Abstract

Nanosized titanium dioxide (TiO2) is one of the most interesting and valuable nanomaterials for the construction industry but also in health care applications, food, and consumer goods, e.g., cosmetics. Therefore, the properties associated with this material are described in detail. Despite its widespread use, the analytical determination and characterization of nanosized metal oxides is not as straightforward as the comparatively easy-to-detect metallic nanoparticles (e.g., silver or gold). This study presents the method development and the results of the determination of tissue titanium (Ti) levels after treatment of rats with the nanosized TiO2. Total Ti levels were chosen to evaluate the presence and distribution of TiO2 nanoparticles. A procedure consisting of incubation with a mixture of nitric acid (HNO3) and hydrofluoric acid (HF), and heating was developed to digest tissues and TiO2 nanomaterials in order to determine the total Ti content by inductively coupled plasma mass spectrometry (ICPMS). For the inter-laboratory comparison, altogether four laboratories analyzed the same samples upon digestion using the available ICPMS equipment. A major premise for any toxicokinetic study is the possibility to detect the chemical under investigation in biological samples (tissues). So, the study has to be performed with a dose high enough to allow for subsequent tissue level measurement of the chemical under investigation. On the other hand, dose of the chemical applied should not induce over toxicity in the animal as this may affect its absorption, distribution, metabolism, and excretion. To determine a non-toxic TiO2 dosage, an acute toxicity study in rats was performed, and the organs obtained were evaluated for the presence of Ti by ICPMS. Despite the differences in methodology and independent of the sample preparation and the ICPMS equipment used, the results obtained for samples with Ti concentrations >4 μg Ti/g tissue agreed well.

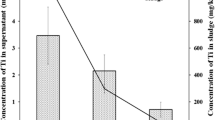

Major Ti concentrations in micrograms per gram of organ as determined by different laboratories.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

On the relevance of titanium dioxide nanoparticles

Due to their outstanding properties like optical, magnetic, catalytic, and electronic characteristics, individual metal oxides are utilized as engineered nanomaterials across an abundant range of very diverse application areas [1]. The attributes of these nanoparticles are governed by the variation in size, structure, and shape on which is capitalized by modern industry. Examples are health care applications like medical diagnostics, or food and consumer goods like cosmetics, but engineered nanomaterials are also used in the petroleum refinery industry and for catalytic converters in automotive applications.

One very prominent and widely used metal oxide is titanium dioxide (TiO2) because of its photocatalytic properties and the related surface phenomena. Self-cleaning materials containing TiO2 have been widely applied for large-scale storage structures, business facilities, and sports centers alike. For instance, the Chūbu Centrair International Airport (NGO), near Nagoya, Japan, used over 20,000 m2 of self-cleaning glass manufactured by the Nippon SheetGlass Co [2]. Nanoscaled TiO2 is one of the most interesting and valuable nanomaterials for the construction industry. The addition of TiO2 nanoparticles improves not only the structural efficiency but also the durability and strength of cementitious materials [3–5]. Based on the analysis by Future Markets Inc., the use of TiO2 nanoparticles in coatings and paints for sanitization and in disinfection products used on a large scale in hospitals against a variety of different microbes including resistant staphylococci (e.g., methicillin-resistant Staphylococcus aureus) is at an advanced stage of commercialization [6]. In addition, TiO2 nanoparticles are widely used in sunscreen formulations for the protection against UV radiation, which is resulting in high sun protection factors of these products; this application is especially of great interest for human exposure studies [7, 8].

Characterization and determination of titanium dioxide nanoparticles in complex matrices

Despite the widespread use of nanosized metal oxides, their analytical characterization and determination is not that straightforward when compared to the comparatively easy-to-detect metallic nanoparticles (e.g., silver or gold). The hurdles and pitfalls to overcome during the analysis of redox-insensitive TiO2 particles are miscellaneous. Firstly, there is the tricky part of sample preparation resulting in acceptable recovery values. Further, there are spectral and non-spectral interferences that may be challenging when it comes to the exact quantification of Ti in complex matrices [9]. These are important aspects to consider especially when aiming at the development of robust and straightforward methods for inter-laboratory comparison.

