Abstract

Chitosan is a cationic natural polymer which has been widely used in various areas. Present study focused on the preparation of the chitosan nanoparticles (NPs) throughout ionic gelation method and using tripolyphosphate (TPP), as non-toxic polyanion counter-ions. Chitosan NPs solutions were prepared by mixing of the 10 mL chitosan solutions, with different concentrations (1, 2 and 3 mg/mL), and different amounts of the TPP (4, 6, 8, 10, 12, 14 mL) at 35 °C. Physico-chemical characteristics of prepared chitosan NPs solutions were evaluated using FT-IR, DLS, TEM and UV-Vis spectroscopy. Achieved results indicated that optimum conditions to prepare opalescent chitosan NPs suspension achieved by using 10 mL of chitosan solution (3 mg/mL) and 14 mL TPP. The provided chitosan NPs at these conditions had highest turbidity (0.317 a.u.) and zeta potential (+15.9 mV) values. The formed spherical chitosan NPs in the solution had minimum mean particle size of 20 nm. Antibacterial activities analysis against both Gram positive and negative bacteria strains indicated that the formed chitosan NPs had higher bactericidal effects as compared to the chitosan solution. Obtained results also revealed that both chitosan solution (3 mg/mL) and its prepared NPs had strong fungicidal activity against Aspergillus flavus.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Organic nanoparticles (NPs) are known as solid particles constructed of organic materials including lipids and polymeric compounds with particle size ranging from 10 nm to 1 μm (Kumar and Lal 2014). Among these NPs, polymer NPs have gained attentions due to their widely applications in numerous areas such as electronics, food packaging, biotechnology, medicines, pharmaceutics and environmental technology (Rao and Geckeler 2011).

Chitosan (poly [β-(1–4)-2-amino-2-deoxy-d-glucon]) is a natural biodegradable polymer which is obtained by partial N-deacetylation of chitin. Chitin is widely found in the shells of insects, shrimp, crab, crawfish, lobster and other crustacean shells (Adlim et al. 2004; Sailaja et al. 2011; Nottagh et al. 2018). As clearly observed in Fig. 1, chitosan has three main reactive functional groups in its structure namely, an amino group (bounded to carbon number 2) and primary and secondary hydroxyl groups bounded to carbon numbers 3 and 6, respectively (Shahidi et al. 1999). These functional groups give unique properties to chitosan including high biocompatibility, biodegradability and antimicrobial, with low immunogenicity and toxicity. However, it has low solubility in aqueous media (Zheng and Zhu 2003; Bodnar et al. 2005). Chitosan is known as a strong antimicrobial agent, which is safe for human body. Several researches and studies have been done on antimicrobial activities of chitosan in different form (i.e. solution, film and composite) against to the algae, bacteria, fungi and viruses (Qi et al. 2004; Goy et al. 2009; Younes and Rinaudo 2015).

As compare to the chitosan in its bulk form, chitosan NPs have considerably special physico-chemical and biological properties such as film forming, hydrophilicity, viscosity, water-uptake ability, biodegradability, mucoadhesion and, antibacterial and antifungal activities (Sharma et al. 2009). Several methods have been developed to prepare chitosan NPs namely, self-assembling, ionic gelation and micro-emulsification or ultrafine milling (Vaezifar et al. 2013). Ionic gelation, is also known as ion-induced gelation, is a mild method for chitosan NPs preparation in an aqueous media without any chemical surface modification of the chitosan molecule. Furthermore, this method is included simple operating conditions (Kunjachan et al. 2010; Vaezifar et al. 2013).

