Abstract

A fast microchip electrophoresis–nano-electrospray ionization-mass spectrometric method (MCE-nanoESI-MS) was developed for analysis of amino acids in biological samples. A glass/poly(dimethylsiloxane) hybrid microchip with a monolithic nanoESI emitter was used in the platform. The proposed MCE-nanoESI-MS analytical method showed high separation efficiency for amino acids. Baseline separation of an amino acid mixture containing Lys, Arg, Val, Tyr, and Glu was completed within 120 s with theoretical plate numbers of >7,500. The method was applied to study cellular release of excitatory amino acids (i.e., aspartic acid (Asp) and glutamic acid (Glu)) under chemical stimulations. Linear calibration curves were obtained for both Asp and Glu in a concentration range from 1.00 to 150.0 μM. Limits of detection were found to be 0.37 μM for Asp and 0.33 μM for Glu (S/N = 3). Assay repeatability (relative standard deviation, n = 6) was 4.2 and 4.5 %, for Asp and Glu at 5.0 μM, respectively. In the study of cellular release, PC-12 nerve cells were incubated with alcohol at various concentrations for 1 h. Both extra- and intracellular levels of Asp and Glu were measured by the proposed method. The results clearly indicated that ethanol promoted the release of both Asp and Glu from the cells.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Microfluidic devices have been gaining a broad interest in chemical and biological applications [1]. Coupled with selective and sensitive mass spectrometric detection (MS), these devices have a great potential in bioanalytical applications [2–4]. Microchip electrophoresis (MCE), a miniaturized format of capillary electrophoresis (CE) performed on a microfluidic chip, offers high separation efficiency, high throughput sampling, and many advantageous microfluidic features. Because of the low flow rate of the effluent from MCE separations (normally at ∼25 nL/min), coupling MCE with mass spectrometric detection is very different from and technically more difficult than coupling other microfluidic devices where liquid flows are generated and controlled by using syringe (or air pressure) pumps. In the majority of these works, electrospray ionization (ESI)–MS was employed by virtue of the simplicity of the interface. Various electrospray configurations including spraying from the flat end of the microchip and monolithically integrated ESI emitter, two independent emitters, and a multinozzle emitter array in glass microchips were reported [5–8]. Integrated polymer SU-8 and poly(dimethylsiloxane) (PDMS) membrane-based microfluidic emitter were recently fabricated and evaluated [9, 10]. More details on coupling of microfluidic devices with MS can be found in recent reviews [11, 12].

Amino acid analysis is an important analytical application in biomedical research, clinical practice, and industrial process. Levels of intracellular excitatory amino acids have been intensively studied due to their association with various medical conditions [13–17]. Aspartic acid (Asp) and glutamic acid (Glu) are excitatory neurotransmitters in the central nervous system that work to stimulate the brain [18]. Numerous studies have shown that ethanol influences Asp and Glu release in various brain regions [19–25]. There has been a continued interest in the development of reliable, rapid, and accurate methods for the determination of amino acids from cellular release for diagnostic and research purposes [26–28]. Quantification of excitatory amino acids by HPLC [29–31], CE [32–36], and microfluidic techniques [37, 38] has been reported. As far as we know, in spite of all the advantages, quantification of amino acids by MCE-MS has not been reported so far.

We herein report the development of an MCE-MS method for analysis of amino acids. A glass/PDMS hybrid microchip with a monolithic nanoESI emitter was deployed. An auxiliary channel intercepting with the MCE separation channel at an angle of 45° was integrated into the microchip transporting a make-up fluid (MUF) generated by a syringe pump at ∼100 nL/min to facilitate the MCE-MS coupling. The proposed MCE-MS method was evaluated for fast separation of amino acids. The separation efficiency, assay reproducibility, detection sensitivity, and linearity of the signal–concentration relationship were investigated. Further, this method was applied in studying excitatory amino acid release by PC-12 cells exposed to ethanol.

