Abstract

This study reports the preparation and performance of a smart material—a carbon paste electrode combined with TiO2 semiconductor (CPE/TiO2) as electrochemical sensor for detecting profenofos—a toxic organophosphates group insecticide widely used in agriculture. Such techniques as real samples tests and electrochemical tests were used to investigate the following parameters: a scan rate, an electrode response, a limit of detection (LoD), and repeatability. Based on the obtained results, the best mass composition of TiO2 combined with CPE was found to be in a ratio of 1 : 1 : 5, with an anodic peak current (Ipa) of 150 μA, an anodic peak potential (Epa) of 0.87 V, and an optimal scan rate measurement of 0.5 V s–1. The LoD based on a linearity curve with a value of 4.0 × 10–5 μM was also observed, and a repeatability test against the working electrode was performed until the 30th day, using the Horwitz ratio of 0.16. A good electrochemical performance of the working electrode tested against a real sample showed the specifically detected profenofos with Ipa value of 7.0 × 10–5 μM.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

INTRODUCTION

Profenofos insecticide, a pesticide, a toxic organophosphate, is quite widely used in agriculture [1–3]. Profenofos works actively and efficiently in controlling insect pests and causes a significant inhibitory effect on the acetylcholinesterase enzyme in microorganisms [4, 5]. In nature, it is presenced in low concentrations making it difficult to detect it, so a fast technique is needed to identify the existence of this pesticide. It is one of the persistent organic pollutants— chemical organic compounds that diminish resistance to environmental degradation and are difficult to detect because they are presented in low concentrations and also spread very quickly in the aquatic environment [6, 7]. Those poputants are pesticide compounds used in agriculture to eradicate plant pests. When farmers use them for pest control, they are injected into the plant, then they stick on the plant surface and fall into the ground [8, 9]. This condition is exacerbated when entering the rainy season, then they will dissolve and can be carried by a water flow into a river [10–12], which can damage the aquatic environment. Those pesticide residues can also seriously affect food security and threaten human health [13–16]. As reported elsewhere, the people living in agricultural areas may be exposed to much higher levels of organophosphate pesticides than non-agricultural populations of Thailand during the dry and wet seasons (p ≤ .001, 0.001 µM) [17].

A common technique that has been applied to detect pesticide residues is chromatography [18–20]. In particular, gas chromatography [21–23], high performance liquid chromatography [24, 25], and gas chromatography-mass spectrometry [26]. Some other techniques are also being used by researchers such as applications of biosensors [27], of printed polymers [28], and fluorescence assays [29]. The last method is quite reliable but requires relatively expensive maintenance and procurement costs, the analysis is quite long, the analytical procedures are complicated and can be done only with specific technical training [22, 23]. To overcome this shortcoming, sensors based on TiO2 nanoparticles were developed using the voltammetry technique [30–32].

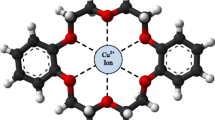

Voltammetry is an electrochemical technique based on the oxidation-reduction (redox) process on the electrode surface, which is widely used in chemical analyses [33–36]. In addition, the voltammetry method has advantages such as having high sensitivity, low detection limit, easy to use and simple preparation [37]. To apply voltammetry, an electrochemical cell with three electrodes such as working electrode, reference electrode, and counter electrode is needed [38, 39]. According to some previous studies by the authors, the effectiveness of graphite/carbon paste as a modifier into TiO2 was quite high in detecting phenolic compounds [40–42]. So far, the electrochemical application is a promising method to determine organic compounds in the aquatic environment. The unique electronic structure in anatase TiO2 has an energy band gap of approximately 3.2 eV, which plays its role as mobility of n-type charge carriers. In addition, the high resistivity and the Hall effect analyses also indicated the existence of an insulator-metal transition in a donor band in anatase TiO2, expanding the applicability of these materials in a broader field, particularly, in nanoelectronics. These unique properties are amongst the key factors for an electrochemical sensor for highly physicochemical activities on the TiO2 surface [43].