In the chitosan NPs preparation using ionic gelation method, the counter-ions have been widely utilized. These compounds can be categories in three main groups namely, low molecular weight materials (e.g. pyrophosphate and tripolyphosphate), hydrophobic counter-ions (e.g. alginate and polyaldehydro-carbonic acid) and high molecular weight ions (e.g. octyl sulphate and cetylstearyl sulphate) (Sinha et al. 2004; Martins et al. 2012). Tripolyphosphate (TPP) is a non-toxic polyanion which its negatively charged ions can be interacted with chitosan protonated amine groups through electrostatic forces and create ionic cross-linked networks (Martins et al. 2012). Particle size of the prepared chitosan NPs using ionic gelation method and TPP, as counter-ions, is strongly affected by several parameters such as concentration of chitosan and TPP, and reaction time (Sinha et al. 2004; Kunjachan et al. 2010; Martins et al. 2012; Vaezifar et al. 2013). There is a direct relationship between antimicrobial activity of the NPs and their particle size, where smaller particle size shows higher bactericidal and fungicidal activities (Eskandari-Nojehdehi et al. 2016). Aspergillus flavus is the most frequently identified Aspergillus species in human infection. Aflatoxins are poisonous carcinogens that are produced by A. flavus (Klich 2007). Streptococcus pyogenes is clinically important for humans. It is an infrequent, but usually pathogenic, part of the skin microbiota (Lamagni et al. 2008). Escherichia coli and Staphylococcus aureus are two main pathogenic food-borne bacteria (Cho et al. 2016).

Therefore, the main aims of the this study were to (i) study the effects of concentrations of chitosan and TPP on the particle size of the prepared chitosan NPs (as manifested in solution turbidity) using ionic gelation method and (ii) evaluate physico-chemical properties and antimicrobial activities of the prepared chitosan NPs against to four mentioned pathogenic bacteria and fungi strains.

Materials and methods

Materials

Medium molecular weight chitosan with deacetylation degree of 85% was bought from Sigma-Aldrich (Aldrich Co. Steinheim, Germany). Sodium tripolyphaphate (TPP) was obtained from Scharlau (Scharlau Co. Barcelona, Spain). Aspergillus flavus (PTCC 5004), Escherichia coli (PTCC 1270), Staphylococcus aureus (PTCC 1112) and Streptococcus pyogenes (PTCC 1447) were attained from microbial Persian type culture collection (PTCC, Tehran, Iran). Potato dextrose agar (PDA) as culture media for A. flavus was provided from Oxoid (Oxoid Ltd., Hampshire, England). Violet red bile agar as culture media for E. coli, baird parker agar as culture media for S. aureus and blood agar as culture media for Str. pyogenes, were purchased from Merck (Merck co. Darmstadt, Germany). Double distilled water was used to prepare all aqueous solutions.

Preparation of chitosan NPs

Chitosan NPs were prepared using the ionotropic gelation between chitosan and sodium TPP. Chitosan solutions with different concentrations (1, 2 and mg/mL) were provided in acetic acid aqueous solution (1% V/V). According to the literature studies, TPP solution with concentration of the 1% W/V was prepared [16]. After that, different amounts of TPP solution (4, 6, 8, 10, 12 and 14 mL) were added into the10 ml of the chitosan solutions on the magnetic stirrer adjusted at 500 rpm and 35 °C. The obtained opalescent suspension indicated that chitosan NPs were prepared.

Physico-chemical characteristics of the prepared chitosan NPs

Chitosan NPs formation can be easily visualized by observation of the opalescent suspension which, samples opacity was determined using a Jenway UV-visible (UV-Vis) spectrophotometer (6705, Jenway Ltd., Essex, UK) adjusted at a wavelength of 625 nm. In fact, the opalescent suspension with higher turbidity (absorbance unit) indicated the higher concentration of the formed chitosan NPs (Du et al. 2009; Martins et al. 2012). Morphological assay (shape and size) of the produced chitosan NPs was done using Transmission electron microscopy (TEM, CM120, Philips, Amesterdam, Netherlands). Mean particle size, particle size distribution and zeta potential of the formed chitosan NPs, were measured using a dynamic light scattering (DLS) particle size analyzer (Nanotrac Wave, Microtrac, USA) and were presented by number.

