Abstract

Laser desorption of organic compound ions from specially prepared surfaces is known as surface-assisted laser desorption/ionization (SALDI). In this work the properties of a SALDI ion emitter obtained by two-stage laser treatment of crystalline silicon surface have been investigated. The laser surface treatment leads to the formation of a layer with nanoscale objects—quantum dots (QDs) less than 10 nm in size, providing laser desorption of organic compound ions. A change in the desorbing laser wavelength from 351 to 263 nm at comparable laser-exposed spot sizes and fluences results in a sharp decrease in the formation efficiency for MH+ ions and appearance of ions M+ for the same analytes. The effect is apparently determined by the spectral properties of the quantum dots formed on the silicon surface under laser irradiation.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 INTRODUCTION

The laser desorption of organic compound ions from specially prepared surfaces has been widely investigated [1–6]. This process is accepted to refer to as surface-assisted laser desorption/ionization (SALDI), which highlights the importance of the surface parameters for ion desorption.

The SALDI method can be implemented in mass spectrometry in two ways: (i) laser ablation of a mixture of analyzed compound (analyte) with nanoparticles, deposited on a metal substrate, and (ii) laser desorption of analyte ions deposited on a specially prepared SALDI-active surface. There are many studies in which nanoparticles of carbon [7], metals [8, 9], and semiconductors (in particular, silicon nanoparticles [10]) were applied.

There is also a wide range of SALDI-active surfaces. Generally, these are nanostructured semiconductor surfaces. It was shown [11‒16] that the most efficient ion emitters are substrates based on crystalline silicon with a modified surface. Examples of SALDI substrates are porous silicon [11, 12], amorphous silicon [13, 14], silicon nanowires [15], silicon nanopost arrays (NAPAs) [16], mechanically processed silicon [14], etc. Analyte deposition on an SALDI-active surface directly in a mass-spectrometer chamber [13, 14, 17] was performed using both a gas chromatograph and a Knudsen cell. It was demonstrated that both porous silicon with a highly developed surface and smooth amorphous silicon can be efficiently used as SALDI substrates. Porosity is not a necessary condition for ionization in SALDI, and ions are formed without participation of solvent. The use of solid-state SALDI substrates in combination with gas phase analyte deposition made it possible to detect some organic compounds with a high sensitivity [13, 18]. In addition, analyte deposition in the absence of solvent reduces significantly the amount of desorbed material, thus minimizing the influence of secondary processes and simplifying the analysis of the laser desorption of organic compound ions.

According to the model of SALDI on silicon surface proposed in [14], the ionization efficiency is determined by the chemical and electronic properties of ion-emitting material (in particular, the concentration of structural defects and the density of related localized states). In case of high concentration of structural defects photoinduced charge carriers can be immobilized which results in localization of holes near proton donor surface groups. According to this model, the proton donors are silanol groups formed on the silicon surface under laser irradiation in the presence of water vapor.

This model qualitatively describes the formation of ions of analyte deposited on an SALDI-active silicon surface in vacuum. However, it does not take into account some observed effects and, apparently, should be refined. The model deals with crystalline silicon without a nanostructure on the surface. At the same time, it was shown in [19, 20] that the formation of an efficient SALDI substrate is accompanied by surface nanostructuring. In addition, activation of amorphous silicon surface was not considered in the model; this process manifests itself as a gradual increase in the ionization efficiency by more than two orders of magnitude under irradiation of amorphous silicon surface by several hundreds of successive laser pulses with fluence below the surface-melting threshold [13]. Finally, the formation of negative ions was also disregarded in the model [20].

As it was shown previously [14, 20], irradiation at different wavelengths (1064, 532, 355, and 337 nm) resulted in similar processes of laser desorption of ions from a pre-prepared SALDI silicon surface. In this study, we used shorter wavelength UV radiation (λ = 263 nm), which may change the ionization channel due to the formation of molecular ions M+. A crystalline silicon wafer subjected to the laser processing [21] was used as a SALDI substrate. Being an efficient ion emitter in SALDI, this material can be used in combination with gas phase analyte deposition.

2 EXPERIMENTAL

A schematic diagram of the experimental setup is shown in Fig. 1.

