Abstract

In this study, the effects of thiourea (CH4N2S) on the efficiency of gold dissolution were investigated for the extraction of gold from an oxide gold ore of the eastern Anatolia region, Turkey. In the thiourea leaching experiments; several parameters such as particle size (–75, –53, and –38 μm), leaching time (30, 60, 120, 180, and 240 min), thiourea concentration (0.1, 0.25, 0.5, 1, and 1.5 mol/dm3), pH (1, 2, 3, 4, and 5), and pulp temperature (20, 40, 60, and 80°C) were examined using hydrogen peroxide (H2O2) as an oxidant. The results from these experiments showed that the highest efficiency for Au dissolution was obtained as 91.94% at –38 μm particle size, 120 min of leaching time, 1 mol/dm3 thiourea concentration, pH 1, and 80°C pulp temperature. The results obtained from this study indicated that the thiourea leaching could be evaluated as an alternative method for the dissolution of gold from oxide gold ores.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 INTRODUCTION

Gold has been one of the most popular metals with its fundamental properties because of its easy handling and acid resistance since ancient times [1]. The world’s gold mining has been growing since the 1970s with the rapid rise in gold prices and the impact of new developments in gold processing technologies [2]. Especially in recent years, Turkey’s gold exports have increased considerably. Due to the physical and chemical properties of gold, the importance given to gold production in the world and Turkey has been increasing gradually, thus the need for gold is also increasing. Having a wide range of uses, gold has become an important economic gain for gold-producing countries [3, 4].

Depending on the formation and mineral contents, physical methods (jigging, shaking table, spiral, and heavy medium separation) for liberated and coarse-grained gold, physico-chemical methods (flotation and amalgamation), and chemical methods (leaching) are the main production technologies for free and fine-grained gold or sulphide and telluride minerals containing gold [5–8].

Today, 85% of the world’s gold production is realized with cyanide leaching generally used for the processing of low-grade gold ores, which are difficult to process with physical and physico-chemical methods. Despite the high efficiency of cyanide leaching, alternative methods have also been investigated in gold processing due to reasons such as environmental constraints on the use of cyanide and potential negative effects on living health [9–13].

Thiourea, which amongst the investigated reagents such as chlorine, thiosulfate, and alkaline chemical substances that could be an alternative to cyanide, has become more prominent because it has faster leaching kinetics and less toxicity than cyanide, and it is less prone to the other ions in the environment [14].

Several studies on the gold recovery with the thiourea process are available in the literature. Promising results have been obtained from these studies investigating the use of thiourea as an alternative to cyanide in the recovery of precious metals, especially from gold and silver containing refractory and sulphide ores. As one of the initial studies on the subject, Groenewald (1976) investigated the gold recovery with thiourea leaching and stated that the use of iron(III) as the oxidant provides rapid dissolution of gold. On the other hand, it was also stated that the use of iron(III) was an unattractive option in thiourea leaching systems because it also leads to higher thiourea consumption [15]. Despite this shortcoming, ferric ion was also used as the oxidant by Shengming et al. (1996). The results of the study, where hydrochloric acid was used to provide acidic conditions, indicated that thiourea and hydrochloric acid concentration showed the most prominent effects on the leaching of gold, while the effect of ferric ion was limited [16]. Moreover, Ubaldini et al. (1998) investigated the gold recovery with thiourea using solid ferric sulphate [Fe2(SO4)3] as the oxidant and obtained about 80% gold recovery from a domestic ore from Italy [17]. Although the acidic conditions have been generally preferred in thiourea leaching systems, the results of the study by Wei et al. (1999) confirmed that dissolution of gold could also be accomplished in the alkaline thiourea solution in the presence of sodium persulfate (Na2S2O8) as the oxidant [18]. Orgul and Atalay (2002) studied the reaction of the chemistry with thiourea leaching of Kaymaz (Turkey) gold ore, again using Fe3+ as the oxidant. The authors reported that the thiourea consumption was proportionally related to oxidant/thiourea molar ratio, and ferric sulfate could make thiourea processing expensive in comparison to cyanidation [19]. Gönen et al. (2007) investigated the recovery of gold from refractory gold ore with thiourea. It was stated that the lower leaching rate and high lixiviant and oxidant consumptions were important disadvantages of the system [14]. In addition to the gold ores, the applicability of the thiourea leaching for the recovery of gold from secondary resources has been also investigated. Jing-Ying et al. (2012) investigated the gold and silver recovery of thiourea from printed circuit boards of waste mobile phones [20]. Birloaga et al. (2013) studied the effects of various factors on hydrometallurgical processes in copper and gold recovery from waste circuit boards and obtained a gold recovery of about 70% with thiourea [21]. The results of these works, where Fe3+ and H2O2 were successfully used in the former and latter studies, respectively, showed that the thiourea leaching was also an amenable method for the recovery of gold and other noble metals from secondary resources. Further details on the additional studies on the gold leaching with acid thiourea solution can be seen from the comprehensive review by Li and Miller (2006) [22].

