Abstract

Predicting carbonation resistance via early site tests is crucial for controlling the longevity and durability of concrete structures. Therefore, this study aimed to provide a nondestructive approach for predicting carbonation resistance utilizing in situ air-permeability and surface moisture measurements. The Torrent air-permeability method, coupled with surface moisture measurements by the electrical impedance method, was applied to 25 specimens produced using different cement types, water-to-binder ratios, and curing periods to obtain test data at various ages from 1 to 18 months; the carbonation depths were measured at 6, 12 and 18 months. To overcome the challenge of the moisture effect on measured values during the drying process, the kT5 indicator, permeability coefficient at the reference moisture of 5.0% was utilized. Strong correlations between kT5 and the carbonation rates were obtained that allowed the latter's prediction from tests of air-permeability and surface moisture performed at relatively early ages (e.g., 1 or 3 months). Guidance on the procedure is outlined.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Concrete cover is the least distance between the surface of the embedded reinforcement and the exposed surface. It plays a crucial function as the first shielding, protecting the inner part of a concrete structure and the embedded steel reinforcement [1,2,3]. Nonetheless, it is the most permeable part of the structure because of its higher porosity than that of the concrete's internal part. The movement of gases, liquids, and ions through this layer occurs during the service life of concrete structures and can cause the deterioration of reinforced concrete structures [4,5,6]. Thus, an appropriate assessment of the transport properties of the concrete cover is crucial for controlling the longevity and durability of concrete structures [7,8,9].

Depending on the process' driving force and the transported matter type, transport qualities can be characterized as diffusion, absorption, or permeation [2, 8]. Among these, air-permeability, a reliable characteristic representing permeation, is closely related to the pore structure of concrete [2, 8, 10] and can be measured via destructive and non-destructive test methods [11,12,13]. Pertaining to the non-destructive aspect, several permeability assessment methods have been proposed and validated [14,15,16,17,18]. Among these methods, a double vacuum cell test, Torrent’s air-permeability test, was proposed to determine the coefficient of permeability kT and the affected depth [15]. The application of the method was preliminarily verified via comparison with the Cembureau method [19, 20].

Indeed, the Torrent air-permeability test has been extensively applied as a non-destructive method for quality control of concrete on site without damaging its structures [15, 21]. Numerous studies have employed the kT measured by the Torrent method, as a robust durability indicator to discuss and verify other indices or other concrete durability characteristics [21,22,23]. Moreover, it has been considered a durability design factor for the residual service life of reinforced structures affected by carbonation and chloride ingress [5, 24].

On the other hand, the measured air-permeability values strongly depend on the drying condition (i.e., the surface moisture content, m) of the measured concrete, as observed via the increment in kT of around three orders of magnitude from near saturation to oven-drying at 105 °C [7, 25,26,27]. For instance, Parrott investigated the correlation between moisture conditioning and transport properties at the surface of concrete test specimen [7]. Based on the experimental results, he found that air-permeability was sensitive to changes in the moisture content of the concrete, especially at relative humidity (RH) > 60%. The corresponding sample preconditions were recommended as a countermeasure to prevent the effect of the surface moisture content. Jacobs studied changes in the gas permeability of partially saturated concrete [26] and demonstrated a linear correlation between the gas permeability and water content in concrete pores using a logarithmic function. Romer monitored the influence of surface moisture content on kT values in controlled environmental conditions for a period of up to one year [27]. They found that the absolute values of kT depend on the concrete age and its surface moisture conditions. The reduction in the kT value owing to the elevated water saturation of concrete can underestimate the intrinsic permeability. As a result, changes in the degree of saturation of the pore system were reflected in variations in surface moisture content and variable blockage of gas flow through the pore system. In addition, it was found that moisture remaining in the pores or low-permeability concrete can evaporate into the test cell at very low vacuum pressures, artificially raising its pressure [28].