Fourier transform infrared (FT-IR) spectrum of chitosan and its NPs was taken with potassium bromide pellets on a spectrometer (Bruker, Tensor27, Karlsruhe, Germany) at wave number range of 400–4000 cm−1.

Chitosan and its NPs antibacterial activity

Antibacterial activity of chitosan NPs was measured by agar well diffusion method against S.aureus and Str.pyogenes as Gram- positive and E.coli as Gram-negative bacteria. The bacterial suspensions containing 1.5 × 108 colony forming unit (cfu) per 1 mL of the suspensions were provided based on the described manner by Eskandari-Nojehdehi et al. (2016). 0.1 mL of the prepared suspensions was then poured in the sterile plates and the provided culture mediums were added into the plates and completely mixed with the suspensions. After solidification of medium inoculated with bacteria suspensions, three wells with diameter of 5 mm were made in the solidified medium. 10 μL of the chitosan solution (1 mg/mL) and its NPs solutions with different concentrations (1, 2 and 3 mg/mL) was added into the wells and the plates were incubated at 37 °C for 24 h. After that, the diameter of the growth inhibition zones was measured as antibacterial activity of the chitosan and its NPs.

Chitosan and its NPs antifungal activity

Antifungal activity of chitosan solution, and its NPs against A. flavus was evaluated using a method based on radial mycelia growth of A. flavus inhibition on the culture media containing PDA incorporated with chitosan and its prepared NPs, as described method by Torabfam and Jafarizadeh-Malmiri (2018). In this method, a pure culture of the A. flavus was prepared on the plate containing PDA, during 72 h of incubation (26 ± 2 °C). After that, three agar disks (5 mm diameter) from plate containing pure culture of the fungus were isolated and located in the center of plates containing PDA (as control sample), PDA conjugated with chitosan and PDA amended with chitosan NPs. The prepared plates were then incubated at 26 ± 2 °C for 5 days. Mycelia growth diameters of the fungus on the plates were monitored daily and antifungal activity of the chitosan and its NPs was stated as inhibition of the fungal hyphae growth (mm).

Statistical analysis

Physico-chemical analysis of the prepared chitosan NPs were carried out in three replications. Data were interpreted by analysis of variance (ANOVA) using Minitab v.16 statistical package (Minitab Inc., PA, USA). Tuky’s comparison test was used to compare the mean values. All comparison was made at 5% level of significance.

Results and discussions

Formation of chitosan NPs

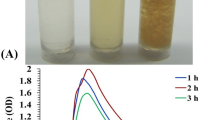

During preparation of chitosan NPs, three different aqueous solutions, namely; clear solutions, opalescent suspensions and aggregates could be obtained which the opalescent suspensions were related to the formed chitosan NPs (Fig. 2). As clearly observed in Fig. 2a, the chitosan solution, without TPP, was completely clear. While the chitosan NPs solution, was opalescent. By addition extra amounts of the TPP, the formed chitosan NPs were aggregated and a two separated phase solution was obtained (Fig. 2c).

The visually obtained results indicated that by increasing the amounts of the TPP solution into the chitosan solutions, with constant concentrations, the turbidity of the samples, as absorbance unit (a.u.), increased. Table 1 shows the turbidity intensity of the prepared solutions. The obtained results indicated that the opalescent suspension solutions with higher turbidity were obtained by incorporating of the 6, 10 and 14 mL of the TPP solution into the 10 mL of chitosan solution with concentrations of the 1, 2 and 3 (W/W), respectively. However, the obtained chitosan NPs solution using 10 mL of chitosan solution (3% W/W) and 14 mL of TPP showed the highest turbidity (0.317 a.u.) which represented the highest concentration of the formed chitosan NPs in the solution. Therefore, this sample was selected to further physico-chemical and antimicrobial analysis.