Although ferric sulphate is generally used as an oxidizer of choice in the gold recovery with thiourea leaching, different oxidants have also been investigated [22]. However, the use of hydrogen peroxide as an oxidant has been studied in a limited number of studies [15, 21, 23, 24]. Hydrogen peroxide, which can be described as a moderately strong oxidant in the thiourea leaching system, is among the suitable alternatives to atmospheric oxygen as its decomposition yields only oxygen and water [15, 25].

Additionally, designing a hydrometallurgical experimental work is a complex task involving various ore properties and their combined effects on the available treatment methods. Specifically, criteria such as ore type and selectivity should be considered for gold lixiviants [26, 27]. In this context, this study aimed to investigate the amenability of acidic thiourea-hydrogen peroxide system as an alternative to cyanide leaching and the optimization of leaching conditions for the extraction of gold from an oxidized gold ore from the eastern Anatolia region, Turkey.

2 EXPERIMENTAL

2.1 Materials

The oxidized gold ore sample used in the experimental studies was obtained from a gold mine of a privately owned company operating in the eastern Anatolia region, Turkey. The moisture analysis of the sample at 105°C in a laboratory-type oven (Memmert, Germany) showed that the sample had 20.45% total moisture. The average density of the sample was determined as 2.62 g/cm3 using a pycnometer method (Isolab, Germany). The chemical analyses of the sample were also performed by the ICP-MS method using the Thermo Elemental X Series ICP-MS device, and the Au content of the sample was determined as 2.461 ppm. The contents of major oxides and other elements in the sample are presented in Table 1.

To prepare the samples for the characterization and the leaching experiments, a jaw crusher (Denver, USA) and a roll crusher (Unal Engineering, Turkey) were used in primary and secondary crushing stages, respectively. Secondary crushing was realized in three stages, and the sample size was reduced to –4 mm. As a result of the particle size analysis carried out by the sieving method on the original (run-of-mine, ROM) and crushed samples, the d50 and d80 sizes of the original sample were found to be 1.27 and 5.7 cm, respectively (Fig. 1), and the d50 and d80 sizes of the roll crusher (RC) output were found to be 0.71 and 1.65 cm, respectively (Fig. 1).

The results of the XRD analysis showed that the sample mostly contained quartz at high levels (Fig. 2). Moreover, kaolinite was determined as the main secondary peak. Additionally, coesite, ammonioalunite, and hematite were determined as minor peaks. As a result of the simultaneous evaluation of the ICP and XRD analyses, the semi-quantitative mineralogical composition of the sample was determined as quartz (75.45%), kaolinite (9.61%), and other mineral phases (14.94%). Additional mineral phases, which were not detected in the XRD analysis due to the detection limits of the method, were revealed by optical microscope studies.

In the optical microscope examinations, quartz was found to be the dominant mineral phase in the sample (Fig. 3), which is in agreement with the results of the XRD analysis. Additionally, chlorite, feldspar, and opaque/iron-rich phases such as hematite and magnetite were also encountered in the sample. On the other hand, pyrite, mica, and rutile were observed in trace amounts. It was observed that the gold in the sample was mainly associated with quartz grains (Fig. 3).

