Abstract

The objective of this study is to investigate the removal of selected pharmaceuticals such as ibuprofen (IBP), diclofenac (DCF), and carbamazepine (CBZ) by activated carbon (AC) when they are present in the aqueous solution as an individual entity or as a mixture. The coconut (ACEco) and lignite (ACDarco) derived ACs after and before the impregnation of cerium were used as the adsorbent. Batch experiments were carried out for assessing the removal efficiency under varying conditions. The removal efficiencies of those pharmaceuticals were in the range of 66.2–99.8%. In the case of IBP and DCF, the removal was found to decrease slightly by ACEco and ACEco-Ce when the mixture of pharmaceuticals was used as compared to individual pharmaceuticals. The sorption kinetics results indicated that IBP (for both ACEco and ACDarco) and CBZ (ACEco) were best fitted to the pseudo-first-order kinetics model, whereas the DCF (both for ACEco and ACDarco) and CBZ (ACDarco) fits better to pseudo-second-order model. The outcome of the study indicates that selected ACs were found effective in removing IBP, DCF, and CBZ when they are present as an individual entity or as a mixture in the aqueous solution.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

INTRODUCTION

Contamination of water by emerging contaminants (ECs) has gained significant concern due to the ubiquitous presence in the environment. Pharmaceuticals are one group of ECs, which are detected in natural environments and are likely to have health hazards and toxic effects. Amongst different pharmaceuticals, ibuprofen (IBP) and diclofenac (DCF) are non-steroidal anti-inflammatory drugs having extensive applications due to their anti-inflammatory and analgesic properties. On the other hand, carbamazepine (CBZ) is an antiepileptic drug widely used to treat epilepsy, partial generalized tonic-clonic seizure, and trigeminal neuralgia. These three pharmaceuticals are consumed widely with hundreds of tons of annual production. These pharmaceuticals can be released into the aquatic environment through different pathways, such as direct discharge of raw or treated wastewater from various sources, improper dumping of expired medicines, research activities, etc. The occurrences of trace amounts of pharmaceuticals, including IBP, DCF, and CBZ, in the sewage treatment plant (STP) effluent or surface water have been reported in the literature. The toxic effects of these pharmaceuticals include morphological deformation, changes in enzyme activities, reproduction, fertilization, and embryo-larval growth in several species have also been reported [1, 2].

Several techniques, such as membrane separations, sorption, advanced oxidation, photocatalytic degradation, etc., have been explored widely to remove pharmaceuticals from water or wastewater effluent [3]. Sorption is found to be the most cost-effective, easy-to-use, and eco-friendly process. Activated carbon (ACs) based sorbent, for water purifications, derived from agricultural waste such as oak, sugarcane bagasse, mugwort, cocoa shell, palm kernel shell, etc., have been explored for the removal of individual pharmaceuticals from aqueous solutions (Table S1 (ESM_1.pdf)). Many of the ACs and activated biochar have shown promising performance in removing IBP, DCF, and CBZ when they are used as an individual entity. There are several types of ACs that are available in granular forms. Metal or organic modified or unmodified granular ACs can be used directly in the fixed bed filter media as the packing material. On the other hand, cerium oxide is an earth metal that is non-toxic to human and could be abundant in the environment. Several studies showed the efficient performance of cerium oxide for the removal of various contaminants such as methylene blue, azo dyes, chloroform, dichloromethane, carbon tetrachloride, arsenate, arsenite, fluoride, and etc. [4–9]. Considering this fact, cerium is taken as a suitable material for modifying the ACs in this study. Furthermore, in the natural system, pharmaceuticals are likely to be present as a mixture. To the best of the authors’ knowledge, not many studies have focused on removing pharmaceuticals when they are present as a mixture in the solution. Thus, there is a scope to explore the suitability of modified or unmodified ACs derived from different sources in removing selected pharmaceuticals from the mix matrix solution. The objective of this study was, therefore, to assess the efficiency of metal modified- and unmodified ACs in removing IBP, DCF, and CBZ when they were used as an individual entity or as a mixture in solution. Here, two ACs, one was synthesized from coconut shells (ACEco) and the other was derived from coal (ACDarco), were used as the adsorbents. The metal cerium (Ce) was impregnated in both the ACs, and the removal efficiency for IBP, DCF, and CBZ by modified or unmodified ACs are assessed in the batch system.

