Abstract

The sorption properties of a modified ethylenediamine humate (EDA–H) sorbent toward Co2+ and Ni2+ metal ions are considered. The results of the influence of sorbent norm (0.05–2.0 g), process time (15–120 min), and metal concentration (0.005, 0.05, and 0.5 g/L) are presented. The advanced extraction of cobalt(II) in solutions with low and medium metal concentrations (0.005–0.05 g/L) and nickel(II) in solutions with a high concentration of cations (0.5 g/L) were detected. Based on the data of physicochemical analysis, it can be assumed that complexation with the sorbent occurred in the course of Co(II) and Ni(II) metal sorption by the sorbent.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Humic substances are natural organic compounds, which contain from 50 to 90% organic matter of peat and coals; they are mixtures of complex high-molecular-weight substances with various functional groups. Humic substances are environmentally friendly, nontoxic, and cheap organic compounds of natural origin with sorption properties [1, 2]. Due to their chemical structure, humic substances can undergo chemical modification to provide the ability to form stable complexes with heavy metal cations [3]. Chemical modification, after which existing properties are improved and new ones appear, is an effective method to develop new sorbents based on humic compounds.

Methods for the methylation of humic substances were described in the literature. The modification was carried out using methylating agents: diazomethane [4, 5] and methyl iodide in the presence of silver oxide, methanol in the presence of HCl or BF3 [6], and dimethyl sulfate [7]. Both phenolic hydroxyls and carboxyl groups were methylated with the use of diazomethane in an ether solution. The concentrations of carboxyl, phenol, and alcohol groups in the structure of humic substances were determined by varying methylation methods and the subsequent processing of the derivative. Methylation experiments with dimethyl sulfate, which led to the modification of phenolic and alcohol groups in humic substances, were carried out [8, 9]. In methylation with methanol, a reaction occurred at their carboxyl groups.

Humic substances were modified by trimethylsilylation followed by the measurement and processing of 29Si NMR spectra [10]. According to experimental data, the trimethylsilylation reaction of humic substances proceeds with the replacement of protons in various functional groups (–OH, =NH, –NH2, –SH, and –COOH) by the silyl group. This leads to disintegration of humic substances. The modification of humic substances by silylation allows one to measure NMR spectra with a higher peak resolution [11].

Hua et al. [12] prepared an absorbing composite by the polymerization of acrylic acid and acrylamide in an aqueous solution using N,N'-methylenebisacrylamide as a crosslinking agent and ammonium persulfate as an initiator in the presence of sodium humate and kaolin. They studied the rate of swelling and the effects of various salt solutions and the pH of external solutions on the absorption of water by highly absorbing composites. The results showed that composites containing 20% sodium humate and 30% kaolin exhibited maximum water absorption of 450 and 39 g/L in a 0.9% solution of NaCl.

The modification of humic acids (HAs) with synthetic polymers was carried out in numerous studies. Graft copolymerization and copolycondensation reactions are the main methods for introducing synthetic polymers into the composition of natural polymers [13, 14]. The grafting of vinyl monomers, such as acrylonitrile, acrylic acid methyl methacrylate, acrylamide, and vinyl ethers, onto HA was carried out. The grafting was performed by copolymerization in aqueous–organic and aqueous solutions at different pH in the presence of peroxide or redox initiators, thereby creating active centers on the HA at which the polymerization of monomers occurred. The resulting graft copolymers of HA are effective soil forming agents, which exert a high growth-promoting and fertilizing effect [15]. Kasatochkin et al. [16] studied the copolycondensation of HAs with maleic anhydride in various dipolar aprotic solvents in the presence of mineral acids. Maleic anhydride copolymers can enter into various chemical reactions due to the high reactivity of anhydride groups.

The modified forms of humic compounds that can effectively bind heavy metals to form insoluble complex compounds are of paramount current interest [17]. In this regard, studies of the complexation and sorption properties of humic compounds with heavy metals are very relevant.

The compounds of cobalt and nickel belong to soluble salts, and toxic Co2+ and Ni2+ ions can be concentrated and accumulated in living organisms. Because of this, it is necessary to purify water, including wastewater, for the removal of these cations.

METHODS OF ANALYSIS

The following well-known methods were used in this study for determining the physicochemical properties of sorbents: infrared (IR) spectroscopy, atomic absorption spectrophotometry (AAS), and scanning electron microscopy (SEM).