Schematic diagram of the experimental setup: (1) silicon ion-emitting wafer, (2) vacuum chamber of time-of-flight mass spectrometer, (3) precision needle valve, (4) Knudsen cell, (5а) 351-nm and (5b) 263-nm lasers, (6) focusing lens, (7) attenuators, (8) dichroic mirror, (9) single-mirror scanner, (10) ion detector, (11) control PC with data acquisition board, (12) high-voltage pulse generator, and (13) multichannel clock generator.

The design of the system makes it possible to prepare a SALDI-active ion-emitting surface directly in a mass spectrometer under high-vacuum conditions and carry out controlled analyte deposition on this surface without exposing it to the atmosphere (solvent is not required in this case). The optical scheme of the system allows one to superpose focal spots of different lasers on the ion-emitting surface.

Silicon flat substrate 0.5 × 5 × 5 mm in size (1), cut from a n-type Sb-doped (111) Si wafer, was introduced (through a vacuum gate device) into an ion source of 0.7-m-long linear time-of-flight mass spectrometer 2. The mass spectrometer with a two-grid ion source and delayed ion extraction was designed in the Wiley–McLaren geometry [22]. The residual pressure in the chamber (4 × 10–8 Torr) was provided by two TV301 turbomolecular pumps (Agilent Technologies Italia S.p.A., Italy) and a dry vacuum pump PDV-250GB (EBARA, Japan).

Analyte molecules were adsorbed onto the substrate from gas phase in the mass-spectrometer vacuum chamber. A constant controlled analyte flux on the ion emitter surface was arranged using precision needle valve 3 (in the case of volatile analytes, such as TEA, aniline, or pyridine) or Knudsen cell 4, installed in the mass-spectrometer chamber (in the case of low-volatile analytes, such as caffeine).

Two pulsed diode-pumped Nd:YLF lasers (TECH 351 Advanced and TECH 263 Advanced, LaserExport, Russia) with wavelengths of 351 and 263 nm were used for ion desorption. The lasers are denoted as 5а and 5b, respectively, in Fig. 1. The laser pulse width was 3 ns in both cases. The laser beam was focused on the substrate surface by lens 6 with a focal length of 250 mm. The pulse energies were controlled independently in a wide range using variable reflectance attenuators 7 from Laseroptik GmbH (Germany): L‑03512 (λ = 263 nm) and L-00224 (λ = 351 nm). A dichroic mirror 1-OS-2-0254-5-[4A45] (Altechna, Lithuania) 8, which provides reflectance of more than 99% at a wavelength of 263 nm and transmittance of more than 90% at a wavelength of 351 nm, was used to superpose both laser beams and align the position of the focal spots on the substrate surface.

To increase the substrate surface area exposed to the laser beam, we used a single-mirror scanner LscanXY (AtekoTM, Russia) 9, which provides line-by-line displacement of focal spot over the surface within a rectangular frame of 0.15 × 0.15 mm with a constant rate. The scan rate and distance between lines were chosen so as to make the overlap area of neighboring spots be about 50% at a laser pulse-repetition frequency of 300 Hz. To ensure maximally uniform surface irradiation within the frame, the latter was scanned successively in three directions: (i) horizontal, (ii) at an angle of 45° with respect to horizontal, and (iii) vertical (Fig. 1, inset). The alignment of scan frames on the ion-emitter surface under laser irradiation at different wavelengths was controlled by imprints made on a photosensitive material.

A chevron multichannel plate assembly FTD-2003 (Galileo Electro-Optics, USA) with a temporal resolution of 1.5 ns was used as ion detector 10. The ion detector signal arrived at a data acquisition board (8‑bit averaging ADC Agilent U1081/Acqiris AP 100 with a sampling rate of 1 GHz), installed in a control computer 11. Synchronization of laser pulses; triggering of high-voltage pulse generator 12, which supplied a high-voltage pulse to the grid of ion-source accelerating gap; and triggering of the data detection system were performed using multichannel clock generator 13. The delay between the laser and high-voltage pulses was 90 ns, which provided a mass-spectrometer resolution of more than 1500 (at half maximum) for a mass of 100 a.m.u.