EXPERIMENTAL

Material

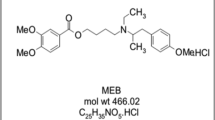

Granular AC, synthesized from coconut shell (ACEco), was obtained from Global Ecocarb Pvt Ltd., Bengaluru. Another AC, which was prepared by Norit–Darco (ACDarco: 12–20 mesh, size: 850–1000 μm), diclofenac (DCF), and carbamazepine (CBZ) were procured from Sigma-Aldrich. Ibuprofen (IBP); and analytical grade water and acetonitrile were obtained from Merck Millipore. Other reagents such as sodium hydroxide (NaOH), hydrochloric acid (HCl), and methanol were procured from Merck, India. De-ionized (DI) water was taken from the Millipore water purification system (Millipore, Billerica, MA) and was used for all purposes.

Adsorbent

In this study, ACEco and ACDarco were taken as unmodified adsorbents. The metal cerium (Ce) was impregnated within both the ACs, following the protocol given elsewhere [9, 10]. The Ce was selected as a reference metal given that it is earth material and does not have any toxic effects. Furthermore, it also showed promising performance in removing several contaminants [3, 4, 9–11]. The Ce impregnated in ACEco and ACDarco are indicated as ACEco-Ce and ACDarco-Ce composites, respectively. The BET surface areas of ACEco, ACDarco, ACEco-Ce, and ACDarco-Ce were 833, 334, 759, and 335 m2/g, respectively, whereas the pore volumes were 0.44, 0.24, 0.40, and 0.27 cm3/g, respectively [12].

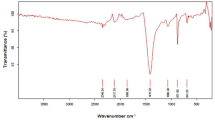

Characterization of Adsorbents

The surface morphology of ACs and modified-ACs composites was characterized using scanning electron microscopy (SEM, GeminiSEM 500, ZEISS). To assess the interaction between the ACs and the pharmaceuticals, the samples were analyzed using Fourier Transform Infrared Spectroscopy (FTIR, Thermo Scientific Nicolet iS50 infrared spectrometer). The chemical bonds on the surface of the adsorbents were identified before and after the sorption experiment of the selected pharmaceuticals. The samples were blended and pressed with KBr subjected to infrared radiation. The transmission spectra were collected in the frequency range of 4000 to 400 cm–1.

Sorption Experiments: Removal of Selected Pharmaceuticals

The batch experiments were conducted to assess the removal efficiency of IBP, DCF, and CBZ by different unmodified and modified ACs. In this set of experiments, the individual IBP, DCF, and CBZ and the mixture of three pharmaceuticals were prepared separately for the experiments. The pH of the solution was maintained at 7 and the temperature at 27°C. Four different adsorbents, namely ACEco, ACDarco, ACEco-Ce, and ACDarco-Ce, were used for the batch experiment. In a series of 30 mL glass vials, each containing 2 g/L of modified or unmodified ACs was taken. After that, 18.1 ± 2.3 mg/L of IBP, DCF, and CBZ, either as an individual entity or as a mixture of pharmaceuticals, was added in a separate vial containing adsorbents. The solution with the adsorbents was equilibrated by mixing at 70 rpm with an end-to-end rotor for 22 h. At the end of the experiment, the samples were withdrawn and filtered with a 0.2 µm filter before analysis. The sample was then analyzed using Liquid Chromatography and Mass Spectroscopy (LC-MS 6545 LC/Q-TOF, Agilent).

Sorption Experiment at Different Doses of Adsorbent

To assess the effect of adsorbent dose on the removal efficiency of pharmaceuticals by different modified and unmodified ACs, the dose of adsorbent was varied within a range of 1 to 4 g/L, keeping other parameters constant. In a series of glass vials, 1, 2, 3, and 4 g/L of adsorbents were taken separately where the concentration of IBP, DCF, and CBZ in the mix-solution was kept at 18.1 ± 2.3 mg/L. The pH, rotation speed, and sampling time were maintained the same as mentioned earlier.

