Abstract

Solar energy is the most sustainable and free source to manage the world energy demand. One aspect of solar-driven energy supply can be observed in cooling systems. Recently, solar energy-based cooling systems have received many attentions. Solar cooling systems utilizing solar collectors, as the renewable and sustainable-based solution, have the good potentials to overcome the challenges associated with consumption of fossil fuels. In this study, the recent advances about the potentials of dish collectors and linear Fresnel reflectors for the usage in the cooling systems are reviewed. In addition, the solar-powered conventional absorption chiller and cryogenic systems are investigated. Hybrid cooling solar systems and solar-based combined cooling, heating, and power systems are also studied. The hydrogen production in cooling integrated systems and cold thermal energy storage are discussed. In each section, in addition to general description of the system, some explanations about the thermodynamic and economic aspects of the systems are provided. Finally, the main results of the review are summarized and based on the available gaps between the literatures, some suggestions are provided for the future studies. It was found that using solar dish collectors in a hybrid system, designed for the freshwater and LNG production, causes carbon dioxide emissions reduction by 40%, and also increases freshwater and LNG production by 95% and 4.7%, respectively. In the hybrid trigeneration solar-biomass power plants, using the linear Fresnel reflector leads to 29% save in biomass and land.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Today, energy security and environmental protection are the most important issues in the world communities. The world’s energy demand is increasing due to the population growth and the economic developments in societies (Oyedepo, 2012). It has been predicted that the world’s population is going to reach 9.7 billion by 2050 and more than 11.2 billion by 2100 (Nations U, 2015). In addition, according to a report published by the International Energy Agency, IEA, in 2015, the world energy demand will be increased more than 1.5 times by 2030 compared to 2015, due to population growth and the economic development of communities (Dincer, 2011). On the other hand, the available energy resources to meet this demand (most of which are fossil resources) are limited and they are rapidly depleting (Dincer, 2011; Shafiee and Topal, 2009). Also, these resources have an unequal distribution in the world (Shafiee and Topal, 2009). The use of fossil resources in recent decades has caused environmental pollutions and the emission of greenhouse gases (IEA 2016) and consequently, climate change and global warming as well as the production of toxic gases such as NOX and SO2. As a result, at the present, finding new ways to prevent energy and environmental crises has become a daily challenge for societies in the twenty-first century (Shafiee and Topal, 2009). For this reason, many countries have made various programs to use different energy sources and they are looking for solutions to replace fossil fuels with sustainable and renewable energy sources (Shafiee and Topal, 2009; IPCC, 2014). For example, the Scandinavian countries have ambitiously goals to use renewable resources in the near future. Denmark seeks to become a country based on 100% renewable energies, and Sweden and Norway are working to reduce the production of greenhouse gases to zero by 2050 (Hoeven 2013). Figure 1 demonstrates the contribution of renewable energy resources in energy supply in 2017 comparing with its values in 2050 (IRENA, 2020). According to Fig. 1, it is predicted that the share of renewable energy consumption in 2050 will reach 86% of the total amount of energy supply and the share of fossil energy resources will significantly decrease.

Contribution of renewable energy sources in 2017 and 2050 (IRENA 2020)

Among the candidates for renewable energy, i.e. the solar, geothermal, wind, gravity-related energy sources, and kinetic energies of the earth surface (such as sea waves), the solar energy is the most sustainable and free source to meet the world energy demand (Dan et al. 2017; Blaschke et al., 2013; Modi et al., 2017). The sun annually radiates \(4\times {10}^{21}\mathrm{ kJ}\) energy to the earth (\(4\times {10}^{14}\mathrm{ kWh}\) daily), which about \(5\times {10}^{19}\mathrm{ kJ}\) can be harvested easily (Van der Hoeven 2013; Gupta, 1999). This energy is not a threat to the environment (Gupta, 1999). The contribution of solar energy to supply the world energy demand is still negligible (Van der Hoeven, 2013). Figure 2 shows the distribution of average annual solar radiation on the Earth’s surface. To better understand the amount of radiant energy of the sun to the earth’s surface, areas marked with dark spots can provide all the primary energy demand of the entire world. It is also assumed that the capturing efficiency of this energy is only 8% (NASA, 2014).

The distribution of solar irradiance over the Earth in one year (NASA, 2014)

Although solar energy is a sustainable and renewable source, the technologies used to harvest this source of energy are immature. This is due to the high cost of instruments (Energysage, 2016) and the issues related to large land required to install instruments. As compared with the energy production density of fossil fuel derived power plants (200–11,000 \({\text{W}}_{\text{e}}/{\text{m}}^{2}\)), solar powered technologies can provide two order of magnitude smaller energy production density (2–10 \({\text{W}}_{\text{e}}/{\text{m}}^{2}\)). This makes it difficult to use this energy source for some communities (Smil, 2015). As reported by Squatrito et al. 2014, 0.1% of Italians agricultural surface area was cultivated with PV systems in 2014. This caused serious debate that led to a ban on the installation of PVs on agricultural lands. On the other hand, IRENA has predicted that the cost of installing solar equipment will decrease around 58% till 2030 compared to 2018 due to advances in solar energy technologies (IRENA, 2020). Increasing the efficiency of solar energy harvesting systems detract the problem associated with the need for vast lands as more energy can be harvested in a certain area by using more efficient technologies.

One aspect of solar driven energy supply can be observed in cooling systems. Approximately 10% of total electricity consumed in the world is used to fulfill the cooling demands (IEA, 2019). In addition, utilization of traditional refrigeration cycles powered by fossil fuels has destructive consequences for the environment. When the availability of the solar resource is high, the cooling demand grows. The solar driven cooling systems are attractive due to use of free source of energy and prevention of pollution emissions. Recently, the use of solar collectors has improved cooling technologies especially sorption refrigeration technologies. This is due to the ability of collectors to provide the desired operating temperature as an important factor in cooling systems (Alsagri et al., 2020). Solar sorption, including adsorption and absorption systems, has high potentials in cooling applications (IEA, 2019). Figure 3 illustrates the number of papers published about solar energy utilization in cooling technologies. It can be seen that the number of articles attributed to the solar-powered cooling systems is increased during recent year (Saikia et al., 2020). Table 1 summarizes the concluded studies on solar-powered cooling systems and their main results.

The number of published papers about solar energy utilization in cooling technologies (Saikia et al., 2020)

Due to high demands for renewable energy resources, the current trend of researches is under the influence of these types of energy especially solar energy. In recent years, researchers have focused on the hybrid systems rather than conventional ones to get more outputs from the solar or biogas as the input energy. In this paper, a comprehensive review is conducted on the different solar-powered cooling systems, as shown in Fig. 4. First, different types of collectors and operating fluids are presented. Then, the studies performed on the use of parabolic dish collector and linear Fresnel reflector in absorption cycles are reviewed. The applications of parabolic dish collector in cryogenic cycle are also investigated. After that, the studies conducted on the use of parabolic dish collector and linear Fresnel reflector in the hybrid production cycles are reviewed. Then, the use of these two collectors in combined cooling, heating, and power (CCHP) systems is discussed. The applications of parabolic dish collector and linear Fresnel reflector in hydrogen production cycles and cold thermal energy storage are investigated. The thermodynamics and economic aspects of different systems are also discussed. Finally, based on the available gaps between the literatures, some suggestions are provided for the future studies.