To address the above problems, several studies have focused on attempts to compensate for the effect of moisture on kT, or on methods used to assess kT at moisture equilibrium [29,30,31,32,33]. In early attempts to compensate for the effect of moisture on kT, two different techniques were investigated: James H2O meter (that failed) and the Wenner method [29]. A solution was proposed to compensate for the influence of moisture using a combination of kT and electrical resistivity measurements (by the Wenner method), which failed owing to difficulties in measuring the electrical resistivity on-site [34] and to the strong effect of the binder type on that property. Another solution requested a waiting time, such as 3–4 weeks after the completion of curing or 2–5 days after the last exposure to moisture, to withstand the high moisture influence (e.g., rain, sea spray) [35, 36]. Furthermore, incorporating in-situ and laboratory-based permeability testing techniques was suggested as part of an integrated strategy [37]. This strategy aimed to reduce the influence of moisture on in situ permeability measurements. The test results indicated that the controlled moisture content did not significantly affect the kT value in the context of the overall classification. However, no specific equation was provided to complement the effect of moisture content on the kT value. Based on experimental data, Misak et al. [30] proposed an equation to assess the impact of moisture content h (measured by KAKASO capacitive humidity meter) on the kT values:

where \({kT}_{0}\) and \(\alpha\) are compensation factors for the kT value measured at moisture h. Based on 153 test results, the proposed values of \({kT}_{0}\) and \(\alpha\) were 5.25 × 10–16 m2 and 0.862, respectively. In Switzerland, a study conducted at the Empa laboratory proved the suitability of a device to assess the surface moisture m of concrete based on changes in electrical impedance [27]. Recently, a comprehensive study was conducted on the relationship between m and kT for drying concretes [38]. Based on a large database from five different independent sources and a robust analysis process, a novel practical approach was proposed to compensate for the effect of moisture content m on kT. The proposed approach uses the kT5 value, which corresponds to a moisture content of 5.0%, as a reference index. The obtained results indicate a promising application of Torrent air-permeability for the flexible assessment of air-permeability at various surface moisture conditions.

In fact, assessing concrete carbonation resistance through Torrent air-permeability has been attended to due to their close correlations and the advantages of the Torrent test as an in-situ non-destructive method [23, 39, 40]. However, thus far, assessing concrete carbonation resistance through Torrent air-permeability considering the effect of surface moisture content has not been investigated, although a potential approach utilizing the application of the kT5 concept was proposed, as mentioned above.

Taking into account the literature results summarized above, the objective of the present study is to establish a unified approach for kT measurement at any moisture state to assess and predict the concrete carbonation resistance based on extensive experimental data in a laboratory. To realize this, the Torrent air-permeability was applied to various specimen qualities to collect the kT values at the ages of 1, 3, 6, 12, and 18 months (hereafter called kTm at the surface moisture content m). The correlations between kT5 calculated from these kTm values and the corresponding carbonation rates collected on the specimens were established and discussed to validate the usability of kT5 as an excellent index for predicting carbonation resistance.

2 Experimental program

2.1 Test variables

To analyze the changes of air-permeability and carbonation rate for different concrete qualities, 25 concrete specimens were prepared with three types of cement, nine water-to-binder ratios (W/B), and five curing conditions, as indicated in Table 1. Here, 20 of the 25 specimens were collected from four earlier works [23, 31, 40, 41]. Details on the specimens, such as the materials, mix compositions and curing procedures, can be found in the earlier publications. To widen the scope of this investigation to include other concrete qualities, five more specimens were cast using the same materials as for the prior specimens: OPC concretes with greater W/B (65% and 75%) and HPC concrete with a W/B of 41%. After curing, the air-permeability kTm and the surface moisture m were measured at five different ages and the carbonation depth at 6, 12, and 18 m, as described below.

2.2 Materials and mix proportions

Three types of cement were used in the concrete mixes: ordinary Portland cement (OPC), blast-furnace slag-type B cement (BBC), and high early strength Portland cement (HPC) according to JIS R 5210 [42] and JIS R 5211 [43]. Fine (S) and coarse (G) aggregates of crushed porphyry were used. Expansive agents of the ettringite type were used. To meet the required workability and improve the performance of fresh concrete even under cold weather conditions, chemical agents were utilized, including superplasticizers (SF500U and type-I VP700) and AE water-reducing agents (EX60 and SV10L) (AD). To mix the cement components, tap water was used. The 13 mix compositions and fresh concrete properties are listed in Table 1.