Sorption Kinetics Test

The outcome of the previous study suggests that the performance of unmodified ACs was better in removing selected pharmaceuticals. Thus, in the kinetics test, only unmodified ACs were considered. To assess the sorption kinetics of IBP, DCF, and CBZ mixture, 2 g/L of different ACs were taken in two different 250 mL conical flasks. Thereafter, the mixture was shaken with a shaker at a speed of 200 rpm. During agitation, the samples were withdrawn at specific time intervals (i.e., 15, 30 min, 1, 2, 3, 6, and 9 h). The aliquots were filtered with 0.2 µm filter and analyzed with LC-MS following the protocol mentioned above.

RESULTS AND DISCUSSION

Removal of Selected Pharmaceuticals by Different Modified and Unmodified ACs

The removal efficiency for IBP, DCF, and CBZ, when used as an individual entity or as a mixture in solution, was conducted at pH 7, with the adsorbent dose of 2 g/L and solute content of 18 ± 2.3 mg/L. The results are shown in Fig. 1. The percentage removal of IBP, DCF, and CBZ were found to be in the range of 86.5–99.7, 94–99.4, 76.7–97.3, and 96.2–100% by ACEco, ACDarco, ACEco-Ce, and ACDarco-Ce, respectively, for individual pharmaceutical (Fig. 1a). The percentage removal of IBP was found to be decreased significantly from 99.7 to 70.8%, and from 95.8 to 66.2% by ACEco, and ACEco-Ce, respectively when the solution was prepared with the mixture of pharmaceuticals instead of an individual entity. There was an insignificant change in removal efficiency by the selected ACs for DCF and CBZ when they were used as individual entities or as a mixture of pharmaceuticals. The removal efficiencies of all three pharmaceuticals were in close proximity by ACDarco (96.8–99.8%) and ACDarco-Ce (96.3–99.6%) (Fig. 1b). Furthermore, the performance of ACDarco and ACDarco-Ce in removing pharmaceuticals didn’t get affected by the conditions that whether they are present as a single entity or as a mixture of pharmaceuticals. Overall, ACDarco shows better removal efficiency as compared to that of ACEco for all the pharmaceuticals. Moreover, the removal efficiency for IBP by ACEco and ACEco-Ce was noted to decrease when it was used within the mix-pharmaceutical compared to that of single entity (Fig. 1). This is likely due to the fact that ACEco has limited active sites for sorption. The other pharmaceuticals (CBZ and DCF) in the solution with higher binding energy might have occupied the sorption active sites. As a result, the sorption of IBP by ACEco and ACEco-Ce has been hindered due to the limited available sites for sorption [12].

Effect of Adsorbent Dose on the Removal of Mix-Pharmaceuticals

The amount of adsorbent is a crucial parameter that influences the removal efficiency of pharmaceuticals [13]. Thus, the effect of adsorbent doses on removing IBP, DCF, and CBZ were investigated for different modified and unmodified ACs. The adsorbent doses were varied from 1 to 4 g/L, where the solution pH was maintained at 7.

The results indicating percentage removal and the sorption capacity of ACEco, ACDarco, ACEco-Ce, and ACDarco-Ce on selected pharmaceuticals are presented in Fig. 2. In the case of IBP, a sharp increase in the removal efficiency was observed with an increase in ACEco (55.5–70.8–91.1%) and ACEco-Ce (47.7–66.2–95.5%) doses from 1 to 2 to 3 g/L. The removal efficiency for IBP was found to be within the range reported in other studies where activated biochar (95–96%, [14]), TiO2-impregnated biochar (92%, [3]) was used as the adsorbent. For DCF, an increase in the removal efficiencies was observed with an increase in ACEco (65.8–87.8–97.9%) and ACEco-Ce (56–72.9–99.1%) doses from 1 to 2 to 3 g/L; however, the effect is slightly less as compared to IBP. In the reported studies, the removal efficiency for DCF by activated biochar was within a range of 62 to 98% [15]. The removal efficiency of CBZ was noted to increase slightly with an increase in ACDarco (94.2–99.6%) and ACDarco-Ce (87.7–96.3%) doses from 1 to 2 g/L. Doses of ACEco seem to have negligible effects on the removal efficiency of CBZ.

