Abstract

Magnesium is attractive for orthopedic implants because of its similar mechanical properties to those of bone but often degrades too rapidly. Coatings such as hydroxyapatite (HA), the mineral component of bone, are useful for modulating degradation, thereby enhancing osseointegration and biocompatibility. The goal of this study was to longitudinally evaluate the effects of solution-deposited HA coating on magnesium degradation. We hypothesized the HA coating would be stable, slowing the degradation of pure magnesium. Analyses of mass; solution pH; magnesium in solution; surface morphology, chemistry, and roughness; and cytotoxicity were performed through 30 days. Despite morphological changes in the HA coating beginning at day 20, the mass, elemental composition, and surface roughness of the HA-coated group were unchanged through 30 days, demonstrating the stability of the coating and its ability to mitigate degradation of the underlying magnesium. This work provides longitudinal insight into the biodegradation of HA-coated magnesium for orthopedic implants.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The investigation for improved orthopedic implant materials (e.g., joint replacement hardware, screws, and plates) is ongoing and started with the development of first generation, bioinert materials [1]. As the definition of a biomaterial shifted from bioinert to bioactive, the need for interactive and dynamic materials emerged. Traditional orthopedic implants that serve to stabilize bone fractures (e.g., screws and pins) are typically manufactured from corrosion-resistant materials such as stainless steel or titanium alloys. Although these materials have demonstrated clinical success and typically elicit no adverse immune response, they are not designed to be absorbed by the body and replaced with native bone. Furthermore, metals like titanium alloys have a much higher Young’s modulus (approximately 110 GPa) than native bone (10–30 GPa), which can cause the implant to bear the majority of mechanical loads [2]. This phenomenon, known as stress shielding, can lead to atrophy of bone surrounding the implant and residual pain [3], necessitating a second surgery to remove the implant [4]. The complications that can arise from traditional non-degradable implants necessitate exploration of new implant materials, such as resorbable magnesium alloys, to improve long-term patient outcomes for applications in which a permanent implant is not needed.

As an alternative, biodegradable materials such as magnesium and its alloys may serve as temporary implants [5,6,7], especially for fracture fixation during bone healing, due to magnesium’s attractive biological and mechanical properties. Recent clinical implementation has already shown magnesium alloy to be an effective biodegradable material in orthopedic applications [8]. Magnesium is a naturally occurring element in the body, obtained mainly through diet and plays a key role in bone remodeling [9]. When pure, unalloyed magnesium is exposed to aqueous fluid environments, degradation begins almost immediately, as evidenced by the formation of a thick layer of degradation products within days of in vivo implantation [10]. Furthermore, magnesium degrades rapidly, forming localized pits and produces hydrogen gas in the process. In vivo studies have shown that large pockets of hydrogen gas collected in the tissues near the site of magnesium implants [11, 12]. It is difficult for the body to process this gas quickly enough, and its accumulation can elicit pressure necrosis on local tissues.

The Young’s modulus of magnesium is approximately 41–45 GPa (same order of magnitude as native bone), which has been shown to minimize the risk of stress shielding [13]. Nonetheless, a non-uniformly degrading implant can introduce uneven stress concentrations and heterogenous load transfer that are inadequate for supporting the surrounding (regenerating) bone over time. The rate of bone healing is typically a slow process and is dependent upon several biological and mechanical factors, but complete remodeling of a fracture or defect may occur over the course of months to years, depending on the severity of the injury [14, 15]. These time frames may even be extended for patients who are elderly or immunocompromised. To reduce the degradation rate of magnesium, it can be alloyed with corrosion-resistant metals. The efficacy of alloying in slowing degradation is dependent on the type and amount of trace elements [16,17,18]. For example, the class of alloys including zinc and aluminum (AZ class) is particularly of interest in biomedical research for their systemic biocompatibility and improved corrosion resistance, although these alloys still undergo rapid ion release that creates an inhospitable alkaline environment for local tissues [19]. Coating magnesium and its alloys is also a suggested method for slowing degradation and encouraging osseointegration [20,21,22,23].

Surface modifications introduced by techniques including acid etching, alkali treatment, laser surface processing, and surface coatings are common approaches to slow the degradation rate of magnesium and facilitate a more uniform degradation [24]. Surface coatings are particularly advantageous for their ability to insulate the magnesium implant, reducing the degradation rate and the pitting degradation without altering the mechanical integrity of the substrate material. Additionally, surface coatings can increase the biocompatibility of the implant due to the inherent biocompatibility of many coating compounds [24]. Coatings vary widely and include ceramics, such as hydroxyapatite (HA) and other calcium phosphate compounds [25], polymer coatings such as polycaprolactone (PCL) [26] or poly l-lactic acid (PLLA) [27], fluoride coatings [28], and composite coatings [29,30,31,32] in which two or more coatings are combined or layered. Ceramic coatings are commonly implemented due to their biocompatibility and resistance to degradation, an advantage over synthetic polymers that are biodegradable but release by-products that may incite an inflammatory response [33, 34].