Experimental section

Reagents and materials

PDMS prepolymer and the curing agent were purchased from Dow Corning (Midland, MI). Fused silica capillaries (254 μm ID, 360 μm OD) were obtained from Polymicro Technologies (Tucson, AZ). Glass slides were obtained from Silicon Valley Microelectronics (Santa Clara, CA). Hexamethyldisilazane (HMDS) was from Ultra Pure Solutions (Castroville, CA). Amino acids were purchased from Sigma-Aldrich Chemical (St. Louis, MO). All reagents used were of analytical grade. Milli-Q water was used throughout the work. All solutions were filtered through a nylon 0.22 μm syringe filter before use.

Microchip fabrication

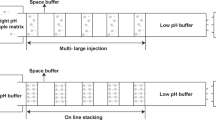

Design of the microchip is shown in Fig. 1a. The chip was composed of a PDMS cover and a glass substrate bearing the channels. The procedure used to create channels was similar to that we reported previously [39]. Briefly, a design on a photomask with microchannels was transferred onto the glass substrate by means of UV exposure. The channels (60 μm wide and 20 μm deep) were etched into the substrate in a well-stirred bath containing diluted HF/NH4F/HCL. To create a PDMS cover, HMDS was applied onto a silicon wafer with a pipette. The wafer was spun at 2,000 rpm for 30 s to completely dry off the liquid. A mixture of PDMS prepolymer and curing agent (10:1) was degassed under vacuum. A small amount of the mixture was applied onto the silicon plate and spun at 2,000 rpm for 50 s to obtain a thin layer of ∼100 μm in thickness. At this time, a platinum electrode was placed at the location as shown in Fig. 1a. After 2 h curing at 50 °C, a cofferdam (∼2 mm deep) was placed on top of the first layer of the PDMS cover and filled with the prepolymer mixture, but leaving a ∼5-mm-long section on the cover's edge uncovered. After 3 h curing, the PDMS cover was removed from the silicon plate. Access holes of 3-mm diameter were drilled on the PDMS cover at channel terminals, forming four reservoirs. The microchip was made by bonding the glass substrate and the PDMS cover together through heating for 5 min via an air plasma cleaner (10.5 W and 500 mTorr, Harrick Plasma, Ithaca, NY). The nanoESI emitter was formed at a corner of the microchip by ∼100 μm PDMS cover and beveled glass substrate as shown in Fig. 1b.

MCE-nanoESI-MS assay

The system consisted of an ion trap mass spectrometer equipped with an ESI source and a syringe pump (LCQ Deca, ThermoFinnigan, San Jose, CA), the microchip prepared above, and a multichannel high-voltage power supply. The syringe pump was used for MUF delivery. Xcalibur software (ThermoFinnigan) was used to control the mass spectrometer and process MS data. House-written software was used for controlling the potentials applied to the microchip for MCE operations. MS detection parameters were optimized in positive mode and selected as follows: ion source voltage was 0 V; a relative collision energy of 25 % was used for MS/MS experiments with an isolation width of 1.0 u; and the activation time was set at 30 ms. The microchip was placed on an XYZ-translational stage and positioned in front of the MS orifice (the nanoESI emitter tip was about 1 mm away from the orifice) as shown in Fig. 1c. To inject sample, potentials of 450, 400, 0, and 600 V were applied at reservoirs 1, 2, and 3 and pt (as labeled in Fig. 1a) for 15 s, respectively. After sample injection, the potentials were changed to 3,050, 1,600, 1,600, and 1,500 V, respectively, to start the MCE-MS assay. At the same time, MS data acquisition was also started. MCE running buffer was a mixture of methanol/water (1:1) containing 25 mM acetic acid/ammonium acetate buffer at pH 4.3. Make-up fluid was the same buffer at a flow rate of 100 nL/min.

Study on release of excitatory amino acids from PC-12 cells exposed to ethanol

PC-12 cells were cultured in complete RPMI medium supplemented with 10 % heat-inactivated horse serum and 5 % FBS. Cells were routinely subcultured every 4–5 days. To investigate the ethanol effects on the release of excitatory amino acids, 50 μL cell suspension (2 × 106 cells/mL in phosphate-buffered saline (PBS) solution) was added to 150 μL PBS solution containing ethanol at 0, 0.1, 0.5, 0.7, and 1.0 % (v/v) and incubated for 1.0 h at 37 °C. After incubation, cells were spun down. The PBS supernatant was completely transferred to another vial for analysis. The cell pellet was suspended in 100 μL PBS and sonicated. After centrifugation at 10,000 rpm for 10 min, the supernatant was collected and diluted 50 times with PBS solution. All samples were filtered through a 0.22-μm membrane filter prior to MCE-MS analysis.