Chitosan NPs characteristics

Particle size, shape and distribution are more important parameters for the prepared nanosuspensions (Sayyar and Jafarizadeh-Malmiri 2018). The dynamic light scattering method based on scattering of a laser light beam at the surface of dispersed NPs and detection of the backscattered light could be effectively used to determine these essential parameters (Eskandari-Nojedehi et al. 2018). Figure 3 shows size distribution profile of the selected chitosan NPs solution with highest formed NPs concentration. As clearly observed in this figure, most of the formed chitosan NPs had particle size values lower than 100 nm. The obtained result by DLS indicated that the prepared chitosan NPs had mean particle size of 74.4 nm.

Zeta potential is related to the charge density of the NPs surface and drastically affects suspension stability based on the electrostatic repulsion between NPs (Qi et al. 2004). Zeta potential measurement revealed that the formed chitosan NPs in the selected solution were more stable and had an average surface charge of +15.9 mV, which the positive charge of this value was related to the presence of protonated amine free groups in the chitosan structure (Fig. 1).

TEM image of the chitosan NPs solution, presents in Fig. 4. As can be seen, the formed chitosan NPs had spherical shape, smooth surface and mean particle size of 20 nm. This revealed that the formed NPs had lowest surface energy with highest thermodynamic stability, and is in agreement with high value of the zeta potential of the created chitosan NPs (Ghanbari et al. 2018).

FTIR analysis

FTIR is widely utilized to determine chemical structure and existing functional groups of the polymers, and investigate their possible interactions. The FTIR spectra of the chitosan and its NPs are indicated in Fig. 5a and b, respectively. For the chitosan (Fig. 5a), the strong and wide peak at 3452.30 cm−1 was attributed to –OH and -NH2, related to extra-molecular hydrogen bonding of molecules stretching vibration (Qi et al. 2004; Zhan et al. 2012; Vaezifar et al. 2013). The peak at 1638.55 cm−1 specified N-H stretching vibrations in amine (R-NH2) and amide (R-CONH2). In the chitosan NPs spectra (Fig. 5b), a shift from 3452.30 to 3445.28 cm−1 is indicated and the peak is sharper in the chitosan NPs, which demonstrates that the hydrogen bonding is enhanced (Qi et al. 2004). In chitosan NPs, the 1638.55 cm−1 peak of –NH2 bending vibration shifts to 1557.81 cm−1 and a new sharp peak 1645.11 cm−1 appears and a new weak peak at 1150 cm−1 corresponding to P=O groups. Therefore, it seems that the tripolyphosphoric groups of TPP and ammonium groups of the chitosan were interconnected together in the formed NPs (Wu et al. 2005).

Antibacterial activities of the chitosan and its NPs

Bactericidal effects of chitosan and its NPs on the growth of Streptococcus pyogenes (Gram-positive) during incubation are presented in Fig. 6. As can be observed (Fig. 6), for chitosan solution (1 mg/mL), the inhibitions zone with 20 mm diameter was created. However, the diameter of the formed clear zone around the chitosan NPs with concentrations of 1 and 3 mg/mL were 25 and 27 mm, respectively. The achieved results revealed that the bactericidal effect of the formed chitosan NPs were higher than that of the chitosan solution. Furthermore, by increasing the concentration of the chitosan in the solutions, bactericidal effects of the formed chitosan NPs increased. The achieved results were in line with findings of Ying Ma et al. (2010). Chitosan has bactericidal effect only in an acidic medium due to its poor solubility in natural and basic solutions (pH > 6.5) (Qi et al. 2004). However the real bactericidal mechanism of chitosan is not yet clear, but it seems that the changes in the microorganisms cell and membrane permeability due to combination of the positively charged groups of the chitosan (amine) and the negatively charged compounds of the membrane (N-acetylmuramic acid, sialic acid and neuraminic acid) is the main mechanism of the chitosan antibacterial activity (Younes and Rinaudo 2015). Bactericidal effects of the prepared chitosan NPs with different concentrations against to the S. aureus and E.coli are indicated in the Figs. 7 and 8, respectively. As clearly observed in this figure, for both selected bacteria, by increasing the concentration of chitosan in the chitosan NPs solutions, the antibacterial activities increased. However, the bactericidal effects of the prepared chitosan NPs on the S. aureus was higher than that of on the E. coli, due to the higher crated clear zone around the wells. The obtained results indicated that, when chitosan NPs interacted with the bacteria cell wall, an impermeable layer formed around the cell which that prevented entering essential solutes inside the bacteria and vice versa (Cruz-Romero et al. 2013).

