Abstract

The paper deals with the design aspects of a 5-megawatt electrical (5-MWe) parabolic trough based concentrated solar thermal power plant located in the city of Jaipur, India using energy, exergy, economic, and environment cost analysis. As a novelty in the study, quantification of the energetic and exergetic potential of heat transfer fluid has also been carried out. Based on the energetic heat of the heat transfer fluid (HTF) going into the boiler, the solar field design is then carried out. The energy–exergy analysis shows that the energetic efficiency of parabolic trough based concentrated solar power plant (PTCSTPP) was 29.38% and exergetic efficiency was 31.86%. The gross thermal efficiency of the power plant was 31.47% and net thermal efficiency is 25.07%. Methodology for arriving at a solar-alone operating power plant has also been enumerated and shown that at a levelized cost of energy (LCOE) of US cent 5.6, the total cost of the plant comes out to be US $ 53 million payback of 19 years, with an annual coal saving worth US $ 0.96 million and CO2 savings of US $ 0.29 million. Analysis has also been carried out to assess the per-hour increment in the design cost owing to additional operating hours of the solar plant.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

INTRODUCTION

Power production using solar energy can be done by way of either solar photo voltaic (PV) technology or through concentrated solar power (CSP), where Sun’s energy is focused onto a line or point geometry so as to result into very high temperatures and high magnitude of heat. The concentrated heat generated by sun’s energy can be transported using suitable heat transfer fluids to heat exchanger where this heat is transferred to convert water into steam and steam turbine is then driven to produce electricity. Out of the two options of solar energy, PV and CSP, CSP based thermal route offers distinct advantages in bringing down the least cost of electricity generated by way of providing storage and despatchability of solar power during off-Sun periods [1].

Energy–Exergy–Economic–Environmental (4-E) analysis of renewable energy systems such as CSP gives a holistic assessment of the impact of the system on its surroundings. 4-E analysis of solar thermal power plants has been attempted by several authors in the past. Odeh et al. [2] proposed using direct steam generation in place of thermic fluid in the parabolic trough based solar power plant. They utilized a model based on a study done at Sandia National Lab. of USA where a synthetic heat transfer fluid was used in the parabolic trough collector. The model was based on absorber wall temperature, by determination of the absorber emissivity, wind speed, radiation level and internal working fluid convection effects, in place of the bulk fluid temperature so as to be able to study the thermal behavior of the collector in the absence of the working fluid. Reducing the absorber tube diameter for a given collector aperture area increases the collector efficiency due to reduced heat loss but improved internal convection heat transfer only had secondary influence.

Kaushik et al. [3] carried out second law analysis of a solar power plant based on exergy as a concept. With the help of energy and exergy flow diagrams, they explained the different thermodynamic and thermal losses in various components of the plant such as parabolic trough collectors, receivers, steam Rankine system etc. They stated that the maximum energy loss happens in the condenser while exergy loss occurs in the receiver–collector assembly of the solar plant. Klychev et al. [4] developed the calculation method for the optical–geometric and optical–energetic parameters and characteristics of parabolic-trough concentrators (PTC) of solar thermal power plants considering inaccuracies of the surface geometry, mounting and sun-tracking. Kopac and Halachi [5] applied energy-exergy analysis to an existing Çatalağzı power plant in Zonguldak, Turkey using low calorific value coal. They analyzed the energetic heat loss and exergy destruction rates of each component of the power plant for different ambient temperatures in a range of 5 to 35°C. They observed that the ambient temperature had high effect on the changes of the irreversibility of boiler but had lower effect on other components of plant.

Montes et al. [6] economically optimized the solar multiple for five different sizes of solar field in case of solar-only parabolic trough plant with same power block configuration, without any hybridization as well as thermal storage. Thermal performance at nominal and part-load conditions for each solar power plant has been analyzed and annual electricity produced by each of the solar plants was calculated. Based on the annual electricity cost, an optimum solar multiple that yielded the minimum levelized cost of energy (LCOE) was obtained. Aljundi [7] carried out the energy and exergy analysis of a steam power plant and also studied the effect of varying the reference environment state on the analysis. The author stated that the maximum energy loss happens in the condenser. The ratio of the exergy destruction to the total exergy destruction was found to be maximum in the boiler system (77%) followed by the turbine (13%), and the forced draft fan condenser (9%). The author concluded that a small change in the ambient temperature would not have any impact on the performance of major components and that the boiler still remained the major source of irreversibility. Chemical reaction is the most significant source of exergy destruction in a boiler system which can be reduced by preheating the combustion air and reducing the air–fuel ratio.

Reddy et al. [8] presented the thermodynamic energy-exergy analysis of a coal based thermal power plant and a gas based cogeneration power plant. Their paper also included a detailed review of boilers in coal based thermal power plants and combustion chambers in gas-steam cogeneration plant. Gupta and Kaushik [9] carried out energy and exergy analysis for a conceptual direct steam generation (DSG) solar–thermal power plant. They too reported that the maximum energy loss happens in the condenser followed by solar collector field while maximum exergy loss happens in the solar collector field. They concluded that for minimum exergy loss in receiver the inlet temperature of water to the receiver, governed by the number of feed water heaters (FWHs), bleed pressure and mass fraction of bleed steam, must be optimum. In an effort to maximize the power plant efficiency, they evaluated various bleed pressures and mass fractions of bleed steam in a configuration of direct steam generation solar power plant having 1, 2 and 3 feed water heaters and observed that as the number of feed water heaters are increased, gain in plant efficiency is possible.