Both lasers had TEM00 energy density distribution across the beam and the beam quality M2 < 1.2. Therefore, the beam waist and the energy density in the focal spots on the surface of ion-emitting substrate could be determined by the sizes of imprints on a photosensitive material, installed in place of the substrate, at pulse energies differing by a factor of two. The laser spot areas were 2 × 10–5 and 1.2 × 10–5 cm2 for the laser beam wavelengths λ = 351 and 263 nm, respectively. The maximum fluences on the substrate surface were 1900 and 2400 mJ/cm2 for λ = 263 and 351 nm, respectively.

3 EXPERIMENTAL RESULTS

3.1 Preparation of Ion-Emitting Substrate

SALDI-active layers on the surface of single-crystal silicon were prepared in two stages [21]. In the first stage, the native oxide film was removed from the silicon surface in 5% alcohol solution of hydrofluoric acid. After drying, the wafer was placed in the mass spectrometer and irradiated by a 351-nm laser beam with the fluence of 650–700 mJ/cm2, which is almost two times higher than the fluence corresponding to the occurrence of m/z 28 silicon ions peak in the mass spectrum. At the first treatment stage 5 to 10 frame passes were required (5 to 10 pulses per surface point).

After 10 frame passes, the laser energy was decreased to the threshold value of silicon peak occurrence in the mass spectrum, and the surface was treated for 1000 s (1000 scan passes). In the second treatment stage, the mass spectra of organic compound ions desorbed from the substrate surface were recorded. The dependence of protonated triethylamine (TEA) ion signal on the number of laser pulses per the same point inside the scanning frame is shown in Fig. 2. Mass-spectrum containing the protonated TEA molecule MH+ peak is shown in Fig. 2 (inset).

The desorption efficiency for protonated molecules from the untreated silicon surface and that after the first treatment stage is low: at a level of several ions for frame pass (1 s). During the second stage of SALDI-active substrate laser treatment, the protonated TEA ion current increased several hundreds times and reached saturation. The peaks that are due to protonated molecules of other analytes under study exhibit similar behavior. This surface-activation process was previously observed on porous silicon substrates and on mechanically treated silicon [14, 20].

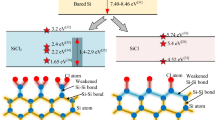

Figure 3 shows SEM (JEOL 7001) photographs of the silicon surface obtained in different laser-treatment stages. As can be seen, the silicon surface after the first treatment stage is relatively smooth. In the second stage, objects with a characteristic size of less than 10 nm (Fig. 3b) start forming on the surface. This size is close to the SEM resolution limit (6 nm). After the end of the treatment (1000 pulses per point or more), as the analyte ion current saturates (see Fig. 2), the density of nanoobjects on the surface reaches 30–50 µm–2 ((3–5) × 109 cm–2).

The above-described method for preparing SALDI-active surfaces using laser modification of crystalline silicon yields the following advantages: (i) the absence of silicon surface contaminations, (ii) possibility of preparing and reconstructing surface directly in the vacuum chamber of mass spectrometer without extracting the substrate from the chamber and exposing it to the atmosphere, and (iii) high reproducibility of SALDI-active surface prepared by this method. In contrast to substrates with high porosity (porous silicon), substrates prepared according to the aforementioned technology do not exhibit any pronounced memory effect.

3.2 Laser Desorption of Analyte Ions at Wavelengths of 263 and 351 nm

The SALDI mechanism was investigated by comparing the desorption efficiencies for ions of various organic compounds from a silicon substrate prepared according to the above-described technique. The desorption of ions was performed by pulsed laser radiation with a wavelength of 351 or 263 nm. Figures 4a and 4b show TEA mass spectra recorded for these two wavelengths. It can be seen that a change in the irradiation wavelength leads to a sharp change in the mass spectrum: molecular M+ ions become dominant instead of protonated MH+ ions. It is well known [14, 20] that SALDI on a nanostructured silicon surface is characterized by a nonlinear dependence of ion current on the laser fluence. Therefore, to perform correct comparison of the irradiation effects at different wavelengths, one must know how the ion yield depends on the laser fluence. Figure 4с shows these dependences for TEA under laser irradiation at λ = 351 and 263 nm. The dependences for all analytes under study are similar and have a characteristic form: initial sharp rise and subsequent saturation with an increase in the laser fluence.