Solar thermal collectors and heat transfer fluids

Solar collectors are devices that absorb solar radiation and convert it into thermal energy (thermal collectors) or electrical energy (photovoltaic panels). A PV panel is a semiconductor, so its electrical performance can be explained by an equivalent circuit consisting of diodes and resistors (Sohani et al., 2021; Shahverdian et al., 2021). The major issue with PV solar modules is the low conversion efficiency compared to the solar thermal collectors (Sharma and Bhattacharya, 2022). One of the requirements of any solar system is a collector. Thermal collectors are used to absorb the sun's radiation and convert it into heat. Different types of solar collectors are shown in Fig. 5. Thermal collectors are divided into two general categories: non-concentrating and concentrating collectors. Flat-plate collector (FPC) and evacuated tube collector (ETC) are in the non-concentrating category, while parabolic dish collector (PDC), compound parabolic collector (CPC), parabolic trough collector (PTC), linear Fresnel reflector (LFR), and heliostat field collector (HFC) are in the concentrating category. Flat plate collectors have an absorber surface that absorbs sunlight, converts it to heat, and then transfers it to fluid tubes. Evacuated tube collectors have the same function as flat plate collectors, except that the absorber tube with an evacuated tube is used instead of the absorber surface. In a compound parabolic collector, a parabolic reflector surface is used to reflect radiation on the absorber tube. Parabolic collectors can track the sun on an axis as shown in Fig. 5, which increases their efficiency compared to the compound parabolic collector. Parabolic collectors have problems such as structural complexity and hydraulic circuit due to receiver motion, high cost of reflector construction, and wind loading. Fresnel collectors do not have the mentioned problems associated with parabolic collectors due to the simpler structure and lack of movement of the receiver and the use of flat reflectors. The Fresnel collector can be considered a broken parabolic reflector so that each reflector can independently track and reflect sunlight to the receiver. Dish collectors are commonly used to achieve high temperatures. This collector, which is a point reflector, can track the sun in two axes. To receive very high radiant energy, a heliostat field collector is used, which has several reflectors to reflect the solar radiation towards the receiver in the center tower (Kalogirou, 2013). For concentrating solar collectors, the use of hollow cylindrical fins increases the heat transfer (Subramaniam and Senthil, 2021).

Different fluids such as water, air, nanofluids, thermal oils, etc. can be used to transfer heat absorbed by the collectors. The nanofluids are often used as the working fluid due to their good potential for heat transfer (Saffarian et al., 2020; Moravej et al. 2021; Siavashi et al., 2019, Gholamalipour et al., 2019). The heat received by these fluids can be used directly or indirectly for heating/cooling and power generation systems. In the direct method, the fluid receives heat and passes through the collector, while in the indirect one, the fluid enters the heat exchanger after receiving the heat and transfers the heat to another fluid. One of the common fluids for the indirect water system is ethylene glycol. Other fluids such as silicone oils and refrigerants are also used. Common fluids for solar cooling in the absorption refrigeration system are water-ammonia and water-lithium bromide, which ammonia is used as the refrigerant and lithium is used for absorption (Kalogirou, 2013).

Cooling effect

In this section, important cooling methods are discussed. At first, absorption and adsorption cooling cycles, as the most frequent cooling methods, powered by parabolic dish collector (PDC) and linear Fresnel reflector (LFR) are reviewed. The studies conducted about the cryogenic and gas liquefaction cycles using PDC are also reviewed. Finally, the cold thermal energy storage powered by solar energy is also investigated.

Absorption and adsorption cooling cycles

In the absorption refrigeration cycle, despite the compression refrigeration cycle, heat is used as input energy. A simple type of this cycle is shown in Fig. 6. The components of this cycle are the generator, absorber, condenser, evaporator, expansion valve, and pump. Various parameters, such as evaporator temperature, condenser temperature, regeneration temperature, cycle time, and inter-stage pressure, affect the coefficient of performance of the adsorption refrigeration system (Chauhan et al., 2022). In a water-ammonia absorption refrigeration system, water acts as an absorbent, and ammonia acts as the refrigerant. In the water-lithium bromide system, lithium bromide acts as an absorbent. These two aforementioned systems are two main types of absorption refrigeration systems. In an absorption refrigeration cycle, the absorber, generator, and pump act like a compressor in the vapor compression cycle. The refrigerant at the outlet of the evaporator is absorbed by the liquid absorbent, and consequently, the strength of the solution increases as the liquid absorbent passes through the absorber. This solution reaches the condenser pressure by passing the pump and in the generator, some of the refrigerants evaporate with direct heat and separate from the solution. The high-pressure refrigerant passes through the condenser and expansion valve and is ready to absorb heat from the environment in the evaporator. The mechanical energy of the pump and the heat of the generator are two required energies for this cycle. Thermal energy is a major part of energy consumption, which can be supplied by solar collectors. The most important advantages of this method are low noise operation, low vibration, and low energy required. Also, the most important disadvantage of this cycle is its lower coefficient of performance than the vapor compression cycle (Hundy et al., 2016).

Layout diagram for a basic circuit of an absorption cycle (Hundy et al., 2016)

Figaj et al. (2019) studied an absorption chiller which, is used for cooling in a single-floor house. In the experimental part, they used the PDC in their system and their computer simulations were performed by TRNSYS software based on a transient model for a hybrid solar cooling system powered by PDC and flat plate collector. Their system is shown in Fig. 7. For the investigation of the system’s performance, they studied the effects of various time and climatic parameters, dish and flat plate collector areas, and energy tariffs. They reported the PDC efficiency of 70%, energy saving of 50%, optimal dish area per absorption chiller capacity of 1.6m2/kW, and payback period between 8 and 23 years for their system. Based on their results, the proposed system is not so economic because of the low gas and electric tariffs of the research location and consequently, the payback period is rather long. One proper solution may be replacing lower-cost collectors like LFR to reduce the payback period and make the system more economical.

Layout diagram for hybrid dish-flat plate collector absorption chiller designed by Figaj et al. (2019)

Begum et al. (2019) investigated experimentally absorption cooling cycle with PDC and three fluids, including ammonia, water, and hydrogen. They conducted their experiments for 2 days and the temperatures of the generator and evaporator were recorded during the experiments. They reported the COP of 1.6 at the minimum evaporator temperature of 23°C and maximum generator temperature of 92°C.

Mehrpooya et al. (2018) focused on an absorption refrigeration cycle that can be used to supply both power and desalinate water. The system of refrigeration is based on ammonia-water absorption and the process of multi-effect is used in its desalination section. The refrigeration production of the proposed cycle was 820.8 kW. The aspen Hysys software simulations and the second law of thermodynamics analysis were performed for all parts of the system. They concluded that about 86% of the total rate of exergy is destructed for heat exchangers and distillation column. Overall exergy efficiency and thermal efficiency for the system were 66.05% and 80.70%, respectively. They also reported a payback period of 5.783 years and a net profit of 6.828 million US$ per year for the aforementioned system.

Patel et al. (2017) focused on the novel cascaded vapor compression-absorption system as shown in Fig. 8. This system is based on the solar-biomass with the usage of organic Rankine cycle (ORC) and can be used as the low-temperature cooling system. They calculated the solar fraction and break-even point via thermo-economic analysis for both PDC and LFR and the results are presented in Table 1. It can be found that the case of LFR has lower values solar fraction and break-even point and this is due to the lower annual efficiency and cost of LFR. They also changed the working fluid of ORC and investigated the effects of working fluid by calculation of break-even values. They showed that depending on the value and cost of calorific, the biomass system has about 39% and 30% lower values of capital cost and break-even point, respectively as compared with the solar-biomass powered system. As a result, to use their proposed system through solar-powered, LFR is more preferred than PDC because of its lower cost. In another hand, PDC for a single cooling output purpose does not have economic Justification.

Layout diagram for a novel cascaded vapor compression-absorption system designed by Patel et al. (2017)

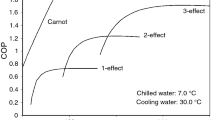

Sioud and Garma (2018) focused on the water/lithium bromide absorption cooling system with ejector single-effect absorption cycle. This system was also coupled with LFR as shown in Fig. 9. Due to the usage of ejector single-effect absorption cycles instead of ordinary cycles, higher temperatures are needed in this system and this leads to higher performance. The optical performance of LFR was studied through a mathematical model. Some simulations and analyses were performed on the system to find the COP of the cycle, the optical performance of LFR, chilled water and cooling medium temperatures, and solar radiation and ambient temperature. The maximum COP of 1.03 was recorded for the generator pressure of 272 kPa. In this study, the application of a novel absorption cycle instead of a traditional one leads to higher COP. However, higher temperature is needed to satisfy the system requirement. PDC can be a desirable option in such systems because of higher operating temperatures with a lower area than LFR. It also may affect collector field area reduction and lower capital cost.

Layout diagram for water/lithium bromide absorption cooling system with ejector designed by Sioud and Garma (2018)

Zhou et al. (2017) performed theoretical and experimental studies on the single/double hybrid effect absorption chiller coupled with LFR and molten salt thermal storage tank. For all components of the proposed system, the dynamic mathematical models were used and the results were validated by the experimental data. In addition, the second law of thermodynamics analysis was done to determine a concentration ratio of 30. They reported COP in the range of 0.73 to 1.09 for the single/double effect chiller and the seasonal thermal COP of 0.88 and the seasonal solar fraction of 27.2% for Shanghai summer conditions.