The IR spectra were recorded on a Perkin Elmer Spectrum 100 IR spectrophotometer and a Specord M-80 double-beam spectrophotometer in a spectral range of 225–4000 cm–1. Samples for analysis were prepared according to a standard procedure by pressing with KBr. Before measuring the IR spectra, the test substance in an amount of 0.4–1.0 mg was introduced into a weighed portion of potassium bromide, and the mixture was pressed into a tablet.

The electron microscopic images of samples were taken on a JEOL JXA-8230 SEM instrument (Japan) and FEI QUANTA 250 FEG model electron microscope (the Netherlands) equipped with an EDAX detector (X-ray microanalyzer). The EDAX detector can operate simultaneously with a SEM instrument to combine elemental and structural analysis.

The yield of humic acids in the test samples was determined according to GOST [State Standard] 9517-94 [18], and the ash and moisture contents were found according to GOST 11022-95 [19] and GOST 11014-2001 [20], respectively.

The concentrations of metals in solutions were determined on Perkin Elmer AAnalyst 400 and ICE 3000 Series AAS instruments (the United States).

CHARACTERISTICS OF TEST SAMPLES AND INITIAL MATERIALS

Sodium humate, which was used in this study, was obtained by extraction from brown coal of the Shubarkul deposit (Republic of Kazakhstan, Almaty region), and it had the following characteristics: yield of humic acids (HAdaf ), 55.3%; moisture content (W а), 18.9%; ash content (Aa), 25.8%; average vitrinite reflection index (Ro, r), 1.12%, (σR) 0.04%; higher calorific value on a wet ash-free basis (\(Q_{s}^{{daf}}\)), 22.9 MJ/kg; and yield of volatile substances on the dry ash-free basis (V daf), 46%.

The modification of sodium humate was carried out using ethylene diamine at a temperature of 30°C and a process time of 48 h. Ethylene diamine–modified humate (EDA–H) with the following characteristics (wt %) was obtained: yield of humic acids (HAdaf ), 54.0; moisture content (W а), 18.0; and ash content (Aa), 28.0. According to the IUPAC classification, the modified sorbent had a porous structure with a specific surface area of 450 m2/g, a total pore volume of 0.23 cm3/g, and a pore diameter of 25.1 nm, which indicate the presence of a sufficient number of micropores in the porous structure of the sample. The mechanical strength of the modified EDA–H sorbent (D) was 89%. The resulting sorbent withstood three regeneration cycles without loss of physicochemical and sorption properties.

To study the sorption properties of the obtained sorbent, the metal salts Co(CH3COO)2 ⋅ 4H2O and NiSO4 ⋅ 6H2O were chosen. Weighed portions (0.05, 0.10, 0.25, 0.50, 1.0, 1.5, and 2.0 g) of the sorbent were added to a certain volume of salt solution with a certain concentration of metals, which was varied from 0.005 to 0.5 g/L (a solid to liquid ratio was 1 : 50), and the mixtures were shaken in a water shaker at room temperature (25°C) for 15–120 min. Next, the contents of the vials were centrifuged for 30 min at 6000 rpm and then filtered. The residual concentrations of metals in the filtrate were determined on an atomic absorption spectrometer (AAS).

The degree of sorption (R, %) was found by difference between the initial and equilibrium concentrations of metal solutions, which were determined on an AAS and calculated from the formula

where C0 is the initial concentration of metal ions in solution, mg/L; Cp is the concentration of metal ions in solution after interaction with the sorbent, mg/L.

RESULTS AND DISCUSSION

The results of studying the sorption of Co2+ and Ni2+ cations by sodium humate modified with ethylene diamine in aqueous solutions are presented.

The influence of the sorbent norm (0.05–2.0 g), process time (15–120 min), and metal concentration (0.005, 0.05, and 0.5 g/L) on the sorption capacity of the modified EDA–H sorbent for divalent metal ions was studied.

Table 1 and Fig. 1 show the results on the influence of the sorbent norm and process time on the degree of sorption of Co(II) and Ni(II) cations in a solution with their concentration of 0.005 g/L. According to the experimental results, an increase in the sorbent norm and process time facilitated an increase in the sorption capacity of the modified humate for the sorbed cations. Thus, 70.0% cations was sorbed upon the sorption of Co2+ ions from a solution with a Co2+ concentration of 0.005 g/L and a sorbent norm of 0.05 g per 100 g of solution to be purified in a 15-min process (Table 1). A sharp increase in the degree of sorption to 96% was observed at a sorbent norm of 0.5 g already in a 15-min process. The highest degree of sorption (97.3%) in solution was also achieved with a sorbent norm of 2 g in a 15-min process.