Direct measuring the current of protonated TEA MH+ molecules under laser irradiation at λ = 263 nm is not feasible because of the interference with the isotopic M+ peak. However, this value can be calculated, because the amplitude of isotopic m/z102 peak for TEA makes 7% of the number of m/z101 molecular ions. The ion current of protonated MH+ molecules, determined as the difference in the amplitudes of the measured ion signal and calculated isotopic peak, is shown (by symbols ◻) in Fig. 4c. The current of molecular M+ ions (m/z101) for desorption by radiation at λ = 351 nm and the current of protonated MH+ molecule (m/z102) for desorption by radiation at λ = 263 nm are comparable at the laser fluence corresponding to the saturation threshold. At lower fluences, the formation efficiency for M+ ions under irradiation at λ = 253 nm is 2 to 3 orders of magnitude higher than that for MH+ ions under irradiation at λ = 351 nm.

Figure 5 shows the mass spectra of caffeine, aniline, and pyridine. Switching of the ionization channel (similar to that observed for TEA) was also found. To compare the ionization efficiencies, dependence of the ion yield on the laser fluence were measured for all these compounds. The results of comparing the formation efficiencies for MH+ ions at a laser wavelength of 351 nm and M+ ions at a wavelength of 263 nm (taken at the fluence corresponding to saturation level) are listed in Table 1, along with some characteristic parameters of the compounds studied.

4 DISCUSSION

According to [14, 20] and our experimental data, the main mechanism of ion formation is the proton transfer from the silanol group on the SALDI-substrate surface to the analyte molecule, which leads to the formation of MH+ analyte ion while using wavelengths 1064, 532, 355, 337, and 351 nm for desorption in SALDI. According to the model proposed previously [14], the proton transfer to an analyte molecule requires the presence of nonequilibrium charge carriers, induced by the laser radiation in the ion-emitter surface layer. In this case, the laser photon energy incident on the ion-emitting surface should exceed the band gap, and the radiation intensity should be sufficiently high to provide significant surface heating. Therefore, a decrease in the laser wavelength should not change the ion-formation mechanism. However, in this work it was experimentally shown that the use of 263-nm radiation for ion desorption from the surface of activated SALDI substrate under the same fluence and the surface temperature reduces significantly the formation efficiency for MH+ ions.

Numerical estimation of the laser heating of substrate surface showed that the temperature regimes implemented under irradiation by 351- and 263-nm beams are almost the same at close energy-density values, because the twofold difference in the silicon optical absorption coefficient is compensated for by the difference in the substrate reflectance at these wavelengths [33]. Thus, this difference cannot change the ionization channel.

It is known that nanoobjects, or quantum dots (QDs), can be efficient donors of both electrons and holes, depending on the type of material, “core” size, and the character of surrounding objects [34, 35]; thus, they facilitate positive or negative charge transfer to analyte molecules. This specific feature of QDs can explain the possibility of forming both positive and negative ions of organic compounds, what was observed in our experiments.

Melting of the upper layer of silicon sample by nanosecond pulse in the first stage of active-layer formation leads to a radical transformation of crystal structure. As was shown in [36], the surface silicon layer becomes amorphous because of extremely rapid cooling of melt after laser irradiation, and the nonuniformity of energy-density distribution in the laser spot leads to simultaneous occurrence of both amorphous and nanocrystalline regions. As SEM images demonstrate, further long-term irradiation with a lower fluence induces growth of QDs less than 10 nm in size with a density of about 5 × 109 cm–2 on the silicon surface in the end of treatment. A similar process of formation of larger structures on a silicon surface was observed previously in [20]. Not only growth of nanodots of about 10 nm in size, but also their transformation and self-organization were observed in [37].