2.3 Specimen preparation

Thirteen concrete mixes were investigated to monitor m, kTm, and carbonation depth. A manufacturer produced ready-mixed concretes for mixes HPC41 and BBC53E. The remaining concrete mixtures were prepared in the laboratory with the use of a pan-type mixer. Prior to casting, the slump (or slump flow), and air content of fresh concrete were measured. The prismatic specimens were then cast, as shown in Fig. 1. The dimensions of the six large prismatic specimens (mixes HPC41 and BBC53E) were 600 × 900 × 600 mm (see Fig. 1a). Those of the two small prismatic specimens (mixes OPC65 and OPC75) were 400 × 100 × 100 mm (see Fig. 1c), and those of the 17 medium prismatic specimens (for the remaining mixes) were 800 × 300 × 200 mm (see Fig. 1b).

The specimens were kept in the moulds for the periods indicated in Table 1 (i.e., 1, 3, 5, 7, and 28 days) to create 25 different concrete qualities, protecting the exposed surface from evaporation and stored in a room at ~ 20.7 °C. Then, specimens were demoulded and exposed to air as follows. The six large prismatic specimens (Fig. 1a) and the two small prismatic specimens (Fig. 1c) were exposed without sealing, whereas the 17 medium prismatic specimens were sealed using aluminium foil with two 800 × 300 mm surfaces left exposed (Fig. 1b). The two small prismatic specimens were stored in a controlled room at 20 °C /60% RH, whilst the other specimens were stored in a normal room at 21.2 °C /62.1% RH on average. Carbon dioxide concentration was around 0.04%, as recorded by the ZG106 CO2 monitor. Four test locations were selected on each measurement surface, avoiding large bubbles and visible cracks to limit their effects on the results.

2.4 Test methods

At each measurement age, the tests (surface moisture content, air permeability, and carbonation) were directly conducted on the given surfaces, i.e., vertical surfaces of the large, medium, and small specimens with the dimensions of 900 × 600 mm, 800 × 300 mm, and 400 × 100 mm, respectively.

2.4.1 Surface moisture measurement

The moisture content of the specimens m was monitored throughout the experiment. An impedance-based CMEXpert II Concrete Encounter Moisture Meter (Tramex, Ireland) was employed in compliance with the American Society for Testing and Materials (ASTM) standard F2659 [44]. The device works by sending a low-frequency signal through parallel co-planar electrodes into the concrete. Its suitability for monitoring changes in the surface moisture content of concrete specimens has been verified in previous investigations, despite the fact that it offers indirect readings [32, 38, 45]. The specimens were measured at the ages of 1, 3, 6, 12, and 18 months later. The arithmetic means of the surface moisture content values measured on four test locations are reported.

2.4.2 Air-permeability measurements

The kTm was assessed by utilizing a Torrent tester, PermeaTORR AC (Active cell) in accordance with the Swiss standard SN 505 262/1:2013 [15, 20]. The tester uses a double chamber cell to create a unidirectional airflow toward the central chamber so that kTm can be calculated using a suitable model [15, 46]. After the surface moisture measurement, the Torrent tests were conducted at 1, 3, 6, 12, and 18 months. The geometric mean of the values obtained at four test locations was utilized to compute the kTm values.

2.4.3 Carbonation depth measurements

After the surface moisture and air permeability measurements, five cores (30 mm, length 50 mm) were drilled at 12 and 18 months for the large and medium specimens and split. The small prismatic specimens were split at 6 and 12 months. Detailed measured carbonation depths of the specimens are provided in Appendix 1. The carbonation depth was measured by spraying the split surface with 1% phenolphthalein indicator solution. The averages of five and ten measured points of the split surfaces were calculated to evaluate the concrete carbonation progress (the carbonation rate was computed as the carbonation depth divided by the square root of the exposure time, averaging the values obtained at both ages).