Palenzuela et al. [10] did a thermodynamic evaluation of the possibilities of coupling parabolic trough based CSP plants with different water treatment technologies. They compared the effect of coupling low temperature multi-effect distillation plant receiving steam from the outlet of the turbine instead of the condenser and another combination of CSP with reverse osmosis (RO) plant. They also evaluated a new concept of CSP with distillation which is powered by the steam from a thermal vapour compressor (TVC) using the exhaust steam of the CSP plant as entrained vapour and steam extracted from the turbine as the motive vapour of the ejector. Marigorta et al. [11] utilized the exergy analysis as a potent tool in developing, evaluating and improving the power cycle of a 50 MWe solar thermal power plant by comparing two different types of cooling systems, a cooling tower and an air cooled condenser. Utilizing Gate Cycle software, the authors simulated the Rankine cycle and analyzed the location, magnitude and sources of thermodynamic inefficiencies thereby suggesting improvements in the overall efficiency of the power system. Xu et al. [12] theoretically analyzed the energy and exergy of solar power tower using molten salt as the heat transfer fluid by testing it against the design such as direct normal irradiation (DNI), concentration ratio, and the type of power cycles. Their results show that the maximum exergy loss occurs in the receiver system, followed by the heliostat field system, while maximum energy loss happens in the power cycles. They stated that the energy and exergy efficiencies of the receiver and the overall system can be increased by increasing the DNI and the concentration ratio and also found that the overall energy and exergy efficiencies of the solar tower system can be increased marginally by integrating advanced power cycles including reheat Rankine cycles and supercritical Rankine cycles. Kaushik et al. [13] studied the exergy analysis to understand the performance of coal fired and gas fired combined cycle thermal power plants and identified possible efficiency improvements through power plant component design modifications. They observed maximum energy loss happens in the boiler of coal thermal power plant and in combustion chamber of gas fired combined cycle thermal power plant. The authors stated that owing to the state of technology available at that time, there were some intrinsic unavoidable irreversibility in the boiler or the combustion chamber. They suggested certain design modifications in the heat exchanger but also cautioned on the increase in cost versus improvement potential of such power plant components.

Kumar and Reddy [14] studied the 4-E aspects of stand-alone line-focusing Linear Fresnel as well as Parabolic Trough based concentrating solar power plants in capacities ranging from 1 to 50 MWe. They concluded that the maximum energy loss occurs in the solar field and power block while maximum exergy loss happens in both the type of solar fields. This paper also quantifies the environmental benefits by annually off-setting about 1800 tons of CO2, 12.5 tons of SO2, 6.23 tons of NOx etc. through a 1 MWe sub-critical power plant. The levelized electricity cost varies from 4.77 to 10.19 Rs for the LFR and 14.7 to 8.48 Rs for the PTC-based stand-alone solar power plant when the plant capacities vary from 1 to 50 MWe. Reddy and Devaraj [15] studied the 4-E aspects of stand-alone solar thermal power plants to establish their techno-economic viability in comparison to a coal-fired and a solar-coal hybrid power plant. They considered a coal fired 50 MWe power plant as a reference and compared the solar stand-alone and solar-coal hybrid power plant with the same. They concluded that owing to low plant efficiencies and high cost of electricity generation, the stand-alone solar power plants are not much viable in comparison to solar-coal hybrid plants. The solar-coal hybrid power plant helps in reduction of CO2, ash generation and lower levelized cost of electricity (LCoE) compared to stand-alone solar plant. They also mentioned that owing to higher LCoEs and low energy and exergy efficiencies at lower plant ratings of 1 to 5 MWe, the stand-alone solar power plants are preferable in higher capacities beyond 20 MWe. Reddy et al. [16] carried out the energy and exergy analysis of parabolic trough based solar thermal power plant coupled with steam Rankine engine under two operating pressures of 90 and 105 bar. They found that by increasing the operating pressure from 90 to 105 bars, the energy and exergy efficiencies of the power plant increases to 1.49 and 1.51% respectively. They considered two geographical locations of Jodhpur and Delhi and on the basis of solar radiation intensity and incident angle effect, concluded that location of Jodhpur is better in terms of land requirement for the same capacities, energetic and exergetic efficiencies etc. Han [17] simulated study for coupling a parabolic trough based concentrated solar power plant with a power tower and found that solar energy can be utilized effectively and efficiently. The parabolic trough plant produced mid temperature from saturated steam at 390°C while the tower generated super-heated steam at 574°C. In this study they found improvement in thermal efficiency by 1.7% and cost of electricity generation lower by 4%. Avezova et al. [18] studied the dynamics of the creation and operation of solar power plants with the thermodynamic conversion, and the criteria for reducing cost of electricity produced from them. Kuchkarov et al. [19] studied a module of parabolic-cylindrical composite mirror concentrating system with an optimal aperture angle and an optimal size of the focal spot of flat mirror elements.