Thus this paper reports a simple preparation of CPE/TiO2 as working electrode used to detect profenofos. The preparation of CPE/TiO2 is based on the graphite oxide mixed with liquid paraffin which has been easily modified and immobilized. In addition, the function of TiO2 is to improve the CPE performance during electrochemical sensing [31, 44]. Generally, TiO2 has been applied to transmit the supply of electrons and high electron signals to provide a considerable increase in the electrochemical activity of some organic compounds [45, 46]. The presence of TiO2 is expected to improve the high-performance of a working electrode in detecting profenofos.

EXPERIMENTAL METHODS

Preparation of CPE/TiO2 Composite used as Working Electrode

The TiO2 powder (Degussa, P-25),was weighed to as much as 10 g, sifted with a 200 mesh, put into a porcelain cup, and then calcined at a temperature of 500°C for 3 h to obtain the TiO2 anatase crystal. After that, graphite, liquid paraffin, and the TiO2 anatase powder were mixed with the mass variations of TiO2 anatase of (1 : 1 : 1), (1 : 1 : 5), and (1 : 1 : 10) w/w. This composition was improved according to the ratio of the graphite composition of 0.1 g (1 : 1 : 1), 0.01g (1 : 1 : 5), and 0.05 g (1 : 1 : 10). First graphite was crushed until smooth and sifted with a 200 mesh, then it was mixed with TiO2 anatase in a watch glass containing paraffin oil. After that, it was heated to 80°C in order to make homogeneous and physical interactions occur with each material. Finally, it was stirred and inserted into the electrode body with a diameter of 3 mm while pressed to solidify, then the surface of the electrode was rubbed until smooth, flat, and shiny.

Electrochemical Tests

To observe the electrochemical behaviour of profenofos using CPE/TiO2 electrode, the cyclic voltammetry was applied with a DY2100B potentiostat where the 15.0 mL electrochemical cell contained 1.0 M NaNO3 and (10–6, 10–5, 10–4, 10–3, 10–2, and 10–1 µM) profenofos, and in which three electrodes such as CPE/TiO2, Pt wire, and Ag/AgCl ones were inserted. Electrochemical sensing of profenofos was investigated using 0.1 M K3[Fe(CN)6] under a scanning rate of 0.1 Vs–1 with a potential range of –0.8 to +2.0 V. Additionally, the scanning rate was evaluated against a 0.1 M NaNO3 electrolyte solution containing 10–4 µM sample, and it was found to range from 0.02 to 0.5 V s–1 in the potential range of +0.8 to –0.8 V. The limit of detection (LoD) is determined respectively using the ratio 3 σ/b, where b is the slope of the calibration curve and σ is the standard deviation value of three voltammograms.

RESULTS AND DISCUSSION

Synthesis and Characterization of Anatase TiO2 Nanoparticles

The successfully synthesized TiO2 anatase can be confirmed by using X-ray diffraction (XRD) (Fig. 1). The diffraction peaks 2θ show that the diffraction characteristics of the TiO2 anatase crystals in the crystalline fields 101, 004, 200, 211, and 204 were in accordance with the Joint Committee on Powder Diffraction Standards card no. 21-1272 [47]. The crystal field 101 in the diffractogram had the highest intensity compared to other fields [48, 49]. This proves that the crystalline plane 101 (25.28) is dominant in TiO2 with a CuKα value of 8.04, this is why it was possible to assume the diameter of TiO2 to be 9.41 Å = 0.941 nm [50]. Although the TiO2 anatase has been formed 25.28 (101), there was a slight peak at 23.26, which indicated the formation of rutile phase, but it did not affect the anatase TiO2 crystals [51]. This factor may occur due to distortion between TiO2 particles during the annealing process. According to the data in [52], the characteristic anatase of TiO2 is 25.28 with the crystal plane 101.

