Abstract

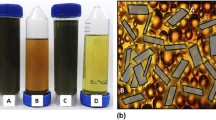

The performance of a lubricant largely depends on the additives it involves. However, currently used additives cause severe pollution if they are burned and exhausted. Therefore, it is necessary to develop a new generation of green additives. Graphene oxide (GO) consists of only C, H and O and thus is considered to be environmentally friendly. So the tribological properties of the few-layer GO sheet as an additive in hydrocarbon base oil are investigated systematically. It is found that, with the addition of GO sheets, both the coefficient of friction (COF) and wear are decreased and the working temperature range of the lubricant is expanded in the positive direction. Moreover, GO sheets has better performance under higher sliding speed and the optimized concentration of GO sheets is determined to be 0.5wt%. After rubbing, GO is detected on the wear scars through Raman spectroscopy. And it is believed that, during the rubbing, GO sheets adhere to the sliding surfaces, behaving like protective films and preventing the sliding surfaces from contacting with each other directly. This paper proves that the GO sheet is an effective lubricant additive, illuminates the lubrication mechanism, and provides some critical parameters for the practical application of GO sheets in lubrication.

Similar content being viewed by others

References

HOLMBERG K, ANDERSSON P, NYLUND N, et al. Global energy consumption due to friction in trucks and buses[J]. Tribology International, 2014, 78: 94–114.

HOLMBERG K, ANDERSSON P, ERDEMIR A. Global energy consumption due to friction in passenger cars[J]. Tribology International, 2012, 47: 221–234.

WEN S Z, HUANG P. Principles of tribology[M]. New York: John Wiley & Sons, 2012.

LUO J B, LU X C, WEN S Z. Developments and unsolved problems in nano-lubrication[J]. Progress in Natural Science, 2001, 11(3): 173–183.

NOVOSELOV K S, GEIM A K, MOROZOV S V, et al. Electric field effect in atomically thin carbon films[J]. Science, 2004, 306(5696): 666–669.

GEIM A K, NOVOSELOV K S. The rise of graphene[J]. Nature Materials, 2007, 6(3): 183–191.

STANKOVICH S, DIKIN D A, DOMMETT G H B, et al. Graphene-based composite materials[J]. Nature, 2006, 442(7100): 282–286.

ZHU Y, MURALI S, CAI W, et al. Graphene and graphene oxide: synthesis, properties, and applications[J]. Advanced Materials, 2010, 22(35): 3906–3924.

HWANG H, KIM H, CHO J. MoS2 nanoplates consisting of disordered graphene-like layers for high rate lithium battery anode materials[J]. Nano Letters, 2011, 11(11): 4826–4830.

CHEN Z, LIU X, LIU Y, et al. Ultrathin MoS2 nanosheets with superior extreme pressure property as boundary lubricants[J]. Scientific Reports, 2015, 5: 12869.

LIANG H, BU Y, ZHANG J, et al. Graphene oxide film as solid lubricant[J]. ACS Applied Materials & Interfaces, 2013, 5(13): 6369–6375.

KIM H, PENKOV O V, KIM D. Tribological properties of graphene oxide nanosheet coating fabricated by using electrodynamic spraying process[J]. Tribology Letters, 2015, 57(273).

PENG Y, WANG Z, ZOU K. Friction and wear properties of different types of graphene nanosheets as effective solid lubricant[J]. Langmuir, 2015: 1279897608.

SONG H, LI N. Frictional behavior of oxide graphene nanosheets as water-base lubricant additive[J]. Applied Physics A-Materials Science & Processing, 2011, 105(4): 827–832.

ELOMAA O, SINGH V K, IYER A, et al. Graphene oxide in water lubrication on diamond-like carbon vs. stainless steel high-load contacts[J]. Diamond and Related Materials, 2015, 52: 43–48.

KINOSHITA H, NISHINA Y, ALIAS A A, et al. Tribological properties of monolayer graphene oxide sheets as water-based lubricant additives[J]. Carbon, 2014, 66: 720–723.