An issue very easily underestimated is the sample preparation, particularly with the involvement of nanoparticles. For quantitative determination of TiO2 nanoparticles, the sample preparation strategy can be quite challenging. While using a conventional analytical setup―ideally a total digestion of the analyte is desirable―at the same time contaminations resulting from artifacts should be avoided. Traditionally, prior to conventional element analysis applying inductively coupled plasma mass spectrometry (ICPMS), the digestion is performed by using either a heating block or a microwave oven. The selection of appropriate acids, however, is rather challenging because the metal oxide nanoparticles have to be transformed into their ionic forms while the organic matrix (tissue and cells) must be completely decomposed without any inclusion or adhesion of nanoparticles.

For method development in the frame of toxicokinetic studies, the main focus lies on the digestion and dissolution of tissue embedded TiO2. TiO2 is practically insoluble and it thus becomes crucial to (1) use a mixture of concentrated hydrofluoric, sulfuric, and/or other acids for dissolution [10–12], and (2) to select a suitable solvent for the biological material prior to analysis by ICPMS [13, 14]. For the dissolution of TiO2, often concentrated sulfuric acid is used, but especially in combination with organic (biological) material this is not the procedure. It can lead to partly dissolved sample material and a lot of black residues. The possible generation of insoluble sulfides can cause adsorption of nanoparticles and consequently results in poor recovery rates [15]. Therefore, a mixture including hydrofluoric acid was preferred [12], though special safety circumstances required consideration.

When conventional quadrupole ICPMS technology is used to determine Ti originating from TiO2 nanoparticles, it is critical to consider the potential formation of polyatomic spectral interferences generated by the plasma gas, argon, residual matrix components from the sample and the different isotopes of the analyte. Although it is impossible to avoid unwanted interferences, by applying the collision/reaction cell technology, which has been developed in the late 1990s, it becomes possible to minimize them [16]. This technology has been proven to be successful even for trace Ti analysis determination in complex matrices.

Although the operation of ICPMS in single particle modus (sp-ICPMS) has been successfully adopted for the analysis of nanoparticles in water samples [17], this approach has not yet been used for tissue digests containing nanoparticles. Within this inter-laboratory comparison, altogether four laboratories analyzed the same samples upon digestion using the in-house available ICPMS equipment and the use of various ICPMS types is a central aspect of interest too.

Materials and methods

Nanomaterials and organs/tissue samples

For the evaluation of tissue levels of Ti, organs were collected from animals that had been subjected to an acute toxicity study for determining a non-toxic dose of TiO2. Six-week-old male Wistar rats (HsdCpb:WU; from Harlan Nederland BV, Horst, The Netherlands) were treated with a single intravenous dose of the maximum nano-TiO2 dose possible dispersed according to the generic NANOGENOTOX protocol [18].

Two TiO2 nanomaterial dispersions (NM-100 and NM-102; see Table 1 for details) with a concentration of 2.56 mg TiO2/mL stock dispersion were prepared by prewetting the amount of TiO2 nanomaterial powder in 96 vol.% ethanol (C2H5OH, ≥96 % purity; Merck, Darmstadt, Germany), resulting in a final concentration of 0.5 vol.% ethanol followed by dispersion in 0.05 wt.% rat serum albumin (Sigma #A6272) in ultrapure water. S Probe sonication of the sample was performed on ice for 16 min (Branson Sonifier S-450D; Branson Ultrasonics Corp., Danbury, CT, USA, equipped with a disruptor horn model number 101-147-037) [18]. Prior to injection, the stock solution was diluted for 10 % using 10× concentrated phosphate buffer (prepared with 702 mg NaH2PO4·2H2O and 4,155 mg NaH2PO4·7H2O in 1 L, pH 7.4; salts from Sigma Aldrich, Zwijndrecht, The Netherlands), resulting in a final solution for administration to rats of 2.3 mg TiO2/mL. So, the dose administered was 2.3 mg TiO2 per animal, ranging from 8.6 to 10.3 mg TiO2/kg depending on the actual weight (range 224–266 g) of the animal.