Based on the XRD pattern, anatase TiO2 has been prepared through a thermal annealing process. Subsequently, the mass variations of TiO2 were determined, which would be combined with CPE to provide a highly sensitive electrochemical behaviour of profenofos. Figure 2a shows a typical microstructure of TiO2 with a smooth surface morphology of TiO2 anatase, with the estimate grains size of ±2.0 µm. Specifically, scanning electron microscopy images of TiO2 have shown white glowing colour when exposed to a high electron energy. Figure 2b demonstrates the combination of TiO2 and CPE differences in the material colour. An even distribution of TiO2 on the graphite surface of the carbon paste is helpful in expanding the electrode surface, thus giving the effect of a faster electron transfer process, which results in an increase in the peak current in the measurement process compared to carbon paste without modifications [53].

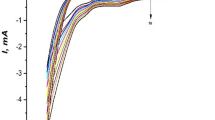

Electrochemical Behavior of CPE/TiO2

Electrochemical characterization was carried out as the initial stage of electrode measurements to observe the electrodes performance with the effect of adding a TiO2 modifier to graphite. Measurements were made in a solution of 0.1 M K3[Fe(CN)6] which acts as a test solution with variations of the scan rate speed. The results in Fig. 3 indicated that the presence of TiO2 in carbon paste has a significant effect with an increase in the peak oxidation current and a reduction compared to those of the carbon paste without modification.

The voltammograms using CPE/TiO2 showed that the anodic peak current reflects the oxidation reaction that occurs in the surface of the working electrodes (Fig. 3a). From these data, it was found that the composition of 0.05 g TiO2 produced higher Ipa values than other compositions (Fig. 3b). The peak flow occurred due to an increase in the total transfer of electrons from profenofos mediated by TiO2 nanoparticles. A decrease in the peak current was caused by a higher concentration of TiO2 nanoparticles covering graphite so as to reduce the conductivity on the electrode surface [54]. A high scanning rate produces a thin diffusion layer, making electron transfer to the electrode surface easier and causing an increase in the peak current. Figure 3c shows the best scanning speed to be 0.1 V s–1.

NaNO3 Electrolyte Test of Profenofos

Figure 4a demonstrates that the best scan rate was indicated on 0.5 V s–1 under 0.1 µM profenofos containing 1.0 M NaNO3 of the electrolyte solution. The Ipa has been obtained with the variation potential in a range of –0.8 to 2.0 V. A high scan rate was produced as response from the electron transfer effect by the electrolyte besides a diffusion layer formed was thinning so that the transfer of electrons on the working electrode on the surface was going well. From the data, scan rate measurement of 0.5 V s–1 obtained an Ipa value of 656 μA and Epa value of 0.62 V. Also the differences of the redox current against NaNO3 were observed in the electrolyte solution compared with those without 0.1 µM of profenofos. These unique properties exhibit a high electrochemical response produced by mixing the electrolyte solution with profenofos. Meanwhile without adding a real sample, the peak current was not reflected because of the redox responses when the studied pesticide interacted with CPE/TiO2 nanoparticles (Fig. 4b).

Determination of Regional Linearity and Limit of Detection

The linear concentration range of profenofos was determined by variating a series of its solutions with concentrations of 10–6, 10–5, 10–4, 10–3, 10–2, and 10–1 µM in 1.0 M NaNO3 solution as electrolyte (Fig. 5a).

The linear concentration of a profenofos standard solution was measured with concentration variations of 10–6–10–4 μM (Fig. 5b). The data range for the LoD has been selected between 10–6 to 10–4 because the working electrode still was detecting profenofos even in low concentrations. The LoD selected based on the limit quantitatively data obtained was used in order to detect the sample in an aquatic environment. Based on the calculation, the LoD measurement of profenofos was 4 × 10–5 µM (Table 1). The linear curve is helpful in determining a good area standard linearity in the measurement of profenofos [38]. This concentration range has a linear correlation between the concentration of profenofos and the produced current with an R2 value of 0.9697. This is based on the data from [55] which state that the level of the correlation value R2 with a range of 0.80–1.0 has a very strong linear relationship.