Serag-Eldin (2014) used a mathematical model for the absorption chiller with roof-mounted LFR. This system was designed to use as the air-conditioning in a desert home. The effects of design parameters on the efficiency of the system were studied. It was found that all the cooling loads can be responded by the proposed system. This system has also less roof space as compared with a photovoltaic-based.

Döll et al. (2014) designed an ammonia-water absorption chiller with a cooling capacity of 12 kW coupled with LFR for the cold storage near Freiburg in Germany. They focused on the optimization of the plant. They concluded that by using the solar cooling system, five times higher electrical efficiency can be achieved and the electrical energy efficiency ratio can be exceeded to 12 in direct cooling.

Popov (2014) studied a gas turbine combined with the cycle plant, which was integrated with the solar power system. This system was named by the solar-assisted combined cycle. In one of the case studies, an absorption chiller was considered for cooling of gas turbine that its required steam was generated by LFR. Finally, Popov (2014) concluded that the usage of absorption chiller leads to lower plant capital costs and smaller land area required for the system as compared with the other cases.

Weber et al. (2014) studied two water-ammonia absorption chillers that were combined with LFR. They investigated the performance for various operation and control parameters. Operation temperatures and collector capacities used in this study are presented in Table 2. An energy efficiency ratio (EER) of 12 and 0.8 were determined for the electrical and thermal systems, respectively at the ideal operating conditions.

Pino et al. (2013) focused on the design and validation of a mathematical model developed for the LFR. Water heating was related to the thermal and optical properties in this model. A double-effect absorption chiller in Seville, Spain was used for the validation. They also developed a one-axis tracking mechanism, which can be used to maximize the radiation reception. The optical and thermal errors in the model were about 3% and 7%, respectively in comparison with the experimental data.

Chemisana et al. (2013) compared two absorption cooling units. The first unit was a single-effect absorption chiller coupled with an evacuated tube collector, while the second one was the double-effect absorption chiller with LFR. They found that the installation area needed for LFR is lower than that for the non-concentrating collectors. In addition, LFR needs a larger aperture area. Heat rejection in a cooling system powered by LFR is lower and this leads to lower operation and investment costs.

Berger et al. (2012) studied two cascading ammonia-water absorption chillers, which can be used for industrial cooling in the cold room. LFR was used in their system to supply the required heat at 200 \(^\circ{\rm C}\) and a cold temperature of -12 \(^\circ{\rm C}\) was also achieved.

Robledo et al. (2011) developed a lumped parameter dynamic model of a LFR used in a refrigeration cycle. They considered their model as a control model or as a simulation tool for testing the controller’s behavior. They validated their model with the data achieved from the plant at different operating conditions. Finally, they showed that their model can reproduce the system behavior with acceptable accuracy due to model complexity.

Bermejo et al. (2010) studied experimentally a double-effect LiBr-water absorption chiller equipped with LFR for a cooling plant. They also used a direct-fired natural gas burner; because only 75% of the generator’s total heat input can be produced by LFR. They investigated the effects of some parameters such as LFR size and dirtiness, climatology, piping heat losses, operation control, and coupling between LFR and chiller. The efficiency of their system is presented in Table 2.

In a numerical study, Velázquez et al. (2010) focused on an advanced absorption refrigeration system with LFR as the generator. They used a one-dimensional numerical model of LFR and then validated their numerical result with the experimental data. Their numerical results showed that using a LFR as a direct generator supplies the energy needed for the advanced cooling system. The energy provided by LFR is 17.9% higher than that supplied by single effect water–lithium bromide with the parabolic through the collector.

Details of studies conducted on the absorption and adsorption cooling cycles with PDC and LFR are presented in Table 2. In conclusion, the solar fraction for the PDC is higher than LFR. However, the lower cost of LFR leads to a lower cost of energy generation and that is the reason for the researcher’s tendency to choose LFR heat sources more than PDCs in absorption cooling systems. In other words, PDCs are economic in the cases that more outputs such as power, domestic hot water, space heating, and distilled water in addition to single cooling load generation is desirable.

Cryogenics

Cryogenics is the science of production and effects of temperatures below approximately -150 \(^\circ{\rm C}\). Among many applications of cryogenics, liquid natural gas (LNG) represents one of the largest and fast-growing industrial usages of cryogenics together with the liquefaction and separation of air gases as shown in Fig. 10 (Zohuri, 2018). These systems require a source of energy like solar energy as a power generation unit. PDCs have the highest performance among all kinds of collectors, as they track the sun in two axes throughout a day and concentrate the irradiation absorbed by the surface of the collector, onto the absorber, which is its focal point. The application of absorber is the conversion of the radiant solar energy to thermal energy through working fluid and this converted energy can be used in a variety of power generation systems like Rankine power cycle, Brayton power cycle, and Stirling engine (Ebrahimi et al., 2020).

Cryogenic air separation plant with distillation column towers (Zohuri, 2018)

Only a few studies are conducted on the cryogenic systems coupled with the solar collectors. PDC is usually used as the collector in these systems and the main application of such systems is LNG production. In this section, the studies conducted on these technologies are reviewed.

Ghorbani et al. (2019) performed both energy and exergy analysis for a hybrid system that is used to produce LNG and freshwater. For the cooling cycle of such a system, they used the ammonia-water absorption system. The needed cooling load and liquefaction process are provided by a refrigeration system with the mixed fluid, which is shown in Fig. 11. Two alternatives were considered to supply the required power and heat for the absorption cycle, including the natural-gas-fired power plant and the solar power plant with the dish collectors. Their results indicated that the heat exchangers are responsible for the highest irreversibilities (61% of irreversibilities). Using solar dish collectors causes carbon dioxide emissions reduction by 40%, and also increases freshwater and LNG production by 95% and 4.7%, respectively. They also reported a total energy efficiency of 85.8%. The prime cost for the production of both structures was 0.2580 and 0.1784 US$ per kg of LNG. According to their results, it is beneficial to use PDCs to reduce inappropriate emissions, but this selection increases the capital cost by 49.32%. As a result, integrating the proposed system with lower-cost collectors like LFR might be helpful to improve economic parameters.

Layout diagram for LNG and freshwater solar power plant designed by Ghorbani et al. (2019)

Ebrahimi et al. (2020) designed the novel integrated structure to produce the liquid nitrogen for the gas platforms. The required power for the separation and liquefaction cycles was provided by PDC thorough the Rankine cycle as shown in Fig. 12. Production of pure liquid nitrogen of this cycle was 40.44 kg/h and the cycle power of 32.34 kW and the heat generation capacity of 130 kW were achieved. They reported an exergy efficiency of 46% and total irreversibility of 57 kW for their system. Finally, according to their economic analysis, the prime production cost and the payback period were 7.309 years and 1.203 $/LN2, respectively.

Block flow diagram of integrated structure for production of liquid nitrogen with PDC designed by Ebrahimi et al. (2020)

Piadehrouhi et al. (2019) performed a study on an integrated structure for simultaneous generation of power and liquefaction of carbon dioxide. An absorption refrigeration cycle and PDC were used for the carbon dioxide liquefaction and heat supply, respectively in this study. Production of pure liquid carbon dioxide of this cycle was 26.27 kg/s and the power heat generation capacity for the cycle was about 179 MW. The exergy analysis showed that the exergy efficiency of the entire system was 60.74% and the total exergy destruction was 416 MW. The prime production cost and the payback period of the system were 3.3 years and 3.04 cents/kWh, respectively.

Details of studies conducted on cryogenic cycles powered by PDC are presented in Table 3. In conclusion, PDC is the only solar collector in previous investigations as a heat source of gas liquefaction and cryogenic cycles. In other words, due to the great potential of PDCs to supply high temperatures with high efficiency, the researchers used this collector. However, because of LFR’s undeniable role in reducing the costs of solar cooling systems, it would be necessary to compare both the performance and economic parameters of PDC and LFR in cryogenic systems.