Hydroxyapatite (HA), the mineral component of bone, is being investigated as a surface coating or additive in composites due to its high thermal stability, biocompatibility, and ease of synthesis [22]. In vitro, HA fibers were reported to increase osteogenic differentiation shown by increased alkaline phosphatase and osteocalcin gene expression [35]. HA coating of pure magnesium screws implanted in rabbit tibiae promoted osseointegration at the implant–tissue interface by enhancing bone–implant interaction when compared to a non-coated magnesium implant [36]. Osseointegration is characterized by a direct connection between the implant and living bone, that is both structural and functional [37]. An important factor affecting an implant’s ability to establish a stable implant–tissue interface is the surface roughness and topography [37]. Currently, numerous methods are being investigated for creation of HA coatings on magnesium surfaces, including electrodeposition, magnetron deposition, plasma spraying, and chemical hydrothermal solution deposition [20, 22, 38]. Electrodeposition uses a calcium phosphate electrolyte solution coupled with an applied potential and has been shown to produce a stable coating that increased the corrosion resistance of magnesium samples [38]. Magnetron deposition is a type of physical vapor deposition that utilizes a magnetic field applied to a target that can be adapted to ceramic and polymer coatings [39, 40]. Plasma spraying is another commercialized method for coating metal substrates with a variety of coatings. Plasma spraying utilizes plasma gas to melt powders into a molten spray that is then projected onto a metal surface. However, the high temperatures required may decompose the hydroxyapatite, and more work is needed to tailor this method for magnesium substrate [41]. Lastly, hydrothermal solution deposition uses high calcium and phosphorus concentrations in solution to chemically bind HA to the magnesium surface [22]. Hydrothermal solution deposition is a single-step technique that requires no specialized equipment, uses commercially available solutes, and is low cost. Further, by varying solution pH, solute concentration, and time, the solution deposition method enables modulation of HA crystal structure and amount of HA deposited. Solution deposition is especially advantageous for coating complex geometries such as orthopedic implants using simple immersion [22, 42]. Porous surfaces are becoming increasingly popular for orthopedic implants designed to undergo osseointegration; solution deposition provides an immersive coating technique for these unique surfaces and has been suggested to more effectively coat the implant, compared to plasma spraying methods [43].

The objective of this study was to facilitate HA-coating of pure magnesium via a hydrothermal solution deposition method and longitudinally evaluate the effects of the HA coating on the degradation of pure magnesium. Outcome measures included characterization of mass; solution pH; magnesium in solution; surface morphology, chemistry, and roughness; and cytotoxicity over 30 days. In this study, we evaluated the physical and chemical changes in magnesium and HA-coated magnesium in a temporal fashion, investigating the efficacy of hydroxyapatite for modulating degradation of the magnesium substrate. It was hypothesized that HA coating of pure magnesium would mitigate material degradation over 30 days when compared to uncoated magnesium. Many studies report only short-term (< 7 days) time points or fail to provide sufficient (if any) intermediate time points in their analysis. The 30-day time frame not only allows evaluation of implant degradation in the acute phase (< 2 weeks) but also elucidates the process until the point at which bone remodeling would be expected to begin (~ 4 weeks) [44]. Here, the longitudinal outcome measures upto 30 days provide valuable insight into mechanisms of coating degradation and overall coating durability [20, 21, 38]. In addition, the solution deposition method demonstrated here is a practical method for coating magnesium implants with geometries for which plasma spraying would be ineffective. Understanding the biomaterial changes during the early degradation period will inform future studies and advance the field of bioresorbable magnesium implants.