Repeatability Tests

In order to determine the stability of CPE/TiO2, repeatability measurements were carried out as many as 30 times against 10–4 μM profenofos solution. The aim was to determine the necessary repetitions of measurements under unchanging conditions so as to obtain the same results [60], calculating the value of the Horwitz Ratio (HorRat) [61]. The HorRat value is the ratio between %RSDR and %PRSDR from the peak current of the standard solution measurementd. The measurement of repeatness is good if the HorRat value is less than 2, and the %RSDR value obtained is lower than the %PRSDR [62]. Based on the data obtained, CPE/TiO2 can be said to be stable in analyzing profenofos. The results of repeated measurements can be seen in Fig. 6.

Electrode Life Time Determination

The lifetime of the electrode was measured by using CPE/TiO2 towards a 10–4 μM profenofos solution for 20 days with a once daily measurement period. The measurement results are shown in Figs. 7a, 7b.

Based on the measurement results (Fig. 7), from the first day to the 10th day, the electrode was still in a stable condition, which is characterized by the resulting peak currents either higher or relatively the same. Meanwhile, from the 11th to the 20th days, the resulting peak current decreased. The occurrence of a decrease in the peak current because the use of the electrode carried out continuously can cause thickening of the diffusion layer on the working electrode surface so that the electron transfer takes place slowly, and the resulting peak current decreases in the electrode response. It can also cause the electrode to decay and be unstable at room temperature after being stored for a long time [63].

Real Sample Test

The real sample test aims to determine the ability of CPE/TiO2 in analyzing profenofos in a real sample (Wanggu river–Southeast Sulawesi, Indonesia) compared with a 10–4 µM profenofos solution. The measurement results are shown in Fig. 8. It is evident that a peak current appeared in the real sample, which indicates the existence of profenofos even though there are differences in the peak currents and the peak potentials between the real sample and the profenofos test solution. The real sample had a lower peak current than that of the profenofos test solution and an increasingly positive shift in the potential range. With 450 µA plotted into a linear curve, the real sample concentrations of profenofos was 6.6 × 10–5 µM. A decrease in the flow of the real sample was smaller than in the profenofos test solution. As to, the potential range shift, it was due to the fact that the commercial pesticides contained other compounds in them so that they can influence the measurements, and the detected current was the peak current of profenofos under the influence of other compounds in the sample.

CONCLUSIONS

Based on the obtained results, good performance of CPE/TiO2 as an electrochemical sensor for detecting profenofos can be stated. The best mass composition of TiO2 combined with CPE is in a ratio of 1 : 1 : 5 (0.05 g), with an anodic peak current (Ipa) of 150 μA, an anodic peak potential (Epa) of 0.87 V, and an optimal scan rate of 0.5 V s–1. Also it was observed that the LoD based on a linearity curve with a value of 4.0 × 10–5 μM and a repeatability test against the working electrode until the 30th day was best with the HorRat of 0.16. A good electro-chemical performance of the working electrode was tested against a real sample was confirmed by the specifically detected profenofos pesticide with Ipa value of 7.0 × 10–5 μM.

REFERENCES

Badawy, M.I., Ghaly, M.Y., and Gad-Allah, T.A., Advanced oxidation processes for the removal of organophosphorus pesticides from wastewater, Desalination, 2006, vol. 194, p. 166.

Burkhard, N. and Guth, J.A., Photolysis of organophosphorus insecticides on soil surfaces, Pestic. Sci., 1979, vol. 10, p. 313.

Martínez-Toledo, M.V., Salmerón, V., and González-López, J., Effect of an organophosphorus insecticide, profenofos, on agricultural soil microflora, Chemosphere, 1992, vol. 24, p. 71.

Nillos, M.G., Rodriguez Fuentes, G., Gan, J., and Schlenk, D., Enantioselective acetylcholinesterase inhibition of the organophosphorous insecticides profenofos, fonofos, and crotoxyphos, Environ. Toxicol. Chem., 2007, vol. 26, p. 1949.