Drinking water and conventional feed were provided ad libitum to the rats. The experiment was approved by an independent Ethical Committee on Animal Experimentation and conducted in compliance with all applicable provisions of the national laws, i.e., the Experiments on Animal Decree and the Experiments on Animal Act. No signs of toxicity were observed and animals were autopsied at day 14 after exposure. Several organs (liver, lung, spleen, heart, kidney, brain, and muscle) were collected and homogenized by manual cutting and stirring, then divided in several fractions, stored, and shipped at −20 °C. Samples were sent to four laboratories for further evaluation. In addition, liver tissue samples of three vehicle-treated animals were evaluated as well.

Method for sample pre-treatment by digestion

The principal steps of the digestion procedure consist of the addition of a mixture of nitric acid (HNO3) conc. and hydrofluoric acid (HF) conc., followed by a suitable heating procedure depending on the equipment used. Microwave digestion or open digestion with a block heater can be used. The digestion temperature and digestion duration were chosen as similar as possible but most suitable related for the equipment used. Afterwards, the digests were diluted with ultrapure water. Details on the used equipment and the procedures applied by all participating laboratories are given in Table 2.

Method for the determination of Ti in digested tissues

The element Ti consists in total of five naturally abundant isotopes. Nevertheless, three of these Ti isotopes should not be used for quantification by ICPMS due to isobaric and polyatomic interferences. The abundances as well as the unresolvable isobaric interferences are given in Table 3.

For 47Ti and 49Ti, the polyatomic interferences are possible which can be resolved by using the medium resolution (MR) mode of a high-resolution (HR) ICPMS, or the collision cell technique (CCT) of a quadrupole (Q) ICPMS; see also Table 3.

For all ICPMS systems, the final concentration of HF in the measured solution was sufficiently low to use the routinely applied sample introduction system or an additional step of neutralization by boric acid (H3BO3) was applied. Blanks and tissue digests were measured against an external calibration with internal standard correction. As internal standards (IS), different isotopes of various elements were tested and used depending on local in-house circumstances in the participating laboratories. Details about the ICPMS measurements and calibration details are presented in Table 2. The squared correlation coefficient (R 2) of all calibration curves was >0.995.

Quality control experiments

Five types of quality control experiments were applied by the different laboratories:

-

1.

Determination of the presence of Ti in digestion tubes in combination with the used chemicals and related correction of the raw data

-

2.

General Ti controls with various aquatic matrices

-

3.

Matrix experiments using matrices/tissue samples spiked with the original TiO2 material

-

4.

Determination of Ti in biological reference samples:

As there is no certified reference material available for TiO2 nanoparticles in a biological matrix, two batches of a commercially available reference blood sample (“Seronorm Trace Elements Whole Blood”), supplied by Sero AS, Billingstad, Norway, with the following total concentrations of Ti (given as additional analytical values) were used:

L-2 LOT 1003129 with a value of 18 ± 5 μg Ti/L;

L-3 LOT 1112691 with a value of 12.8 ± 0.4 μg Ti/L

-

5.

Analysis of independent duplicate samples from selected tissues

Results and discussion

Performance and quality control experiments

Additional samples of control animals were used for the determination of the limit of detection (LOD). The LOD (as 3× STD, n = 20) was estimated on the results obtained for around 0.5 g tissue material from control animals after applying the complete procedure of digestion and measurement by ICPMS. The LOD for both tissue samples and blood was determined as 0.05 μg Ti/g tissue.

Quality control experiments for different experimental aspects were applied by the laboratories involved; the results demonstrated the importance and relevance of these controls.

-

1.

Determination of the presence of Ti in digestion tubes in combination with the chemicals used and related correction of the raw data

Due to the fact that TiO2 can be also abundantly present in polypropylene tubes [19] and possibly also in Teflon as well as in the chemicals (acids and water) used, it is of great importance to determine the blank concentration of Ti in the laboratory consumables used and to appropriately correct the raw data of the analysis for this concentration. For the digestion procedure as applied at laboratory A, the blank concentration of Ti was determined for 15 mL polypropylene tubes from three suppliers, and the results obtained are given in Table 4. In all routine series, tubes from one supplier were used and regularly controlled (Table 4). The concentration of Ti was found to be extremely stable and the systematic blank correction was in agreement with those attained by the other laboratories which had significant lower Ti backgrounds.