Antifungal activities of the chitosan and its NPs

Antifungal activities of the chitosan solution (3 mg/mL) and chitosan NPs solution (3 mg/mL) as their effects on the inhibition of mycelia growth of A. flavous during 5 days of incubation are indicated in Fig. 9. As clearly observed in this figure, as compared to the control sample the chitosan and its NPs effectively limited the mycelia growth of A. flavous. Obtained result can be explained by the fact that, chitosan can easily penetrate inside the fungus hyphae and by binding to the specific enzymes, those are responsible for the fungus growth, decreases their activities. Furthermore, the intensity of chitosan fungicidal can be mainly related to its concentration, deacetylation degree and pH of the aqueous solution (Yien 2012). It is known that by increasing the concentration of chitosan, the number of cations (NH3+) in the chitosan solution increases which those can easily bind to the fungus membrane and alter its permeability which in turn, that causes microorganisms death. Antifungal activity of chitosan is greater at lower pH values due to its higher solubility as compared to that of in natural and basic solutions (Kong et al. 2010). On the other hand, by increasing deacetylation of chitosan its mucoadhesion increased which in turn, increases the binding capacity of chitosan to the microorganism cell membrane (Goy et al. 2009).

Conclusions

The simple, low energy and cost-effective ionic gelation fabricated technique using medium molecular weight chitosan and TPP was developed to produce chitosan NPs solution, with the desired morphological characteristics, higher stability and strong antimicrobial activities against to numerous bacteria and fungi strains. Smaller particle size of chitosan NPs increased surface area to volume ratio of the formed NPs, high surface energy and a lot of surface active centers as compared to the chitosan in bulk form, which those increased bactericidal and fungicidal effects of the fabricated chitosan NPs and make them more useful and applicable in the medicine and pharmaceutical fields.

Abbreviations

- ANOVA:

-

Analysis of variance

- DLS:

-

Dynamic light scattering

- FT-IR:

-

Fourier transform infrared

- NPs:

-

Nanoparticles

- PTCC:

-

Persian type culture collection

- PDA:

-

Potato dextrose agar

- TEM:

-

Transmission electron microscopy

- TPP:

-

Tripolyphosphate

References

Adlim M, Abu bakar M, Liew KY, Ismail J (2004) Synthesis of chitosan-stabilized platinum and palladium nanoparticles and their hydrogenation activity. Mol Catal A Chem 212:141–149. https://doi.org/10.1016/j.molcata.2003.08.012

Bodnar M, Hartmann JF, Borbely J (2005) Preparation and characterization of chitosan-based nanoparticles. Biomacromolecules 6:2521–2527. https://doi.org/10.1021/bm0502258

Cho TJ, Kim NH, Kim SA, Song JH, Rhee MS (2016) Survival of foodborne pathogens (Escherichia coli O157: H7, Salmonella Typhimurium, Staphylococcus aureus, Listeria monocytogenes, and Vibrio parahaemolyticus) in raw ready-to-eat crab marinated in soy sauce. Int J Food Microbiol 238:50–55. https://doi.org/10.1016/j.ijfoodmicro.2016.08.041

Cruz-Romero M, Murphy T, Morris M, Cummins A, Kerry JP (2013) Antimicrobial activity of chitosan, organic acids and nano-sized solubilisates for potential use in smart antimicrobially-active packaging for potential food applications. Food Control 34:393–397. https://doi.org/10.1016/j.foodcont.2013.04.042