LIU Y, WANG X, PAN G, et al. A comparative study between graphene oxide and diamond nanoparticles as water-based lubricating additives[J]. Science China-Technological Sciences, 2013, 56(1): 152–157.

SARNO M, SENATORE A, CIRILLO C, et al. Oil lubricant tribological behaviour improvement through dispersion of few layer graphene oxide[J]. Journal of Nanoscience and Nanotechnology, 2014, 14(7): 4960–4968.

SENATORE A, D’AGOSTINO V, PETRONE V, et al. Graphene oxide nanosheets as effective friction modifier for oil lubricant: materials, methods, and tribological results[J]. ISRN Tribology, 2013, 2013: 1–9.

KINOSHITA H, KONDO M, NISHINA Y, et al. Anti-wear effect of graphene oxide in lubrication by fluorine-containing ionic liquid for steel[J]. Tribology Online, 2015, 10(1): 91–95.

RABASO P, VILLE F, DASSENOY F, et al. Boundary lubrication: Influence of the size and structure of inorganic fullerene-like MoS2 nanoparticles on friction and wear reduction[J]. Wear, 2014, 320(1–2): 161–178.

DONG L, SHU G, LIANG X, et al. Effect of lubricating oil additives on particle size distribution and total number concentration in diesel engine[J]. Lubrication Science, 2012, 24(7): 325–338.

HAMROCK B J, DOWSON D. Isothermal elastohydrodynamic lubrication of point contacts 1. theoretical formulation[J]. Journal of Lubrication Technology-Transactions of the ASME, 1976, 98(2): 223–229.

KUDIN K N, OZBAS B, SCHNIEPP H C, et al. Raman spectra of graphite oxide and functionalized graphene sheets[J]. Nano Letters, 2008, 8(1): 36–41.

KLEMENZ A, PASTEWKA L, BALAKRISHNA S G, et al. Atomic scale mechanisms of friction reduction and wear protection by graphene[J]. Nano Letters, 2014, 14(12): 7145–7152.

PACI J T, BELYTSCHKO T, SCHATZ G C. Computational studies of the structure, behavior upon heating, and mechanical properties of graphite oxide[J]. Journal of Physical Chemistry C, 2007, 111(49): 18099–18111.

GOMEZ-NAVARRO C, BURGHARD M, KERN K. Elastic properties of chemically derived single graphene sheets[J]. Nano Letters, 2008, 8(7): 2045–2049.

BERTOLAZZI S, BRIVIO J, KIS A. Stretching and breaking of ultrathin MoS2[J]. ACS Nano, 2011, 5(12): 9703–9709.

Author information

Authors and Affiliations

Corresponding author

Additional information

Supported by National Natural Science Foundation of China(Grant Nos. 51335005, 51321092), National Key Basic Research Program of China (973 Program, Grant No. 2013CB934200), and the Foundation for the Supervisor of Beijing Excellent Doctoral Dissertation(Grant No. 20111000305)

Biographical notes

CHEN Zhe, born in 1988, is currently a PhD candidate at State Key Laboratory of Tribology, Tsinghua University, China. He received his bachelor degree from Northwestern Polytechnical University, China, in 2011. His research interests include nanotribology and 2D nanometerials.

LIU Yuhong, born in 1978, is currently an associate professor at State Key Laboratory of Tribology, Tsinghua University, China. She received her PhD degree from Instituent of Chemistry, CAS, China, in 2005. Her research interests include nanotribology and 2D nanometerials.

LUO Jianbin, born in 1961, is a member of Chinese Academy of Sciences and a professor at State Key Laboratory of Tribology, Tsinghua University, China. He has long been engaged in nanotribology research and nanomanufacturing.

Rights and permissions

About this article

Cite this article

Chen, Z., Liu, Y. & Luo, J. Tribological properties of few-layer graphene oxide sheets as oil-based lubricant additives. Chin. J. Mech. Eng. 29, 439–444 (2016). https://doi.org/10.3901/CJME.2015.1028.129

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3901/CJME.2015.1028.129