Chu, S., Baker, M.R., Leong, G., Letcher, R.J., et al., Covalent binding of the organophosphate insecticide profenofos to tyrosine on α- and β-tubulin proteins, Chemosphere, 2018, vol. 199, p. 154.

Jones, K.C. and De Voogt, P., Persistent organic pollutants (POPs): State of the science, Environ. Pollut., 1999, vol. 100, p. 209.

Wibowo, D., Sufandy, Y., Irwan, I., Azis, T., et al., Investigation of nickel slag waste as a modifier on graphene-TiO2 microstructure for sensing phenolic compound, J. Mater. Sci.: Mater. Electron., 2020, no. 17, p. 1.

Campbell, R. and Campbell, R.C., Biological Control of Microbial Plant Pathogens, Cambridge: Cambridge Univ. Press, 1989.

Bonmatin, J.-M., Giorio, C., Girolami, V., Goulson, D., et al., Environmental fate and exposure; neonicotinoids and fipronil, Environ. Sci. Pollut. Res., 2015, vol. 22, p. 35.

Musa, M., Buwono, N.R., Iman, M.N., Ayuning, S.W., et al., Pesticides in Kalisat River: Water and sediment assessment, Aquacult., Aquarium, Conserv. Legis., 2019, vol. 12, p. 1806.

Yi, X., Zhang, C., Liu, H., Wu, R., et al., Occurrence and distribution of neonicotinoid insecticides in surface water and sediment of the Guangzhou section of the Pearl River, South China, Environ. Pollut., 2019, vol. 251, p. 892.

Kreuger, J., Pesticides in stream water within an agricultural catchment in southern Sweden, Sci. Total Environ., 1998, vol. 216, p. 227.

Mostafalou, S. and Abdollahi, M., Pesticides: an update of human exposure and toxicity, Arch. Toxicol., 2017, vol. 91, p. 549.

Dawson, A.H., Eddleston, M., Senarathna, L., Mohamed, F., et al., Acute human lethal toxicity of agricultural pesticides: a prospective cohort study, PLoS Med., 2010, vol. 7, p. e1000357.

Ravelo-Péreza, L.M., Hernández-Borges, J., and Rodríguez-Delgado, M.Á., Multi-walled carbon nanotubes as efficient solid-phase extraction materials of organophosphorus pesticides from apple, grape, orange and pineapple fruit juices, J. Chromatogr. A, 2008, vol. 1211, p. 33.

Yu, R., Liu, Q., Liu, J., Wang, Q., et al., Concentrations of organophosphorus pesticides in fresh vegetables and related human health risk assessment in Changchun, Northeast China, Food Control, 2016, vol. 60, p. 353.

Jaipieam, S., Visuthismajarn, P., Sutheravut, P., Siriwong, W., et al., Organophosphate pesticide residues in drinking water from artesian wells and health risk assessment of agricultural communities, Thailand, Hum. Ecol. Risk Assess., 2009, vol. 15, p. 1304.

Payá, P., Anastassiades, M., Mack, D., Sigalova, I., et al., Analysis of pesticide residues using the Quick Easy Cheap Effective Rugged and Safe (QuEChERS) pesticide multiresidue method in combination with gas and liquid chromatography and tandem mass spectrometric detection, Anal. Bioanal. Chem., 2007, vol. 389, p. 1697.

Maštovská, K. and Lehotay, S.J., Evaluation of common organic solvents for gas chromatographic analysis and stability of multiclass pesticide residues, J. Chromatogr. A, 2004, vol. 1040, p. 259.

Hajšlová, J., Holadová, K., Kocourek, V., Poustka, J., et al., Matrix-induced effects: A critical point in the gas chromatographic analysis of pesticide residues, J. Chromatogr. A, 1998, vol. 800, p. 283.