Solar hybrid generation cycles

Solar hybrid generation cycles are the new approach in solar cooling cycles. They are replaced with traditional cycles, which had only one product. In this section, all studies conducted on these cycles, in which the number of their products is more than one, are classified and reviewed in four subsections including, multigeneration, polygeneration, cogeneration, and trigeneration cycles. The number of useful outputs in the first and second cycles is more than three and for the third and fourth aforementioned cycles are two and three, respectively. Hybrid generation cycles are efficient systems that can generate multiple energies, such as electricity, and can also be used for cooling, heating, desalination, and hydrogen production. (Kasaeian et al., 2020) Using solar energy in combination with hybrid systems leads to the achievement of several high-efficiency outputs with a clean source. Solar energy usually can be used in hybrid generation systems using solar collectors to generate heat directly or indirectly.

Multigeneration

Ghorbani et al. (2020) studied a multigeneration system combined with PDC. The useful outputs of this system were power, cooling, and hydrogen. Thorough energy and exergy analysis, they reported the overall energy and exergy efficiencies of 90.77% and 92.19%, respectively for their system. Moreover, a COP of 0.39 was achieved. Finally, the production capacity for the electricity, cooling, and hydrogen was 4.36 MW, 1.65 MW, and 2026 kg/h, respectively in their system.

Onder et al. (2019) performed a study on a multigeneration system equipped with PDC. The outputs of this system were power, cooling, heating, hydrogen, and hot water. They calculated the energy and exergy efficiencies of 54.17% and 50.46%, respectively for their system. They also investigated the effects of different parameters such as reference temperature, solar irradiation, thermochemical reaction temperature, and compression pressure on the thermodynamics performance of the system. They concluded that an increase in solar radiation flux causes an increase in electricity and hydrogen production rates of the multigeneration system. They also showed the significant impact of ambient temperature on the system performance. Furthermore, an increase in reference temperature increases hydrogen production rates and the whole exergy efficiency of the multigeneration system.

Hogerwaard et al. (2017) focused on a multigeneration system coupled with PDC. This system had different parts, including the organic Rankine cycle-based gas turbine, absorption chiller, single-stage flash desalination unit, and direct space heating system. Through the energy and exergy analysis, the energy and exergy efficiencies of 0.284 and 0.27 were recorded, respectively. Finally, the results showed that this system is more promising and sustainable than a single heat source system for residential or commercial applications.

Ozturk and Dincer (2013) designed a multigeneration system equipped with PDC. Their design is shown in Fig. 13. Their system has some productions such as power, heating, cooling, hot water, hydrogen, and oxygen. They reported the energy and exergy efficiencies of 52.71% and 57.35% of the system, respectively. They showed that the highest exergy destruction occurs in PDC. They also investigated the effects of operating conditions such as the reference temperature, direct solar radiation, and receiver temperature. They showed that the increase of the collector receiver temperature and solar radiation flux affect the receiver outputs and increase the exergy efficiency of the system. They also concluded that an increase in the reference temperature affects positively the exergy efficiency of hydrogen production, the Rankine, organic Rankine, and utilization cycles in addition to the multigeneration system. In addition, an increase in reference temperature affects inversely the absorption system exergy efficiency. Due to their findings, the reason for the highest exergy destruction in PDC is the enormous temperature difference between the working fluid of the collector and the collector receiver’s surface temperature. The solution for this problem may be the proper design of the receiver and its optimization. Furthermore, comparative economic studies are needed between PDC and LFR to find the cost-effective solar-powered option in these systems.

Schematic diagram of a multigeneration system equipped with PDC (Ozturk and Dincer, 2013)

Rady et al. (2015) focused on a LFR multigeneration solar plant. Their plant was capable to produce solar thermal power of 120 kW, electric power of 4.3 kW with organic Rankine cycle, and refrigeration of 35 kW with its absorption chiller. They also compared the potentials of parabolic thorough collector and LFR for the usage in their plant and found that LFR reduces the operation hours of organic Rankine cycle and absorption chiller about 50% and 30%, respectively.

The details of studies conducted on multigeneration systems equipped with PDC and LFR are presented in Table 4. It can be concluded that multigeneration systems have many outputs and are applicable by both PDC and LFR. The main products are the same in all the studies but may differ in one or two, such as fresh water and hydrogen production. These systems seem to be applicable in power plants rather than domestic usage. This shows the need of further studies for domestic feasibility potential of them. Moreover, comparative economic studies between LFR and PDC in these cycles are preferred to achieve the most cost-effective system.

Polygeneration

Yilmaz et al. (2020) studied a polygeneration cycle equipped with PDC as shown in Fig. 14. This cycle can be used to produce different useful outputs such as hydrogen, electricity, fresh and hot water, and heating–cooling. The Rankine cycle, membrane distillation, and PEM electrolyzer were used for the production of electricity, freshwater, and hydrogen, respectively. Through the thermodynamics analysis, the energy and exergy efficiencies of 58.43% and 54.18%, respectively were achieved. Based on their results, the highest irreversibility was for PDC with 29.81%, which shows the importance of focusing on its receiver design and optimization. Furthermore, economic studies are needed to evaluate the economic feasibility of these systems.

Schematic diagram of a polygeneration cycle equipped with PDC (Yilmaz et al., 2020)

Ullvius and Rokni (2019) designed the polygeneration system equipped with PDC, reversible solid oxide fuel cell, and desalination unit. Their design is shown in Fig. 15. The solid oxide fuel cell was used to produce hydrogen, power, and freshwater. They reported the capacities of 500 kW and 8464 L per day for the electricity and freshwater, respectively for their system. Finally, the energy and exergy efficiencies of 19.3% and 26.4%, respectively were achieved for this polygeneration system. In another study conducted by Rokni (2019) about this system, it was concluded that the rate of daily freshwater production is at least 6500 L and hydrogen can be produced continuously even on winter days with low irradiation.

Schematic diagram of a polygeneration cycle combined with solid oxide fuel cell (Rokni, 2019)

El-Emam and Dincer (2017) studied a polygeneration cycle equipped with PDC. This system can be used to produce power, cooling, and hydrogen. In this system, biomass fuel was considered as the backup source when solar energy is absent. Through a thermodynamics analysis, the energy and exergy efficiencies of 39.99% and 27.47%, respectively were reported. They also performed a parametric study to investigate the effects of environmental parameters and operating conditions on the performance of the system. They concluded that the overall efficiency of the system reduces with the high receiver temperature, with less influence on the exergy efficiency in comparison with energy efficiency. Also, they showed that the cost rate is highly affected by the receiver temperature. Furthermore, receiver design to obtain the optimum temperature for overall efficiency improvement is essential in PDC-based polygeneration systems.

Askari et al. (2019) conducted a study on a polygeneration system powered by the LFR. They compared their system with that powered by photovoltaic panels. The useful outputs of this system were power, cooling, and freshwater. They also performed a techno-economic comparison between two power systems and concluded that the payback period of LFR is higher as compared with the photovoltaic panels. In this study, the thermal-based system with LFR had a better operation in different aspects such as energy-saving, annual electricity generation, capital cost, and payback period than the electric-based system. Furthermore, a comparative study in these types of studies is needed between LFR and PDC to determine the best thermal option scenario as thermal and economic parameters.

Calise et al. (2019) studied the polygeneration cycle powered by a LFR. They compared the results of this system with those of the system powered by the evacuated tube solar collector. The useful outputs were heating and cooling, hot water, and fresh desalinated water. They simulated the energy trend of both systems in TRNSYS software. They also conducted a thermo-economic analysis for both collectors. They concluded that the evacuated tube solar collector is more economic than LFR based on their payback period. In this study, the evacuated tube collectors were better than LFR in operation. However, LFRs are not weak collectors in the polygeneration cycle and based on available solar radiation, the high performance also can be achieved for them. Hence, for a polygeneration system with hydrogen production and power generation, LFR and PDC are feasible options because of their high concentration ratios and operating temperature ranges.

The details of studies conducted on polygeneration systems equipped with PDC and LFR are presented in Table 5. In conclusion, polygeneration systems have various outputs and are applicable by PDC and LFR. The research works in this field have great potential to be continued as the economic aspect in PDC-based systems and other outputs such as power and hydrogen in LFR-based systems are important.

