Abstract

A special type of diffusive discharge (glow discharge) on which a low-current spark discharge is superimposed is created experimentally in a gas flow, in the form of atmospheric pressure plasma jets. The flow of current in the discharge gap is a steady regime of periodical current pulses. A highly efficient portable low-temperature nonequilibrium argon plasma source (the PortPlaSter) is designed on the basis of this glow discharge with superimposed low-current spark discharges.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

INTRODUCTION

Studies aimed at developing the physical principles of creating and technically implementing fundamentally new types of low-temperature non-equilibrium plasma sources based on atmospheric pressure plasma jets (APPJ) have grown rapidly in recent years [1–5]. The field of plasma jet applications is expanding quickly, and new lines of investigation are emerging: studying the use of plasma jets in systems for plasma combustion, the conversion (reforming) of hydrocarbons, and surface modification (especially with low–melting point dielectrics) [1, 6]. A promising field of plasma jet application is plasma medicine [7–11]. The use of low-temperature nonequilibrium argon plasma is now one of the most preferred approaches that ensure the activation of an immune response and the processes of healing, along with reducing the microbial contamination of infected wounds and ulcers without creating new multiresistant strains [12, 13].

A conventional plasma jet is formed in a discharge (e.g., glow, arc, radio-frequency, barrier) and exits through a narrow nozzle due to the excess atmospheric pressure in the discharge zone. Present-day domestic and foreign plasma coagulators and decomposers with small plasma areas and plasma temperatures of 3000–4000°С at the outlet are mainly designed for the dissection, removal, destruction, and evaporation of soft and dense tissues, along with coagulation. This considerably narrows the possibilities of using them for the effective treatment of large thermosensitive surfaces (including wounds), since it results in surface damage and the destruction of animal and human tissues.

In light of the above, the requirements for plasma sources that generate low-temperature argon plasma for the disinfection and sterilization of large surfaces, including infected wounds and non-healing ulcers, are notably different from those for scalpel–coagulator–stimulator plasma sources. The parameters of low-temperature argon plasma and the characteristics of an operational plasma generator must ensure the annihilation of highly resistant pathogenic microflora over large surfaces (including wounds), exclude additional damage to wound tissues, and initiate the healing of infected wounds.

The problem of obtaining a volume nonequilibrium plasma on a large surface can be now be solved using different devices that consist of plasma jet systems with special ways of controlling the process [14‒16].

A model of a stationary low-temperature argon plasma generator for treating large infected wounds and ulcers was created in 2007 [17–21]. It was proposed that a multi-electrode microwave generator using argon as a plasma-forming gas (purity, 99.999%) with the controllable introduction of other gases (e.g., CO2, N, or air) be used to create a plasma jet [22].

A fundamentally new approach to designing an atmospheric pressure plasma jet was discussed in [1, 6, 23], based on a special way of forming a nonstationary discharge in a vortex gas flow. The discharge is a low-current glow-like discharge on which brief high-current spark discharge pulses (produced by spontaneous glow-to-spark discharge transitions) with a typical duration of 100 ns are superimposed.

A spatial discharge structure is a column of glow discharge and a background of weakly ionized gas filling a plasmatron nozzle. The discharge burns in the form of a glow discharge with eventual transitions to a spark discharge. The spark discharges are low-current with an energy input on the level of 1 mJ [1].

Spark discharges are known as a form of nonstationary electric discharges in dense gas media (~105 Pa) that emerge at the final stage of the process referred to as electrical breakdown on the gas gap [24‒26]. The intensity of a spark discharge is associated with the energy released per unit length, and sparks with a linear energy release of less than several J/cm are characterized as moderate and weak [27, 28].

In light of the above, plasma jets based on a low-current spark discharge are an effective and simple way of generating low-temperature (cold) nonequilibrium argon plasma [29, 30], due to their technical simplicity and attractive characteristics (e.g., strong plasma disequilibrium [27], low temperature of the gas, and the possibility of obtaining a volume plasma).