Thus, the increase in the analyte signal intensity observed during long-term laser treatment of SALDI substrate (activation) can be explained by the rise in the number of QDs on the newly formed surface. As it was noted above, nanoparticles (QDs) are used in mass spectrometry of organic compounds [38]. Nanoparticles prepared beforehand are introduced into the analyte solution, after which the solution is dried and subjected to laser irradiation in a mass spectrometer. In our case, QDs were generated directly in the mass spectrometer chamber during the substrate surface activation, due to which reproducible contamination-free active surfaces could be obtained.

At the same time, the QD energy band structure is fairly complex: it contains many isolated electronic states and, depending on the irradiation wavelength, may undergo both interband and intraband photoinduced electronic transitions [39]. One might suggest that, in contrast to longer wavelength irradiation (λ = 351 nm), the 263-nm irradiation of QDs on the emitter surface provides an interband transition but does not lead to efficient excitation of a state facilitating the charge (proton) transfer to analyte molecule. This fact can qualitatively explain the decrease in the proton-transfer efficiency. The decrease in the luminescence efficiency of silicon QDs of some types in the spectral range near λ = 263 nm may be in favor of this suggestion [40–42].

The formation of M+ molecular ions under irradiation at λ = 263 nm can be explained by two well-studied processes. An analyte molecule located on the surface can be desorbed under electronic excitation by laser beam in the form of a neutral molecule or ion. This process, referred to as desorption induced by electronic transitions (DIET), was described in several studies [43, 44]. Neutral molecules desorbed during a laser pulse can be ionized due to the two-photon absorption, because the energy of photon with λ = 263 nm is 4.66 eV. The participation of QDs in this process is unlikely, because the ionization is observed with equal efficiency on both the SALDI-processed surface and on pure untreated silicon surface.

5 CONCLUSIONS

The laser desorption of ions of organic compounds from nanostructured silicon surface under laser irradiation at wavelengths of 351 and 263 nm was investigated. An SALDI-active substrate prepared by two-stage laser treatment of crystalline silicon directly in the mass-spectrometer chamber was used as an ion emitter. It was shown that a change in the laser wavelength from 351 to 263 nm at comparable lasers radiation parameters sharply reduces the formation efficiency of MH+ ions and results in appearance of the molecular analyte ions M+. The decrease in the efficiency is likely related to the spectral properties of QDs, which are formed on the SALDI substrate surface as the result of the laser treatment. The formation efficiency for M+ molecular ions is mainly determined by the analyte optical absorption at a wavelength of 263 nm. The use of 263-nm laser irradiation for ion desorption is advisable when analyzing materials with a relatively low proton affinity and significant absorption in the spectral region near 263 nm. Thus, the use of laser irradiation at wavelengths of 351 and 263 nm may extend significantly the range of compounds accessible for SALDI analysis.

REFERENCES

J. Sunner, E. Dratz, and Y.-C. Chen, “Graphite surface-assisted laser desorption/ionization time-of-flight mass spectrometry of peptides and proteins from liquid solutions,” Anal. Chem. 67 (23), 4335–4342 (1995). https://doi.org/10.1021/ac00119a021

P. Kraft, S. Alimpiev, E. Dratz, and J. Sunner, “Infrared, surface-assisted laser desorption ionization mass spectrometry on frozen aqueous solutions of proteins and peptides using suspensions of organic solids,” J. Am. Soc. Mass Spectrom. 9 (9), 912–924 (1998). https://doi.org/10.1016/S1044-0305(98)00063-4

J. A. Stolee, B. N. Walker, V. Zorba, R. E. Russo, and A. Vertes, “Laser–nanostructure interactions for ion production,” Phys. Chem. Chem. Phys. 14 (24), 8453–8471 (2012). https://doi.org/10.1039/C2CP00038E

K. P. Law and J. R. Larkin, “Recent advances in SALDI-MS techniques and their chemical and bioanalytical applications,” Anal. Bioanal. Chem. 399 (8), 2597–2622 (2011). https://doi.org/10.1007/s00216-010-4063-3

A. S. Borodkov, I. I. Kuz’min, N. B. Polyakov, A. A. Grechnikov, and S. S. Alimpiev, “Comparison of the laser desorption/ionization methods for detecting metal complexes,” Phys. Wave Phenom. 25 (4), 243–248 (2017). https://doi.org/10.3103/S1541308X1704001X