Figure 1 shows that, in the sorption of Ni2+ ions from a solution with a Ni2+ concentration of 0.005 g/L for 15 min at sorbent norms of 0.05, 0.5, and 2 g per 100 g of the solution to be purified, the degrees of sorption were 33.5, 76.5, and 83.9%, respectively.

From the above data, it follows that the EDA–H sorbent exhibited a higher sorption capacity for Co2+ cations under the test conditions.

Figure 2 illustrates the influence of the sorbent norm and time on the sorption capacity of EDA–H in a solution with a higher concentration of Co2+ and Ni2+ ions (0.05 g/L). The results obtained indicate that the degree of sorption of cobalt(II) cations increased with the sorbent norm and time (Fig. 2a). For example, at a sorbent norm of 0.05 g per 100 g of the purified solution, the degrees of sorption of Co2+ cations were 44.0, 46.0, 53.0, and 62.0% after 15, 30, 60, and 120 min, respectively (Fig. 2a). Upon a further increase in the sorbent norm to 0.5 g and time from 15 to 30 min, the degree of sorption increased to 82.0 and 84.0%, respectively, and it reached 87.6–91.0% after 60–120 min. The degree of sorption of cobalt increased significantly at a sorbent norm of 2 g per 100 g of solution, and it was 97.3, 98.4–99.1, and 99.4% after 15, 30–60, and 120 min, respectively.

As can be seen in Fig. 2b, the sorption curves of nickel(II) ions in a test solution (СNi = 0.05 g/L) increased with time. A simultaneous increase in the sorbent norm and process time increased the degree of sorption of Ni2+ ions. Thus, the degree of sorption increased from 72.6 to 94.2% as the sorbent norm and time were increased from 0.1 to 2 g and from 15 to 120 min, respectively. Moreover, a high degree of Ni2+ extraction was observed already in a 15–30-min process. For example, at a sorbent norm of 0.05 g and a time of 15 min, the degree of sorption is 22.0%, and it reached 23.0, 25.0, and 28.5% for 30, 60, and 120 min, respectively. As the sorbent norm was increased to 0.5 g, the degree of sorption increased to 61.5 and 63.5% after 15 and 30 min, respectively, and it reached 68.5–71.5% at 60–120 min. The degree of sorption increased significantly at a sorbent norm of 2 g within a 15-min process and reached 83.9%; after 30–60 and 120 min, the degree of sorption increased to 89.8–92.5 and 94.2%, respectively. The experiments also demonstrated the higher extraction of Co(II) ions by a new sorbent, as compared to Ni(II) ions.

The influence of the sorbent norm and time on the sorption capacity of EDA–H in a solution with an even higher concentration of Co2+ and Ni2+ ions (0.5 g/L) is shown in Fig. 3. A study of the process of sorption of Co(II) and Ni(II) cations from a solution with a higher Co2+ concentration (0.5 g/L) revealed that the degree of cation extraction by the sorbent increased with the sorbent amount and process time. Thus, the degrees of sorption with the modified sorbent were 5.0 and 14.0% in 15-min and 120-min processes, respectively (Fig. 3a); at a sorbent norm of 2.0 g, the degrees of sorption after 15 and 120 min were 60.0 and 70.0%, respectively. As for the sorption of Ni2+ cations, in a 15-min process, the degree of sorption by the modified sorbent was 15.0%, and it was 21.0% after 120 min (Fig. 3b); in the case of using a sorbent norm of 2.0 g for 15 min, the degree of sorption was 79.0%, and then it reached 88.6% after 120 min.

In a 15-min process at a consumption of 0.5 g of the modified sorbent per 100 g of solution, the degree of sorption of Ni2+ ions was 10% higher than that of the cations of Co, or it was 19% higher with a sorbent norm of 2 g per 100 g of solution. This behavior remained unchanged over the entire time interval studied at the above solid to liquid ratio.

From the experimental results, it follows that the modified sorbent exhibited a preferred sorption ability with respect to Ni2+ cations in a concentrated solution (0.5 g/L) in terms of cation content.

An analysis of the results showed that the highest degree of sorption of cobalt and nickel was manifested in metal-containing solutions of low and medium concentrations. For example, at a sorbent norm of 2 g per 100 g of the solution to be purified for 15 min, the degree of sorption from solutions with CCo = 0.005 and 0.05 g/L was 97.3%, and that from a solution with CCo = 0.5 g/L was 60%. This regularity was preserved in the purification of nickel-containing solutions.

Thus, the sorption capacity of the modified sorbent largely depends on the concentration of sorbed cations. Moreover, in low-concentrated solutions (0.005 and 0.05 g/L), the EDA–H sorbent had a preferred sorption capacity for Co2+ cations, and a preferred sorption capacity for Ni2+ cations was observed in concentrated solutions (0.5 g/L).