Safety considerations

All high-voltage connections were carefully shielded, and instrument and electrically conductive parts were grounded.

Results and discussion

Microchip design and fabrication

We recently reported a microchip design that integrated a pressure-driven make-up flow into the MCE-MS system to facilitate the MCE-MS coupling [40]. To improve the separation efficiency, the channel features were fabricated in a glass substrate in this work. In addition, a monolithic nanoESI emitter was deployed. To achieve a stable nano-electrospray, the tip surface area of the nanoESI emitter must be minimal. Therefore, a corner of the glass substrate (i.e., the fluidic exit of the microchip) was beveled before the channels were etched. The PDMS cover was also fabricated by using the multilayer soft lithography technique [41] to make it very thin (∼100 μm) at the section of the emitter tip. The combined thickness of the emitter (i.e., beveled glass substrate and the thin PDMS cover) was <250 μm which was well suited for nano-electrospray. It was found in this work that the monolithic emitter such made was very efficient to generate nano-electrospray from flows at flow rates at the 100-nL/min level. The emitter was also durable. In a test of 1 h continuous spraying, repeatability of MS background signals (relative standard deviation (RSD)) was 2.7 % (n = 100), indicating a stable nanoESI process was achieved during this extended time period.

MCE-nanoESI-MS analysis of amino acids

To evaluate the proposed MCE-MS analytical platform for amino acid analysis, a mixture of five amino acids, including Lys, Arg, Val, Tyr, and Glu, was analyzed with the MS detector set for full scan from m/z 80 to m/z 250. Figure 2 shows the total ion count (TIC) electropherogram obtained. As can be seen, the five amino acids were baseline separated within 120 s. The electrophoretic peaks were very narrow, indicating high separation efficiency. Theoretical plate numbers (N = 16 (t R/w b)2) were calculated to be >7,500 for all of the compounds separated. Analytical figures of merit were studied for the analysis of amino acids, taking Asp and Glu as model analytes. Standard curves were prepared by analyzing a series of standard mixtures of Asp and Glu at various concentrations ranging from 1.00 to 150 μM. Transitions m/z 134→88 and m/z 148→102 were used for quantification of Asp and Glu, respectively. The following calibration curves based on peak height versus analyte concentration were obtained:

where Y was peak height, and X was analyte concentration in micromolar. Detection limits (S/N = 3) were estimated to be 0.37 and 0.33 μM for Asp and Glu, respectively. This assay sensitivity is comparable with those of HPLC-MS methods, but far better than those of CE-MS methods [42]. Although it is not as sensitive as the CE methods with laser-induced fluorescence or electrochemical detection [28, 32–36], the present method has the capability of peak identification because MS detection offers structural information of the compounds detected, which is essential in many cases of analyzing biological samples. Assay repeatability was determined by repeatedly analyzing two standard mixtures of Asp and Glu (5.0 and 50.0 μM each, respectively) for six times. The results are summarized in Table 1. RSDs were 4.2 and 4.5 % for Asp and Glu at 5.0 μM, respectively. Reproducibility of the migration times (RSD, n = 6) was 1.70 % for Asp and 1.57 % for Glu. As far as we know, there have been no reports on quantification of amino acids by using a MCE-MS method [28].

MCE-MS separation of an amino acid mixture containing Lys, Arg, Val, Tyr, and Glu (50.0 μM each). The MCE conditions are as follows: MCE separation channel, 3.5 cm long × 60 μm wide × 20 μm deep; pinched electrokinetic injection of sample; and running buffer, 25 mM ammonium acetate/acetic acid buffer (pH 4.3) in methanol/water (1:1). MS detection conditions include make-up flow at 100 nL/min, capillary temperature 220 °C, sheath gas 20 arbitrary units (au), auxiliary gas, 0 au, positive ion mode, full scan from m/z 80 to 250. Peak identification: Lys (R t = 1.07), Arg (R t = 1.27), Val (R t = 1.49), Tyr (R t = 1.72), and Glu (R t = 1.88)

