Abstract

The interaction between the spectral characteristics of laser diodes is considered along with the possibility of establishing the optimum pump current for their maximum service life. The relationship between approximated spectral lines of irradiation and their variances caused by characteristic features of the laser driver during pump tuning is investigated experimentally and analytically.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

INTRODUCTION

Single-mode laser diodes (LDs) with highly stable power and radiation wavelengths are of practical interest to developers of precision measuring systems. The power regime of an LD is considered optimal if a number of conditions are fulfilled. First, the radiation power must be maintained at the required level. Second, the fundamental mode must be generated. Third, the service life must be long enough to avoid having to replace moduli under emergency conditions.

The survey of the literature presented in [1] showed convincingly that a low-inertia feedback link with a service life of at least 50 000 h is needed to obtain a laser power regime that ensures the required fundamental mode generation and its stability for 5000–10 000 h. Priority is given to controlling the parameters of the LD power source (i.e., the voltage at the driver input and the pump current of the laser diode [2, 3]).

An LD’s generation of the fundamental mode is controlled by measuring its radiation patterns and using quantitative analysis to process them [2–6]. A considerable shortcoming of this means of control is the need to remove the LD from the measuring system. The service life of state-of-the-art LDs is determined via accelerated tests (i.e., at elevated ambient temperatures), which also requires that moduli be removed from the measuring system [1].

The aim of this work was to develop a way of optimizing and controlling the parameters of an LD power supply of without having to remove it from the optoelectronic apparatus. The only way of exercising such control is to analyze the current’s dependence on the spectral characteristics of the LD.

OPTIMIZING THE POWER SUPPLY OF LASER DIODES EMBEDDED IN PRECISION MEASURING SYSTEMS

Two demands were considered in developing our way of optimizing the regime of LD generation. First, generation of the fundamental mode and a long service life had to be ensured. Second, to avoid prolonged analysis of LD spectral characteristics, we had to use results obtained earlier for laser diodes in which these two conditions are met at certain values of pump current ild opt (i.e., when function \({{f}_{{{\text{emp}}}}}(\nu ),\) describing the envelope of the experimental radiation spectrum of the LD can be approximated by a Gaussian [5, 6]).

Since the pump current is the main parameter of an LD’s power supply, optimizing the module’s power mode requires that we determine it as ild opt.

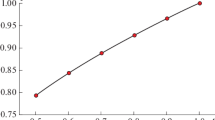

The first step in determining parameter \({{i}_{{{\text{ld}}\;{\text{opt}}}}}\) is establishing the pump current values to analyze current dependence \({{f}_{{{\text{emp}}}}}(\nu ).\) To determine the boundary values, we must measure the current–voltage characteristics (CVCs) of the LD. A typical LD CVC is shown in Fig. 1.

CVCs can be approximated by two linear segments with strongly differing tilt angles. No analysis of functions \({{f}_{{{\text{emp}}}}}(\nu )\) was done at pump currents within the range of CVCs that had a pronounced dependence of the pump current on the voltage at the LD input, since even small voltage fluctuations Uin of the power supply drastically alter the pump current and thus result in strong instability of the radiation parameters.

The range of CVCs with small tilt angles corresponds to the LD supply voltages at which the driver operates in the mode of limiting the pump current. Over the range of Uin at the input of a driver operating in this mode, there is a notable drop in pump current fluctuations upon varying Uin, which ensures high stability of the LD radiation parameters.

Since the tilt angle of a CVC is quasi-constant within a Uin range of 3 to 5 V, the same degree of stability of the LD radiation parameters can be achieved at any level of Uin in the above range [7].

The developers of LDs recommend using a power supply with an output voltage of 5 V. This is because such voltage at the driver input ensures not only the steady operation of the driver but also the maximum LD radiation power. In addition to a rise in radiation power, analysis of the current dependence of the \({{f}_{{{\text{emp}}}}}(\nu )\) function reveals the long-wave shear of the LD radiation spectrum. This shear can be attributed to the growing pump current of the LD and to the rise in the temperature of the LD heterostructure induced by this increase in pump current. To determine the boundaries of the range of pump currents with the optimum ild opt value, a quantitative analysis of the \({{f}_{{{\text{emp}}}}}(\nu )\) function was performed with different voltages at the driver input and thus the LD pump currents.

Function \({{f}_{{{\text{emp}}}}}(\nu )\) was compared to a Gaussian within width \(\Delta \nu ,\) of the line enveloping the radiation spectrum of a laser diode with central frequency ν0 of the line. The measure of the deviation of function \({{f}_{{{\text{emp}}}}}(\nu )\) from the Gauss function in range \(\Delta \nu \) of frequencies is parameter A, which is defined so that function \({{f}_{{{\text{emp}}}}}(\nu )\) almost matches the Gaussian (Fig. 2) if A → 1. According to [6], this means the LD is operating in the fundamental mode, and its service life is at the maximum level for a series of devices manufactured within a single technological cycle.