2.2 Methods

In the context of the experimental studies, pH profile measurements were performed before the leaching experiments to determine the time-dependent change in pH of suspensions prepared using the sample and different acidic and alkaline solutions, and the buffering properties of the sample. The suspensions at 1% solids ratios were prepared by mixing 1 g of sample (d100 = –75 μm) with 100 mL of acidic and alkaline solutions at different pH values. Desired pH values of the acidic and alkaline solutions were adjusted by using 0.1 M NaOH or 0.1 M HCl, respectively. The prepared suspensions were then stirred using a magnetic stirrer at room temperature (24°C) at 500 rpm, and the pH profiles of the suspensions at each initial pH level were recorded for 1 h.

The roll crusher output was ground to obtain particle sizes of –75, –53, and –38 μm by grinding in a closed circuit ball mill process, and then, representatively sub-sampled with a splitter to be used for the leaching experiments. There was no significant variance or nugget effect was observed in the preliminary analyses on the sub-samples as Au was generally locked with the quartz particles rather than completely liberated gold grains. The leaching process was carried out in a shaking water bath with mixing speed and temperature control, and after the leaching, solid-liquid separation was applied to the suspensions. The evaluation of leaching performance was realized by ICP-MS analyses on the residues which were obtained after the leaching procedure due to the relatively low Au grade of the ore and weight (50 g) of the feed samples, in addition to the low Au concentration of the leach liquors (~5 × 10–4 g/dm3).

The evaluation of leaching performance by the analyses of residue grade has been a common practice in the related literature [28–31]. The residues obtained from the leaching experiments were dried at 105°C for 12 h, and subsequently, the chemical analyses of the samples were carried out using the ICP-MS method. The error of analyses was approximately ±0.01 ppm. The leaching efficiency was calculated according to Eq. (1):

where L.E. is leaching efficiency, Mf is the mass of feed, Mr is the mass of residue, F is Au grade of feed in ppm, and R is Au grade of residue in ppm. However, the leaching efficiencies were calculated based only on the Au grades of the feed and residue as no significant change was obtained in the mass after the leaching process.

Thiourea (CH4N2S) dissolves in water and forms cationic species with gold according to the reaction given in Eq. (2) [15, 19]:

However, to achieve an acceptable leaching rate, the presence of an oxidant is necessary. The oxidant also oxidizes the thiourea and forms formamidine disulphide, which is also an oxidant itself. The mechanism of oxidation of thiourea by hydrogen peroxide (H2O2) and formation of formamidine disulphide [NH2(NH)CSSC(NH)NH2] in the acidic (at pH 1.5) thiourea leaching system is given in Eqs. (3) and (4) (17, 19, 32, 33).

Analytical grade (≥99%) thiourea was used as the lixiviant in the leaching experiments. Hydrogen peroxide (50 wt % in H2O) was used as an oxidant in the leaching experiments. Moreover, sulphuric acid (H2SO4) (98%) was used as a pH modifier in the leaching experiments owing to some advantages over HCl such as the lower price and easier handling [34‒36].

In thiourea (CH4N2S) leaching experiments, the optimum conditions were determined by investigating the effects of parameters of –75, –53, and –38 μm particle sizes; 30, 60, 120, 180, and 240 min leaching times; 0.1, 0.25, 0.5, 1, and 1.5 mol/dm3 thiourea concentrations; 1, 2, 3, 4, and 5 of pH values; 20, 40, 60, and 80°C pulp temperatures on the efficiency of Au dissolution.

3 RESULTS AND DISCUSSION

3.1 pH Profile

As can be seen from the pH profile of the samples given in Fig. 4, the sample does not show a tendency to form a pH-dependent buffer at highly acidic and alkaline pH values. There were no significant changes in pH over 60 min for the measurements performed at pH 2, 3, and 11. This finding indicated that the periodical pH control may not be necessary for the leaching experiments to be performed in environments that have acidity and alkalinity properties close to pH 2–3 and 11, respectively, in terms of regulating the pH value of the medium. On the other hand, a slight buffering effect was also observed in the measurements performed at pH 5 and 9 as the pH of the medium was tended to approach the pH of the ore in DI water (~7.3). According to this finding, the pH of the pulp was periodically measured at the leaching experiments performed at pH 4 and 5.