More recently, Kariman et al. [20] carried out the exergy analysis of an industrial desalination system powered by electricity and reported that most exergy destruction occurs in the boiler compartment and central heat exchanger of the system. The researchers used a two-objective genetic algorithm to optimize the system so as to reduce energy consumption and increase freshwater production. Hoseinzadeh et al. [21] carried out exergoeconomic analysis of a reverse osmosis desalination system powered by integrated carbon dioxide power cycle through geothermal energy and reported that desalination system, sodium hypochlorite generator, carbon dioxide turbine, and natural gas turbine have the highest rate for the sum of capital gain and exergy destruction cost.

Kariman et al. [22] further studied the different types of desalination systems and their governing equations and modeled the presented evaporative vacuum easy desalination system with brine tank for its energy consumption. They also carried out economic modeling and feasibility study of the system for three cities, Abu Dhabi, Las Palmas, and Perth and reported that the difference in electricity prices has a profound bearing on the cost of fresh water produced. Hoseinzadeh et al. [23] further thoroughly investigated a solar thermal based cogeneration system of electricity and freshwater and modeled a gas power plant thermodynamically and verified the results with an actual power plant data. The researchers also observed an increase in energy from 35 to 46% and exergy efficiency increase to 48 from 37% while studying a solar thermal based multi-effect desalination with thermal vapor compression. Yargholi et al. [24] studied the integrated carbon dioxide power cycle based reverse osmosis desalination powered by geothermal energy. They carried out the exergy analysis and observed that the condenser has the highest exergy destruction rate and the same should be focused upon to improve the exergy destruction in the whole system. Kariman et al. [25] carried out the exergy analysis of a high performance multi-effect desalination system and reported that the brine tank has the highest performance and very little exergy destruction and can be focused upon to improve upon the overall system performance. Kuchkarov et al. [26] proposed a calculation and optimization algorithm for operating modes of composite parabolic trough mirror-concentrating systems and reported the thermal and exergy efficiency values of 0.4438 and 0.0932, respectively.

CONCENTRATED SOLAR THERMAL POWER PLANT

Energy–exergy–economics–environmental (4-E) analysis of a mini-grid connected parabolic trough collector based captive solar power plant (PTCSTPP) located in Jaipur, India, has been carried out. The geographical coordinates of Jaipur are a latitude of 26°55′19.4520″ N and longitude of 75°46′43.9860″ E. The location of Jaipur was considered as the city lies on the fringe of high direct normal incidence (DNI) region of India. Also because it is a city where individual income of the general populace is comparatively high so that driven by ethical values, they can set a trend of affording for their own power instead of depending upon the government’s support. The power plant consists of a parabolic trough based concentrated solar thermal field and a 5-megawatt electrical (5-MWe) power block running on steam Rankine Cycle. The low capacity of the power plant coupled with its location in the city is considered owing to the fact that the electricity produced can be utilized in the vicinity without a need to be transported to long distances through transmission lines. This study is carried out with an assumption that the humanity in general will become increasingly aware of the climate change and general public along with the governments shall start to play more proactive and responsible role in managing their energy needs. Whether mankind will want it or not, the extremities of climate being experienced in greater frequencies in the recent times will warrant stricter action with a very high moral ground on the part of public as well as authorities to off-set the negative effects of energy being produced in the conventional manner [27–29].

Parabolic trough CSP are deployed with suitable one-axis tracking systems which move from east to west with the solar plant generally installed in north–south (N–S) direction. The direct normal solar rays, which are perpendicular to the surface of the collector are useful to heat the thermic fluid flowing inside the receivers. The angle of incidence is the angle between the direct beam of Sun falling on the surface of the collector and a hypothetical plane normal to that surface. Since, the trough collectors are set in horizontal plane, the incidence angle varies continuously throughout the day with the tracker movement. The incidence angle falling on the collector also varies on different days with the orientation of the collector in a location and Sun’s position in the sky.

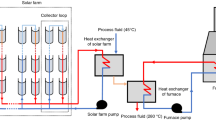

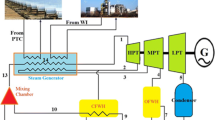

The layout of the 5-MWe parabolic trough concentrated solar power plant is shown in Fig. 1 and various state-points of the power plant are enumerated in Table 1. The hot oil from solar field is assumed to be entering the boiler at 399°C and re-entering the solar field at 205°C after imparting its heat into the boiler.

The concentrated solar thermal plants are generally designed optimally for the shortest day of the year so that it can produce sufficient energy to be able to run the power plant in worst case scenario. The solar plant once designed will then be able to produce excess energy in other months that can be taken up for storage so that the plant can also run during off-Sun hours. For the design basis, the winter solstice which has the shortest length of day is taken during the design stage. For the location of Jaipur, winter solstice occurs on 21st December while the summer solstice, having the longest length of the day, falls on 21st June. Hence the incidence angle variation with time of the day is calculated for these two days of the year and the same is shown in Figs. 2 and 3. In the analysis for solar incidence angle, the direct solar beam radiation (DNI) data has been taken from latest solar radiation map of India [30].

The DNI for Jaipur is very low in December compared to June and the incidence angle variation is more in December. This causes a drastic decrease in the effective DNI falling on the collector surface in December and hence the parabolic trough solar field for the 5 MWe power plant has been designed taking the month of December as the basis. Eurotrough collector is considered in the design [31, 32]. The weather conditions of Jaipur for June and December months is summarized in Table 2.