However, the definitive concentration of the blank can be very different. As evidenced by laboratory C for 50 mL polypropylene tubes from DigiPrep (n = 5), the concentration was 0.007 ± 0.002 μg/L Ti. Laboratory B and laboratory D, which applied microwave digestion and used Teflon tubes, did not find relevant concentrations of Ti for the necessity of a blank correction.

-

2.

General Ti controls with aquatic matrices

Laboratory B systematically used the Certified Reference Material (CRM) from filtered Lake Ontario water (TM-15.2, supplied by HORIBA Scientific, Longjumeau, France) containing Ti (14.6 ± 1.3) μg/L to monitor instrumental drift and to control analytical precision at the beginning and at the end of the experiment. This CRM was not digested and it was directly analyzed by ICPMS. The results of the recovery are not presented in detail, but they are in the range of 80 to 120 %. All recoveries were considered satisfactory.

Laboratory D performed controls with spiked deionized water in the concentration range of 2 to 50 μg/L Ti. The results of the recovery are not presented in detail, but they are in the range of 95 to 115 %.

-

3.

Matrix spike experiments with the original TiO2 material

For these experiments, laboratory B used five suitable biological matrices (calf heart, liver, muscle, brain, and bovine kidney) spiked at different concentrations of the original TiO2 material (from 0.17 to 7.45 μg/g). Laboratory D applied comparable experiments by using liver, spleen, kidney, heart muscle, brain, and lung from mice. The results of the recovery are not presented in detail, but they are in the range of 80 to 120 % and were considered satisfactory.

-

4.

Determination of Ti in biological reference samples

To check the accuracy of the analytical method, as no certified reference material exists, two commercially available reference samples were digested and analyzed according to the same procedure in various series. This procedure was applied by laboratory A and laboratory C. It should be noted that the Ti values in these control sample were presented as additional analytical values and cannot be considered certified reference values. However, they are useful as control samples as they provide an independent value for their Ti content. As shown in Table 5, there is a good agreement between all results.

-

5.

Analysis of independent duplicate samples from selected tissues

Depending on the available sample amount, all laboratories analyzed several liver samples as independent duplicates. The intra-laboratory repeatability is presented in this way. The results are especially presented in Fig. 1A and B as well as in the Tables 6 and 7.

Inter-laboratory comparison

The overall results for the Ti determination of 28 samples by four different laboratories are given in Tables 6 and 7. The results of the significant concentrations are also presented in Fig. 1A and B. Additionally, the data of all inter-laboratory results of the three main tissues (liver, lung, and spleen) are evaluated in Tables 8 and 9. It was found that using in-house digestion procedures, ICPMS equipment, and reagents at four different locations, in general similar results were obtained for the Ti content in various tissue samples (details of the equipment used are summarized in Table 2). There was reasonable agreement when concentrations were >4 μg Ti/g tissue, independent of the equipment and reagents. The exception was one lung sample from a rat treated with NM-102. Note that spleen measurements from laboratory C were systematically higher than the measurements obtained by the other laboratories, whereas all the other measurements were in the same order of magnitude. An explanation might be the non-optimal sample mass used for the digestion method for these particular spleen samples. The spleen samples available were quite small, resulting in a deviation of the developed digestion method that was validated for samples of ≥100 mg. Each spleen was divided in five subsamples for Ti determination. The mean spleen weight was 576 ± 89 mg (n = 4) and 555 ± 38 mg (n = 4) for spleens of animals treated with NM-100 and NM-102, respectively. The weights of the subsamples evaluated in the participating laboratories were 110 ± 22 mg (n = 20) and 96 ± 26 mg (n = 20) for NM-100 and NM-102, respectively.