In general, the removal efficiencies (%) increased with an increase in sorbent doses from 1–3 g/L (ACEco and ACEco-Ce) and 1–2 g/L (ACDarco and ACDarco-Ce), and beyond that, the stable removal efficiency of more than 99% was achieved (Fig. 2). This phenomenon can be explained by the fact that sorption active surface area increases with increased adsorbent doses. The rate of diffusion is high at the initial stage when more sorption active sites are available [16]. However, a further increase in adsorbent dose leads to no change in the percentage removal of contaminants due to abatement of the active surface area. The adsorbent doses have an insignificant influence on the removal of CBZ. This observation was in accordance with the previous observation, which suggests that CBZ has the most affinity towards the sorbent surface, and thus it sorbed better than IBP and DCF. Though the removal efficiency increases with an increase in adsorbent doses, a decrease in the sorption capacity was observed at higher dosages of adsorbent (Fig. 2). This is likely to be attributed to the fact that at the higher dose of adsorbents, all the sorption active sites are not occupied with the contaminants. This resulted in a lower value of sorption capacity at a higher dose of adsorbents. Overall, the removal efficiency indicates that impregnation of Ce either in ACEco or ACDarco did not improve the sorption of any of the selected pharmaceuticals. Furthermore, the sorption capacity and the removal efficiency trends indicate that the adsorbent dose between 1 to 2 g/L was optimal. Thus, for further study, only ACEco and ACDarco were considered as the adsorbent, and an adsorbent dose of 2 g/L is selected.

Sorption Kinetics

The sorption kinetics of selected pharmaceuticals in the mix-solution was assessed. In this set of experiments, only ACEco and ACDarco were selected, given that impregnation of Ce has not improved the sorption of those pharmaceuticals. In the kinetics test, the dose of ACs was taken as 2 g/L, and the concentration of IBP (23.93 ± 2.18 mg/L), DCF (14.39 ± 1.43 mg/L), and CBZ (17.81 ± 0.78 mg/L) was taken in close proximity. The batch experiment was conducted at a pH of 7 and 27°C temperature. The pseudo-first-order, pseudo-second-order, and Weber–Morris models were fitted to the experimental data.

The sorption kinetics data presented in Fig. 3 indicates that the extent of sorption was relatively high for CBZ by both ACs. The sorption was reported to slow at the initial stage for IBP, and at a later stage, it increased sharply. DCF shows a comparatively lesser extent of sorption at equilibrium. The fitting parameters for pseudo-first-order, pseudo-second-order, and Webber–Morris models are presented in Table 1. The result indicates that the sorption kinetics of IBP by ACEco (R2: 0.949), and ACDarco (R2: 0.962), and the kinetics of CBZ by ACEco (R2: 0.998) were better fitted to the pseudo-first-order model. This probably indicates physisorption is likely to be the rate-limiting factor for IBP sorption [17]. Sorption kinetics of DCF by both ACEco (R2: 0.965) and ACDarco (R2: 0.993) and of CBZ by ACDarco (R2: 0.999) were observed to better fit the pseudo-second-order kinetic model. This probably suggests that chemisorption is likely to be the rate-determining mechanism for those cases. The rate of sorption of IBP, DCF and CBZ were noted to be 0.015 g/mg/min, 0.044 g/mg/min, and 0.092 g/mg/min by ACEco and are 0.020, 0.193, and 0.121 g/mg/min by ACDarco, respectively. The rate of sorption by different biochar-based material under similar conditions are reported in the range of 0.001–1.491 g/mg/min [18–20]. This suggests that the sorption rates of selected pharmaceuticals by ACs used in this study were reasonably good and fall in ranges reported in other studies. Korzh et al. demonstrated the adsorption behaviour of activated carbons for the removal of various emerging contaminants such as caffeine, levamisole, procaine, sulfanilamide, and sulfathiazole. The studies demonstrated that the sorption rate depends on the organizations of micropores and surface characteristics of adsorbate molecules [21, 22].