J. Li and R. H. Lipson, “Insights into desorption ionization on silicon (DIOS),” J. Phys. Chem. C.117 (51), 27114–27119 (2013). https://doi.org/10.1021/jp4074653

H.-W. Tang, K.-M. Ng, W. Lu, and C.-M. Che, “Ion desorption efficiency and internal energy transfer in carbon-based surface-assisted laser desorption/ionization mass spectrometry: Desorption mechanism(s) and the design of SALDI substrates,” Anal. Chem. 81 (12), 4720–4729 (2009). https://doi.org/10.1021/ac8026367

K. Tanaka, H. Waki, Y. Ido, S. Akita, Y. Yoshida, T. Yoshida, and T. Matsuo, “Protein and polymer analysis up to m/z 100 000 by laser ionization time-of-flight mass spectrometry,” Rapid Commun. Mass Spectrom. 2 (8), 151–153 (1988). https://doi.org/10.1002/rcm.1290020802

K.-M. Ng, S.-L. Chau, H.-W. Tang, X.-G. Wei, K.-C. Lau, F. Ye, and A. M.-C. Ng, “Ion-desorption efficiency and internal-energy transfer in surface-assisted laser desorption/ionization: More implication(s) for the thermal-driven and phase-transition-driven desorption process,” J. Phys. Chem. C.119 (41), 23708–23720 (2015). https://doi.org/10.1021/acs.jpcc.5b05957

X. Wen, S. Dagan, and V. H. Wysocki, “Small-molecule analysis with siliconnanoparticle-assisted laser desorption/ionization mass spectrometry,” Anal. Chem. 79 (2), 434–444 (2007). https://doi.org/10.1021/ac061154l

Z. Shen, J. J. Thomas, C. Averbuj, K. M. Broo, M. Engelhard, J. E. Crowell, M. G. Finn, and G. Siuzdak, “Porous silicon as a versatile platform for laser desorption/ionization mass spectrometry,” Anal. Chem. 73 (3), 612–619 (2001). https://doi.org/10.1021/ac000746f

S. Alimpiev, S. Nikiforov, V. Karavanskii, T. Minton, and J. Sunner, “On the mechanism of laser-induced desorption–ionization of organic compounds from etched silicon and carbon surfaces,” J. Chem. Phys. 115 (4), 1891–1901 (2001). https://doi.org/10.1063/1.1381531

S. N. Zhabin, A. V. Pento, A. A. Grechnikov, A. S. Borodkov, B. G. Sartakov, Ya. O. Simanovsky, S. M. Nikiforov, and S. S. Alimpiev, “On the role of laser irradiation in the processes of laser desorption/ionisation from silicon surfaces,” Quantum Electron. 41 (9), 835–842 (2011). https://doi.org/10.1070/Qe2011v041n09abeh014678

S. Alimpiev, A. Grechnikov, J. Sunner, V. Karavanskii, Ya. Simanovsky, S. Zhabin, and S. Nikiforov, “On the role of defects and surface chemistry for surface-assisted laser desorption ionization from silicon,” J. Chem. Phys. 128 (1), 014711 (2008). https://doi.org/10.1063/1.2802304

E. P. Go, J. V. Apon, G. Luo, A. Saghatelian, R. H. Daniels, V. Sahi, R. Dubrow, B. F. Cravatt, A. Vertes, and G. Siuzdak, “Desorption/ionization on silicon nanowires,” Anal. Chem. 77 (6), 1641–1646 (2005). https://doi.org/10.1021/ac048460o

J. A. Stolee and A. Vertes, “Polarization dependent fragmentation of ions produced by laser desorption from nanopost arrays,” Phys. Chem. Chem. Phys. 13 (20), 9140–9146 (2011). https://doi.org/10.1039/C0CP02709J

S. Alimpiev, A. Grechnikov, J. Sunner, A. Borodkov, V. Karavanskii, Ya. Simanovsky, and S. Nikiforov, “Gas chromatography/surface-assisted laser desorption ionization mass spectrometry of amphetamine-like compounds,” Anal. Chem. 81 (3), 1255–1561 (2009). https://doi.org/10.1021/ac802176j