3 Results and discussion

3.1 Assessing concrete carbonation resistance via kT m index

Correlations between the carbonation rate and kTm—the latter measured at the ages of 1, 3, 6, 12, and 18 months- are presented in Fig. 2 (dashed lines). Regardless of the cement type, for each measurement age, the plots indicate a single correlation between carbonation rate and kTm, for the 25 concrete specimens, which agrees with and expands the findings of previous studies [22, 47, 48]. The resulting high coefficients of determination (R2 ≥ 0.797) validated the regressions obtained by fitting power lines. However, the results indicated that the correlation is dependent on the age at which kTm was measured and the resulting moisture conditions. As shown in Fig. 2, the coefficient of determination gradually increases with the age of the kTm (from 0.797 to 0.916). A single estimated red line covering all data with high correlation could not be obtained (R2 = 0.753). It means that kTm can be proposed as a promising durability index for predicting the carbonation progress of different concrete types, when the measurement age could be selected, in particular, when later measurement age was selected.

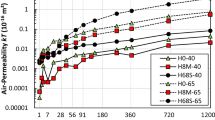

Figure 3 shows the significant changes in kTm with surface moisture m for the 25 concrete specimens investigated. A monotonic increase in kTm for lower m (drier concrete) can be observed for each mix. In other words, the moisture conditions of the specimens (i.e., the surface moisture content of the specimens) play a vital role in obtaining representative measurements of the air-permeability coefficient. Even though the short-age correlations in Fig. 2 are acceptable [20, 40], later age measurements of kTm yield better coefficients of determination. In particular, the kTm values at 18 months are considered highly representative measurements for predicting the carbonation progress.

Nevertheless, a sufficient drying stage strongly depends on the surrounding conditions during the exposure period for in situ measurements. Even under laboratory conditions, a late-age measurement (e.g., at 18 months) requires a prolonged waiting time for representative measurements, which is not practical. Thus, concrete structures' changing surface moisture content is the main barrier preventing the above approach for assessing concrete carbonation resistance through kTm. To address this issue and provide a flexible approach for predicting the concrete carbonation resistance, a new approach utilizing kT5 was presented in the next section.

3.2 Predicting concrete carbonation resistance based on the kT 5 index

This section proposes a flexible and practical approach for predicting the concrete carbonation resistance using the kT5 index. Herein, kT5 is the air-permeability value corresponding to a moisture m = 5.0% [38], computed as,

where \({F}_{5}\) is a compensation factor for the value of kTm measured at moisture m, and is computed as follows,

Equations (2) and (3) were derived from the analysis of the variation of kT with m during the drying of 50 concrete mixes which originated from five different sources [38]. Ideally, for a particular concrete and m ranging between 1 to 6%, the kT5 value is expected to compensate the effect of m on kTm and remain unchanged [38]. To clarify this idea, in this study, the kT5 values at 1, 3, 6, 12, and 18 months were calculated based on Eqs. (2) and (3), and correlations with the carbonation rate were established. Figure 4 shows the correlations between the carbonation rate and kT5 calculated from kTm and m at the ages of 1, 3, 6, 12, and 18 months. Two aspects are worth mentioning in Fig. 4. First, for each measurement age, especially for early measurement ages from 1 to 6 months, the scatter of the kT5 values is smaller compared with that of the kTm values shown in Fig. 3. This supports the use of the former as a valid indicator of the air-permeability of the mix. Second, regardless of the measurement age, a single line (solid red line) giving unique correlations with high coefficients of determination (R2 = 0.856) can be established between the carbonation rate and kT5 for all concretes. This means that the results in Fig. 4 indicate the differences between the regression dashed lines (carbonation rate and kT5) obtained for each testing age, and the overall red solid line, are insignificant. Additionally, the values for three binders follow reasonably well the general trend and, therefore, are not differentiated.

