Summary

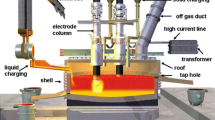

Norddeutsche Affinerie and Métallurgie Hoboken-Overpelt have cooperated together since 1968 in developing a new continuous and energy saving process for the production of copper anodes. The two-stage process comprises a relatively short reverberatory furnace with a shaft mounted eccentrically on its roof, and a drum-type continuous poling furnace which also serves as a holding furnace. Auxiliary equipment includes a skip hoist for charging, waste heat boiler, baghouse, and control room.

Raw material, such as blister copper slabs, anode scrap, used anode molds, and copper scrap, is melted continuously and the molten copper drops are refined instantaneously while flowing down the foot of the charge column. Arriving at the hearth, copper and slag separate freely. Slag is skimmed from the bath, and oxidized copper flows through the poling furnace and then, well poled, onto the casting machine.

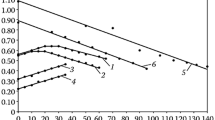

To produce 400 tons of anodes in a conventional reverberatory furnace requires a batch time of at least 24 hours. Contimelt® needs as little as 8 hours, i.e., one shift, for the same output.

Compared with conventional reverberatory anode furnaces, Contimelt consumes less than half their primary energy requirements and reduces labor costs by approximately one third.

Similar content being viewed by others

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Kapell, G., Leutloff, W. Contimelt: A New Continuous Melting and Refining Process for Copper. JOM 36, 62–66 (1984). https://doi.org/10.1007/BF03339917

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03339917