The FTIR results (Fig. S1 (ESM_1.pdf)) indicate the appearance and shifts of several peaks between 400 and 1600 cm–1 after sorption. The peaks appear at a wavenumber of 714, 735, 1171, 1264, 1438, and 1458 cm–1 in the case of ACEco, and 796, 776, 1090, and 1166 cm–1 in the case ACDarco clearly indicates the addition of benzene or aromatic compound after the sorption. However, the SEM image (Fig. S2 (ESM_1.pdf)) indicates not much difference in the morphology of ACs after sorption of those pharmaceuticals.

The fitting of the Weber–Morris model to the kinetics data (Table 1, Fig. S3 (ESM_1.pdf)) indicates that the rate of diffusion was maximum for CBZ (4.43–5.07 mg/g/\(\surd \)min) followed by DCF (1.83–3.22 mg/g/\(\surd \)min) and IBP (0.8–1.07 mg/g/\(\surd \)min) by both the ACs. This observation was also in accordance with the sorption data that suggests CBZ has more affinity towards sorption active sites of ACs, as indicated earlier. The model fit (Fig. S3 (ESM_1.pdf)) indicates that for DCF, when ACEco was used as the adsorbent, the qt varies linearly with √t, and the line passes through the origin. This possibly implies that the rate of sorption of DCF by ACEco is likely to be limited by the intraparticle diffusion process [23]. Fitting the Weber Morris model to the kinetics data for IBP and CBZ by both the ACs and of DCF by ACDarco indicates multiple lines that were not passing through the origin can fit the data. This observation probably suggests that adsorption was being limited by multiple processes that include bulk phase mass transfer, boundary layer diffusion, and solid-phase mass transfer.

where \({{q}_{t}}\) is sorption at time t, \({{q}_{{e1}}}~\,\,{\text{and }}~{{q}_{{e2}}}~\) fitted value of equilibrium sorption for pseudo-first-order and pseudo-second-order kinetic model, k1, k2, and k3 the rate constant fitted to pseudo-first-order, pseudo-second-order and Webber–Morris model, respectively.

CONCLUSIONS

The pharmaceuticals such as ibuprofen (IBP), diclofenac (DCF), and carbamazepine (CBZ) have a wide range of applications, and trace amounts of those contaminants are detected in different components of the environment. The removal of IBP, DCF, and CBZ by coconut shell (ACEco) and lignite (ACDarco) derived activated carbon-based adsorbent after and before impregnation of cerium were assessed. The removal efficiencies of the selected pharmaceuticals by those ACs were reported in the range of 76.7–100% and 66.2–99.7% when the pharmaceuticals are applied as a single entity or as a mixture in a solution, respectively. In the case of IBP and DCF, the removal efficiencies were noted to decrease slightly by ACEco and ACEco-Ce when the mix of pharmaceuticals is used compared to that when individual pharmaceuticals was applied. Furthermore, the results show that the impregnation of Ce in both types of ACs has not improved the removal efficiencies of the pharmaceuticals. Thus, for further studies, only ACEco and ACDarco were taken as the reference adsorbents. The sorption kinetics of IBP (for both ACEco and ACDarco) and CBZ (ACEco) were best fitted to the pseudo-first-order kinetics model, where the sorption of DCF (both for ACEco and ACDarco) and CBZ (ACDarco) were found to have a better fit to the pseudo-second-order kinetics model. Overall, the study indicates, both ACEco and ACDarco can be effectively used for the removal of IBP, DCF, and CBZ from water, and the performance was promising when those are present in a mixture in the solution which is likely to be present in the natural condition.

REFERENCES

Chhaya, Raychoudhury, T., and Prajapati, S.K., Bioremediation of pharmaceuticals in water and wastewater, in Microbial Bioremediation and Biodegradation, Singapore: Springer, 2020, pp. 425–446.