3.2 Leaching Experiments

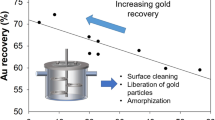

3.2.1. Effect of particle size. In the first group of leaching experiments, the effect of the feed particle size on the efficiency of Au dissolution was examined. The variation of the efficiency of Au dissolution depending on the particle size is shown in Fig. 5.

According to the results obtained from the experiments, it was observed that the efficiency of Au dissolution increased in parallel to the decrease in the feed particle size. The increase in the feed particle size increased the efficiency of Au dissolution, which was an expected result due to both the reasons for the opening of the gold surfaces in the sample and the increase of the specific surface area of the material. This finding is in agreement with the previous literature where the leaching of gold from oxide ores was investigated [37, 38]. The efficiencies of Au dissolution were obtained as 63.08, 63.32, and 65.00% for –75, –53, and 38 μm particle sizes, respectively. However, the increase in the efficiency was not proportional to the decrease in the particle size. This phenomenon can be attributed to the simultaneous liberation of clay minerals within the ore and their prevention of further increase of the efficiency of Au dissolution by absorbing the lixiviant within their structure. On the other hand, the relatively fine size of the Au phases in the minerals could have been prevented the further increase in Au dissolution efficiency apart from very fine sizes. Therefore, the optimum particle size was determined as –38 μm because the highest efficiency for Au dissolution was obtained, and the feed with the particle size of –38 μm was used in the subsequent experiments.

3.2.2. Effect of pH. In these groups of experiments, the effect of the acidity of the pulp on the efficiency of Au dissolution was examined. The efficiency of Au dissolution with respect to pH values is seen in Fig. 6. As seen in Fig. 6 that the efficiency of Au dissolution decrease with the increase in the pH value. The efficiencies of Au dissolution for the pH values of 1, 2, 3, 4, and 5 were obtained as 78.53, 69.42, 65.00, 49.59, and 34.73%, respectively. Previous work indicated that there was an inverse relationship between pH value and yield and that the best efficiency for gold dissolution was obtained in high acidic media [3]. The pH values investigated in this study supported the findings of a previous study in terms of a general trend. On the other hand, the variation of the increase obtained in the efficiency of Au dissolution between the experiments performed at pH 1 and 2 was higher than the aforementioned study as the efficiencies of Au dissolution were almost equal at the given pH range. This observed difference could be related to the different dissoluble species within ores with different mineralogical compositions. Therefore, the optimum pH value was taken as pH 1 where the highest efficiency of Au dissolution was obtained with a rate of 78.53%.

3.2.3. Effect of leaching time. Figure 7 shows the result for the efficiency of Au dissolution depending on the leaching time. According to the results shown in Fig. 7, it can be concluded that the thiourea leaching had relatively fast kinetics compared to the cyanide leaching, and the efficiency of Au dissolution increased significantly to a certain point depending on the leaching time. The efficiencies of Au dissolution for the dissolution times of 30, 60, 120, 180, and 240 min were obtained as 11.58, 69.30, 78.53, 78.53, and 78.61%, respectively. The optimum leaching time was determined to be 120 min since a significant change in the efficiency of Au dissolution was not observed after 120 min with the increased leaching time and reached the plateau point. The tendency of the efficiency of Au dissolution to reaching a plateau after a certain time can be explained by the fact that the reactions of Au dissolution may have been completed or the solvent phase may have reached the depletion point.

3.2.4. Effect of thiourea concentration. The efficiency of the Au dissolution as a function of the thiourea concentration is shown in Fig. 8. In these experiments, 0.1, 0.25, 0.5, 1, and 1.5 mol/dm3 thiourea concentrations were tested. It was observed that the efficiency of Au dissolution increased to a certain point depending on the amount of thiourea and tended to become fixed after this point. The efficiencies of Au dissolution were obtained as 73.21, 74.89, 78.53, 88.50, and 87.95% for the aforementioned thiourea concentrations, respectively. Accordingly, the optimum amount of thiourea was determined as 1 mol/dm3 where the highest efficiency of Au dissolution was obtained with a rate of 88.50%. The possible reason for the increase in the thiourea amount does not positively affect the dissolution efficiency after 1 mol/dm3 can be explained by the fact that the stoichiometric reagent amount (~6.34 × 10–7 mol/dm3) is met to complete the dissolution reactions at the 1 mol/dm3 thiourea concentration.