Cogeneration

Jabari et al. (2020) studied a cogeneration system powered with PDC. This system can be used to generate power and cooling for large buildings on hot and humid days. Dish Stirling technology was used in this cycle for air blower derivation and provision of the building load. The outlet heat of Stirling engine was used in the humidification dehumidification desalination unit of this system. They also simulated and modeled mathematically their system to investigate its performance and feasibility. They concluded that the optimum operating point of the humidification dehumidification and Stirling cycles is determined by an approach that not only the electricity requirement are obtained and the thermal efficiency of the Stirling cycle is maximized, but also the heat extracted from the solar power generation process should be equal to the heating demand of the humidification dehumidification desalination unit.

Hou and Zhang (2019) investigated a novel cogeneration system equipped with a PDC, vacuum thermionic generator, and an absorption refrigerator. The maximum efficiency of the system was about 27.06%. They also studied the effects of the design parameters, such as absorber temperature of PDC, solar concentration ratio, and solar irradiance, on the performance of the system. They concluded that solar irradiance, solar concentration ratio, heat transfer area ratio, heat transfer coefficient, and ambient temperature have positive roles in performance enhancement. Moreover, the efficiency of their proposed system could be maximized through optimizing parameters, including PDC receiver temperature and heat transfer area ratio.

Abdul Shukoor and Reddy (2019) studied a 19 kW PDC-based cogeneration cycle. They also used the lithium bromide water absorption chiller in their system. The schematic diagram of their cogeneration system is shown in Fig. 16. In this study, they also performed a thermodynamics analysis, which was also validated with experimental data. It can be found that 2.37 kW and 0.41 kW exergy can be destructed in desorber and absorber, respectively.

Schematic diagram of cogeneration system equipped with PDC proposed by Abdul Shukoor and Reddy (2019)

Bellos et al. (2019) focused on the cogeneration system powered with LFR. Their system is displayed in Fig. 17. In their proposed system, electricity and cooling were provided by organic Rankine cycle and lithium-bromide/water single-effect absorption chiller. They used Engineering Equation Solver software at the steady-state conditions to perform a parametric study on this system. They also performed the optimization for the dynamic case of the model. Through a thermo-economic analysis, the energy and exergy efficiencies of 17.5% and 8.3%, respectively were calculated. In addition, 8 k€ was dedicated for the net income of the system, and 18 MWh was the yearly production of this system. Furthermore, the concentrating area for this research was enormous for 150 m2, and a PDC was better for this system with a smaller size. Moreover, a comparative study is crucial by replacing a PDC with LFR in this system to evaluate economic parameters changes.

Schematic diagram of cogeneration system equipped with LFR proposed by Bellos et al. (2019)

The details of studies conducted on cogeneration systems equipped with PDC and LFR are presented in Table 6. As a result, cogeneration systems have two main outputs: power and cooling. Also, in some works, one product may be replaced by desalinated water. In general, researchers prefer PDC because of its higher temperature range and smaller concentrating area rather than LFR. In PDC-based systems, the extracted heat from the Stirling engine can produce another output.

Trigeneration

Jabari et al. (2016) studied a novel trigeneration system equipped with PDC. This system has useful outputs such as electricity, heating, and cooling. Their system was based on air to an air heat pump and the required heat was also supplied by the dish Stirling engine. They found that this system has the potential to considerably decrease CO2 and NOX and also save fuel consumption. They also used the thermodynamic approach to investigate the tri-generation microgrid. Finally, the results of their proposed trigeneration system indicate that this system can be considered as a near-zero energy/greenhouse gas emissions technology, especially in the case of demand response programs and battery storage systems.

Calise et al. (2013) studied a Photovoltaic/Thermal trigeneration system. They used the PDC and photovoltaic panels to produce power, heating–cooling, and hot water. In the case of heating–cooling, an absorption chiller was used. Their economic results showed the beneficial aspect of the system under a suitable funding policy. They had also a parametric investigation on the effects of operating and design parameters, such as solar plant area, tank volumes, and setpoint temperatures, on the performance of the system. Based on their results, the significant potential of energy savings of the system under investigation especially in the summer was observed. Furthermore, they concluded that the external radiation and temperature fluctuations induce fluctuations in thermal and electrical productions. They also explained that the aforementioned fluctuations could be decreased by using the large tank volumes. Although, by using large volumes, large thermal losses and high capital costs must be considered.

Buonomano et al. (2013) studied a trigeneration system. They used the combined unit of PDC and photovoltaic panels in the form of Photovoltaic/Thermal collectors. Their system is disclosed in Fig. 18. They designed this system to produce electricity and heating–cooling with the usage of a two-effect absorption chiller. They also conducted mathematical modeling and simulation on their system to investigate its performance. They achieved good values for the electrical and thermal efficiencies with respect to the operating conditions. Moreover, based on the results, their system is so expensive because of the usage of triple-junction PV cells. Hence, further studies are needed to compare this system with the fully thermal system by employing dish Stirling to obtain the most economical option.

Schematic diagram of trigeneration system powered with PDC proposed by Buonomano et al. (2013)

Dabwan et al. (2019) performed a study on a LFR based trigeneration system used to provide cooling and produce heat and electricity. Schematic diagram of this system is displayed in Fig. 19. Thorough a thermo-economic analysis, they found that using this LFR integrated system leads to 7.6% decrease in the levelised electricity cost and also CO2 emissions reduction in comparison with the simple gas turbine trigeneration plant without LFR. They also developed an optimum design for their proposed system via a conceptual approach. As a result, an LFR-based system is a prominent solution to make the system more economical. However, this system needs to be compared with the PDC-powered system to find the most suitable option for high energy efficiency.

Schematic diagram of trigeneration system equipped with LFR proposed by Dabwan et al. (2019)

Nixon et al. (2012) studied the hybrid trigeneration solar-biomass power plants powered by the LFR. This system can be used for power generation and process heat purposes. The maximum thermal capacity of this system was in the range of 2 to 10 MW. They conducted an economic analysis and found that their system is more profitable than other renewable systems despite its higher levels of energy costs. In comparison with a pure biomass system, their proposed system has a longer payback period. However, 3.2 times increase in the feedstock makes their system affordable. They also observed that using the Fresnel-based system leads to a 29% save in biomass and land but also increases the levels of energy cost and exergy loss.

The details of studies conducted on trigenration systems equipped with PDC and LFR are presented in Table 7. In conclusion, trigeneration systems have at least three main outputs, and the type of output can be different according to the system’s design. These systems can be integrated with other heat and energy sources like photovoltaic panels and biomass power plants. Furthermore, the large-scale application of these systems is rather than residential usage.

Combined cooling, heating, and power systems

In this section, studies conducted on the combined cooling, heating, and power (CCHP) cycle are reviewed. Although this cycle has a similar structure to those investigated in the previous sections, it can be used to provide cooling, heating, and power, separately. As a result, it is important to focus on this cycle in a separate section.

Wu et al. (2020) proposed a novel steam/air biomass system in combination with the CCHP system powered by PDC. In this system, high-temperature steam produced by PDC acts as a biomass gasification agent. According to their study, reaction kinetics models of steam biomass gasification using solar energy were developed and also thermodynamics performance has been studied numerically. It was found that under certain conditions, the primary energy efficiency of 51.34% can be achieved. Based on local weather, the off-design performance of the system and the annual energy-saving potential were investigated. In addition, to analyze the feasibility of this system, an economic analysis was also performed. According to the economic analysis, the payback period of the proposed system was determined 2.70 years, which is 3.94 years less than the reference system. Moreover, they showed that based on the economic benefit, there is no reduction in the total investment and maintenance costs of the hybrid system, but an increase in the annual electricity, heating, and cooling profits can be observed.

Wu et al. (2019) performed the exergy and exergoeconomic analysis for a novel CCHP system. This system was based on solar thermal biomass gasification. The required heat of the system was supplied by using PDC. The gas produced is used for driving the internal combustion engine to generate electricity. The chilled/hot water is also produced by a waste heat unitization system. The results of this study revealed that about 49.2% of the total exergy loss of the system occurs in the internal combustion engine.

Su et al. (2018a, b) studied the potentials of biogas for the usage in CCHP system powered with PDC. Their system is displayed in Fig. 20. The results showed that the use of solar energy and biogas in the proposed system improves the annual electricity production and the refrigeration capacity about 8.70% and 2.57%, respectively, and reduces the natural gas consumption by 8.66%. Their proposed hybrid CCHP with solar or biogas energy is applicable in industrial sites like milk plants. Moreover, a fully solar-powered system is enough for small-scale residential applications.