EXPERIMENTAL

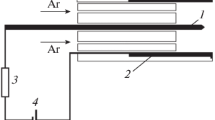

A low-temperature nonequilibrium plasma source based on low-current spark discharge plasma jets was developed to generate a low-temperature (cold) argon plasma. A schematic of the corresponding experimental setup is shown in Fig. 1. The discharge chamber contains tip cathode 1 with a 30-µm radius of tip curvature. The cathode is installed on the axis of the insulator in a cylindrical dielectric housing with a diameter of 2 cm. Anode 2 is a metal cylinder 1.5 cm long with an internal diameter of 2.5 cm, spanning the tip cathode coaxially. To stabilize a discharge, the tip cathode is loaded by tunable ballast resistance 3. The insulator is equipped with longitudinal bores for feeding in argon. A constant voltage as high as 10 kV is fed in from tunable high-voltage source 4. Ballast voltage 3 in the external circuit varies from 10 to 63 MΩ. Argon consumption G is measured up to 28 × 10—3 kg/s using rotameters.

RESULTS AND DISCUSSION

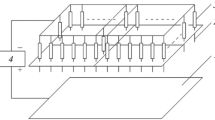

Upon reaching critical voltage U applied to the tip cathode through the high ballast resistance (>1 MΩ), a special form of a glow-like discharge is excited, on which low-current spark discharges are superimposed (Fig. 2) [1, 6]. A characteristic feature of such discharges is that they emerge in a gas flow.

The spatial structure of a discharge is a dimly glowing region inside it that covers the entire area of the source nozzle. The spontaneous formation of low-current sparks is also observed. Low-current sparks are visible as thin white strands of current overlapping the discharge gap. Raising voltage U results in denser filling of the discharge gap by spark discharges (Fig. 2). The low-temperature nonequilibrium plasma formed by the argon flow as a plasma jet exits from the discharge gap. The diameter of the plasma jet is 2.5 cm and it is 1–2 cm long at a low level of gas consumption (G < 15 × 10−3 kg/s). The temperature of the argon torch at a distance of 0.5 cm from the generator nozzle is on the level of room temperature (18–20°С).

The current passing through the discharge gap is a series of periodic current pulses. The current pulse amplitude of a low-current spark rises as gas consumption G increases, due to elongation of the plasma jet. The discharge current can be tuned by changing the voltage of the power supply and the ballast resistance. Reducing the ballast resistance substantially narrows the region of the discharge current. The volume form of discharge combustion breaks down, and the mode of constricted glow discharge is achieved. The current’s region of combustion uniformity and discharge stability grow along with gas consumption G.

We determined the distribution of the potential of a mesh probe in a plasma jet at the exit from the generator nozzle. The probe consists of a metal mesh with a diameter of 2.5 cm, and the size of the cell is 0.5 mm. The potential falls drastically as the distance from the generator nozzle increases. It is worth noting that the potential at a distance of ≥3 cm from the nozzle is not zero, testifying to the presence of charged particles. The higher the rate at which the gas is pumped through the discharge gap of the generator, the higher the potential.

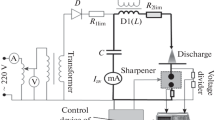

A portable plasma complex (Fig. 3) was thus designed. It consists of a DC source, a system of gas supply and control, and a PortPlaSter portable low-temperature (cold) argon plasma source based on low-current spark discharge plasma jets. The portable plasma source is a metal tip electrode with a diameter of 1.5 mm and a radius of curvature of 18 µm. The electrode is placed inside a grounded metal cylinder with an internal diameter of 0.8 cm.

CONCLUSIONS

A special form of diffusion discharge (a glow discharge on which low-current spark discharges are superimposed) was achieved experimentally. This type of discharge is formed in a gas flow by atmospheric pressure plasma jets. The current in the discharge gap flows in a steady regime of periodic current pulses. The highly efficient PortPlaSter portable low-temperature nonequilibrium argon plasma source was developed on the basis of this special form of discharge.

REFERENCES

Korolev, Yu.D., Russ. J. Gen. Chem., 2015, vol. 85, no. 5, p. 1311.

Schutze, A., Jeong, J.Y., Babayan, S.E., et al., IEEE Trans. Plasma Sci., 1998, vol. 26, no. 6, p. 1685.

Kirillov, A.A., Pavlova, A.V., Safronov, E.A., et al., Prikl. Fiz., 2013, no. 5, p. 52.

Sosnin, E.A., Panarin, V.A., Skakun, V.S., Tarasenko, V.F., Pechenitsin, D.S., and Kuznetsov, V.S., Tech. Phys., 2016, vol. 61, no. 5, p. 789.

Savkin, K.P., Nikolaev, A.G., Oks, E.M., et al., Usp. Prikl. Fiz., 2017, vol. 5, no. 6, p. 549.