Du WL, Niu SS, Xu YL, Xu ZR, Fan CL (2009) Antibacterial activity of chitosan tripolyphosphate nanoparticles loaded with various metal ions. Carbohydr Polym 75:385–389. https://doi.org/10.1016/j.carbpol.2008.07.039

Eskandari-Nojedehi M, Jafarizadeh-Malmiri, Rahbar-Shahrouzi J (2018) Hydrothermal green synthesis of gold nanoparticles using mushroom (Agaricus bisporus) extract: physico-chemical characteristics and antifungal activity studies. Green Process Synth 7:38–47. https://doi.org/10.1515/gps-2017-0004

Eskandari-Nojehdehi M, Jafarizadeh-Malmiri H, Rahbar-Shahrouzi J (2016) Optimization of processing parameters in green synthesis of gold nanoparticles using microwave and edible mushroom (Agaricus bisporus) extract and evaluation of their antibacterial activity. Nanotechnol Rev 5:537–548. https://doi.org/10.1515/gps-2017-0004

Ghanbari S, Vaghari H, Sayyar Z, Adibpour M, Jafarizadeh-Malmiri H (2018) Autoclave-assisted green synthesis of silver nanoparticles using A. fumigatus mycelia extract and the evaluation of their physico-chemical properties and antibacterial activity. Green Process Synth 7:217–224. https://doi.org/10.1515/gps-2017-0062

Goy RC, Britto D, Assis OB (2009) A review of the antimicrobial activity of chitosan. Polímeros 19:241–247. https://doi.org/10.1590/S0104-14282009000300013

Klich MA (2007) Aspergillus flavus: the major producer of aflatoxin. Mol Plant Pathol 8:713–722. https://doi.org/10.1111/j.1364-3703.2007.00436.x

Kong M, Chen XG, Xing K, Park HJ (2010) Antimicrobial properties of chitosan and mode of action: a state of the art review. Int J Food Microbiol 144:51–63. https://doi.org/10.1016/j.ijfoodmicro.2010.09.012

Kumar R, Lal S (2014) Synthesis of organic nanoparticles and their applications in drug delivery and food nanotechnology: a review. J Nanomater Mol Nanotechnol 3. https://doi.org/10.4172/2324-8777.1000150

Kunjachan S, Jose S, Lammers T (2010) Understanding the mechanism of ionic gelation for synthesis of chitosan nanoparticles using qualitative techniques. Asian J Pharm 4:148–153. https://doi.org/10.4103/0973-8398.68467

Lamagni TL, Darenberg J, Luca-Harari B, Siljander T, Efstratiou A, Henriques-Normark B, Vuopio-Varkila J, Bouvet A, Creti R, Ekelund K, Koliou M (2008) Epidemiology of severe Streptococcus pyogenes disease in Europe. J Clini Microbiol 46:2359–2367. https://doi.org/10.1128/JCM.00422-08

Ma Y, Liu P, Si C, Liu Z (2010) Chitosan nanoparticles: preparation and application in antibacterial paper. J Macromol Sci 49:994–1001. https://doi.org/10.1080/00222341003609542

Martins AF, De oliveira DM, Pereira AGB, Rubira AF, Muniz EC (2012) Chitosan/TPP microparticles obtained by microemulsion method applied in controlled release of heparin. Int J Biol Macromol 51:1127–1133. https://doi.org/10.1016/j.ijbiomac.2012.08.032

Nottagh S, Hesari J, Peighambardoust SH, Rezaei-Mokarram R, Jafarizadeh-Malmiri H (2018) Development of a biodegradable coating formulation based on the biological characteristics of the Iranian Ultra-filtrated cheese. Biologia 73:403–413. https://doi.org/10.2478/s11756-018-0039-0