In another study, Su et al. (2018a, b) designed a PDC-based CCHP system. They used the optimization model based on the comprehensive evaluation criteria that were developed under Lhasa Tibet weather data. They optimized the key parameters of the CCHP and the electric load by the genetic algorithm. Based on their results, the biogas-fired CCHP and PDC/Stirling power system reduce the natural gas consumption and electricity received from outside the system by about 3.3% and 77.8%, respectively.

Su et al. (2017) studied a PDC-based CCHP integrated with the biogas energy system. In their system, the caloric value of biogas was enhanced before combustion by the special solar heat based on the thermochemical process. With the usage of PDC, the exergy efficiency of the system was enhanced and carbon dioxide footprint was also decreased. Their thermodynamic investigation showed that the energy and exergy efficiencies of 46.8% and 26.49%, respectively were achieved. The carbon dioxide was also decreased by about 18.27% in this system. They also studied the critical parameters and performed a dynamic simulation of the system. They concluded that the steam/carbon ratio selection affects the optimum carbon dioxide footprint and exergy efficiency of the system.

Moradi and Mehrpooya (2017) studied a CCHP system powered with PDC and integrated with SOFC. They designed this system for a commercial tower in Tehran. They developed a MATLAB software electrochemical model for the SOFC used in the system. They recorded the values of 79.49%, 48.73%, and 41.49% for the thermal, electrical, and SOFC efficiencies, respectively. They also showed that 3.47 million dollars is needed for investment and 3.43 years is the payback period of this system.

Marefati et al. (2019) focused on a new LFR based CCHP cycle. The schematic diagram of their system is shown in Fig. 21. It can be seen that this system consisted of a SOFC, double-effect absorption chiller, Stirling engine, and steam turbine. They conducted a thermodynamic analysis on their proposed system. The values of 67.5%, 55.6%, and 12,560 kW were achieved for the energy efficiency, exergy efficiency, and irreversibility of the system, respectively. Finally, they conducted the sensitivity analysis to determine the effect of system parameters like inlets flow rate, the outlet pressure of the components, and temperature changes of the solar system on the hybrid system performance. They concluded that an increase in the flow rate of fuel causes a reduction in the thermal efficiency of the proposed system. Also, an increase in the flow rate of fuel reduces the total exergy efficiency of the CCHP cycle. Based on their results, their proposed system is very sensitive to the temperatures of stream numbers 25 and 26 (see Fig. 21). With the increase of this parameter, the exergy efficiency and destruction of LFR for stream 25 increases and decreases, respectively.

Schematic diagram of LFR-based CCHP system proposed by Marefati et al. (2019)

Moaleman et al. (2018) performed a study on the LFR/photovoltaic-based CCHP system. The TRNSYS software was used to simulate the system. The system was designed for a typical residential building. The electricity demand of the building cannot be totally provided by the proposed system and 6030 kWh of the electrical energy must be supplied by the grid. The values of 12.8% and 58.01% were achieved for the electrical efficiencies of the LFR and CCHP cycle, respectively.

The details of studies conducted on CCHP systems equipped with PDC and LFR are presented in Table 8. In conclusion, CCHP systems are preferable renewable-based systems with residential applications. It has three main outputs that can support all the ventilation and power demand of a building all over the year. It is common to combine CCHP systems with other renewable sources like biomass and SOFC, especially for larger energy demand applications. However, PDC and LFR can also supply all the energy demands of these systems. It is crucial to compare PDC and LFR for a CCHP system in different aspects of energy and economic to provide the best commercial CCHP for residential applications.

Hydrogen production and cold thermal energy storage

The methods involved for hydrogen production from the solar source have achieved a degree of maturity and effectiveness thanks to the forthcoming of new technological ideas and the formation of modern solar thermodynamic bases. These technologies enable the conversion of solar radiations into heat with a temperature ranging between 200 \(^\circ{\rm C}\) and 2000 \(^\circ{\rm C}\) and with a maximum efficiency of 70%. This primary heat will later be converted to hydrogen energy. Several various pieces of research have been conducted for the usage of solar energy as the main source of energy production. The methods of hydrogen production employing solar energy are featured in Fig. 22 (Ngoh and Njomo, 2012).

A schematic diagram of the methods of hydrogen production from solar energy proposed by Ngoh and Njomo (2012)

In this section, the studies conducted about the hydrogen production and solid oxide fuel cell and also the cold thermal energy storage systems used in the cooling plants equipped with the PDCs and LFRs are reviewed. It should be noted that the hydrogen in these multigeneration systems is one of the major outputs. Due to the special focus on hydrogen production in these systems, a separate section is considered for this topic in this review study. In addition, the cold thermal energy storage systems used in the refrigeration cycles coupled with the PDCs are also reviewed.

Koc et al. (2020) studied a combined power plant equipped with the PDC and biomass gasifier. This system was developed for the production of liquefied hydrogen. In addition to the hydrogen, their system was also able to generate the power and hot water and provide heating–cooling. The production rates for this plant were 3.9 MW, 6584 kW, 4206 kW, and 0.087 kg/s for the electricity, cooling, heating, hydrogen, and hot water, respectively. The values of 51.93% and 47.14% were reported for the energy and exergy efficiencies of this system, respectively. In this study, they also investigated the effects of some parameters, such as the reference temperature, solar radiation intensity, gasifier temperature, combustion temperature, and parameters related to the Brayton and organic Rankine cycles. They concluded that the increase of reference temperature causes a reduction in the energy and exergy efficiencies of the single-effect absorption cooling process. The energy and exergy efficiencies of the whole plant increase. Moreover, an increase in solar intensity rate makes an increase in plant performance. They also reported a rise in gasifier and gasification temperature, causing a reduction in the exergy destruction rate of the entire system. Finally, they showed that a rise in combustion temperature increases the thermodynamic efficiency of the proposed plant.

Ghorbani and Mehrpooya (2020) focused on the idea of refrigeration storage for usage in industrial applications. Their system is shown in Fig. 23. It can be seen that there is a hybrid solar-driven refrigeration system, which is coupled with the cold thermal energy storage unit. The PDC is also used in this system to provide the power required to drive the water-ammonia absorption cycle. The method considered for the storage of exceeding produced refrigeration in their system was based on the phase change material (PCM) system. The cold energy stored in the PCM was used at night time. They also performed the simulations on this system with TRNSYS, HYSYS, and MATLAB software. They observed that the exergy destruction rate of PDC is 77.33% and the exergy efficiency of the whole system is 45.14%. One crucial point about this PDC-based system is relative high exergy efficiency of PDC with low irreversibility, which is beneficial to reach a lower amount of exergy destruction to improve the system efficiency.

Schematic diagram of refrigeration storage system equipped with PDC proposed by Ghorbani et al. (2020)

Yilmaz et al. (2019) studied a multigeneration system powered by the PDC. The hydrogen, heating, cooling, drying, and power were the outputs of this system. The layout diagram of this system is displayed in Fig. 24. The results of this study showed that the PDC has the highest irreversibility rate of 24,750 kW. In addition, the values of 48.19% and 43.57% were reported for the energy and exergy efficiencies, respectively. The effects of different parameters such as the reference temperature, solar irradiation, and related pressure of high-pressure turbine were investigated. They concluded that the increase of reference temperature of the system causes an increase in exergy efficiency, whereas reduces irreversibility rate. Moreover, it can be concluded that an increase in solar irradiation has a positive effect on the exergy efficiency of the whole plant. Finally, an increase in the input pressure of a high-pressure turbine causes an increase in the exergy performance of the entire system. As a result, hydrogen production in a PDC-based multigeneration system is efficient because these systems have good potential in terms of energetic and exergetic efficiencies.

Layout diagram of multigeneration system with hydrogen production designed by Yilmaz et al. (2019)

Sanz-Bermejo et al. (2014) used the solid-oxide electrolysis cells (SOEC) to produce the hydrogen. SOEC in this study worked at the operating temperature in the range of 600 to 1000ºC. The power of SOEC was supplied by the LFR. The castable ceramic thermal energy storage unit was also used in this system. They considered two cases, including the case about the direct use of produced hydrogen for bus refueling stations and the case of storing produced hydrogen for the later usage of electricity production.