ENERGY–EXERGY CALCULATIONS

The energy and exergy values presented in Table 3 for individual points of the Rankine cycle power block were calculated using the Engineering Equation Solver (EES) [33] where the governing equations for energy and exergy calculations are presented in Appendix A.

Role of Heat Transfer Fluid

The steam cycle from the power block imparts some residual heat energy into the steam entering the boiler from the power block side. This is the energy retained by the steam coming out from the turbines and passing through feed water heaters, boiler feed pump etc. The remaining energy requirement in the boiler is fulfilled by the HTF coming from the solar field. Thus, only partial stored energy of HTF from the storage tank is released into boiler by controlling the flow of hot oil into the boiler.

Two-tank thermal storage energy system (cold-oil tank and hot-oil tank) was utilized in the study with heat transfer fluid acting as the thermal energy storage medium also. Since the 5 MWe PTCSTPP was being designed for the location of Jaipur in a cost-effective manner, which is moderately high DNI endowed geographical region, achieving very high temperature thru solar field and storing the solar thermal energy into other high temperature medium such as molten salts, metal blocks etc would have made the design too costly and cumbersome. Hence, heat transfer fluid was chosen as the heat storage medium as well as the heat transfer medium.

In the analysis, the inlet oil temperature was taken as 205°C and outlet HTF temperature was restricted to 399°C. The restriction on maximum outlet HTF temperature is mandated owing to the chemical nature of the HTF wherein it would undergo faster thermal and oxidative property deterioration beyond this temperature. The parabolic trough solar field is designed with an aim to reduce the number of solar collector assemblies to as minimum as possible owing to the engineering challenges related to alignment and leakages from the joints. Thus, the design of solar field is attempted by an effort to increase the number of rows and reducing the number of solar collector assemblies. Therefore, the solar field in the present study was designed so as to accommodate HTF at lower temperature upto 205°C only.

The criteria to choose the oil based heat transfer fluid are for minimizing the cost and maximizing the profits. Amongst the known various types of heat transfer medium used in parabolic trough based concentrated solar power plant, oil based HTF is generally chosen. This is owing to the fact the oil based HTF can result into sufficiently high temperatures of 400°C so as to generate the desired steam quality, is easy to maintain, easy to pump and has minimum requirement of pipeline & pump metallurgy as compared to other HTFs such as molten salts, etc.

The amount of energy required from the HTF by the boiler is dictated by the power block requirement. For the given turbine rated capacity, the energy required by the boiler “BQi” is sum of energy being acquired by the steam “∆BQi-power block” from the power block’s balance-of-plant components such as high pressure feed water heaters, boiler feed pump, low pressure feed water heaters etc and the balance energy taken from the hot fluid coming from storage tank of the solar field as shown in Table 4. The energetic potential of the HTF can be calculated by dividing the total heat stored in the HTF by the heat released by HTF into the boiler per cycle. Similarly, the exergetic potential of the HTF is calculated by total exergetic heat stored in the HTF divided by the exergetic heat released by HTF into the boiler per cycle.

The 5 MWe solar field power block combined system being studied, the design conditions considered had the boiler efficiency as 85%, efficiency of high pressure turbine as 85% and isentropic efficiency of low pressure turbine as 89.5%, steam inlet temperature of 325°C at 110 bar in high pressure turbine and steam inlet condition at inlet of low pressure turbine as 300°C at 110 bar. The condenser pressure was kept at 10 bars. The steam entering the turbine after completing the cycle was at 240°C and 25 bar pressure. Based on the calculations through EES, following are the salient observations:

• The energetic efficiency of the system is 29.38% and the exergetic efficiency is 31.86%.

• The maximum percentage energy loss happens in the condenser, followed by the solar collector and then in the turbines and the boiler.

• As compared to the concentrator, exergy loss/destruction in the condenser is minimal. In the condenser, the amount of useful energy available to convert into work is less. Hence, exergy loss is less.

• In an irreversible process, exergy is always destroyed, for example loss of heat to the environment in the condenser. This destruction is proportional to the increase in entropy of the system together with its surroundings.

• The energetic/exergetic potential of HTF is calculated by dividing the total energy/exergy available in the HTF stored in the tanks by the amount of energy/exergy desired in the boiler through HTF. Thus, the energetic potential of the HTF is 4.78 and the exergetic potential of HTF is 2.33.

• The reheated steam entering the boiler from the power block side does not lose its energy and exergy because no heat transfer takes place in its case in the boiler.

• Within the power block configuration, condenser is one component where maximum energy and exergy lose happens.

• The energy and exergy gets added into the system from boiler reheater, boiler feed water pump and condensate extract pump.

• The gross thermal efficiency of the power plant is 31.47% and the net thermal efficiency is 25.07%.

CONFIGURATION OF PARABOLIC TROUGH SOLAR FIELD

The latest cost figures from Indian sources for parabolic trough based concentrated solar thermal plants is not available in the open domain and hence the same has been taken from various literature sources [34, 35] as shown in Table 5. For the land cost, the guidelines issued by Central Electricity Regulatory Authority of India, has been considered [36].