Korolev, Y.D., Frants, O.B., Nekhoroshev, V.O., Suslov, A.I., Kas’yanov, V.S., Shemyakin, I.A., and Bolotov, A.V., Plasma Phys. Rep., 2016, vol. 42, no. 6, p. 592.

Montie, T.C., Kelly-Wintenberg, K., and Roth, J.R., IEEE Trans. Plasma Sci., 2000, vol. 28, p. 41.

Daeschlein, G., von Woedtke, T., and Kindel, E., Plasma Processes Polym., 2010, vol. 7, nos. 3–4, p. 224.

Lee, H.W., Nam, S.H., Mohamed, A.H., et al., Plasma Processes Polym., 2010, vol. 7, p. 274.

Jeong, J.Y., Babayan, S.E., Tu, V.J., et al., Plasma Sources Sci. Technol., 1998, vol. 7, no. 4, p. 282.

Fricke, K., Hartmut, S., von Woedtke, T., et al., Plasma Processes Polym., 2011, vol. 8, no. 1, p. 51.

Ermakov, A.M., Ermakova, O.N., Maevskii, E.I., et al., Medline.ru, 2010, vol. 11, p. 160.

Ermakov, A.M., Ermakova, O.N., Maevskii, E.I., et al., Medline.ru, 2011, vol. 12, p. 948.

Foest, R., Kindel, E., Ohl, A., et al., Plasma Phys. Controlled Fusion, 2005, vol. 47, no. 12B, p. B525.

Ehlbeck, J., Ohl, A., Maaß, M., et al., Surf. Coat. Technol., 2003, vols. 174–175, p. 493.

Weltmann, K.D., Brandenburg, R., von Woedtke, T., et al., J. Phys. D, 2008, vol. 41, p. 194008.

Shimizu, T., Nosenko, T., Morfill, G.E., et al., Plasma Processes Polym., 2010, vol. 7, p. 288.

Shimizu, T., Steffes, B., Pompl, R., et al., Plasma Processes Polym., 2008, vol. 5, p. 577.

Isbary, G.A., Morfill, G., Schmidt, H.U., et al., Br. J. Dermatol., 2010, vol. 163, p. 78.

Isbary, G., Zimmermann, J.L., Shimizu, T., et al., Clin. Plasma Med., 2013, vol. 1, p. 19.

Isbary, G., Heinlin, J., Shimizu, T., et al., Br. J. Dermatol., 2012, vol. 167, p. 404.

Maevskii, E.I., Bogdanova, L.A., Selezneva, I.I., et al., Medline.ru, 2009, vol. 10, p. 198.

Korolev, Yu.D. and Mesyats, G.A., Fizika impul’snogo proboya gazov (The Physics of Impulse Breakdown of Gases), Moscow: Nauka, 1991.

Bazelyan, E.M. and Raizer, Yu.P., Iskrovoi razryad (Spark Discharge), Moscow: Mosk. Fiz.-Tekh. Inst., 1997.

Meek, J.M. and Craggs, J.D., Electrical Breakdown of Gases, Clarendon, 1954.

Raizer, Yu.P., Fizika gazovogo razryada (Gas Discharge Physics), Moscow: Nauka, 1992.

Akishev, Yu.S., Aponin, G.I., Grushin, M.E., Karal’nik, V.B., Monich, A.E., Pan’kin, M.V., and Trushkin, N.I., Plasma Phys. Rep., 2007, vol. 33, no. 7, p. 584.

Rep’ev, A.G., Repin, P.B., and Danchenko, N.G., Tech. Phys. Lett., 2007, vol. 33, no. 12, p. 1011.

Baldanov, B.B., Semenov, A.P., Ranzhurov, Ts.V., Nikolaev, E.O., and Gomboeva, S.V., Tech. Phys., 2015, vol. 60, no. 11, p. 1729.

Semenov, A.P., Baldanov, B.B., Ranzhurov, Ts.V., et al., Prikl. Fiz., 2014, no. 3, p. 47.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by O. Maslova

About this article

Cite this article

Baldanov, B.B., Semenov, A.P. & Ranzhurov, T.V. Source of a Volume Plasma Jet Based on a Low-Current Nonstationary Discharge. Bull. Russ. Acad. Sci. Phys. 83, 1407–1409 (2019). https://doi.org/10.3103/S1062873819110066

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1062873819110066