Release of Asp and Glu from PC-12 cells exposed to ethanol

Although ethanol effects on glutamate release in various brain regions were studied intensively [19–25], no reports have been seen on similar in vitro studies with neuronal models. We applied the present MCE-MS/MS method to study ethanol-stimulated release of Asp and Glu from PC-12 cells. Cells were incubated with PBS containing ethanol at concentrations ranging from 0 to 1 % (v/v) for 1 h. The results from a trypan blue assay of the cell cultures confirmed that no changes in cell viability were caused by the incubation. After incubation, cells were spun down and the supernatant was collected and analyzed to determine the extracellular levels of Asp and Glu. The cells were resuspended in PBS and lysed by sonication for quantification of intracellular Glu and Asp. A typical electropherogram obtained from these analyses is shown in Fig. 3. The MS detector was set for selected ion monitoring (m/z 134 and 148), and thus, very clean electropherograms were obtained. From the TIC electropherogram (Fig. 3a), Asp and Glu were well separated within 120 s. Peak identities were confirmed by the MS2 spectra (Fig. 3d, e). The analytical results of both intra- and extracellular Glu and Asp levels are summarized in Fig. 4. As can be seen, the extracellular levels of both Glu and Asp increased as ethanol concentration increased while the intracellular levels decreased. These results clearly indicated that ethanol promoted the release of Asp and Glu from the PC-12 cells.

Electropherograms from the proposed MCE-MS quantification of Asp and Glu in PC-12 cells. (A) TIC of m/z 134 and 148. (B) Extracted mass electropherogram of m/z 134 for Asp from (A). (C) Extracted mass electropherogram of m/z 148 for Glu from (A). (D) and (E) MS2 spectra of Asp and Glu, respectively, verifying the peak identities. MCE-MS conditions were as in Fig. 2

Ethanol influence on Asp and Glu release from PC-12 cells: extracellular (A) and intracellular (B) Asp and Glu levels in PC-12 cultures exposed to ethanol (at various concentrations) for 1 h. MCE-MS assay conditions were as in Fig. 2. *p < 0.05, n = 3

Conclusions

An MCE-nanoESI-MS was developed for fast quantification of amino acids. New features of the microfluidic chip used in the MCE-MS platform included an easy-to-make monolithic nano-electrospray emitter. By the proposed MCE-MS method, baseline separation of Lys, Arg, Val, Tyr, and Glu was achieved within 120 s, which was much faster than the absolute majority of separations reported previously for amino acids. Limits of detection were found to be 0.37 μM for Asp and 0.33 μM for Glu (S/N = 3). The method was employed to study the release of Asp and Glu from PC-12 cells exposed to ethanol. It was found that ethanol promoted cellular release of both amino acids, and further, the influence was concentration dependent. This work showed that the proposed MCE-nanoESI-MS method might have a potential for fast quantification of amino acids in various applications.

References

Yager P, Edwards T, Fu E, Helton K, Nelson K, Tam MR, Weigl BH (2006) Nature 442:412–418

Baker CA, Roper MG (2012) Anal Chem 84:2955–2960

Chen Q, Wu J, Zhang Y, Lin JM (2012) Anal Chem 84:1695–1701

Mellors JS, Jorabchi K, Smith LM, Ramsey JM (2010) Anal Chem 82:967–973

Mao P, Gomez-Sjoberg R, Wang D (2013) Anal Chem 85:816–819

Chambers AG, Ramsey JM (2012) Anal Chem 84:1446–1451

Dayon L, Josserand J, Girault HH (2005) Phys Chem Chem Phys: PCCP 7:4054–4060

Iannacone JM, Jakubowski JA, Bohn PW, Sweedler JV (2005) Electrophoresis 26:4684–4690

Nordman N, Sikanen T, Aura S, Tuomikoski S, Vuorensola K, Kotiaho T, Franssila S, Kostiainen R (2010) Electrophoresis 31:3745–3753