A refined analysis of the \({{f}_{{{\text{emp}}}}}(\nu )\) function was performed that considered criterion A > 0.855 [6]. The coincidence between parameters A measured in accordance with this criterion shows that the laser diode is operating in the regime of fundamental mode generation.

The service life of LDs in a series of devices mass produced within the same technological cycle was found to vary from 2500 to 3500 h. In addition to parameter A, the quality of each LD from one series or another was estimated using parameter T:

where τ is the real-time service life of an LD from a given series of devices, and τmax is the maximum operating time of an LD from the same series.

Parameters Т and А when A > 0.855 (i.e, in the LD generation of the fundamental mode) were established to be correlated:

The dependence of the current on the radiation spectrum of an LD-3 laser diode enabled us to determine optimum value ild opt of its pump current. According to Eqs. (1) and (2). the service life of an LD grows along with parameter А. Analysis of the power regime of an LD-3 diode revealed that the maximum value of parameter А is reached at a pump current of 25.7 mA and a voltage at the driver input of 3 V (i.e., within the weak dependence of the LD pump current on Uin).

Along with the LD-3 diode, we considered the power supply regimes of operation for LD-2 and LD‑5 laser modules. As with the LD-3, these were manufactured in a single technological cycle and had the same CVCs. However, the LD-2 pump current of 24.7 mA at which parameter А reaches a maximum of 0.970 lies within the strong dependence of the pump current on Uin, thus preventing us from considering it as \({{i}_{{{\text{ld}}\;{\text{opt}}}}}.\) The optimum value of the LD-2 pump current was therefore assumed to be 26.1 mA, though parameter А was equal to 0.960, which is less than at a current of 24.7 mA.

Analysis of a series of devices revealed that LDs manufactured in a single technological cycle had the same bottom boundary of the sloping part of their CVCs. This allowed us to determine for each series of LDs input voltage Uinmin on the driver above which it operates as a pump current limiter.

LD input voltage Uin was equal to the output voltage of the power supply, excluding the possibility of using a pump current meter and complicating the scheme for controlling the LD power regime.

The LD-105 model contains a laser with a power of 40 mW. Figure 3 shows the CVC of this LD. The variation in pump current is limited by the condition that A > 0.855. From the CVC of the LD-105, we can see that given this limitation, the optimum pump current is 85.6 mA at Uin = 4.5 V.

CONCLUSIONS

A way of optimizing an LD supply power mode was considered, based on an analysis of current dependence fexp(ν) enveloping the LD radiation spectrum. Integrated spectral parameter A was chosen so that as A → 1, function fexp(ν) matched the Gaussian. It was established experimentally that the LD power regime is optimal if there is generation of the fundmental mode and A → 1. At the same time, optimum pump current ild opt must lie within the characteristic voltammeric range with a weak dependence of the pump current on the voltage at the input to the LD driver.

REFERENCES

Zhukov, A.E., Osnovy fiziki i tekhnologii poluprovodnikovykh lazerov (Physics and Technology of Semiconductor Lasers), St. Petersburg: Akadem. Univ., 2016.

Leshko, A.Yu., Lyutetskii, A.V., Pikhtin, N.A., Slipchenko, S.O., Sokolova, Z.N., Fetisova, N.V., Golikova, E.G., Ryaboshtan, Yu.A., and Tarasov, I.S., Semiconductors, 2002, vol. 36, no. 11, p. 1308.

Gordeev, N.Yu., Novikov, I.I., Kuznetsov, A.M., Shernyakov, Yu.M., Maximov, M.V., Zhukov, A.E., Chunareva, A.V., Payusov, A.S., Livshits, D.A., and Kovsh, A.R., Semiconductors, 2010, vol. 44, no. 10, p. 1357.

Bliznyuk, V.V., Berezovskaya, N.V., Brit, M.A., Koval, O.I., Parshin, V.A., and Rzhanov, A.G., Bull. Russ. Acad. Sci.: Phys., 2017, vol. 81, no. 1, p. 1.

Bliznyuk, V.V., Berezovskaya, N.V., Parshin, V.A., and Tarasov, A.E., Dokl. Tomsk.Gos. Univ. Sist. Upr. Radioelektron., 2016, vol. 19, no. 3, p. 55.

Bliznyuk, V.V., Berezovskaya, N.V., Brit, M.A., et al., Phys. Wave Phenom., 2017, vol. 25, no. 2, p. 95.

Eliseev, P.G. and Akimova, I.V., Semiconductors, 1998, vol. 32, no. 4, p. 428.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by O. Maslova

About this article

Cite this article

Bliznyuk, V.V., Galstyan, K.P., Grigoriev, V.S. et al. Analyzing the Spectral Characteristics of Laser Diodes to Optimize Their Pumping. Bull. Russ. Acad. Sci. Phys. 84, 27–29 (2020). https://doi.org/10.3103/S1062873820010086

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1062873820010086