To find out the most appropriate measurement procedure for accessing carbonation resistance utilizing the kT5 index, correlations between carbonation rate and kT5 calculated from different accumulated ages were established and discussed. In detail, correlations between carbonation rate and kT5 calculated from double and triple measurements were then established, as presented in Figs. 5a and b, respectively. The procedure to calculate kT5 from single, double, triple, and accumulated measurement ages was presented in Appendix 2. The result indicates that the strongest correlation was found in the case of kT5 calculated at all accumulated ages rather than other measurement cases. The obtained R2 value of 0.914 for all accumulated ages (1 + 3 + 6 + 12 + 18 months) was higher than those from single (Fig. 4), double (Fig. 5a), and triple (Fig. 5b) measurements. Outcomes suggested that the adopted approach was the most appropriate for accessing carbonation resistance under a standard environmental condition (~ 20 °C and ~ 60%RH). Based on the found correlation, concrete carbonation resistance can be assessed by utilizing the kT5 index, as shown in Eq. (4).

where Kc denotes carbonation rate, (mm/\(\sqrt{month}\)), obtained from concrete specimens with OPC, BBC, or HPC around 20 °C /60%RH /0.04%CO2, kT5 is the air-permeability value, (10–16 m2), corresponding to a moisture m = 5.0%, and is calculated from kTm and m via Eqs. (2) and (3).

For a detailed comparison of kTm and kT5 for predicting concrete carbonation resistance, their accuracies were further evaluated using additional analytical indices: mean, standard deviation (SDs), and coefficient of variation (CoV) of the ratio of the predicted carbonation rate to the measured carbonation rate (see Table. 2). Here, the carbonation rates were predicted by using kTm in the equation for all the data (\({K}_{c}= 1.16{{ kT}}_{{m}}^{0.29}\)) in Fig. 2 or kT5 in Eq. (4). As expected, the mean, SDs, and CoV indices were improved significantly from 1.076, 0.427, and 39.7% for kTm to 1.028, 0.230, and 22.3% for kT5, respectively. The results verified the higher accuracy of the kT5 index for predicting concrete carbonation resistance. Furthermore, the results indicated that variations in the analytical indices using kT5 predicted from multiple measurement times (geomean) were slightly reduced compared to those from a single measurement. These imply that the measured coefficient of air-permeability, kTm, can be used to obtain the moisture-compensated air-permeability indicator, kT5, for accurately predicting the carbonation resistance of concrete. They also indicate that multiple measurements can further improve accuracy.

On the basis of the obtained results, a novel approach for predicting concrete carbonation resistance using kT5 as an indicator can be formulated as described below.

The proposed procedure used to predict the carbonation rate consists of the following steps:

-

1.

Define concrete lots following, for instance, the recommendations of [20].

-

2.

Measure the kTm values and the surface moisture m on at least six random test locations of each lot, at an age that ranged from 1 and 18 months, preferably between 1 and 6 months. Multiple measurements can be conducted at two or more different ages for improved prediction.

-

3.

For each single age measurement, kT5 value is calculated from the geometric mean of kTm and average moisture m, calculated from single measurement age, applying Eqs. (2) and (3). For multiple measurements, kT5 value is calculated from the geometric mean value of kT5 at several measurement ages, as presented in Appendix 2.

-

4.

Calculate the predicted carbonation rate Kc by applying Eq. (4).

4 Conclusions

This study presented and validated the application of the Torrent method to measure the coefficient of air-permeability kTm, coupled with the parallel measurement of the surface moisture m for the assessment of the concrete carbonation resistance. Both non-destructive tests were applied on 25 concretes of various qualities, which were produced by using different cement types, W/B ratios, and curing periods to collect kTm and m values measured at the ages of 1, 3, 6, 12, and 18 months. At ages of 12 ± 6 months, the carbonation depth was measured, from which the carbonation rate of each mix could be computed based on the assumption of a “square-root law” of the carbonation process. The measured values of kTm increased whilst those of m decreased with age owing to the continuous exposure to a relatively dry environment. For each mix and age of test, a kT5 value –corresponding to a reference moisture content of 5.0%– was computed, which compensated for the effect of m on kTm. Strong correlations were found between the calculated kT5 and the corresponding carbonation rates. These correlations indicated the usability of kT5 as a good indicator for predicting the carbonation resistance of various concrete qualities, for which a simple procedure was proposed.

