Abstract

In this study, a technology producing undoped crystalline zinc oxide films with purposefully changed electrical resistance ρ = 3 × 10–4–1 × 107 Ω cm has been developed. The relationship between the electrical characteristics of ZnO layers and the parameters of their deposition has been studied, and the conditions for the formation of high-resistance i-ZnO and low-resistance n-ZnO films with specified values of electrical resistance have been determined. It has been established that the dominant factor determining the conductivity of ZnO films is a change in the concentration of free carriers, controlled by oxygen vacancies. To select the optimal conditions for the formation of highly transparent coatings with a given conductivity, the microstructure and spectral properties (edge absorption and transmission spectra in the transparency region) of n-ZnO films deposited by reactive magnetron sputtering of a zinc target in an argon atmosphere with oxygen (10% Ar, 90% O2) at a pressure of 5 × 10–3 Torr have been studied. It has been shown that the developed method for the discrete formation of ZnO films on amorphous substrates provides stoichiometric crystal structures with a high packing density and spatial orientation of crystallites in the [002] direction. Even in the case of n-ZnO films with ρ = 3 × 10–3 Ω cm, the microstructure causes a high transmittance of the coatings.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

INTRODUCTION

Currently, the development of miniature sources (laser and luminescent), detectors, and radiation converters of the visible wavelength range raise special interest in wide-gap crystalline media with a high concentration of thermo-, photo-, and radiation-stable optically active defects (intrinsic and impurity), providing the possibility of a predictable change in physical (optical, electrical) parameters of the medium, as well as its intense glow at low volumes and low-power pump sources.

Deposition and studying the physical properties of zinc oxide films continues to be one of the most important areas of physics of semiconductor materials, which is confirmed by hundreds of scientific articles published annually and numerous conferences. In optoelectronics, ZnO films are used as a transparent current collector contacts, modification of optical properties (for example, for matching refractive indices), and as a diffusion barrier [1, 2]. In photovoltaics, the study of ZnO layers is important due to their use as highly transparent electric contacts [3], buffer layers in thin-film Cu(In,Ga)Se2 solar cells [4], other materials (Fig. 1) [1, 2, 5–8], and as short-wave semiconductor diode emitters [2]. It is also interesting to use p/n-ZnO structures for the development of thin-film emitters and absorbers with А2В6 semiconductor nanocrystals formed between p/n-ZnO layers or in their volume [2].

Zinc oxide is one of the promising wide-gap materials, characterized by the ability to achieve high concentrations of intrinsic defects: oxygen vacancies and interstitial zinc atoms, superstoichiometric oxygen (zinc vacancies, VZn), providing the ability to change the optical properties, the conductivity of the medium, and intense glow in green and luminescence in the red region of the spectrum [2, 9]. To obtain ZnО layers, pulsed laser deposition, chemical vapor deposition, and sol–gel technology are widely used [1, 2, 6, 7]. These methods use high temperatures either during deposition or subsequent annealing. Magnetron deposition is a modern technology for producing ZnO films using low temperatures [2, 10, 11]. However, the properties of polycrystalline films deposited by this method have not been studied well so far, which hinders the process of their practical use. Thus, problems associated with the development of the physical foundations for controlling structurally-sensitive properties of layers of photoactive microelectronic devices based on ZnO films, and the optimization of their structural, electrophysical, and optical characteristics are relevant [12].

In contrast to the developed methods of epitaxial growth of ZnO layers on orienting crystalline substrates, reactive magnetron sputtering technology is a relatively simple, cheap, and highly controlled method for depositing high optical quality crystalline ZnO film coatings on glass substrates. In this study, we analyze the key parameters that affect the formation of highly oriented n-ZnO films with given values of electrical resistance.

To study the parameters for deposition of ZnO films for solar cells by reactive magnetron sputtering and to develop sparing modes of deposition of ZnO buffer layers that do not have a destructive effect on the surface of an absorbing layer based on Cu(In,Ga)Se2 materials, we studied the microstructures and optical properties of n-ZnO films with different electrical resistance deposited under identical technological conditions on amorphous substrates.