Garrido Frenich, A., González-Rodríguez, M.J., Arrebola, F.J., and Martínez Vidal, J.L., Potentiality of gas chromatography—triple quadrupole mass spectrometry in vanguard and rearguard methods of pesticide residues in vegetables, Anal. Chem., 2005, vol. 77, p. 4640.

Gotoh, M., Sakata, M., Endo, T., Hayashi, H., et al., Profenofos metabolites in human poisoning, Forensic Sci. Int., 2001, vol. 116, p. 221.

Ismail, S.M.M., Ali, H.M., and Habiba, R.A., GC-ECD and GC-MS analyses of profenofos residues and its biochemical effects in tomatoes and tomato products, J. Agric. Food Chem., 1993, vol. 41, p. 610.

odríguez-Delgado, M.Á., and Hernández-Borges, J., Rapid analysis of triazolopyrimidine sulfoanilide herbicides in waters and soils by high performance liquid chromatography with UV detection using a C18 monolithic column, J. Sep. Sci., 2007, vol. 30, p. 8

Ahmadi, F., Assadi, Y., Hosseini, S.M.R.M., and Rezaee, M., Determination of organophosphorus pesticides in water samples by single drop microextraction and gas chromatography-flame photometric detector, J. Chromatogr. A, 2006, vol. 1101, p. 307.

Wong, J.W., Hennessy, M.K., Hayward, D.G., Krynitsky, A.J., et al., Analysis of organophosphorus pesticides in dried ground ginseng root by capillary gas chromatography–mass spectrometry and –flame photometric detection, J. Agric. Food Chem., 2007, vol. 55, p. 1117.

Li, C., Zhang, G., Wu, S., and Zhang, Q., Aptamer-based microcantilever-array biosensor for profenofos detection, Anal. Chim. Acta, 2018, vol. 1020, p. 116.

Gao, N., Dong, J., Liu, M., Ning, B., et al., Development of molecularly imprinted polymer films used for detection of profenofos based on a quartz crystal microbalance sensor, Analyst, 2012, vol. 137, p. 1252.

Wang, L., Ye, H., Sang, H.Q., and Wang, D.D., Aptamer-based fluorescence assay for detection of isocarbophos and profenofos, Chin. J. Anal. Chem., 2016, vol. 44, p. 799.

Nurdin, M., Agusu, L., Putra, A.A.M., Mauli- diyah, M., et al., Synthesis and electrochemical performance of graphene-TiO2-carbon paste nanocomposites electrode in phenol detection, J. Phys. Chem. Solids, 2019, vol. 131, p. 104.

Nurdin, M., Maulidiyah, M., Salim, L.O.A., Muzakkar, M.Z., et al., High performance cypermethrin pesticide detection using anatase TiO2-carbon paste nanocomposites electrode, Microchem. J. 2019, vol. 145, p. 756.

Maulidiyah, Ritonga, H., Faiqoh, C.E., Wibowo, D., et al., Preparation of TiO 2 -PEG thin film on hydrophility performance and photocurrent response, Biosci. Biotechnol. Res. Asia, 2015, vol. 12, p. 1985.

Sá, É.S., da Silva, P.S., Jost, C.L., and Spinelli, A., Electrochemical sensor based on bismuth-film electrode for voltammetric studies on vitamin B2 (riboflavin), Sens. Actuators, B, 2015, vol. 209, p. 423.

Hassaninejad-Darzi, S.K. and Shajie, F. Simultaneous determination of acetaminophen, pramipexole and carbamazepine by ZSM-5 nanozeolite and TiO2 nanoparticles modified carbon paste electrode, Mater. Sci. Eng., C, 2018, vol. 91, p. 64.

Nurdin, M., Zaeni, A., Rammang, E.T., Maulidiyah, M., et al., Reactor design development of chemical oxygen demand flow system and its application, Anal. Bioanal. Electrochem., 2017, vol. 9, p. 480.