3.2.5. Effect of pulp temperature. In this group of experiments, the effect of the pulp temperature on the efficiency of Au dissolution was examined. The efficiency of Au dissolution depending on the pulp temperature is given in Fig. 9.

According to the results shown in Fig. 9, it was observed that the efficiency of Au dissolution increased in parallel with the increase in the pulp temperature. In the chemical dissolution processes, the reaction temperature is an important parameter because it has a significant effect on both the dissolution time and the solubility of soluble elements in the solvent phase. In these groups of experiments, the efficiencies of Au dissolution were found to be 86.05, 88.50, 90.93, and 91.94% for 20, 40, 60, and 80°C pulp temperature, respectively. As expected, the effect of the pulp temperature on the efficiency of Au dissolution was generally less dramatic compared to the other parameters investigated. This might be caused by the decreased solubility of oxygen when elevating temperature [39]. Accordingly, the optimum pulp temperature was determined as 80°C where the highest efficiency of Au dissolution at which a 1% yield increase over 60°C, was obtained with a rate of 91.94%. However, since the increase in the efficiency of Au dissolution has generally started to slow down after 60°C, and considering the applicable limits in the actual processing plant environment, the temperatures higher than 80°C were not investigated in this study.

4 CONCLUSIONS

In this study, the effect of several leaching conditions on Au dissolution with thiourea as an alternative method, as the environmental and social impact of the prejudice to cyanide consumption opens the way for new processes, was investigated for the extraction of gold from an oxidized gold ore of the eastern Anatolia region, Turkey.

As a result of the characterization of the samples, it was determined that the sample contained quartz at a high rate and gold content (2.461 ppm) was associated with quartz grains. The results of pH profile analysis demonstrated that the sample showed no buffering property at pH 2–3 and pH 11.

The gold extraction rate obtained within this study (91.94%) is comparable in terms of the gold extraction rates (69–95.5%) achieved in the previous work [15, 21, 23, 24] on the subject, where thiourea (CH4N2S)-hydrogen peroxide (H2O2) leaching system were used for the extraction of gold from various primary and secondary resources. The variance in the extraction rates of gold is clearly associated with not only the difference in physical, chemical, and mineralogical properties of ores and materials but also experimental conditions, used in these studies.

On the other hand, to provide a better understanding of the underlying mechanism behind the obtained results, several other factors such as thiourea consumption and oxidation-reduction potential of the system should be investigated in future studies as they have considerable effects on the efficiency of Au extraction. Additionally, investigation of the cyanide leaching for the Au extraction from the ore in terms of a direct comparison of the kinetics of different systems is also advised.

The results obtained from this study indicated that the processing of oxidized gold ores using thiourea leaching in the presence of hydrogen peroxide (H2O2) as an oxidant is a considerable alternative to cyanide leaching.

REFERENCES

Kursun, I. and Kahriman, A., The importance of our natural resources in European Union membership process, Turk. Diary, 2002, no. 70, pp. 71–72.

Oygur, V., Dünya altın madenciliği ve Türkiye'nin altın potansiyeli, J. Geol. Eng., 1996, no. 49, pp. 55–62.

Altıntepe, M., The dissolution behaviour of gold in different leaching solutions, MSc Thesis, Istanbul: Istanbul Technical Univ., 2003.

Kursun, I. and Gungor, Y., Evaluation of gold content in Coruh placer deposits, Asian J. Chem., 2005, vol. 17, pp. 2098–2104.

Yuce, A. E., Gold and silver extraction with thiourea and a gold, silver containing auriferous sulfide copper ores, PhD Thesis, Istanbul: Istanbul Technical Univ., Graduate School of Science Engineering and Technology, 1995.

Arslan, F., Yuce, A.E., Acarkan, N., Dincer, H., and Onal, G., Recovery of valuable metals from various ores in Turkey, Proc. Int. Valuable Stones and Metals Symposium, Istanbul, April 29–30, 2005, pp. 89–104.