Chhaya, Dibyanshu, Singh, S., and Raychoudhury, T., Nanoparticles and nanocomposite materials for water treatment: Application in fixed bed column filter, in Sustainable Water Treatment: Advances and Technological Interventions, New York: Wiley, 2022, pp. 171–244.

Gao, X., Tang, G., Peng, W., Guo, Q., and Luo, Y., Surprise in the phosphate modification of BiOCl with oxygen vacancy: In situ construction of hierarchical Z-scheme BiOCl–OV–BiPO4 photocatalyst for the degradation of carbamazepine, Chem. Eng. J., 2019, vol. 360, pp. 1320–1329. https://doi.org/10.1016/j.cej.2018.10.216

Alhooshani, K.R., Adsorption of chlorinated organic compounds from water with cerium oxide-activated carbon composite, Arab. J. Chem., 2019, vol. 12, no. 8, pp. 2585–2596. https://doi.org/10.1016/J.ARABJC.2015.04.013

Cheng, S., Zhang, L., Ma, A., Xia, H., Peng, J., Li, C., and Shu, J., Comparison of activated carbon and iron/cerium modified activated carbon to remove methylene blue from wastewater, J. Environ. Sci., 2018, vol. 65, pp. 92–102. https://doi.org/10.1016/J.JES.2016.12.027

Goscianska, J., Marciniak, M., and Pietrzak, R., Ordered mesoporous carbons modified with cerium as effective adsorbents for azo dyes removal, Sep. Purif. Technol., 2015, vol. 154, pp. 236–245. https://doi.org/10.1016/J.SEPPUR.2015.09.042

Kalidindi, S., Vecha, M., Kar, A., and Raychoudhury, T., Aluminum–cerium double-metal impregnated activated carbon: A novel composite for fluoride removal from aqueous solution, Water Sci. Technol. Water., 2017, vol. 17, no. 1, pp. 115–124. https://doi.org/10.2166/ws.2016.114

Yu, Y., Zhang, C., Yang, L., and Paul Chen, J., Cerium oxide modified activated carbon as an efficient and effective adsorbent for rapid uptake of arsenate and arsenite: Material development and study of performance and mechanisms, Chem. Eng. J., 2017, vol. 315, pp. 630–638. https://doi.org/10.1016/J.CEJ.2016.09.068

Raychoudhury, T., Boindala, S.P., and Kalidindi, S., Performance evaluation of metal impregnated activated carbon composite for removal of fluoride under varying solution chemistry, Water Sci. Technol.: Water Supply, 2017, vol. 17, no. 5, pp. 1377–1385. https://doi.org/10.2166/ws.2017.040

Faisal, H.A., Kar, A., and Raychoudhury, T., Fluoride removal by novel composite material and its performance in the fixed-bed column filter, Curr. Sci., 2019, vol. 116, no. 12, p. 00113891. https://doi.org/10.18520/cs/v116/i12/2072-2077

Chen, J., Dai, Q., Wang, J., and Chen, J., Ozonation catalyzed by cerium supported on activated carbon for the degradation of typical pharmaceutical wastewater, Sep. Purif. Technol., 2014, vol. 127, pp. 112–120. https://doi.org/10.1016/J.SEPPUR.2014.01.032

Ren, X., Chen, C., Nagatsu, M., and Wang, X., Carbon nanotubes as adsorbents in environmental pollution management: A review, Chem. Eng. J., 2011, vols. 2–3, pp. 395–410. https://doi.org/10.1016/j.cej.2010.08.045

Lung, I., Soran, M.L., Stegarescu, A., Opris, O., Gutoiu, S., Leostean, C., Lazar, M.D., Kacso, I., Silipas, T.D., and Porav, A.S., Evaluation of CNT-COOH/MnO2/Fe3O4 nanocomposite for ibuprofen and paracetamol removal from aqueous solutions, J. Hazard. Mater., 2021, vol. 403, p. 123528. https://doi.org/10.1016/j.jhazmat.2020.123528