EXPERIMENTAL

In this study, we used zinc oxide films (geometrical thickness h ~ 0.2–0.6 μm) with a technologically specified specific resistance ρ and a high packing density of oriented crystals. Polycrystalline ZnO films were formed by reactive magnetron sputtering of a zinc target in an argon atmosphere with oxygen (10% Ar, 90% O2) at a pressure of 5 × 10–3 mm Hg and various technological parameters (spraying time and, accordingly, thickness). The developed films are characterized by simplicity and high reproducibility of production under the conditions of technological control of the resistivity parameters in the range ρ = 3 × 10–4–1 × 107 Ω cm.

The relationship between the electrical characteristics of ZnO layers and the parameters of their deposition was examined at room temperature (300 K). The electrical characteristics of films (resistivity, TEMF, conductivity type, carrier mobility, free carrier concentration, and Hall effect) were measured using the four-contact method. An upper Ni electrode with a diameter of 0.5 mm was deposited onto a layer of zinc oxide through a mask by ion beam sputtering. A magnetic field with an induction of up to 6 T was generated by a superconducting solenoid.

The reproduction of the stoichiometric composition in ZnO films was controlled by measuring the absorption intensity (optical density) of samples in the spectral region of edge absorption, as well as in the transparency region of pure ZnO crystals. The elemental distribution of oxygen and zinc over the thickness of ZnO films was carried out by Auger scanning spectroscopy.

The microstructure (structural and morphological properties) of a series of ZnO coatings with significantly different resistivities, including the distribution of crystals over the surface and volume of the samples, was determined by X-ray phase analysis and scanning electron microscopy (SEM). The phase composition and structural characteristics of ZnO films were studied using a DRON-3M setup (CuKα radiation, λ = 1.5405 Å) with a graphite monochromator in the 2θ range of 10°–90°. The phase composition of the films was identified by comparing experimentally determined interplanar distances with the data of the Joint Committee on Powder Diffraction Standard, JCPDS (ZnO card 067848). The surface morphology of the films was studied by SEM (an S-800, Hitachi, Japan).

The transmission spectra of ZnO films were recorded in the wavelength range of 0.19–3.00 μm with a Cary-500 Scan spectrophotometer (UV–Vis–NiR Spectrometer, Varian, USA).

RESULTS AND DISCUSSION

We developed soft modes of deposition of thin buffer layers of i-ZnO coatings, which do not have a destructive effect on the surface of the absorbing layer. Along with high-resistance i-ZnO films, optimization of the process parameters allowed us to obtain intentionally undoped n-ZnO layers with a transmittance of more than 80% in the visible and near-IR spectral regions and resistivities of up to 3 × 10–4 Ω cm, promising for use as transparent conductive electrodes.

A study of the relationship between the electrical characteristics of ZnO layers and the parameters of their deposition allowed us to determine the conditions for the formation of films with reproducible values of electrical resistivity in the range ρ = 3 × 10–4–1 × 107 Ω cm. It was established that the resulting ZnO films have n-type conductivity. Based on preliminary results of the study on the electrical characteristics of the films, it can be assumed that oxygen vacancies, zinc inclusions, and embedded hydrogen molecules determine a high electron concentration in the film since they form a shallow donor level located at 10–50 meV below the bottom of the conduction band. The results are consistent with the data in [2].

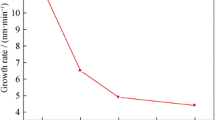

Based on the results of resistivity measurements of a series of ZnO films (Table 1), n-ZnO coatings with different specified conductivity were selected for examination of the structural phase composition and optical properties. The influence of the microstructural factor (phase composition, packing density, and spatial orientation of ZnO crystals) on the optical transmittance of coatings in the transparency region was established by comparing the spectral characteristics of nominally pure ZnO coatings with significantly different resistivity characteristics.