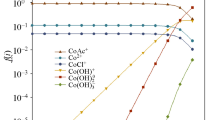

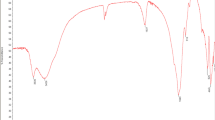

An analysis of the IR spectra of samples extracted from cobalt and nickel-containing solutions showed the presence of intense absorption bands in all spectra in regions of 3414–3418 cm–1 (Fig. 4) and 3102–3225 cm–1 in the spectra of nickel humate (Fig. 4b), which are characteristic of the vibrations of –NH and –OH groups. In this case, the intensity of these frequencies was redistributed as the concentration of metals in solution was increased; this was due to the strengthening of hydrogen bonds. In addition, new low-frequency absorption bands were recorded in the spectra of the test samples at 3111.5 cm–1 for cobalt humate and 2944 cm–1 for nickel humate, which are characteristic of the stretching vibrations of aliphatic –CH2 groups (curves 3).

In the IR spectra of cobalt-containing humate, absorption bands with frequencies of 2940 cm–1 (Fig. 4a, curve 2) and 2920 and 2939 cm–1 (curve 3) correspond to the stretching vibrations of hydrogen atoms bonded to carbon in methylene groups. A weakly pronounced band at 1704 cm–1 related to the vibrations of the carboxyl group shifted to the low-frequency region of 1611, 1613, 1618, and 1384 cm–1 with increasing intensity. These absorption bands characterize the asymmetric and symmetric vibrations of the carboxylate anion. In addition, the IR spectra of the samples exhibited a number of characteristic bands due to the stretching vibrations νС–О (1258 and 1271 cm–1) and νС–N (1085, 1087, 1088, and 1142 cm–1). The appearance of bands at 411, 412, and 416 cm–1, which are characteristic of stretching vibrations of the νMe–O bond, and absorption bands at 512, 517, and 525 cm–1, which correspond to vibrations of the νMe–N bond, in the spectrum of cobalt-containing humate indicates the sorption of cobalt ions by the EDA–H sorbent and confirms the νCo–O bond formation in the resulting complexes.

In the IR spectra of nickel-containing samples isolated at different nickel(II) concentrations, the characteristic absorption band at 1705 cm–1 belongs to the carboxyl group (Fig. 4b, curve 1), which disappeared with increasing concentration of Ni2+ cations (curves 2, 3); however, at the same time, new absorption bands at 1593, 1598, and 1384 cm–1 appeared in the spectrum of the samples, which related to the ionized form of the carboxyl group, i.e., to the carboxylate anion. It is likely that two absorption bands at 1593 and 1598 cm–1 can also be due to the deformation vibrations of N–H groups. The presence of intense absorption bands at 1088, 1252, and 1276 cm–1 was associated with the C–N bond vibrations of aliphatic amines, providing convincing evidence of the presence of amino groups in the test samples. In addition, new absorption bands at 536, 537, 538, 619, and 620 cm–1, which are characteristic of the vibrations of νМе–N and νМе–О bonds, were detected in the IR spectra of the EDA–H sorbent samples isolated after the sorption of Ni2+ cations. The intensity of these bands increased with the concentration of nickel in solution (curves 2, 3). An analysis of the IR spectra confirmed the formation of a nickel-containing complex.

Figure 5 shows the electron microscopic images of samples isolated after sorption at a sorbent norm of 2.0 g and a process time of 120 min at different concentrations of cations (Co2+, Ni2+).

The micrograph of the EDA–H–Co sample shows an increase of slit-like pores, a change in the shape of the sorbent surface, and an increase in the grain size of the sorbent with increasing the concentration of Co2+ cations (Fig. 5a). The surface morphology included enlarged and small dark particles. The elemental composition of EDA–H–Co samples showed that the cobalt contents were 0.12, 0.45, and 0.88 wt %.

With increasing the concentration of nickel(II) on the surface, the fraction of large crystals in the electron microscopic image of the EDA–H–Ni sample increased. Cracks on the surface increased (Fig. 5b). The elemental analysis data showed that the concentrations of nickel in the test samples were 0.28, 0.52, and 1.03 wt %.