It can be seen from Table 3, that the energy required from HTF into the boiler is 18 145 kW and the exergy of HTF into the boiler is 16 504 kW. It is based on this value of 18 145 kW energy required by the boiler from HTF that the solar field has been designed. Initially, the parabolic solar field is adjusted by assembling the collector elements serially so that the outlet temperature of the HTF just reaches 399–400°C on the shortest day of the year, taken as 21st December for the year 2016 at Jaipur. Then, the number of rows are selected so that enough solar energy is produced to have an energy input of at least 18 145 kW going into the boiler from the solar field, at least till such time that the Sun is available on that day. This gives the number of solar collector assembly as 10 and number of rows of such solar collector assemblies as 9. Table 6 lists out the solar field configuration for the months of December and June.

Subsequently, taking into consideration the longest and hottest day of the year, 21st June 2016 for Jaipur, the storage tank capacity is designed so that the excess solar energy can be stored using the same solar field configuration. The calculated time for which the energy in June can be stored compared to that of December month is 6.89 h. In order to increase the storage time for 24 h’ operation of the solar-alone power plant, the solar collector assembly was retained at 10 only so as to restrict the temperature of the outlet heat transfer fluid. However, in order to collect more energy from the solar field, number of rows was increased to 18. In doing so, the solar field got increased by 36 acres from 18 acres of initial design and accordingly the storage tank capacity also got increased. It is to be pointed out here that had the initial solar field design based on the month of June instead of the month of December, the storage system capacity would have been too large and wasteful when the plant was to operate on December. It is additionally assumed that the storage tank can still get hot oil through other sources of energy such as biomass or biogas combustion as per need during off-Sun periods. The solar field so designed could cater to solar-alone operation for 24 h as shown in Table 7.

ECONOMIC AND ENVIRONMENTAL COST

Calculations for assessing the economic and environmental benefits of the solar-alone power plant having 24 h operation has been carried out. The coal quality considered in the study is Grade-A Indian non-coking coal with GCV of 27 004 kJ/kg @ cost of US $ 45 per ton [37]. CO2 emissions of 2.82 tons per ton of coal was considered. Though, the price of carbon credits based on information mentioned in this paper, hovered around US $ 20–25, it was also learnt that the market for carbon trading is very irregular and erratic [38–40]. Hence, a carbon price of US $ 5 was considered into calculations. Table 8 summarizes the saving from coal and earnings from carbon credits by installing the PTCSTPP.

The cost of the PTCSTPP has been arrived at by taking into considerations certain financial assumptions such as the discount rate of 10%, annual escalation of 5%, debt-to-equity ratio of 70:30, life of the plant as 25 year, plant capacity factor of 85% and an auxiliary power consumption of 7.5%. With these assumptions, the least cost of electricity (LCoE) of the plant is US cents 5.6 per unit of electricity produced [41, 42]. Out of the total PTCSTPP cost, the cost of the power block, balance of plant including land for the power block is US $ 4.92 million. With the arrived LCoE of US cents 5.6 at an installed capital cost of US $ 5.43 million, the coal-only based power plant will have a payback period of about 3 year. For all the further analysis in this paper pertaining to the cost of solar plant, reference shall be made with the coal-only power plant producing electricity at an LCoE of US cents 5.6 for the purpose of calculations.

ANALYSIS OF A STAND-ALONE SOLAR THERMAL PLANT COST

The solar plant designed in the previous sections runs on stored energy for a total of 19 h; assuming 5 h of Sun shine. At present there is no concentrated solar power plant based on parabolic trough technology operating 24 × 7 in the world [43]. However, as part of the present study, an analysis has been carried out to assess the per hour storage cost of the concentrated solar power plant by designing it for 12, 13 and then 24 h of storage capacity as summarized in Table 7. From Table 9, it can be seen that for per-hour enhanced solar-hour operation of the PTCSTPP, the revenue from the plant remains constant at US $ 1.92 million. There is a benefit of coal saving to the tune of Rs 0.28 crore and carbon credit earnings of Rs 0.08 crore at an additional solar field cost of Rs 24 crores.

CONCLUSIONS

The paper deals with the design aspects of a 5 MWe parabolic trough based concentrated solar thermal power plant located in the city of Jaipur, India, employing the energy, exergy, economic, and environment analysis. Following are the salient points of the study:

• Several researchers and solar energy scientists have carried out 4-E (energy, exergy, economic, environment) analysis of different configurations of solar thermal power plant located in various parts of the world. However, none of the past publications have quantified the energetic and exergetic potential of heat transfer fluid and the present study also discusses the methodology of calculating the energetic and exergetic potential of heat transfer fluid.

• Based on the energy–exergy analysis, the energetic efficiency of PTCSTPP was found to be 29.38% and exergetic efficiency was 31.86%. The gross thermal efficiency of the power plant was 31.47% and net thermal efficiency is 25.07%.

• The solar field design methodology has been enumerated and shown that the winter month is generally to be considered while designing the solar collector assembly layout and rows are then adjusted to achieve the desired energetic heat capacity from HTF going into the boiler. For running the solar plant entirely dependent of the solar energy, i.e. solar-alone mode, the number of rows are then increased keeping the SCA same so as to control the outlet temperature of heat transfer fluid.

• The solar-alone designed PTCSTPP has 10 × 18 collector assembly and rows configuration, occupies 36 acres of land, has the designed 24 h energy storage capacity costing US $ 14.29 million, a total financial cost of US $ 53 million and owing to having the additional potential of annually saving coal worth US $ 0.96 million and CO2 savings of US $ 0.29 million, has a payback period of 19 year when the levelized cost of electricity is US cents 5.6 per unit.