Celep, O., Alp, I., Deveci, H., Vicil, M., and Yilmaz, T., Gold recovery from Mastra (Gümüşhane) ore using Knelson centrifugal separator, Istanbul Univ. Eng. Fac. J. Earth Sci., 2006, vol. 19, no. 2, pp. 175–182.

Kekeç, M., The environmental impact assessment of gold mine, MSc Thesis, Kahramanmaras: Kahramanmaras Sutcu Imam Univ., 2014.

Logsdon, M.J., Hagelstein, K., and Mudder, T., The management of cyanide in gold extraction, Proc. Int. Council on Metals and the Environment, Ottawa, 1999, p. 10.

Kursun, I., Kahriman, A., Demir, I., and Turgut S., Gold mining in Turkey and environmental impact assessment, Proc. 7th Int. Scientific Conference on Modern Management of Mine Producing, Geology and Environmental Protection SGEM-2007, Albena, 2007, pp. 173–174.

Akcil, A. and Ciftci, H., Pre-treatments methods applied to refractory gold ores, J. Min., 2009, vol. 48, no. 1, pp. 17–30.

Basturkcu, H., Kursun, I., and Demir, I., The application of cyanide leaching with agitation method in Kisladag gold mine ore, Proc. 12th Int. Mineral Processing Symposium, Cappadocia Nevşehir, 2010, pp. 681–689.

Celep, O., Application of alkaline pretreatments for gold and silver recovery from refractory ores, PhD Thesis, Trabzon: Karadeniz Technical Univ., 2011.

Gonen, N., Korpe, E., Yildirim, M.E., and Selengil, U., Leaching and CIL processes in gold recovery from refractory ore with thiourea solutions, Miner. Eng., 2007, vol. 20, no. 6, pp. 559–565.

Groenewald, T., The dissolution of gold in acidic solutions of thiourea, Hydrometallurgy, 1976, vol. 1, no. 3, pp. 277–290.

Shengming, X., Chuanfu, Z., and Tiancong, Z., Thiourea leaching of gold from a calcine of gold-bearing arsenical pyrite concentrate, Trans. Nonferrous Met. Soc. China, 1996, vol. 6, no. 1, pp. 21–24.

Ubaldini, S., Fornari, P., Massidda, R., and Abbruzzese, C., An innovative thiourea gold leaching process, Hydrometallurgy, 1998, vol. 48, no. 1, pp. 113–124.

Wei, D., Chai, L., Ichino, R., and Okido, M., Gold leaching in an alkaline thiourea solution, J. Electrochem. Soc., 1999, vol. 146, no. 2, pp. 559–563.

Orgul, S. and Atalay, U., Reaction chemistry of gold leaching in thiourea solution for a Turkish gold ore, Hydrometallurgy, 2002, vol. 67, no. 1, pp. 71–77.

Jing-Ying, L., Xiu-Li, X., and Wen-Quan, L., Thiourea leaching gold and silver from the printed circuit boards of waste mobile phones, Waste Manage., 2012, vol. 32, no. 6, pp. 1209–1212.

Birloaga, I., Michelis, I.D., Ferella, F., Buzatu, M., and Francesco, V., Study on the influence of various factors in the hydrometallurgical processing of waste printed circuit boards for copper and gold recovery, Waste Manage., 2013, vol. 33, no. 4, pp. 935–941.

Li, J. and Miller, J. D., A review of gold leaching in acid thiourea solutions, Miner. Process. Extr. Metall. Rev., 2006, vol. 27, no. 3, pp. 177–214.

Deschenes, G. and Ghali, E., Leaching of gold from a chalcopyrite concentrate by thiourea, Hydrometallurgy, 1988, vol. 20, pp. 179–202.

Tremblay, L., Deschenes, G., Ghali, E., Mcmullen, J., and Lanouette, M., Gold recovery from a sulphide bearing gold ore by percolation leaching with thiourea, Int. J. Miner. Process., 1996, vol. 48, pp. 225–244.

Guzman, L., Segarra, M., Chimenos, J.M., Fernandez, M.A., and Espiell, F., Gold cyanidation using hydrogen peroxide, Hydrometallurgy, 1999, vol. 52, pp. 21–35.