Sun X, Kelly RT, Tang K, Smith RD (2011) Anal Chem 83:5797–5803

Kleparnik K (2013) Electrophoresis 34:70–85

Flangea C, Serb A, Sisu E, Zamfir AD (2011) Biochim Biophys Acta 181:513–535

Cai Z, McCaslin PP (1992) Neurochem Res 17:803–808

Aronica E, Nicoletti F, Canonico PL (1990) Funct Neurol 5:15–20

Przewlocki R (2004) Eur J Pharmacol 500:331–349

Sattler R, Rothstein JD (2006) Handbook of experimental pharmacology. Springer, Heidelberg, pp 277–303

Kawamata M, Omote K (1996) Pain 68:85–96

Brown JA, Nijjar MS (1995) Mol Cell Biochem 151:49–54

Aschner M, Mutkus LA, Allen JW (2001) Ann N Y Acad Sci 939:23–27

Brodie MS, Scholz A, Weiger TM, Dopico AM (2007) Alcohol Clin Exp Res 31:1625–1632

Ward RJ, Colivicchi MA, Allen R, Schol F, Lallemand F, de Witte P, Ballini C, Corte LD, Dexter D (2009) J Neurochem 111(5):1119–1128

Deng C, Li KY, Zhou C, Ye JH (2009) Neuropsychopharmacology 34(5):1233–1244

Chefer V, Meis J, Wang G, Kuzmin A, Bakalkin G, Shippenberg T (2011) Addict Biol 16(2):229–237

Santofimia-Castaño P, Salido GM, Gonzalez A (2011) Brain Res 1402:1–8

Ding ZM, Engleman EA, Rodd ZA, McBride WJ (2012) Alcohol Clin Exp Res 36(4):633–640

Jeong JS, Kim SK, Park SR (2012) Electrophoresis 33(14):2112–2121

Kaspar H, Dettmer K, Gronwald W, Oefner PJ (2009) Anal Bioanal Chem 393(2):445–452

Ou G, Feng X, Du W, Liu X, Liu BF (2013) Anal Bioanal Chem. doi:10.1007/s00216-013-6830-4

Hyzinski-Garcia MC, Vincent MY, Haskew-Layton RE, Dohare P, Keller RW Jr, Mongin AA (2011) J Neurochem 118:140–152

Kuribayashi K, Kitaoka Y, Kumai T, Munemasa Y, Kitaoka Y, Isenoumi K, Motoki M, Kogo J, Hayashi Y, Kobayashi S, Ueno S (2006) Brain Res 1071:34–41

Sarchielli P, Alberti A, Floridi A, Gallai V (2002) J Neurol Sci 198:9–15

O'Shea TJ, Weber PL, Bammel BP, Lunte CE, Lunte SM, Smyth MR (1992) J Chromatogr 608:189–195

Li H, Yan ZY (2010) Biomed Chromatogr: BMC 24:1185–1192

Vyas CA, Rawls SM, Raffa RB, Shackman JG (2011) J Pharmacol Toxicol Methods 63:119–122

Wang C, Zhao S, Yuan H, Xiao D (2006) Analytical technologies in the biomedical and life sciences. J Chromatogr B 833:129–134

Kristensen HT (1998) J Pharm Biomed Anal 18:827–838

Cellar NA, Burns ST, Meiners JC, Chen H, Kennedy RT (2005) Anal Chem 77:7067–7073

Rathnasingham R, Kipke DR, Bledsoe SC Jr, McLaren JD (2004) IEEE Trans Bio-med Eng 51:138–145

Zhao S, Li X, Liu YM (2009) Anal Chem 81:3873–3878

Li X, Zhao S, Liu YM (2013) J Chromatogr A (in press). doi: 10.1016/j.chroma.2013.02.031

Unger MA, Chou HP, Thorsen T, Scherer A, Quake SR (2000) Science 288:113–116

Otter DE (2012) Br J Nutr 108(Suppl 2):S230–S237

Acknowledgments

Financial support from US NIH (GM089557 to YML and G12MD007581-15 to PBT) is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Published in the topical collection Amino Acid Analysis with guest editor Toshimasa Toyo'oka.

Rights and permissions

About this article

Cite this article

Li, X., Xiao, D., Sanders, T. et al. Fast quantification of amino acids by microchip electrophoresis–mass spectrometry. Anal Bioanal Chem 405, 8131–8136 (2013). https://doi.org/10.1007/s00216-013-7260-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-013-7260-z