Abstract

Maintenance and repair of electrical products related with production, transmission, and distribution of electric power can result in interruption of consumer power supply. Under such circumstances, it important to minimize duration of maintenance and repair. At present, the performance characterizing the duration of maintenance is not normalized for most electrical devices and depends on the complexity of the device and its circuit design. This article presents a mathematical model relating the aforementioned parameter with operation efficiency and other operational performances.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Operational activities concerning electrical devices usually involve maintenance and repair. Performance of such works in electrical devices related with production, transmission, and distribution of electric power can result in interruption of consumer power supply. Under such circumstances, it important to minimize the duration of maintenance and repair. At present, the performance characterizing the duration of maintenance is not normalized for most of electrical devices and depends on the complexity of device and its circuit design. For theoretical substantiation of the considered performance (duration of maintenance), it is required to develop a mathematical model relating the mentioned parameter with operation efficiency and other operational performances.

In addition to periodicity, the duration of maintenance also exerts significant influence of operation efficiency of electrical products. Therefore, in the course of optimization of this parameter, the basis should be founded on utilization efficiency of products Pe = kepP(t) [1], where kep is the integrated reliability index accounting for scheduled and emergency repair activities and P(t) is the probability of fault-free operation.

The time of fault-free operation increases with an increase in the maintenance duration due to more complete detection and elimination of faults. However, this is valid only up to a certain threshold of duration; the availability factor of elements then decreases.

Let the initial equation be the expression [2]

where Top is the cumulative operation time of electric products, TmaintΣ is the total time of delays due to scheduled and nonscheduled maintenances, TtΣ is the total time of delays due to scheduled and nonscheduled repairs, t is the preset time of fault-free operation, and T0 is the time between two successive faults of an electrical device.

Provided that Top ≈ T0n, TmainΣ = Tmaintm, and TtΣ = Ttn, after transformations of Eq. (1), we obtain the following equation:

where m is the number of maintenances of electrical products in time Top and n is the number of failures.

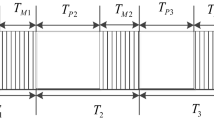

Since maintenance of equipment during operation is performed on a regular basis, Eq. (2) can be presented in the form

where γ = Z(Teff)(1 – δ) is the coefficient characterizing the number of prevented failures and quality of their elimination, δ is the probability of omission of failed element due to low accuracy of control means and errors of maintenance personnel, and T1 is the ultimate possible increase in duration of maintenance.

The equation of optimum duration of maintenance can be obtained by analysis of Eq. (3) regarding its extreme value. Herewith, the following constraints should be preset: T0 \( \gg \) Tt; T0 \( \gg \) t, T1 > Tmaint, and m > n.

At \(\frac{{{{T}_{{{\text{maint}}}}}}}{{{{T}_{1}}}} \leqslant 1\), we have the following:

Equation (4) allows to the optimum value to be calculated of the relative duration of maintenance on the basis of the known performances of reliability and parameters characterizing operational activities and required time of fault-free operation. Introducing several new notations with the aim of simplification the subsequent analytical apparatus, solving jointly Eqs. (3) and (4), it is possible to obtain the following equation for estimation of the utilization efficiency of electric products:

where \({{\alpha }} = \frac{{{{T}_{{\text{t}}}}}}{{{{T}_{{\text{0}}}}}}\); \({{\beta }} = \frac{{{{T}_{{\text{t}}}}}}{t}\); \({{\sigma }} = \frac{t}{{{{T}_{{\text{0}}}}}}\) and \({{\mu }} = \frac{{{{T}_{{\text{1}}}}}}{t}\) are the indices accounting for the reliability and utilization efficiency of equipment.

The subsequent calculations by the considered analytical equation obtained by simulation allowed initial data to be obtained for graphical presentation of duration maintenance as a function of the operational efficiency of electric equipment. Figure 1 illustrates operation efficiency of an electrical device Peff as a function of relative duration of maintenance \(\frac{{{{T}_{{{\text{maint}}}}}}}{{{{T}_{1}}}}\) with the following initial data: T0 = 500 h, T1 = 10 h, n = 0.8m, α = 0.1, σ = 0.2, β = 0.5, and μ = 1.

Let us estimate the obtained simulation results. If before maintenance numerous defects were detected and the quality of their elimination is considered as good (γ > 0.7–0.8), then the duration of each maintenance should be considered as corresponding to the corresponding preset norm Tmaint = T1. If γ < 0.5, the increase in duration of maintenance can result in a decrease in the performance of utilization efficiency of electric equipment.

It follows from Fig. 1 that the performance of operation efficiency of electric equipment, in addition to the maintenance duration, depends on γ, which includes two constituents: coefficient Z related with suitability of equipment for detection and elimination of defects and the constituent (1 – δ) allowing the capabilities of a control system to be estimated.

As a consequence, if equipment is poorly adapted for detection of defects (low Z) and personnel are not equipped sufficiently with control means (high δ), then maintenance can result not in an increase, but a decrease, in the operation efficiency of electrical products.

CONCLUSIONS

(1) Solution of the problem of determination of optimum duration of maintenance of electrical products allowed an analytical expression required for engineering computations to be obtained.

(2) The proposed apparatus is not related with serious difficulties and can be successfully used by operating personnel.

REFERENCES

Shishonok, N.A., Repkin, V.F., and Barvinskii, L.L., Osnovy teorii nadezhnosti i ekspluatatsii radioelektronnoi tekhniki (Foundations of the Theory of Reliability and Operation of Radioelectronics), Moscow: Sovetskoe radio, 1964.

Khorol’skii, V.Ya. and Taranov, M.A., Nadezhnost’ elektrosnabzheniya (Reliability of Electric Supply), Moscow: Forum, Infra-M, 2019.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Additional information

Translated by I. Moshkin

About this article

Cite this article

Isupova, A.M., Mastepanenko, M.A., Khorolsky, V.Y. et al. Procedure for Determination of Optimum Maintenance Duration. Russ. Electr. Engin. 93, 456–457 (2022). https://doi.org/10.3103/S1068371222070070

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068371222070070