Mondal, S., Bobde, K., Aikat, K., and Halder, G., Biosorptive uptake of ibuprofen by steam activated biochar derived from mung bean husk: Equilibrium, kinetics, thermodynamics, modeling and eco-toxicological studies, J. Environ. Manage., 2016, vol. 182, pp. 581–594. https://doi.org/10.1016/j.jenvman.2016.08.018

Shirani, Z., Song, H., and Bhatnagar, A., Efficient removal of diclofenac and cephalexin from aqueous solution using Anthriscus sylvestris-derived activated biochar, Sci. Total Environ., 2020, vol. 745, p. 140789. https://doi.org/10.1016/j.scitotenv.2020.140789

Ghaedi. M., Ansari, A., Habibi, M.H., and Asghari, A.R., Removal of malachite green from aqueous solution by zinc oxide nanoparticle loaded on activated carbon: Kinetics and isotherm study, J. Ind. Eng. Chem., 2014, vol. 20, no. 1, pp. 17–28. https://doi.org/10.1016/j.jiec.2013.04.031

Junejo, R., Memon, S., Memon, F.N., Memon, A.A., Durmaz, F., Bhatti, A.A., and Bhatti, A.A., Thermodynamic and kinetic studies for adsorption of Reactive Blue (RB-19) dye using calix[4]arene-based adsorbent, J. Chem. Eng. Data., 2019, vol. 64, no. 8, pp. 3407–3415. https://doi.org/10.1021/ACS.JCED.9B00223

Baccar, R., Sarrà, M., Bouzid, J., Feki, M., and Blánquez, P., Removal of pharmaceutical compounds by activated carbon prepared from agricultural by-product, Chem. Eng. J., 2012, vols. 211–212, pp. 310–317. https://doi.org/10.1016/j.cej.2012.09.099

Baghdadi, M., Ghaffari, E., and Aminzadeh, B., Removal of carbamazepine from municipal wastewater effluent using optimally synthesized magnetic activated carbon: Adsorption and sedimentation kinetic studies, J. Environ. Chem. Eng., 2016, vol. 4, no. 3, pp. 3309–3321.

Viotti, P.V., Moreira, W.M., dos Santos, O.A.A., Bergamasco, R., Vieira, A.M.S., and Vieira, M.F., Diclofenac removal from water by adsorption on Moringa oleifera pods and activated carbon: Mechanism, kinetic and equilibrium study, J. Cleaner Prod., 2019, vol. 219, pp. 809–817. https://doi.org/10.1016/j.jclepro.2019.02.129

Korzh, E.A., Smolin, S.K., and Klymenko, N.A., Kinetics of adsorption of pharmaceutical substances from aqueous solutions on activated carbons, J. Water Chem. Technol., 2016, vol. 38, no. 4, pp. 187–193. https://doi.org/10.3103/S1063455X16040019

Korzh, E.A., Smolin, S.K., and Klymenko, N.A., Impact of characteristic of activated carbons on the efficiency of removal from water of pharmaceutical preparations of various chemical nature, J. Water Chem. Technol., 2016, vol. 38, no. 2, pp. 83–88. https://doi.org/10.3103/S1063455X16020041

Campos, N.F., Barbosa, C.M., Rodríguez-Díaz, J.M., and Duarte, M.M., Removal of naphthenic acids using activated charcoal: Kinetic and equilibrium studies, Adsorpt. Sci. Technol., 2018, vol. 36, nos. 7–8, pp. 1405–1421. https://doi.org/10.1177/0263617418773844

Funding

We would also like to thank the Department of Science and Technology for supporting the work under the program INSPIRE-Fellowship (no. DST/INSPIRE Fellowship/2018/IF180765).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Supplementary Information

About this article

Cite this article

Chhaya, Bag, R. & Raychoudhury, T. Pharmaceutical-Based Emerging Contaminants Removal from Aqueous Solution by Different Granular Activated Carbon-Based Adsorbents. J. Water Chem. Technol. 45, 411–418 (2023). https://doi.org/10.3103/S1063455X23050041

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1063455X23050041