This study's findings contributed to the establishment of a simple and practical method for predicting carbonation resistance from the moisture-compensated index, kT5. In practice, the proposed Eq. (4) can be employed flexibly as a promising solution for predicting carbonation resistance of concrete structures produced by OPC, BBC, or HPC under a drying process at a standard condition (i.e., around at temperature/RH of 20 °C /60%). Given the limitation of this study, the approach is valid with three cement types at the standard condition. Thus, further investigations should be conducted with other binders, such as fly ash or limestone filler cement, to clarify the extended application of the proposed approach in the broader range. In addition, the effect of moisture state on carbonation progress under various environmental conditions will be another research topic in the future.

References

Committee 318 ACI (2005) Building code requirements for structural concrete (ACI 318-05) and commentary (ACI 318R-05). American Concrete Institute

Long AE, Henderson GD, Montgomery FR (2001) Why assess the properties of near-surface concrete? Constr Build Mater 15:65–79. https://doi.org/10.1016/S0950-0618(00)00056-8

Basheer PAM, Nolan É (2001) Near-surface moisture gradients and in situ permeation tests. Constr Build Mater 15:105–114. https://doi.org/10.1016/S0950-0618(00)00059-3

Mahdikhani M, Bamshad O, Fallah Shirvani M (2018) Mechanical properties and durability of concrete specimens containing nano silica in sulfuric acid rain condition. Constr Build Mater 167:929–935. https://doi.org/10.1016/j.conbuildmat.2018.01.137

Neves R, Torrent R, Imamoto K (2018) Residual service life of carbonated structures based on site non-destructive tests. Cem Concr Res 109:10–18. https://doi.org/10.1016/j.cemconres.2018.04.002

Ahmad S (2003) Reinforcement corrosion in concrete structures, its monitoring and service life prediction––a review. Cement Concr Compos 25:459–471. https://doi.org/10.1016/S0958-9465(02)00086-0

Parrott LJ (1994) Moisture conditioning and transport properties of concrete test specimens. Mater Struct 27:460–468. https://doi.org/10.1007/BF02473450

Basheer L, Kropp J, Cleland DJ (2001) Assessment of the durability of concrete from its permeation properties: a review. Constr Build Mater 15:93–103. https://doi.org/10.1016/S0950-0618(00)00058-1

Mather B (2004) Concrete durability. Cement Concr Compos 26:3–4. https://doi.org/10.1016/S0958-9465(02)00122-1

Yokoyama Y, Nakarai K, Sakai Y, Kishi T (2021) Influences of moisture change and pore structure alteration on transport properties of concrete cover. Cement Concr Compos 122:104090. https://doi.org/10.1016/j.cemconcomp.2021.104090

Neville AM (2011) Properties of concrete, 5th edn. Pearson, London

Malhotra VM, Carino NJ (2003) Handbook on nondestructive testing of concrete. CRC Press, London

Maierhofer C, Reinhardt H-W, Dobmann G (2010) Non-destructive evaluation of reinforced concrete structures: non-destructive testing methods. Elsevier, London

Schonlin K, Hilsorf HK (1988) Permeability as a measure of potential durability of concrete–development of a suitable test apparatus. Special Publ 108:99–116. https://doi.org/10.14359/3608

Torrent RJ (1992) A two-chamber vacuum cell for measuring the coefficient of permeability to air of the concrete cover on site. Mater Struct 25:358–365. https://doi.org/10.1007/BF02472595

Basheer PAM, Andrews RJ, Robinson DJ, Long AE (2005) ‘PERMIT’ ion migration test for measuring the chloride ion transport of concrete on site. NDT & E Int 38:219–229. https://doi.org/10.1016/j.ndteint.2004.06.013

Yang K, Basheer PAM, Magee B, Bai Y (2013) Investigation of moisture condition and Autoclam sensitivity on air permeability measurements for both normal concrete and high performance concrete. Constr Build Mater 48:306–314. https://doi.org/10.1016/j.conbuildmat.2013.06.087

