powder reinforced hybrid bio-composites. ECS Trans. 107(1), 7265 (2022)

Mohan, T.P., Kanny, K.: Chemical treatment of sisal fiber using alkali and clay method. Compos. Part. Appl. Sci. Manuf. 43(11), 1989–1998 (2012)

Sood, M., Dharmpal, D., Gupta, V.K.: Effect of Fiber Chemical Treatment on Mechanical Properties of Sisal Fiber/Recycled HDPE Composite, in Materials Today: Proceedings, pp. 3149–3155. (2015)

Author information

Authors and Affiliations

Contributions

Hemlata Vikrant Ganvir: Conceptualization, methodology development, investigation, data analysis, and manuscript preparation. Vikrant Yashwant Ganvir: Experimental design, data collection, analysis of results, interpretation of findings, and critical review of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original online version of this article was revised: The author name ‘P. Ramkumar’ was incorrectly written as ‘P. Ramumar’. The original article has been corrected.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ganvir, H.V., Ganvir, V.Y. A comparative study on optimizing chemical treatment parameters to enhance mechanical properties of sisal fiber-polycaprolactone composites. Interactions 245, 227 (2024). https://doi.org/10.1007/s10751-024-02062-1

Accepted:

Published:

DOI: https://doi.org/10.1007/s10751-024-02062-1