A. A. Grechnikov, A. S. Borodkov, S. S. Alimpiev, S. M. Nikiforov, and Ya. O. Simanovsky, “Gas-phase basicity: Parameter determining the efficiency of laser desorption/ionization from silicon surfaces,” J. Anal. Chem. 68 (1), 19–26 (2013). https://doi.org/10.1134/S1061934812110056

Y. Chen and A. Vertes, “Adjustable fragmentation in laser desorption/ionization from laser-induced silicon microcolumn arrays,” Anal. Chem. 78 (16), 5835–5844 (2006). https://doi.org/10.1021/ac060405n

S. S. Alimpiev, S. M. Nikiforov, A. A. Grechnikov, and J. A. Sunner, “Novel technique for ultra sensitive detection of organic compounds,” in Vapour and Trace Detection of Explosives for Anti-Terrorism Purposes, NATO Science Series (Ser. II: Mathematics, Physics and Chemistry), Ed. by M. Krausa and A. A. Reznev (Springer, Dordrecht, 2004), Vol. 167, p. 101–112. https://doi.org/10.1007/978-1-4020-2716-1_12

A. A. Grechnikov, S. S. Alimpiev, S. M. Nikiforov, and Ya. O. Simanovsky, RF Patent No. 2426191, Byull. Izobret., No. 22 (2011).

W. C. Wiley and I. H. McLaren, “Time-of-flight mass spectrometer with improved resolution,” Rev. Sci. Instrum. 26 (12), 1150–1157 (1955). https://doi.org/10.1063/1.1715212

S. G. Lias, “Gas phase ion energetics data,” in NIST Chemistry WebBook—NIST Standard Reference Database Number 69, Eds. P. J. Linstrom and W. G. Mallard (Nat. Inst. Standards and Technol., Gaithersburg MD, 2020) (retrieved February 13, 2020). https://doi.org/10.18434/T4D303

E. P. L. Hunter and S. G. Lias, “Evaluated gas phase basicities and proton affinities of molecules: An update,” J. Phys. Chem. Ref. Data. 27 (3), 413–656 (1998). https://doi.org/10.1063/1.556018

V. Talrose, E. B. Stern, A. A. Goncharova, N. A. Messineva, N. V. Trusova, and M. V. Efimkina, “UV/visible spectra,” in NIST Chemistry WebBook—NIST Standard Reference Database Number 69, Eds. P. J. Linstrom and W. G. Mallard (Nat. Inst. Standards and Technol., Gaithersburg MD, 2020) (retrieved February 13, 2020). https://doi.org/10.18434/T4D303

D. Dougherty, E. S. Younathan, R. Voll, S. Abdulnur, and S. P. McGlynn, “Photoelectron spectroscopy of some biological molecules,” J. Electron Spectrosc. Relat. Phenom. 13 (3), 379–393 (1978). https://doi.org/10.1016/0368-2048(78)85042-7

H. Bahrami, M. Tabrizchi, and H. Farrokhpour, “Protonation of caffeine: A theoretical and experimental study,” Chem. Phys. 415, 222–227 (2013). https://doi.org/10.1016/j.chemphys.2013.01.022

A. Belay, K. Ture, M. Redi, and A. Asfaw, “Measurement of caffeine in coffee beans with UV/vis spectrometer,” Food Chem. 108 (1), 310–315 (2008). https://doi.org/10.1016/j.foodchem.2007.10.024

M. A. Smith, J. W. Hager, and S. C. Wallace, “Two color photoionization spectroscopy of jet cooled aniline: Vibrational frequencies of the aniline \({{\tilde {X}}^{2}}{{B}_{1}}\) radical cation,” J. Chem. Phys. 80 (7), 3097–3105 (1984). https://doi.org/10.1063/1.447124

J. E. Mathis and R. N. Compton, “Single and multiple photon ionization of triethylamine,” J. Chem. Phys. 104 (21), 8341–8347 (1996). https://doi.org/10.1063/1.471585

M. Berton, R. Mello, R. Acerete, and M. E. González Núñez, “Photolysis of tertiary amines in the presence of CO2: The paths to formic acid, α-amino acids, and 1,2-diamines,” J. Org. Chem. 83 (1), 96–103 (2018). https://doi.org/10.1021/acs.joc.7b02407