• Analysis has also been carried out to assess the per-hour increment in the design cost owing to additional operating hours of the solar plant. The per hour addition of energy storage in the solar plant shall result in a benefit of coal saving to the tune of US $ 0.05 million and carbon credit earnings of US $ 0.01 million.

REFERENCES

Srivastva, U., Malhotra, R.K., and Kaushik, S.C., Recent developments in heat transfer fluids used for solar thermal energy applications, J. Fundam. Renewable Energy Appl., 2015, vol. 5, no. 6, id. 1000189. https://doi.org/10.4172/20904541.1000189

Odeh, S.D., Morrison, G.L., and Behnia, M., Modeling of parabolic trough direct steam generation solar collectors, Sol. Energy, 1998, vol. 62, no. 6, pp. 395–406.

Kaushik, S.C., Misra, R.D., and Singh, N., Second law analysis of a solar thermal power system, Int. J. Sol. Energy, 2000, vol. 20, pp. 239–253.

Klychev, Sh.I., Mukhitdinov, M.M., Bakhramov, S.A., et al., Calculation methodology for the parabolic-cylindrical concentrator – tube receiver system for solar thermal power plants, Geliotekhnika, 2004, no. 4, pp. 50–54.

Kopac, M. and Hilalci, A., Effect of ambient temperature on the efficiency of the regenerative and reheat Çatalağzı power plant in Turkey, Appl. Therm. Eng., 2007, vol. 27, pp. 1377–1385.

Montes, M.J., Abánades, A., Martínez-Val, J.M., and Valdés, M., Solar multiple optimization for a solar-only thermal power plant using oil as heat transfer fluid in the parabolic trough collectors, Sol. Energy, 2009, vol. 83, pp. 2165–2176.

Aljundi, I., Energy and exergy analysis of a steam power plant in Jordan, Appl. Therm. Eng., 2009, vol. 29, pp. 324–328.

Reddy, V.S., Kaushik, S.C., Tyagi, S.K., and Panwar, N.L., An approach to analyse energy and exergy analysis of thermal power plants: A review, Smart Grid Renewable Energy, 2010, vol. 1, pp. 143–152.

Gupta, M.K. and Kaushik, S.C., Exergy analysis and investigation for various feed water heaters of direct steam generation solar thermal power plant, Renewable Energy, 2010, vol. 35, no. 6, pp. 1228–1235.

Palenzuela, P., Zaragoza, G., Alarcon-Padilla, D.C., Guillen, E., Ibarra, M., and Blanco, J., Assessment of different configurations for combined parabolic-trough (PT) solar power and desalination plants in arid regions, Energy, 2011, vol. 36, no. 8, pp. 4950–4958.

Blanco-Marigorta, A.M., Sanchez-Henríquez, M.V., and Peña-Quintana, J.A., Exergetic comparison of two different cooling technologies for the power cycle of a thermal power plant, Energy, 2011, vol. 36, no. 4, pp. 1966–1972.

Xu, C., Wang, Z., Li, X., and Sun, F., Energy and exergy analysis of solar power tower plants, Appl. Therm. Eng., 2011, vol. 31, pp. 3904–3913.

Kaushik, S.C., Reddy, V.S., and Tyagi, S.K., Energy and exergy analysis of thermal power plants: A review, Renewable Sustainable Energy Rev., 2011, vol. 15, pp. 1857–1872.

Kumar, K.R. and Reddy, K.S., 4-E (energy–exergy–environmental–economic) analyses of line-focusing stand-alone concentrating solar power plants, Int. J. Low-Carbon Technol., 2012, vol. 7, no. 2, pp. 82–96. https://doi.org/10.1093/ijlct/cts005

Reddy, K.S. and Devaraj, V.A., (4-E) Energy–exergy–economic–environment analysis of stand-alone solar thermal power plants and solar-coal hybrid plants, J. Fundam. Renewable Energy Appl., 2012, vol. 2, pp. 1–6. https://doi.org/10.4303/jfrea/R120308

Reddy, V.S., Kaushik, S.C., and Tyagi, S.K., Exergetic analysis and performance evaluation of parabolic trough concentrating solar thermal power plant (PTCSTPP), Energy, 2012, vol. 39, pp. 258–273.

Han, W., Hongguang, J., Rumou, L., and Qibin, L., Performance enhancement of a solar trough power plant by integrating tower collectors, Energy Procedia, 2014, vol. 49, pp. 1391–1399.

Avezova, N.R., Khaitmukhamedov, A.E., Usmanov, A.Yu., and Boliyev, B.B., Solar thermal power plants in the World: the experience of development and operation, Appl. Sol. Energy, 2017, vol. 53, no. 1, pp. 72–77.

Kuchkarov, A.A., Kholova, Sh.R., Abdumuminov, A.A., and Abdurakhmanov, A., Optical energy characteristics of the optimal module of a solar composite parabolic-cylindrical plant, Appl. Sol. Energy, 2018, vol. 54, no. 4, pp. 293–296.

Kariman, H., Hoseinzadeh, S., and Heyns, P.S., Energetic and exergetic analysis of evaporation desalination system integrated with mechanical vapor recompression circulation, Case Studies Therm. Eng., 2019, vol. 16, id. 100548.