Results

Confirmation of HA coating

Prior to the immersion experiment, parameters of solution deposition were optimized using AZ31, as the mechanism of HA formation has been shown to be the same on AZ31 and pure magnesium [45]. Surface profilometry showed no significant difference in line average roughness (Ra) between the 8, 16, and 24 h timepoints [Fig. 1(B)]. FTIR comparison showed the amount of HA deposited on the surface increased from 8 to 16 h then remained stable to 24 h [Fig. 1(C)]. The phosphate v3 stretching mode band between 976 and 1190 cm−1 and the phosphate v4 stretching mode band between 520 and 660 cm−1 have similar intensities in the 16 h and 24 h spectra, suggesting consistent HA content at the two time points [46]. Spectra collected pre- and post-sonication showed no change in HA chemical composition after sonication [Fig. 1(D)]. SEM images visually showed the presence of HA crystals on the surface [Fig. 1(E)]. Based on this analysis, a 16-h treatment time and a solute concentration of 0.25 M were determined to be adequate coating conditions, and samples used for subsequent immersion degradation experiments were coated using these parameters. XRD analysis confirmed the presence of the HA coating, with peaks indicative of the HA coating present including the HA(0 0 2) peak, HA(2 1 1) peak, and HA(1 1 2) peak (Supplemental Fig. 1A). Additionally, the full width at half-maximum (FWHM) of the HA(0 0 2) peak has a value of 0.21, which suggests high crystallinity of the deposited coating [22, 45].

(A) Location of four profiles that were extracted for line average roughness (Ra) measurements from Talysurf. (B) Ra (mean ± SD) of HA-coated disks under varying conditions. (C) FTIR spectra, % transmittance, of 8 h, 16 h, and 24 h HA treatment at 0.25 M concentration. Vertical lines indicate peaks of interest. (D) FTIR spectra, % transmittance, pre- and post-sonication of 16 h, 0.25 M concentration samples, indicating the coating was not removed by sonication. (E) SEM images of 8 h, 16 h, and 24 h samples at 0.25 M concentration. Images shown at × 1000 magnification.

Mass change

One of the most direct measures to track degradation is by measuring the mass at each time point throughout an immersion experiment, in this study at days 0, 3, 10, 20, and 30 [Fig. 2(A)]. An overall effect of HA coating on mass was observed, and a difference in mass between the two groups was seen at day 30 (*p < 0.05), indicating that the coating minimized degradation over the 30-day period. Although there was no significant change between the mass at any time points for either the HA-coated or non-coated group, the non-coated group showed a generally decreasing trend in mass.

(A) Mass of HA-coated and non-coated Mg samples at days 0 (initial weight pre-degradation), 3, 10, 20, and 30 of degradation. (B) pH of extract medium at days 3, 10, 20, and 30. (C) Mg ion concentration in extract medium at days 3, 10, 20, and 30. (D) Cumulative Mg ion concentration at days 0, 3, 10, 20, and 30. *Significant difference between coated and non-coated groups at the same time point. #Significant difference compared to non-coated day 3. Data are mean ± SD.

Solution pH and magnesium ion release

The degradation solution pH was ~ 8.0 to 8.5 for both the HA-coated and non-coated groups throughout the 30-day study, and pH of the non-coated group was higher than that of the HA-coated group on day 30 [*p < 0.05, Fig. 2(B)]. A more gradual increase in magnesium ion concentration in solution was observed for the HA-coated group compared to the non-coated group, which experienced spikes in concentration at days 10 and 30 (Fig. 2(C)]. Cumulative ion concentration was significantly higher in the non-coated group at all immersion time points—days 3, 10, 20, and 30 (*p < 0.05, Fig. 2D). Solutions from the non-coated samples had an average concentration of 22.0 mM by day 30, while solutions from the HA-coated samples had an average concentration of 8.8 mM by day 30.

Scanning electron microscopy (SEM)

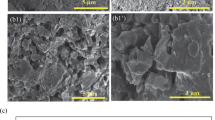

SEM imaging at × 250 magnification revealed changes to the surfaces of both coated and non-coated samples over the 30-day degradation period (Fig. 3). Initial (day 0) scans of the HA-coated samples showed a base layer of HA, with scattered particulate crystals. The morphology of these crystals was rod-like (Supplemental Fig. 1B). At days 3 and 10 of degradation, these crystals were still apparent, but appeared to be changing morphologically into a more rounded shape. By day 20, the HA base layer and the particulate crystals were distinguishable from each other in the coating. Interestingly, two of the five coated samples lacked particulate crystals at day 20 (Fig. 3), and these samples underwent pitting behavior beginning at this time point. Two HA-coated samples were chosen for the × 250 images in Fig. 3 to represent the samples that underwent both early (day 20) and later (day 30) pitting. The other three coated samples maintained prominent crystallization, but similarly to the other two coated samples, also showed signs of significant cracking at day 20. By day 30, all coated samples appeared similar in the extent of pits and cracks present.

SEM images of HA-coated samples at × 250 (first and second row) and × 1000 (third row). Two representative samples were chosen for the HA-coated × 250 images due to surface variations within the group. Non-coated samples at × 250 are also shown (fourth row). Images representative of sample surfaces at days 0, 3, 10, 20, and 30. Scale bar at × 250 is 20 µm. Scale bar at × 1000 is 10 µm.