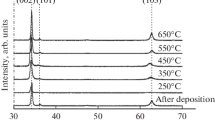

The isotropic microstructure and the homogeneous preferential orientation of a film-forming ZnO crystals to the substrate plane was established. Average crystal size d estimated for ZnO films is ~60–70 nm, regardless of the conductivity of the coatings. Coherent ordering of the growth direction of crystallites (Figs. 2, 3) for n-ZnO coatings of different conductivity values indicates a high crystallinity of the film structures. According to X-ray phase analysis data shown in Fig. 2, i-ZnO and n-ZnO films are polycrystalline and crystallize in the hexagonal structure with a predominant orientation in the [002] direction. The diffraction patterns of n-ZnO films show reflections of the (002) plane of the first- and second-order reflections (004) at 2θ = 34.34° and 72.41°, respectively. The angular position of both peaks is in a good agreement with JCPDS card data for nominally pure zinc oxide. A similar situation is also characteristic of i‑ZnO films.

The data of X-ray phase analysis correlate well with SEM results of the surface and cross-section (Fig. 3) of ZnO sample 64. As can be seen from Fig. 3, close-packed ZnO crystalline structures are characterized by the self-organization of crystals into layers parallel to the substrate plane (Fig. 3a), and relatively low surface roughness (Fig. 3b). SEM images of the surface microrelief and cross-section of the samples under study and the data of their X-ray phase analysis confirm the high optical quality of crystalline ZnO films and the reproducibility of their structure regardless their conductivity.

Typical transmittance spectra of ZnO films of various thicknesses measured at 300 K are characterized by the presence of a wide absorption band in the region of 400–1600 nm (Figs. 4a, 4b), and a shift of the absorption edge to the short-wavelength region of the spectrum (Figs. 4c, 4d), which correlates with an increase in absorption in the infrared region. The average transmittance in the visible and IR spectral regions was 0.80–0.85. The position of the transmission peaks depends on the optical thickness of the deposited layers.

CONCLUSIONS

The results of studying the electrical, microstructural, and spectral properties of the samples under study showed that the developed technology of sequential deposition of ZnO films on amorphous substrates by reactive magnetron sputtering of the zinc target in an argon atmosphere with oxygen (10% Ar, 90% O2) at a pressure 5 × 10–3 mm Hg and different technological parameters allows manufacturing of highly ordered crystalline structures with predictable and reproducible values of resistivity in the range ρ = 3 × 10–4–1 × 107 Ω cm. The parameters of the deposition process change the electrical resistance of the developed ZnO films in a wide range, thus the conditions for the formation of two-layer n-ZnO/i-ZnO structures in a single technological cycle were determined. This is important for reducing the cost of solar cells in serial production. The proposed n-ZnO structures are also promising for the development of a new class of miniature, highly efficient optoelectronic transistors and emitters. In this regard, it is also advisable to note the following characteristics of the studied film structures.

The insulating buffer layers based on i-ZnO films with close packing of crystallites have high resistance (ρ = 1 × 107 Ω cm), while conducting n-ZnO layers are characterized by carrier mobility of ~18 cm2 V–1 s–1, characteristic of crystalline film coatings of high optical quality. ZnO films are polycrystalline and crystallize in a hexagonal structure with a predominant orientation in the [002] direction. ZnO coatings with substantially different resistivities ρ are characterized by the self-organization of crystals with diameter d ~ 60–70 nm into layers parallel to the substrate plane and high transparency (~90%) in a wide spectral range. With a decrease in specific resistance ρ, a short-wavelength shift of the absorption is observed in the spectra of coatings, which correlates with an increase in the intensity of the absorption band in the region of ~2000–2600 nm. The established pattern of variation in the spectral properties of ZnO coatings depending on specific resistance ρ can be explained by an increase in the concentration of oxygen vacancies, as well as the inclusion of zinc and hydrogen molecules since they form a shallow donor level. It should be noted that the concentration of oxygen vacancies is the dominant factor determining the concentration of free carriers and the conductivity of the developed ZnO coatings.

The studied crystalline n-ZnO films and bilayer n‑ZnO/p-ZnO structures formed on their basis can be used in the development of integrable transistors, as well as emitters tunable in the blue—green–red region of the spectrum (450–700 nm) [2, 13–15]. Moreover, in emitters based on film structures, all components of the working element, namely the emitting layer and p/n components, can be obtained within the same technological process, including 3–80 nm layers with semiconductor nanocrystals or LiF/CaF2 nanostructures [15].