Hoseinzadeh, S., Yargholi, R., Kariman, H., and Heyns, P.S., Exergoeconomic analysis and optimization of reverse osmosis desalination integrated with geothermal energy, Environ. Prog. Sustainable Energy, 2020, vol. 39, no. 5, id. e13405. https://doi.org/10.1002/ep.13405

Kariman, H., Hoseinzadeh, S., Shirkhani, A., Heyns, P.S., and Wannenburg, J., Energy and economic analysis of evaporative vacuum easy desalination system with brine tank, J. Therm. Anal. Calorim., 2020, vol. 140, pp. 1935–1944. https://doi.org/10.1007/s10973-019-08945-8

Hoseinzadeh, S., Ghasemiasl, R., Javadi, M.A., and Heyns, P.S., Performance evaluation and economic assessment of a gas power plant with solar and desalination integrated systems, Desalin. Water Treat., 2020, vol. 174, pp. 11–25. https://doi.org/10.5004/dwt.2020.24850

Yargholi, R., Kariman, H., Hoseinzadeh, S., Bidi, M., and Naseri, A., Modeling and advanced exergy analysis of integrated reverse osmosis desalination with geothermal energy, Water Supply, 2020, vol. 20, no. 3, pp. 984–996. https://doi.org/10.2166/ws.2020.021

Kariman, H., Hoseinzadeh, S., Heyns, P.S., and Sohani, A., Modeling and exergy analysis of domestic MED desalination with brine tank, Desalin. Water Treat., 2020, vol. 197, pp. 1–13. https://doi.org/10.5004/dwt.2020.26105

Kuchkarov, A.A., Khaitmukhamedov, A.E., Shukurov, A.O., Dekhkonova, M.Kh., and Mukhiddinov, M.R., Calculation of thermal and exergy efficiency of solar power units with linear radiation concentrators, Appl. Sol. Energy, 2020, vol. 56, pp. 42–46. https://doi.org/10.3103/S0003701X20010089

Srivastva, U., Kumar, K.R., Malhotra, R.K., and Kaushik, S.C., Analytical assessment of a concentrated solar subcritical thermal power plant using low temperature heat transfer fluid, Energy Environ., 2020. https://doi.org/10.1177/0958305X20921593

Srivastva, U., Malhotra, R.K., and Kaushik, S.C., Review of heat transport properties of solar heat transfer fluids, J. Therm. Anal. Calorim., 2017, vol. 130, no. 2, pp. 605–621.

Srivastva, U., Malhotra, R.K., and Kaushik, S.C., Experimental investigation of convective heat transfer properties of synthetic fluid, J. Therm. Anal. Calorim., 2018, vol. 132, pp. 709–724.

National Renewable Energy Laboratory. National Solar Radiation Database, 2018. https://maps.nrel.gov/nsrdb. Accessed March 2019.

Lupfert, E., Geyer, M., Schiel, W., Esteban, A., Osuna, R., Zarza, E., and Nava, P., EuroTrough design issues and prototype testing at PSA, Proc. ASME International Solar Energy Conference – Forum 2001, Solar Energy: The Power to Choose, Washington, DC, April 2001, pp. 389–394.

Price, H., Eckhard, L.P., David, K., Zarza, E., and Gilbert, C., Randy, G., Advances in parabolic trough solar power technology, J. Sol. Energy Eng., 2002, vol. 124, pp. 109–125.

Klein, S.A. and Alvarado, F., Engineering Equation Solver, version 8.629, Middleton, WI: F Chart Software, 2010.

Dieckmann, S., Dersch, J., Giuliano, S., Puppe, M., Lupfert, E., Hennecke, K., Pitz-Paal, R., Taylor, M., and Ralon, P., LCoE reduction potential of parabolic trough and solar tower CSP technology until 2025, AIP Conf. Proc., 2017. https://doi.org/10.1063/1.4984538

Kurup, P. and Turchi, C.S., Parabolic trough collector cost update for the system advisor model (SAM), Technical Report NREL/TP-6A20-65228, Golden, CO: Natl. Renewable Energy Lab., 2015.

Central Electricity Regulatory Commission. Petition No. 17/SM/2015. www.cercind.gov.in/2016/orders/ SO17.pdf. Accessed on March 2019.

Gold Standard, 2019. https://www.goldstandard.org/blog-item/carbon-pricing-what-carbon-credit-worth, https://en.wikipedia.org/wiki/Carbon_credit. Accessed on March 2019.

Carbon Credit, 2019. https://en.wikipedia.org/wiki/Carbon_credit. Accessed on October 2019.

Coal India Limited, 2018. https://coal.nic.in/content/coal-grades, https://www.coalindia.in/ DesktopModules/DocumentList/documents/Price_Notification_dated_08.01.2018_effective_from_0000_Hrs _of_ 09.01.2018_09012018.pdf. Accessed on March 2019.

Levelized cost of energy calculator (2015) – LcoE calculator, methodology, assumptions and guidelines. https://ens.dk/en/our-responsibilities/global-cooperation/levelized-cost-energy-calculator. Accessed on October 2019.

Suresh, M.V.J.J., Reddy, K.S., and Ajit Kumar, K., 4‑E (Energy–Exergy–Environment, and Economic) Analysis of solar thermal aided coal-fired power plants, Energy Sustainable Dev., 2010, vol. 14, pp. 267–279.

Twidell, J.W., The political and ethical case for renewable energy. www.jri.org.uk/brief/energy%20renewables.pdf. Accessed on March 2019.