Maulidiyah, M., Wibowo, D., Herlin, H., Andarini, M., et al., Plasmon enhanced by Ag-doped S-TiO2/Ti electrode as highly effective photoelectrocatalyst for degradation of methylene blue, Asian J. Chem., 2017, vol. 29, p. 2504.

Beitollahi, H., Garkani-Nejad, F., Tajik, S., and Ganjali, M.R., Voltammetric determination of acetaminophen and tryptophan using a graphite screen printed electrode modified with functionalized graphene oxide nanosheets within a Fe3O4SiO2 nanocomposite, Iran. J. Pharm. Res., 2019, vol. 18, p. 80.

Arham, Z., Nurdin, M., and Buchari, B., Photo-electrocatalysis performance of La2O3 doped TiO2/Ti electrode in degradation of rhodamine B organic compound, Int. J. ChemTech Res., 2016, vol. 9, p. 113.

Maulidiyah, M., Azis, T., Nurwahidah, A.T., Wibowo, D., et al., Photoelectrocatalyst of Fe co-doped N-TiO2/Ti nanotubes: pesticide degradation of thiamethoxam under UV–visible lights, Environ. Nanotechnol., Monit. Manage., 2017, vol. 8, p. 103.

Maulidiyah, M., Azis, T., Lindayani, L., Wibowo, D., et al., Sol-gel TiO2/carbon paste electrode nanocomposites for electrochemical-assisted sensing of fipronil pesticide, J. Electrochem. Sci. Technol., 2019, vol. 10, p. 1.

Nurdin, M., Prabowo, O.A., Arham, Z., Wibowo, D., et al., Highly sensitive fipronil pesticide detection on ilmenite (FeO·TiO2)-carbon paste composite electrode, Surf. Interfaces, 2019, vol. 16, p. 108.

Nurdin, M., Dali, N., Irwan, I., Maulidiyah, M., et al., Selectivity determination of Pb2+ ion based on TiO2-ionophores BEK6 as carbon paste electrode composite, Anal. Bioanal. Electrochem., 2018, vol. 10, p. 1538.

Umar, A.A., Md Saad, S.K., Ali Umar, M.I., Rahman, M.Y.A., et al., Advances in porous and high-energy (001)-faceted anatase TiO2 nanostructures, Opt. Mater., 2018, vol. 75, p. 390.

Shi, H., Zhao, G., Cao, T., Liu, M., et al., Selective and visible-light-driven profenofos sensing with calixarene receptors on TiO2 nanotube film electrodes, Electrochem. Commun., 2012, vol. 19, p. 111.

Raoof, J.B., Ojani, R., and Baghayeri, M., Sensitive voltammetric determination of captopril using a carbon paste electrode modified with nano-TiO2/ferrocene carboxylic acid, Chin. J. Catal., 2011, vol. 32, p. 1685.

Nurdin, M., Ramadhan, L.O.A.N., Darmawati, D., Maulidiyah, M., et al., Synthesis of Ni, N co-doped TiO2 using microwave-assisted method for sodium lauryl sulfate degradation by photocatalyst, J. Coat. Technol. Res., 2018, vol. 15, p. 395.

Saraswati, A. and Nugraha, I., Sintesis komposit montmorillonit-TiO2 dan aplikasinya untuk pengolahan limbah cair pabrik gula, VI Prosiding Seminar Nasional Kimia dan Pendidikan Kimia, Surakarta, 2014.

Wibowo, D., Maulidiyah, Ruslan, Azis, T., et al., A high-performance electrochemical sensor based on FeTiO3 synthesis coated on conductive substrates, Anal. Bioanal. Electrochem., 2018, vol. 10, p. 465.

Nurdin, M., Muzakkar, M.Z., Maulidiyah, M., Maulidiyah, N., et al., Plasmonic silver–N/TiO2 effect on photoelectrocatalytic oxidation reaction, J. Mater. Environ. Sci., 2016, vol. 7, p. 3334.