The details of study conducted about hydrogen production and cold thermal energy storage systems powered with PDC and LFR are presented in Table 9. It can be concluded that hydrogen production has received many attentions in recent years, especially in combination with hybrid generation systems. It is possible to produce hydrogen by both PDC and LFR, but PDC is preferable because of the high temperature and efficiency. Cold thermal energy storage is currently under development and investigation, and only a few studies have used the PDC in such systems. However, it is necessary to use this method and investigate its operation in LFR-based system.

Conclusions and future works

In this paper, a review was conducted on the solar-powered cooling systems coupled with the parabolic dish collector and linear Fresnel reflector. The solar-powered conventional absorption chiller and cryogenic systems were investigated. The hybrid cooling solar systems and solar-based combined cooling, heating, and power systems were also studied. Finally, hydrogen production in the cooling integrated systems and cold thermal energy storage were discussed. The main results of this review are summarized as follows:

-

The absorption and adsorption cooling cycles in the form of a hybrid cooling plant can be powered by the PDC., The LFR can be used in common absorption chillers. The PDC-based absorption chillers are more complex and efficient systems and the LFR based cooling systems are more economic and cheaper.

-

Solar cryogenic systems are a new technology used in solar cooling and there is a lack of study about the applications of LFR in these systems. For PDC-based systems, a few theoretical studies are conducted bout gas liquefaction and LNG production.

-

There are different solar hybrid generation systems such as multigeneration, polygeneration, cogeneration, and trigeneration systems. The literature review showed that most of the studies conducted in this field are theoretical and very little experimental data is available. The common outputs of these systems are electricity, desalinated and freshwater, heating–cooling, domestic hot water, and hydrogen. In these systems, it is important to design a compact plant to supply all the energy required in a building. The previous studies showed that PDC is preferable in these solar hybrid generation systems due to its higher efficiency.

-

CCHP systems are similar to hybrid generation systems. However, they have special outputs and applications. One important feature of CCHP systems is the potential of these systems for the combination with a biogas system. These systems can be used in residential buildings.

-

Hydrogen production by renewable resources is a rather new topic for study. The plants of hydrogen production integrated with solar cooling systems have mostly appeared in the hybrid generation plant. The hydrogen production unit and solid oxide fuel cell-powered with PDC and LFR were designed. Cold thermal energy storage is a smart technique to make the system sustainable as the non-stop supplement of refrigeration, especially in the nighttime.

Based on this literature review, the following suggestions are provided for future studies:

-

More experimental studies should be conducted on the hybrid systems powered by both PDC and LFR to compare their performance in real conditions. Hybrid cascaded vapor compression-absorption systems have a good potential for the combination with the PDC and LFR. More theoretical and experimental studies should be conducted in this field.

-

LFR based cryogenic systems are a rather new topic for the investigation and more studies are needed to compare their performance and economic results with PDC-based systems. There is also a lack of experimental data about the PDC-based gas liquefaction systems.

-

There are a few studies about the multiple generation systems combined by LFR and this can be the subject of future studies.

-

There is a lack of experimental data for the CCHP systems, such as solar hybrid generation systems, powered by both PDC and LFR. These systems have a high potential for usage in residential buildings. More studies must be conducted to provide a low-cost and simple design of these systems.

-

Solar-based hydrogen production systems have a high potential for future studies. Some studies can also be conducted on high-performance PDC and LFR plants used to produce and store hydrogen energy. Cold thermal energy storage in LFR based plants can be the subject of the future studies.

Data availability

Current work is a review paper and does not contain any data such as a research paper. Hence, this part is not applicable to this manuscript. Moreover, the permission for the figures was gotten from the related publications.

References

Abdelhay A, Fath HS, Nada S (2020) Solar driven polygeneration system for power, desalination and cooling. Energy 198:117341

Abdul Shukoor P, Reddy KS (2019) Investigations on water–LiBr-based absorption refrigerator with solar parabolic dish in cogeneration mode. IET Renew Power Gener 13:2310–2318

Aghaziarati Z, Aghdam AH (2021) Thermoeconomic analysis of a novel combined cooling, heating and power system based on solar organic Rankine cycle and cascade refrigeration cycle. Renewable Energy 164:1267–1283

Al-hamzawi A (2022) Experimental Investigation of the Thermal Performance of a Fresnel Solar Collector. Master Thesis , Semnan University, Semnan, Iran (in Persian).

Alsagri AS, Alrobaian AA, Almohaimeed SA (2020) Concentrating solar collectors in absorption and adsorption cooling cycles: an overview. Energy Convers Manag 223:113420

Askari IB, Calise F, Vicidomini M (2019) Design and comparative techno-economic analysis of two solar polygeneration systems applied for electricity, cooling and fresh water production. Energies 12:4401

Begum Neelophar CRk S, Vasundara K, (2019) Design Analysis and Fabrication of Solar Vapour Absorption. International Journal of Innovative Technology and Exploring Engineering (IJITEE) 8:22783075

Bellos E, Skaltsas I, Pliakos O, Tzivanidis C (2019) Energy and financial investigation of a cogeneration system based on linear Fresnel reflectors. Energy Convers Manag 198:111821

Berger M, Weckesser M, Weber C, Döll J, Morgenstern A, Häberle A (2012) Solar driven cold rooms for industrial cooling applications. Energy Procedia 30:904–911

Bermejo P, Pino FJ, Rosa F (2010) Solar absorption cooling plant in Seville. Sol Energy 84:1503–1512

Blaschke T, Biberacher M, Gadocha S, Schardinger I (2013) ‘Energy landscapes’: Meeting energy demands and human aspirations. Biomass Bioenerg 55:3–16

Buonomano A, Calise F, d’Accadia MD, Vanoli L (2013) A novel solar trigeneration system based on concentrating photovoltaic/thermal collectors. Part 1: Design and simulation model. Energy 61:59–71

Buonomano A, Calise F, Palombo A (2018) Solar heating and cooling systems by absorption and adsorption chillers driven by stationary and concentrating photovoltaic/thermal solar collectors: Modelling and simulation. Renew Sustain Energy Rev 82:1874–1908

Burton N, Padilla R, Rose A, Habibullah H (2021) Increasing the efficiency of hydrogen production from solar powered water electrolysis. Renew Sust Energ Rev 135:110255

Calise F, d’Accadia MD, Palombo A, Vanoli L (2013) Dynamic simulation of a novel high-temperature solar trigeneration system based on concentrating photovoltaic/thermal collectors. Energy 61:72–86

Calise F, d’Accadia MD, Vanoli R, Vicidomini M (2019) Transient analysis of solar polygeneration systems including seawater desalination: A comparison between linear Fresnel and evacuated solar collectors. Energy 172:647–660

Chauhan P, Kaushik S, Tyagi S (2022) Current status and technological advancements in adsorption refrigeration systems: A review. Renew Sust Energ Rev 154:111808

Chemisana D, Lopez-Villada J, Coronas A, Rosell JI, Lodi C (2013) Building integration of concentrating systems for solar cooling applications. Appl Therm Eng 50:1472–1479

Dabwan YN, Pei G, Gao G, Li J, Feng J (2019) Performance analysis of integrated linear fresnel reflector with a conventional cooling, heat, and power tri-generation plant. Renew Energy 138:639–650

Dan A, Barshilia HC, Chattopadhyay K, Basu B (2017) Solar energy absorption mediated by surface plasma polaritons in spectrally selective dielectric-metal-dielectric coatings: a critical review. Renew Sustain Energy Rev 79:1050–1077

Dincer F (2011) Overview of the photovoltaic technology status and perspective in Turkey. Renew Sustain Energy Rev 15:3768–3779

Döll J, Bentaher H, Morgenstern A (2014) First results of a pilot installation of a solar thermally driven cold store. Int J Refrig 39:77–85

Ebrahimi A, Ghorbani B, Lohrasbi H, Ziabasharhagh M (2020) Novel integrated structure using solar parabolic dish collectors for liquid nitrogen production on offshore gas platforms (exergy and economic analysis). Sustain Energy Technol Assess 37:100606

Ebrahimi A, Ghorbani B, Skandarzadeh F, Ziabasharhagh M (2021) Introducing a novel liquid air cryogenic energy storage system using phase change material, solar parabolic trough collectors, and Kalina power cycle (process integration, pinch, and exergy analyses). Energy Convers Manag 228:113653

El-Emam RS, Dincer I (2017): Assessment and evolutionary based multi-objective optimization of a novel renewable-based polygeneration energy system. J Energy Resour Technolog 139

Energysage (2016) How Much Does the Average Solar Panel Installation Cost in the U.S. ?