Yang K, Basheer PAM, Bai Y et al (2014) Development of a new in situ test method to measure the air permeability of high performance concretes. NDT and E Int 64:30–40. https://doi.org/10.1016/j.ndteint.2014.02.005

R.J. Torrent, L. Fernández (Eds.), Non-destructive evaluation of the penetrability and thickness of the concrete cover, RILEM TC 189 NEC, RILEM Report 40 (2007) 223

Sn 505 262/1 Construction en béton—Spécifications complémentaires, Annexe E: perméabilité à l’air dans les structures SSIA, Switzerland (2013)

Andrade C, Gonzalez-Gasca C, Torrent R (2000) Suitability of torrent permeability tester to measure air-permeability of covercrete. pp 301–317

Neves R, da Fonseca BS, Branco F et al (2015) Assessing concrete carbonation resistance through air permeability measurements. Constr Build Mater 82:304–309. https://doi.org/10.1016/j.conbuildmat.2015.02.075

Nguyen MH, Nakarai K, Nishio S (2019) Durability index for quality classification of cover concrete based on water intentional spraying tests. Cement Concr Compos 104:103355. https://doi.org/10.1016/j.cemconcomp.2019.103355

Torrent R (2013) Service life prediction: theorecrete, labcrete and realcrete approaches Keynote Paper. In: SCTM3 conference, Kyoto, Japan, pp. 18–21 August

Chen W, Liu J, Brue F et al (2012) Water retention and gas relative permeability of two industrial concretes. Cem Concr Res 42:1001–1013. https://doi.org/10.1016/j.cemconres.2012.04.003

Jacobs F (1998) Permeability to gas of partially saturated concrete. Mag Concr Res 50:115–121. https://doi.org/10.1680/macr.1998.50.2.115

Romer M (2005) Effect of moisture and concrete composition on the torrent permeability measurement. Mat Struct 38:541. https://doi.org/10.1007/BF02479545

Torrent R (2012) Non-destructive air-permeability measurement: from gas-flow modelling to improved testing. Paper 151, Microdurability 2012, Amsterdam, pp. 11–13

Torrent R, Ebensperger L (1993) Studie über methoden zur messung und beurteilung der Kennwerte des Überdeckungsbetons auf der Baustelle. Office Fédéral des Routes, Rapport No. 506, Bern, Suisse

Misák P, Kucharczyková B, Vymazal T, et al (2010) Determination of the quality of the surface layer of concrete using the TPT method and specification of the impact of humidity on the value of the air permeability coefficient

Nguyen MH, Nakarai K, Kai Y, Nishio S (2020) Early evaluation of cover concrete quality utilizing water intentional spray tests. Constr Build Mater 231:117144. https://doi.org/10.1016/j.conbuildmat.2019.117144

Torrent R, Bueno V, Moro F, Jornet A (2019) Suitability of impedance surface moisture meter to complement air-permeability tests. In: RILEM PRO 128, durability, monitoring and repair of structures, pp 56–63

Nakarai K, Shitama K, Nishio S et al (2019) Long-term permeability measurements on site-cast concrete box culverts. Constr Build Mater 198:777–785. https://doi.org/10.1016/j.conbuildmat.2018.11.263

Jacobs F, Denarié E, Leemann A, and Teruzzi T, (2009) Empfehlungen zur Qualitätskontrolle von Beton mit Luftpermeabilitätsmessungen, Office Fédéral des Routes, VSS Report 641, December 2009, Bern, Switzerland, 53 p

Torrent R, Denarié E, Jacobs F et al (2012) Specification and site control of the permeability of the cover concrete: the Swiss approach. Mater Corros 63:1127–1133. https://doi.org/10.1002/maco.201206710