Supriyanto, E., Holikin, A., and Suwardiyanto, S., The thermal annealing effect on crystal structure and morphology of titanium dioxide (TiO2) powder, J. Ilmu Dasar, 2014, vol. 15, p. 37.

Wibowo, D., Muzakkar, M.Z., Saad, S.K.M., Mustapa, F., et al., Enhanced visible light-driven photocatalytic degradation supported by Au–TiO2 coral-needle nanoparticles, J. Photochem. Photobiol., A, 2020, vol. 398, p. 112589.

Md Saad, S.K., Ali Umar, A., Ali Umar, M.I., Tomitori, M., et al., Two-dimensional, hierarchical Ag-doped TiO2 nanocatalysts: effect of the metal oxidation state on the photocatalytic properties, ACS Omega, 2018, vol. 3, p. 2579.

Maulidiyah, Wibowo, D., Hikmawati, Salamba, R., et al., Preparation and characterization of activated carbon from coconut shell-doped TiO2 in water medium, Orient. J. Chem., 2015, vol. 31, p. 2337.

Balal, K., Mohammad, H., Bahareh, B., Ali, B., et al., Zeolite nanoparticle modified carbon paste electrode as a biosensor for simultaneous determination of dopamine and tryptophan, J. Chin. Chem. Soc., 2009, vol. 56, p. 789.

Fisher, M.E., The renormalization group in the theory of critical behavior, Rev. Mod. Phys., 1974, vol. 46, p. 597.

Sroysee, W., Chunta, S., Amatatongchai, M., and Lieberzeit, P.A., Molecularly imprinted polymers to detect profenofos and carbofuran selectively with QCM sensors, Phys. Med., 2019, vol. 7, p. 100016.

Liu, T., Xu, M., Yin, H., Ai, S., et al., A glassy carbon electrode modified with graphene and tyrosinase immobilized on platinum nanoparticles for sensing organophosphorus pesticides, Microchim. Acta, 2011, vol. 175, p. 129.

Selvolini, G., Băjan, I., Hosu, O., Cristea, C., et al., DNA-based sensor for the detection of an organophosphorus pesticide: profenofos, Sensors, 2018, vol. 18, p. 2035.

Amatatongchai, M., Sroysee, W., Sodkrathok, P., Kesangam, N., et al., Novel three-dimensional molecularly imprinted polymer-coated carbon nanotubes (3D-CNTs MIP) for selective detection of profenofos in food, Anal. Chim. Acta, 2019, vol. 1076, p. 64.

Kumar, S.A., Tang, C.-F., and Chen, S.-M., Electro-analytical determination of acetaminophen using nano-TiO2/polymer coated electrode in the presence of dopamine, Talanta, 2008, vol. 76, p. 997.

Horwitz, W. and Albert, R., The Horwitz ratio (HorRat): A useful index of method performance with respect to precision, J. AOAC Int., 2006, vol. 89, p. 1095.

Belkhamsa, N., Ouattara, L., and Ksibi, M., Voltammetric monitoring of Pb(II) by TiO2 modified carbon paste electrode, J. Electrochem. Soc., 2015, vol. 162, p. B212.

Khani, H., Rofouei, M.K., Arab, P., Gupta, V.K., et al., Multi-walled carbon nanotubes-ionic liquid-carbon paste electrode as a super selectivity sensor: Application to potentiometric monitoring of mercury ion (II), J. Hazard. Mater., 2010, vol. 183, p. 402.

Funding

The authors are grateful to the Ministry of Research and Technology/National Research and Innovation Agency (KEMRISTEK/BRIN), Republic of Indonesia, for providing the financial support under Grant No. 171/SP2H/AMD/LT/DRPM/2020.

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Thamrin Azis, Maulidiyah, M., Muzakkar, M.Z. et al. Examination of Carbon Paste Electrode/TiO2 Nanocomposite as Electrochemical Sensor for Detecting Profenofos Pesticide. Surf. Engin. Appl.Electrochem. 57, 387–396 (2021). https://doi.org/10.3103/S1068375521030029

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068375521030029