REFERENCES

Thin Film Solar Cells: Fabrication, Characterization, and Application, Poortmans, J. and Arkhipov, V., Eds., Leuven: Wiley, 2007.

Godlewski, M., Zinc oxide for electronic, photovoltaic and optoelectronic application, Low Temp. Phys., 2011, vol. 37, no. 3, pp. 235–240.

Kashkul, K.I.N., Technology and properties of zinc oxide films for thin-film solar modules, Extended Abstract of Cand. Sci. (Eng.) Dissertation, St. Petersburg: St. Petersburg Electrotechnical Univ., 2017.

Kobulov, R.R., Matchanov, N.A., Ataboev, O.K., and Akbarov, F.A., Solar cells based on Cu(In, Ga)Se2 thin-film layers, Appl. Sol. Energy, 2019, vol. 55, no. 2, pp. 83–90.

Ramanujam, J. and Singh, U.P., Copper indium gallium selenide based solar cells – a review, Energy Environ. Sci., 2017, vol. 10, pp. 1306–1319.

Luka, G., Godlewski, M., Guziewicz, E., et al., ZnO films grown by atomic layer deposition for organic electronics, Semicond. Sci. Technol., 2012, vol. 27, no. 7, pp. 074006–074013.

Zaretskaya, E.P., Gremenok, V.F., Semchenko, A.V., et al., Structural properties of ZnO:Al films produced by the sol-gel technique, Semiconductors, 2015, vol. 49, no. 10, pp. 1253–1258.

Snigurenko, D., Kopalko, K., Krajewski, T.A., et al., Nitrogen doped p-type ZnO films and p–n homojunction, Semicond. Sci. Technol., 2015, vol. 30, no. 1, pp. 015001–015007.

Gieraltowska, S., Wachnicki, L., Witkowski, B.S., et al., Atomic layer deposition grown composite dielectric oxides and ZnO for transparent electronic applications, Thin Solid Films, 2012, vol. 520, no. 14, pp. 4694–4697.

Zima, V.N., Kozlov, A.G., Tanskaya, T.N., et al., Structure and morphology of zinc oxide films obtained by reactive magnetron sputtering, Vestn. Omsk. Univ. Fiz., 2013, no. 2, pp. 75–79.

Belyanin, A.F., Krivchenko, V.A., Lopaev, D.V., et al., ZnO nanostructured films for microelectronics and optics, Tekhnol. Prots. Oborud., 2006, no. 6, pp. 48–55.

Temirov, A.T., Formation of ZnO films of a specific structure with given electrical and structural properties, Sist. Teknol., 2016, no. 20, pp. 78–83.

Kotlyarevskii, M.B., Rogozin, I.V., Marakhovskii, A.V., and Georgobiani, A.N., Luminescence of ZnO having a superstoichiometric content of oxygen, J. Appl. Spectrosc., 2003, vol. 70, no. 1, pp. 95–98.

Jayatissa, A.H., Preparation of gallium-doped ZnO films by oxidized ZnS films, Semicond. Sci. Technol., 2003, vol. 18, no. 6, pp. 27–30.

Voitovich, A.P., Goncharova, O.V., Kalinov, V.S., and Stupak, A.P., Spectral-luminescent properties of gamma-irradiated fluoride crystals and film structures, J. Appl. Spectrosc., 2003, vol. 70, no. 1, pp. 130–138.

Funding

The study was financially supported by the Belarusian–Uzbek project no. MRB-AN-2019-17, Research of Broadband Composite Anti-Reflective Coatings for Solar Cells, financed by the Ministry of Innovative Development of the Republic of Uzbekistan and the Belarusian Republican Foundation for Fundamental Research (Grant T19UZBG-002).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by D. Kharitonov

About this article

Cite this article

Gremenok, V.F., Ivanov, V.A., Petlitskii, A.N. et al. ZnO Films Obtained by Reactive Magnetron Sputtering: Microstructure, Electrical, and Optical Characteristics. Appl. Sol. Energy 56, 186–191 (2020). https://doi.org/10.3103/S0003701X20030044

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0003701X20030044