Baharoon, D.A., Rahman, H.A., Wan, Z., Wan, O., and Saeed, O.F., Historical development of concentrating solar power technologies to generate clean electricity efficiently – A review, Renewable Sustainable Energy Rev., 2015, vol. 41, pp. 996–1027.

ACKNOWLEDGMENTS

The authors would like to place on record sincere thanks and gratitude to the management of Indian Oil Corporation Limited, Research and Development Centre, Faridabad, India and also Indian Institute of Technology – Delhi, New Delhi, India, for their permission and support in carrying out the above studies.

Author information

Authors and Affiliations

Corresponding author

APPENDIX A

APPENDIX A

ENERGY AND EXERGY CALCULATIONS

Solar Field

The solar power incident on the collector system (Qi) is given by the equation

Qi = DNIAacos θN,

where N is the product of number of collectors in a row, number of modules in a collector and number of rows of collector array in the solar field.

Actual aperture area (Aa) is given by

Aa = (w – Dco)LN,

where w is the aperture width, L is the aperture length and Dco, is the outer diameter of absorber (receiver) cover.

The exergetic solar power input to parabolic trough is given by

where Ts = 5600 K is apparent black body temperature of sun and T0 the ambient temperature.

The solar power absorbed by the receiver (absorber tube) is given by

k(θ) is known as the incidence angle modifier for the collector and is calculated by

End losses (EL) factor is given by

where f and L are focal length and length of the collector.

The exergetic solar power absorbed by the receiver is given as

where Tr is the receiver temperature (K).

The useful thermal power gain (Qu) by the heat transfer fluid is given by

\({{Q}_{{\text{u}}}} = {\text{Fr}}\left[ {{{Q}_{{\text{a}}}} - {{U}_{{\text{L}}}}{{A}_{{\text{r}}}}\left( {{{T}_{{\text{i}}}} - {{T}_{0}}} \right)} \right],\)

Qu = mfCpf(Ti – T0),

Ar = πDiL.

The collector heat removal factor Fr for the segmental length of the collector is given by

The collector efficiency factor F' is given by

The heat loss coefficient UL for various values of receiver temperatures have been found iteratively [20] using the following set of equations:

where

hg–o heat transfer coefficient from glass tube outer surface to ambient, (W m–2 °C–1).

hg–a heat transfer coefficient from glass tube inner surface to absorber, (W m–2 °C–1).

The outside convective heat transfer coefficient by wind hw [20] for flow of air across a tube can be obtained from the correlations

or

Power Block

[Refer the schematic of the Parabolic Trough based Concentrated Solar Power Plant (PTCSTPP) with 5 MWe turbine rating as per Fig. 3].

Boiler

Energy equation:

Qhtf = m10(h10 – h1) + m2(h2 – h3).

Exergy flow equation

High Pressure Turbine (HPT)

Energy equation: WHPT = m1(h1 – h11) + (m1 – m11)(h11 – h2).

Exergy flow equation

Low Pressure Turbine (LPT)

Energy equation: WLPT = m3(h3 – h12) + (m3 – m12)(h12 – h4).

Exergy flow equation

Condenser

Energy equation: Qhtf = m4(h4 – h5).

Exergy flow equation

Condensate Extract Pump (CEP)

Energy equation: –WCEP = m5(h5 – h6) – energy loss.

Exergy flow equation

Boiler Feed Pump (BFP)

Energy equation: –WBFP = m8(h8 – h9) – energy loss.

Exergy flow equation

\({{T}_{{\text{a}}}}{{S}_{{{\text{gen}}}}}\, = \,{{m}_{8}}({{\psi }_{8}} - {{\psi }_{9}})\, + \,{{W}_{{{\text{BFP}}}}} = {{T}_{{\text{a}}}}{{m}_{8}}({{s}_{9}} - {{s}_{8}})\, = \,{{I}_{{{\text{destroyed}}}}},\)

\({{n}_{{{\text{11,BHP}}}}} = 1 - \frac{{{{I}_{{{\text{destroyed}}}}}}}{{{{W}_{{{\text{BFP}}}}}}} = \frac{{{{m}_{8}}({{\psi }_{8}} - {{\psi }_{9}})}}{{{{W}_{{{\text{BFP}}}}}}}.\)

High Pressure Feed Water Heater (HPH)

Energy equation: 0 = m11(h11 – h14) + m9(h9 – h10).

Exergy flow equation

\(0 = {{m}_{{11}}}({{\psi }_{{11}}} - {{\psi }_{{14}}}) + {{m}_{9}}({{\psi }_{9}} - {{\psi }_{{10}}}) - {{T}_{{\text{a}}}}{{S}_{{{\text{gen}}}}},\)

Low Pressure Feed Water Heater (LPH)

Energy equation: 0 = m12(h12 – h13) + m6(h6 – h7).

Exergy flow equation

Deaerator

Energy equation: m8h8 = m14h14 + m7h7.

Exergy flow equation

About this article

Cite this article

Umish Srivastva, Kumar, K.R., Malhotra, R.K. et al. Designing a Concentrated Solar Thermal Power Plant Using Energy–Exergy–Economic–Environment Analysis. Appl. Sol. Energy 56, 477–489 (2020). https://doi.org/10.3103/S0003701X20060109

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0003701X20060109