Based on published and experimental data and the results obtained using scanning electron microscopy and IR-spectroscopic analysis, we found that the binding of modified humates with heavy metal ions (complex formation) occurs due to donor–acceptor interaction of the nitrogen atom of an amine group and the oxygen atom of a hydroxyl (OH) group according to the following reaction scheme:

Thus, we found that the sorption of Co2+ and Ni2+ ions by ethylenediamine-modified humate (EDA–H) depends on the sorbent norm, process time, and cation concentration. The dependence of the sorption of cations on the test factors was established. It was shown that the degree of sorption of heavy metal ions by the modified sorbent increases in the order Co2+ > Ni2+. The complexation of the modified sorbent with heavy metal ions was established using scanning electron microscopy and IR-spectroscopic analysis, and a mechanism of the process was presented. It was demonstrated that the binding of the EDA–H sorbent to the cations occurs due to the donor–acceptor interaction of the nitrogen atom of an amine group and the oxygen atom of a hydroxyl (OH) group.

REFERENCES

Budaeva, A.D., Zoltoev, E.V., Khanturgaeva, G.I., and Zhambalova, B.S., Khim. Interesakh Ustoich. Razvit., 2008, no. 2, p. 251.

Erdogan, S., Baysal, A.K., Akba, O.R., and Hamamci, C.T., Polish Environ. Stud., 2007, no. 5, p. P. 706.

Novak, J.P., Kozler, J.S., Janus, P.J., Cezikova, J.S., Tokarova, V.S., and Madronova, L.A., React. Funct. Polym., 2001, vol. 47, p. 213.

Arsenie, I.S., Boren, H.T., and Allard, B.A., Sci. Total Environ., 1992, vol. 116, p. 275.

Almendros, G.S. and Dorado, J.E., Eur. J. Soil Sci., 1999, vol. 50, p. 294.

Noyes, T.I. and Leenheer, J.A., Geological Survey Water-Supply Paper, 1994, p. 208.

Stevenson, F.J. and Goh, K.M., Soil Sci., 1972, vol. 113, no. 5, p. 397.

Arsenie, I.S., Boren, H.D., and Allard, B.B., Sci. Total Environ., 1992, vol. 116, p. 286.

Briggs, G.C. and Lawson, G.J., Fuel, 1970, vol. 49, p. 101.

Herzog, H.D., Burba, P.S., and Buddrus, J.V., Anal. Chem., 1996, vol. 354, no. 3, p. 402.

Dec, J.F., Haider, K.G., and Shaffer, A.A., Environ. Sci. Technol., 1997, vol. 31, p. 3134.

Hua, S.-B., Zheng, Y.-A., and Wang, A.-Q., Polym. Mater. Sci. Technol., 2008, no. 7, p. 204.

Akkulova, Z.G., Utegenova, A.S., Zhubanov, B.A., Amirkhanova, A.K., and Karabaev, K.U., Izv. Nats. Akad. Nauk Resp. Kazakhstan, Ser. Khim., 2004, no. 5, p. 231.

Utegenova, A.S, Akkulova, Z.G., Amirkhanova, A.K., Zhakina, A.Kh., and Suleimenova, A.A., Mater. Mezhdunar. nauch. konf. “Vzaimodeistvie guminovykh kislot s prostymi vinilovymi efirami” (Proc. Int. Sci. Conf. “The Interaction of Humic Acids with Vinyl Ethers”), Karaganda: Izd. KarGU, 2005, p. 326.

Safanov, S.A. and Akhmedov, K.S., Guminovye udobreniya, teoriya i praktika ikh primeneniya (Humic Fertilizers, Theory and Practice of Their Application), Moscow: Nauka, 1967.

Kasatochkin, V.I., Nefedova, L.N., and Larina, N.K., Khim. Tverd. Topl. (Moscow), 1971, no. 5, p. 97.

Zhernakova, Z.M., Deeva, N.N., Pecherskikh, E.G., and Polyakov, E.V., Voda: Khim. Ekol., 2011, no. 6, p. 91.

GOST (State Standard) 9517-94 (ISO 5073-85): Solid Fuel. Methods for Determining the Yield of Humic Acids, Moscow: Izd. Standartov, 1996, p. 9.

GOST (State Standard) 11022-95 (ISO 1170-97): Solid Mineral Fuels. Methods for Determination of Ash, Moscow: Izd. Standartov, 2007, p. 6.

GOST (State Standard) 27314-91 (ISO 589-81): Solid Mineral Fuel. Determination of Moisture, Moscow: Izd. Standartov, 2007, p. 10.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by V. Makhlyarchuk

About this article

Cite this article

Dzhusipbekov, U.Z., Nurgalieva, G.O., Shakirova, A.K. et al. Influence of Different Factors on the Sorption of Metals (Co2+ and Ni2+) by Modified Sodium Humate. Solid Fuel Chem. 54, 232–238 (2020). https://doi.org/10.3103/S0361521920040047

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0361521920040047