H. R. Wendt and H. E. Hunziker, “The UV spectra of primary, secondary, and tertiary alkyl radicals,” J. Chem. Phys. 81 (2), 717–723 (1984). https://doi.org/10.1063/1.447755

D. E. Aspnes and A. A. Studna, “Dielectric functions and optical parameters of Si, Ge, GaP, GaAs, GaSb, InP, InAs, and InSb from 1.5 to 6.0 eV,” Phys. Rev. B.27 (2), 985–1009 (1983). https://doi.org/10.1103/PhysRevB.27.985

J.-S. Chen, M. Li, and M. Cotlet, “Nanoscale photoinduced charge transfer with individual quantum dots: Tunability through synthesis, interface design, and interaction with charge traps,” ACS Omega. 4 (5), 9102–9112 (2019). https://doi.org/10.1021/acsomega.9b00803

N. V. Tkachenko, “Photoinduced charge separation in semiconductor-quantum-dot/organic-molecule hybrids,” ChemPhotoChem. 2 (3), 112–120 (2018). https://doi.org/10.1002/cptc.201700161

P. L. Liu, R. Yen, N. Bloembergen, and R. T. Hodgson, “Picosecond laser-induced melting and resolidification morphology on Si,” Appl. Phys. Lett.34 (12), 864–865 (1979). https://doi.org/10.1063/1.90703

S. Watanabe, Y. Yoshida, S. Kayashima, S. Yatsu, M. Kawai, and T. Kato, “In situ observation of self-organizing nanodot formation under nanosecond-pulsed laser irradiation on Si surface,” J. Appl. Phys. 108 (10), 103510 (2010). https://doi.org/10.1063/1.3512888

M. Han and J. Sunner, “An activated carbon substrate surface for laser desorption mass spectrometry,” J. Am. Soc. Mass Spectrom. 11 (7), 644–649 (2000). https://doi.org/10.1016/S1044-0305(00)00129-X

C. Bulutay, “Interband, intraband, and excited-state direct photon absorption of silicon and germanium nanocrystals embedded in a wide band-gap lattice,” Phys. Rev. B.76 (20), 205321 (2007). https://doi.org/10.1103/PhysRevB.76.205321

M. Dasog, Z. Yang, S. Regli, T. M. Atkins, A. Faramus, M. P. Singh, E. Muthuswamy, S. M. Kauzlarich, R. D. Tilley, and J. G. C. Veinot, “Chemical insight into the origin of red and blue photoluminescence arising from freestanding silicon nanocrystals,” ACS Nano. 7 (3), 2676–2685 (2013). https://doi.org/10.1021/nn4000644

Q. Li and R. Jin, “Photoluminescence from colloidal silicon nanoparticles: Significant effect of surface,” Nanotechnol. Rev. 6 (6), 601–612 (2017). https://doi.org/10.1515/ntrev-2017-0145

L. Patrone, D. Nelson, V. I. Safarov, M. Sentis, W. Marine, and S. Giorgio, “Photoluminescence of silicon nanoclusters with reduced size dispersion produced by laser ablation,” J. Appl. Phys. 87 (8), 3829–3837 (2000). https://doi.org/10.1063/1.372421

D. Menzel and R. Gomer, “Desorption from metal surfaces by low-energy electrons,” J. Chem. Phys. 41 (11), 3311–3328 (1964). https://doi.org/10.1063/1.1725730

D. Menzel, “Thirty years of MGR: How it came about, and what came of it,” Nucl. Instrum. Methods Phys. Res.,Sect. B.101 (1-2), 1–10 (1995). https://doi.org/10.1016/0168-583X(95)00060-7

Funding

This study was supported in part by the Russian Foundation for Basic Research, project no. 18-32-01018.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by Yu. Sin’kov

About this article

Cite this article

Pento, A.V., Nikiforov, S.M. & Simanovsky, Y.O. Laser Desorption of Organic Compound Ions from a Silicon Surface Modified by Laser Irradiation. Phys. Wave Phen. 28, 213–221 (2020). https://doi.org/10.3103/S1541308X20030164

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1541308X20030164