Erzen S, Açıkkalp E, Hepbasli A (2020) Performance analysis of a solar–hydrogen driven multigeneration system. Energy Rep 6:403–408

Figaj R, Szubel M, Przenzak E, Filipowicz M (2019) Feasibility of a small-scale hybrid dish/flat-plate solar collector system as a heat source for an absorption cooling unit. Appl Therm Eng 163:114399

Gholamalipour P, Siavashi M, Doranehgard MH (2019) Eccentricity effects of heat source inside a porous annulus on the natural convection heat transfer and entropy generation of Cu-water nanofluid. Int Commun Heat Mass Transf 109:104367

Ghorbani B, Mehrpooya M (2020) Concentrated solar energy system and cold thermal energy storage (process development and energy analysis). Sustain Energy Technol Assess 37:100607

Ghorbani B, Shirmohammadi R, Amidpour M, Inzoli F, Rocco M (2019) Design and thermoeconomic analysis of a multi-effect desalination unit equipped with a cryogenic refrigeration system. Energy Convers Manag 202:112208

Ghorbani B, Mehrpooya M, Sadeghzadeh M (2020) Process development of a solar-assisted multi-production plant: power, cooling, and hydrogen. Int J Hydrogen Energy 45:30056–30079

Gupta P (1999) Renewable energy sources—A longway to go in India. Renewable Energy 16:1216–1219

Van der Hoeven M (2013) World energy outlook 2012. International Energy Agency: Tokyo, Japan

Hoeven M (2013) Nordic energy technology perspectives: Pathways to a carbon neutral energy future. 2013 Nordic Energy Technology Perspectives OECD/IEA. Tech. Rep

Hogerwaard J, Dincer I, Naterer GF (2017) Solar energy based integrated system for power generation, refrigeration and desalination. Appl Therm Eng 121:1059–1069

Hou S, Zhang H (2019) A novel solar assisted vacuum thermionic generator-absorption refrigerator cogeneration system producing electricity and cooling. Energy Convers Manage 187:83–92

Hundy GF, Trott AR, Welch TC (2016) The Refrigeration cycle. In: Hundy GF, Trott AR, Welch TC (eds) Refrigeration, air conditioning and heat pumps, 5th edn. Butterworth-Heinemann, pp 19–39

IEA (2016): Energy, Climate Change and Environment

IEA (2019): https://www.iea.org/topics/energyefficiency/buildings. Accessed 13 May 2019

IPCC (2014): Mitigation of climate change. Contribution of Working Group III to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change, 1454.

IRENA (2020) Global Renewables Outlook: Energy transformation 2050. International Renewable Energy Agency, 292 pp

Jabari F, Nojavan S, Ivatloo BM, Sharifian MB (2016) Optimal short-term scheduling of a novel tri-generation system in the presence of demand response programs and battery storage system. Energy Convers Manage 122:95–108

Jabari F, Nazari-heris M, Mohammadi-ivatloo B, Asadi S, Abapour M (2020) A solar dish Stirling engine combined humidification-dehumidification desalination cycle for cleaner production of cool, pure water, and power in hot and humid regions. Sustain Energy Technol Assess 37:100642

Jafary S, Khalilarya S, Shawabkeh A, Wae-hayee M, Hashemian M (2021) A complete energetic and exergetic analysis of a solar powered trigeneration system with two novel organic Rankine cycle (ORC) configurations. J Clean Prod 281:124552

Kalogirou SA (2013): Solar energy engineering: processes and systems. Academic press

Kasaeian A, Bellos E, Shamaeizadeh A, Tzivanidis C (2020) Solar-driven polygeneration systems: Recent progress and outlook. Appl Energy 264:114764

Koc M, Tukenmez N, Ozturk M (2020) Development and thermodynamic assessment of a novel solar and biomass energy based integrated plant for liquid hydrogen production. Int J Hydrogen Energy 45:34587–34607

Li Z, Chen H, Xu Y, Ooi KT (2020) Comprehensive evaluation of low-grade solar trigeneration system by photovoltaic-thermal collectors. Energy Convers Manag 215:112895

Lu Z, Wang R, Xia Z, Lu X, Yang C, Ma Y, Ma G (2013) Study of a novel solar adsorption cooling system and a solar absorption cooling system with new CPC collectors. Renew Energy 50:299–306

Luqman M, Bicer Y, Al-Ansari T (2020) Thermodynamic analysis of an oxy-hydrogen combustor supported solar and wind energy-based sustainable polygeneration system for remote locations. Int J Hydrogen Energy 45:3470–3483

Marefati M, Mehrpooya M, Mousavi SA (2019) Introducing an integrated SOFC, linear Fresnel solar field, Stirling engine and steam turbine combined cooling, heating and power process. Int J Hydrogen Energy 44:30256–30279

Mehrpooya M, Ghorbani B, Hosseini SS (2018) Thermodynamic and economic evaluation of a novel concentrated solar power system integrated with absorption refrigeration and desalination cycles. Energy Convers Manage 175:337–356

Mehrpooya M, Ghorbani B, Manizadeh A (2020) Cryogenic biogas upgrading process using solar energy (process integration, development, and energy analysis). Energy 203:117834

Mendecka B, Tribioli L, Cozzolino R (2020) Life Cycle Assessment of a stand-alone solar-based polygeneration power plant for a commercial building in different climate zones. Renewable Energy 154:1132–1143

Moaleman A, Kasaeian A, Aramesh M, Mahian O, Sahota L, Tiwari GN (2018) Simulation of the performance of a solar concentrating photovoltaic-thermal collector, applied in a combined cooling heating and power generation system. Energy Convers Manage 160:191–208

Modi A, Bühler F, Andreasen JG, Haglind F (2017) A review of solar energy based heat and power generation systems. Renew Sustain Energy Rev 67:1047–1064

Mohammadi K, Khanmohammadi S, Khorasanizadeh H, Powell K (2020) A comprehensive review of solar only and hybrid solar driven multigeneration systems: Classifications, benefits, design and prospective. Applied Energy 268:114940

Mohsenipour M, Ebadollahi M, Rostamzadeh H, Amidpour M (2020) Design and evaluation of a solar-based trigeneration system for a nearly zero energy greenhouse in arid region. J Clean Prod 254:119990

Moradi M, Mehrpooya M (2017) Optimal design and economic analysis of a hybrid solid oxide fuel cell and parabolic solar dish collector, combined cooling, heating and power (CCHP) system used for a large commercial tower. Energy 130:530–543

Moravej M, Doranehgard MH, Razeghizadeh A, Namdarnia F, Karimi N, Li LK, Mozafari H, Ebrahimi Z (2021) Experimental study of a hemispherical three-dimensional solar collector operating with silver-water nanofluid. Sustain Energy Technol Assess 44:101043

NASA (2014) National Aeronautics and Space Administration. Plotted from satellite data supplied by NASA Clouds and the Earth’s Radiant Energy System (CERES)

Nations U (2015) World population prospects. the 2015 Revisions Geneva

Ngoh SK, Njomo D (2012) An overview of hydrogen gas production from solar energy. Renew Sustain Energy Rev 16:6782–6792

Nixon J, Dey P, Davies P (2012) The feasibility of hybrid solar-biomass power plants in India. Energy 46:541–554

Onder G, Yilmaz F, Ozturk M (2019) Exergetic examination of a novel solar-thermochemical-based integrated system for multigeneration. Int J Exergy 28:46–71

Oyedepo SO (2012) Energy and sustainable development in Nigeria: the way forward. Energy Sustain Soc 2:1–17

Ozturk M, Dincer I (2013) Thermodynamic analysis of a solar-based multi-generation system with hydrogen production. Appl Therm Eng 51:1235–1244

Patel B, Desai NB, Kachhwaha SS (2017) Thermo-economic analysis of solar-biomass organic Rankine cycle powered cascaded vapor compression-absorption system. Sol Energy 157:920–933

Piadehrouhi F, Ghorbani B, Miansari M, Mehrpooya M (2019) Development of a new integrated structure for simultaneous generation of power and liquid carbon dioxide using solar dish collectors. Energy 179:938–959