Jacobs F, Denarie E, Leemann A, Teruzzi T (2009) Empfehlungen zur Qualitätskontrolle von Beton mit Luftpermeabilitätsmessungen. Forschungsauftrag AGB 2007/007. Office Fédéral des Routes, VSS Report 641 (2010), Zürich, Switzerland. Transl. (Chapters 1 and 2), R. Torrent. Recommendations for quality control of concrete with air-permeability measurements. Buenos Aires, Argentina. www.m-a-s.com.ar. 26 Sept 2011

Starck S, Beushausen H, Alexander M, Torrent R (2017) Complementarity of in situ and laboratory-based concrete permeability measurements. Mater Struct 50:177. https://doi.org/10.1617/s11527-017-1037-3

Bueno V, Nakarai K, Nguyen MH et al (2021) Effect of surface moisture on air-permeability kT and its correction. Mater Struct 54:89. https://doi.org/10.1617/s11527-021-01666-1

Neves R, Branco F, de Brito J (2012) About the statistical interpretation of air permeability assessment results. Mater Struct 45:529–539. https://doi.org/10.1617/s11527-011-9780-3

Nguyen MH, Nakarai K, Torrent R (2020) Service life prediction of steam-cured concrete utilizing in-situ air permeability measurements. Cement Concr Compos 114:103747. https://doi.org/10.1016/j.cemconcomp.2020.103747

Nguyen MH, Nishio S, Nakarai K (2022) Effect of temperature on nondestructive measurements for air permeability and water sorptivity of cover concrete. Constr Build Mater 334:127361. https://doi.org/10.1016/j.conbuildmat.2022.127361

Japanese Industrial Standards, JIS R 5210, Portland cement, (2009)

Japanese Industrial Standards, JIS R 5211, Portland blast-furnace slag cement, (2009)

ASTM F2659 Standard guide for preliminary evaluation of comparative moisture condition of concrete, gypsum cement and other floor slabs and screeds using a non-destructive electronic moisture meter, ASTM International, West Conshohocken (2015)

Torrent R, Moro F, Jornet A (2013) Coping with the effect of moisture on air permeability measurements. RILEM international work performance-based specific control concrete durability, pp 489–498

Torrent R, Frenzer G (1995) A method for rapid determination of the coefficient of permeability of the “covercrete,”. In: International Symposium on Non-Destructive Testing in Civil Engineering, pp. 985–992

Belgacem ME, Neves R, Talah A (2020) Service life design for carbonation-induced corrosion based on air-permeability requirements. Constr Build Mater 261:120507. https://doi.org/10.1016/j.conbuildmat.2020.120507

Bonnet S, Balayssac J-P (2018) Combination of the Wenner resistivimeter and Torrent permeameter methods for assessing carbonation depth and saturation level of concrete. Constr Build Mater 188:1149–1165. https://doi.org/10.1016/j.conbuildmat.2018.07.151

Japanese Standards Association (2011) JIS A 6204:2011, Chemical admixtures for concrete

Acknowledgements

The experiments were supported by Mr. Toshikazu Matsuyama and students, especially Mr. Daiki Yamamoto, from the Structural Engineering Laboratory of Hiroshima University. The authors are grateful for the assistance provided.

Funding

This research was financially supported by the Chugoku Regional Development Bureau, Ministry of Land, Infrastructure, Transport and Tourism, Japan.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

Author declares that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix 1

Table 3 shows the carbonation depth and carbonation rate of the concrete specimens used in this study.

Appendix 2

The procedure to calculate kT5 from single and multiple (double, triple, and accumulated) measurement ages can be assessed by the following equation:

where \({kT}_{5,i}\) is a value calculated at i-th measurement, utilizing Eqs. (2) and (3); \({kT}_{5}\) is the geometric mean value of \({kT}_{5,i}\) values; n is the total number of measurements (1 for kT5 at single age, 2 for kT5 at double ages, 3 for kT5 at triple ages, and 5 for kT5 at accumulated ages).

Rights and permissions

About this article

Cite this article

Nguyen, M.H., Nakarai, K., Torrent, R.J. et al. Concrete carbonation prediction based on air-permeability tests with moisture compensation. Mater Struct 56, 3 (2023). https://doi.org/10.1617/s11527-022-02081-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1617/s11527-022-02081-w