At the low concentrations (<1.5 μg Ti/g tissue), measurements of laboratory A (using HR-ICPMS) were similar to those obtained by laboratory B using Q-ICPMS in both standard and He (CCT) modes and lower to those obtained by Laboratory C and D (both using CCT mode with different Q-ICPMS instruments), except for lung #13 where laboratory A determined only 0.3 μg Ti/g tissue and thus largely below the other laboratories (range 10–17 μg Ti/g tissue).

One may explain the differences that were observed also by the different approaches used by the laboratories for the total procedure of Ti determination. Table 2 compiles the different procedures used. Besides differences in ICPMS equipment used in the four laboratories, there were also differences in the actual digestion method regarding the amounts of acids used, digestion temperature, digestion times, sample mass, and the tubes used during the digestion procedure. All these differences may have contributed to the differences seen in the Ti determination of the tissue samples. In addition, the tissue samples were not completely homogenized using a blender, but the tissue was cut in small pieces and homogenized by hand (due to the small available organ amount). By hindsight, this procedure may also have had an effect on the homogeneity of the tissue samples. However, in view of the number of samples obtained in the various studies, mechanical homogenization was considered to be not feasible.

Conclusions

The results obtained for the Ti detection in various organs were generally in agreement with each other when Ti concentrations were >4 μg/g tissue. However, some spleen measurements in one laboratory were higher compared to the measurements at the others, and also at the lower concentrations some differences were noted between the four laboratories.

In conclusion, the method for the determination of Ti in tissues was successfully developed and, with some modifications, applied in various laboratories. A combination of HNO3 and HF gave the best results for tissue digestion and Ti dissolution prior to measurement of the samples in the ICPMS. Despite the differences in methodology and independent of the sample preparation and the ICPMS equipment used, the results obtained for samples with Ti concentrations >4 μg Ti/g tissue agreed well.

The differences that were observed between the four laboratories might be also due to local conditions, and sample preparation may have a more pronounced effect on the outcome of the measurements than the actual ICPMS equipment used. It was shown that all used ICPMS instruments used achieved comparably good analytical results for the analysis of metal oxide nanoparticles. The advantage of these instruments is, however, especially for routine laboratories, their higher robustness and affordable price. However, the measurement of very low levels may be more critical, and further investigations may be required in view of the differences observed between the laboratories.

References

Fernández-Garcia M, Rodriguez JA (2008) Metal oxide nanoparticles. In: Lukehart CM, Scott RA (eds) Nanomaterials: inorganic and bioinorganic perspectives. EIC Books. Wiley, West Sussex, UK

Fujishima A, Zhang X, Tryk DA (2008) TiO2 photocatalysis and related surface phenomena. Surf Sci Rep 63:515–582

Nazari A, Riahi S (2011) The effects of TiO2 nanoparticles in flexural damage of self-compacting concrete. Int J Damage Mech 20:2049–2072

Nazari A, Riahi S (2011) TiO2 nanoparticle effects on physical, thermal and mechanical properties of self compacting concrete with ground granulated blast furnace slag as binder. Energy Build 43:995–1002

Zhang M-H, Li H (2011) Pore structure and chloride permeability of concrete containing nano-particles for pavement. Constr Build Mater 25:608–616

Future Markets Inc. (2011) Nanotechnology and nanomaterials commercialisation chart: nanoparticle titanium dioxide (TiO2). http://www.futuremarketsinc.com/images/Charts/tio2charts.pdf. (retrieved August 2013)

Nohynek GJ, Antignac E, Re T, Toutain H (2010) Safety assessment of personal care products/cosmetics and their ingredients. Toxicol Appl Pharmacol 243:239–259

Nischwitz V, Goenaga-Infante H (2012) Improved sample preparation and quality control for the characterization of titanium dioxide nanoparticles in sunscreens using flow field flow fractionation on-line with inductively coupled plasma mass spectrometry. J Anal At Spectrom 27:1084–1092

von der Kammer F, Ferguson PL, Holden PA, Masion A, Rogers KR, Klaine SJ, Koelmans AA, Horne N, Unrine JM (2011) Analysis of engineered nanomaterials in complex matrices (environment and biota): general considerations and conceptual case studies. Environ Toxicol Chem 31:32–49