Hilson, G. and Monhemius, A.J., Alternatives to cyanide in the gold mining industry: what prospects for the future?, J. Cleaner Prod., 2006, vol. 14, pp. 1158–1167.

Leikola, M., Rintala, L., Sauer, C., Roth-Berghofer, T., and Lundstrom, M., Applicability of case-based reasoning for selection of cyanide-free gold leaching methods, Proc. Int. Conference on Case-Based Reasoning, Atlanta, GA, 2016, pp. 249–264.

Wang, X., Zheng, S., Xu, H., and Zhang, Y., Leaching of niobium and tantalum from a low-grade ore using a KOH roast–water leach system, Hydrometallurgy, 2009, vol. 98, pp. 219–223.

Liu, J., Wen, S., Liu, D., Lv, M., and Liu, L., Response surface methodology for optimization of copper leaching from a low-grade flotation middling, Min., Metall. Explor., 2011, vol. 28, pp. 139–145.

Liu, X.W., Feng, Y.L., Li, H.R., Yang, Z.C., and Cai, Z.L., Recovery of valuable metals from a low-grade nickel ore using an ammonium sulfate roasting-leaching process, Int. J. Miner., Metall. Mater., 2012, vol. 19, pp. 377–383.

Kursun, I., Tombal, T.D., and Terzi, M., Solubility of Eskisehir thorium/rare earth ores in sulphuric and nitric acids, Physicochem. Probl. Miner. Process., 2018, vol. 54, pp. 476–483.

Hoffmann, M. and Edwards, J.O., Kinetics and mechanism of the oxidation of thiourea and N,N'-dialkylthioureas by hydrogen peroxide, Inorg. Chem., 1977, vol. 16, pp. 3333–3338.

Gao, Q., Wang, G., Sun, Y., and Epstein, I.R., Simultaneous tracking of sulfur species in the oxidation of thiourea by hydrogen peroxide, J. Phys. Chem. A, 2008, vol. 112, pp. 5771–5773.

Gallup, D.L., pH modification scale control technology, Proc. Int. Workshop on Mineral Scaling, Manila, 2011, pp. 39–46.

Pingitore, N., Clague, J., and Gorski, D., Round Top Mountain rhyolite (Texas, USA), a massive, unique Y‑bearing-fluorite-hosted heavy rare earth element (HREE) deposit, J. Rare Earths, 2014, vol. 32, pp. 90–96.

Onghena, B., Valgaeren, S., Vander Hoogerstraete, T., and Binnemans, K., Cobalt(II)/nickel(II) separation from sulfate media by solvent extraction with an undiluted quaternary phosphonium ionic liquid, RSC Adv., 2017, vol. 7, pp. 35992–35999.

Celep, O., Alp, I., Deveci, H., and Vicil, M., Characterization of refractory behaviour of complex gold/silver ore by diagnostic leaching, Trans. Nonferrous Met. Soc. China, 2009, vol. 19, pp. 707–713.

Karimi, P., Abdollahi, H., Amini, A., Noaparast, M., Shafaei, S.Z., and Habashi, F., Cyanidation of gold ores containing copper, silver, lead, arsenic and antimony, Int. J. Miner. Process., 2010, vol. 95, pp. 68–77.

Schulze, R.G., New aspects in thiourea leaching of precious metals, JOM, 1984, vol. 36, pp. 62–65.

ACKNOWLEDGMENTS

This work was supported by the Scientific Research Projects Coordination Unit of Istanbul University-Cerrahpasa with project numbers BYP-2017-23859 and FBA-2017-25729. The author would like to thank Prof. Ilgin Kursun and Prof. Orhan Ozdemir from Istanbul University-Cerrahpasa, and Mining Engineer Zafer Tanriver for their valuable contributions.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors state that they have no conflict of interest.

About this article

Cite this article

Terzi, M. Gold Extraction from an Oxide Ore by Thiourea Leaching with Hydrogen Peroxide as an Oxidant. Russ. J. Non-ferrous Metals 62, 514–521 (2021). https://doi.org/10.3103/S1067821221050084

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821221050084