Qi L, Xu Z, Jiang X, Hu C, Zou X (2004) Preparation and antibacterial activity of chitosan nanoparticles. Carbohydr Res 339:2693–2700. https://doi.org/10.1016/j.carres.2004.09.007

Rao JP, Geckeler KE (2011) Polymer nanoparticles: preparation techniques and size-control parameters. Prog Polym Sci 36:887–913. https://doi.org/10.1016/j.progpolymsci.2011.01.001

Sailaja A, Amareshwar P, Chakravarty P (2011) Different techniques used for the preparation of nanoparticles using natural polymers and their application. Int J Pharm Pharm Sci 3:45–50

Sayyar Z, Jafarizadeh-Malmiri H (2018) Photocatalytic and antibacterial activities study of prepared self-cleaning nanostructure surfaces using synthesized and coated ZnO nanoparticles with curcumin nanodispersion. Z Kristallogr. https://doi.org/10.1515/zkri-2018-2096

Shahidi F, Arachchi JKV, Jeon YJ (1999) Food applications of chitin and chitosans. Trends Food Sci Technol 10:37–51. https://doi.org/10.1016/S0924-2244(99)00017-5

Sharma VK, Yngard RA, Lin Y (2009) Silver nanoparticles: green synthesis and their antimicrobial activities. Adv Colloid Interf Sci 145:83–96. https://doi.org/10.1016/j.cis.2008.09.002

Sinha V, Singla AK, Wadhawan S, Kaushik R, Kumria R, Bansal K, Dhawan S (2004) Chitosan microspheres as a potential carrier for drugs. Int J Pharm 274:1–33. https://doi.org/10.1016/j.ijpharm.2003.12.026

Torabfam M, Jafarizadeh-Malmiri H (2018) Microwave-enhanced silver nanoparticle synthesis using chitosan biopolymer: optimization of the process conditions and evaluation of their characteristics. Green Process Synth 7:530–537. https://doi.org/10.1515/gps-2017-0139

Vaezifar S, Razavi S, Golzar MA, Karbasi S, Morshed M, Kamali M (2013) Effects of some parameters on particle size distribution of chitosan nanoparticles prepared by ionic gelation method. Cluster Sci 24:891–903. https://doi.org/10.1007/s10876-013-0583-2

Wu Y, Yang W, Wang C, Hu J, Fu S (2005) Chitosan nanoparticles as a novel delivery system for ammonium glycyrrhizinate. Int J Pharm 295:235–245. https://doi.org/10.1016/j.ijpharm.2005.01.042

Yien L (2012) Antifungal activity of chitosan nanoparticles and correlation with their physical properties. Int J Biomater 2012. https://doi.org/10.1155/2012/632698

Younes I, Rinaudo M (2015) Chitin and chitosan preparation from marine sources. Structure, properties and applications. Marine Drugs 13:1133–1174. https://doi.org/10.3390/md13031133

Zhan W, Zhang J, Jiang Q, Xia W (2012) Physicochemical and structural characteristics of chitosan nanopowders prepared by ultrafine milling. Carbohydr Polym 87:309–313. https://doi.org/10.1016/j.carbpol.2011.07.057

Zheng LY, Zhu JF (2003) Study on antimicrobial activity of chitosan with different molecular weights. Carbohydr Polym 54:527–530. https://doi.org/10.1016/j.carbpol.2003.07.009

Acknowledgments

The authors would like to acknowledge the Iran Nanotechnology Initiatives Council (INIC) for funding the development of an innovative methodology for safety assessment of industrial nanomaterials (grant no. 103762).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shafiei, M., Jafarizadeh-Malmiri, H. & Rezaei, M. Biological activities of chitosan and prepared chitosan-tripolyphosphate nanoparticles using ionic gelation method against various pathogenic bacteria and fungi strains. Biologia 74, 1561–1568 (2019). https://doi.org/10.2478/s11756-019-00299-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.2478/s11756-019-00299-8