Wildhagen D, Krivan V, Gercken B, Pavel J (1996) Multi-element characterization of titanium(IV) oxide by electrothermal atomic absorption spectrometry, inductively coupled plasma atomic emission spectrometry, inductively coupled plasma mass spectrometry and total reflection X-ray fluorescence spectrometry. J Anal At Spectrom 11:371–377

Wang Z, Ni Z, Qiu D, Chen T, Tao G, Yang P (2004) Determination of metal impurities in titanium dioxide using slurry sample introduction by axial viewing inductively coupled plasma optical emission spectrometry. J Anal At Spectrom 19:273–276

Korn MDA, Ferreira AC, Costa ACS, Nobrega JA, Silva CR (2002) Comparison of decomposition procedures for analysis of titanium dioxide using inductively coupled plasma optical emission spectrometry. Microchem J 71:41–48

Lomer MCE, Thompson RPH, Commisso J, Keen CL, Powell JJ (2000) Determination of titanium dioxide in foods using inductively coupled plasma optical emission spectroscopy. Analyst 125:2339–2343

Sarmiento-Gonzalez A, Encinar JR, Marchante-Gayon JM, Sanz-Medel A (2009) Titanium levels in the organs and blood of rats with a titanium implant, in the absence of wear, as determined by double focusing ICP-MS. Anal Bioanal Chem 393:335–343

Sun HW, Zhang XZ, Niu Q, Chen YS, Crittenden JC (2007) Enhanced accumulation of arsenate in carp in the presence of titanium dioxide nanoparticles. Water Air Soil Pollut 178:245–254

Yip Y, Sham W (2007) Applications of collision/reaction-cell technology in isotope dilution mass spectrometry. TrAC Trends Anal Chem 26:727–743

Laborda F, Jiménez-Lamana J, Bolea E, Castillo JR (2011) Selective identification, characterization and determination of dissolved silver(I) and silver nanoparticles based on single particle detection by inductively coupled plasma mass spectrometry. J Anal At Spectrom 26:1362–1371

Jensen KA, Kembouche Y, Christiansen E, Jacobsen NR, Wallin H, Guiot C, Spalla O, Witschger O (2012) Final protocol for producing suitable manufactured nanomaterial exposure media. The generic NANOGENOTOX dispersion protocol. July 2012; www.nanogenotox.eu

Mina F, Seema S, Matin R, Rahaman J, Sarker RB, Gafur A, Bhuiyan AH (2009) Improved performance of isotactic polypropylene/titanium dioxide composites: effect of processing conditions and filler content. Polym Degrad Stab 94:183–188

Brunauer S, Emmett PH, Teller E (1938) Adsorption of gases in multimolecular layers. J Am Chem Soc 60:309–319

Acknowledgments

This work was mainly sponsored by the NANOGENOTOX Joint Action which has received funding from the European Union, in the framework of the Health Programme under Grant Agreement n°2009 21. Additional financial support for the overarching introduction and interpretation was received by NANONEXT.nl which was sponsored by the Government of the Netherlands. This work was additionally supported by an intramural grant at the German Federal Institute for Risk Assessment (SFP 1322-527). The authors would like to thank Harald Jungnickel (BfR) for critical comments on this manuscript and the technical staff at all departments involved for their excellent technical assistance, especially Willem den Otter and Carry Hermans (PInS), Henny Verharen, Hans Strootman and Piet van Schaaik (RIVM), Philipp Reichardt and Dorothé Storm (BfR), as well as Cynthia Denize (Ineris).

Author information

Authors and Affiliations

Corresponding author

Additional information

Published in the topical collection Characterisation of Nanomaterials in Biological Samples with guest editors Heidi Goenaga-Infante and Erik H. Larsen.

Rights and permissions

About this article

Cite this article

Krystek, P., Tentschert, J., Nia, Y. et al. Method development and inter-laboratory comparison about the determination of titanium from titanium dioxide nanoparticles in tissues by inductively coupled plasma mass spectrometry. Anal Bioanal Chem 406, 3853–3861 (2014). https://doi.org/10.1007/s00216-013-7580-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-013-7580-z