Initial scans of the non-coated samples prior to immersion showed a smooth surface. By day 3 of degradation, all non-coated samples showed obvious cracking on the surfaces, while HA-coated samples did not begin cracking until day 20. By day 10, small pits (~ 30 μm diam.) began to form on the non-coated samples. These pits grew progressively larger (~ 60 μm diam.) by day 20 and were more difficult to distinguish from one another by day 30 due to the severe extent of degradation. The non-coated surface at day 30 showed the presence of smaller degradation particles, likely products such as Mg(OH)2 produced from reactions with the immersion solution [47, 48].

Chemical microanalysis via EDS

EDS was used to quantify the chemical composition of the sample surfaces. At each time point, the magnesium and oxygen composition of the non-coated group was significantly higher than those for the HA-coated group [*p < 0.05, Fig. 4(A–B)]. This was expected due to the presence of the HA coating. Within the non-coated group, the magnesium composition was significantly reduced from day 0 to day 3 (ap < 0.05), and from day 3 to days 10, 20, and 30 (bp < 0.05), showing the percentage of magnesium on the surface of the non-coated samples was undergoing significant changes. For the HA-coated group, the composition of all elements—magnesium, oxygen, calcium, and phosphorus—remained consistent over time [Fig. 4(A–D)].

Chemical composition of the surface of HA-coated and non-coated samples at days 0, 3, 10, 20, and 30 using energy-dispersive X-ray spectroscopy. (A) Magnesium percentage by weight for coated and non-coated groups. (B) Oxygen percentage by weight for coated and non-coated groups. (C)–(D) Phosphorus and calcium percentage by weight, respectively, for coated samples only. *Significant difference between coated and non-coated groups. “a” indicates a significant difference compared to day 0 within a group. “b” indicates a significant difference compared to day 3 within a group. Data are mean ± SD.

Surface profilometry

Surface profilometry was used to analyze initial coating thickness and quantify changes on the surface of the samples over time. Prior to degradation, the thickness of the HA coating was approximately 3.5 μm. Greater variation in surface topography over time was observed in the non-coated group compared to the HA-coated group [Fig. 5(A)]. The HA-coated group showed no significant change in line average roughness (Ra), further demonstrating the stability of the coating [Fig. 5(B)]. Ra of the non-coated group was higher at day 30 than days 0, 3, and 10 (a,b,cp < 0.05, respectively). Three-dimensional surface renderings of the HA-coated and non-coated surfaces at day 30 are markedly different [Figs. 5(C), 6], with a more textured, roughened surface in the non-coated group compared to the HA-coated group. Larger and deeper pits were evident in the three-dimensional surface renderings of the day 30 non-coated group compared to the HA-coated group (Fig. 6). Ra and area roughness (Sa) were not significantly different between the two groups at day 30 [Fig. 7(A, B)]. In contrast, maximum height (Sz), maximum peak height (Sp), and maximum pit height (Sv) were significantly higher for the non-coated group compared to the HA-coated group at day 30 [*p < 0.05, Fig. 7(C–E)].

(A) Representative 3-dimensional axonometric rendering of the surface of an HA-coated sample (top row) and a non-coated sample (bottom row) at days 0, 3, 10, 20, and 30. (B) Line average roughness (mean ± SD) at days 0, 3, 10, 20, and 30. “a” indicates the non-coated group showed significant change from day 0. “b” indicates the non-coated group showed significant change from day 3. “c” indicates the non-coated group showed significant change from day 10. (C) 3D maps of the entire surface of representative HA-coated and non-coated samples at day 30.

Cytotoxicity assay

After 24 h of incubation with magnesium extracts, no cytotoxic effects on MC3T3s were observed for any HA-coated or non-coated groups, as all groups demonstrated cell proliferation above the 5000 cells originally seeded [Fig. 8(A)]. The 100 mM Mg2+ group (highest concentration standard) had significantly fewer cells than all other groups (*p < 0.05), but no other differences were observed. As expected, the HA-coated and non-coated groups had similar cell numbers as the standards that contained comparable magnesium concentrations [Fig. 8(B)]. Although HA-coated samples generally contained less magnesium than non-coated samples, magnesium concentrations below 100 mM had no effect on cell number.

(A) Number of MC3T3 preosteoblasts after 24-h incubation with magnesium extract groups (HA-coated and non-coated collected from immersion degradation at day 3, 10, 20, and 30) and standards (0, 2.5, 5, 7.5, 10, 25, 50, 75, and 100 mM Mg2+) (n = 4–5). The dotted line represents the original number of cells seeded. Proliferation occurred in all groups except the 100 mM standard, which had a significantly lower cell number compared to all groups. (B) Cell number at 24 h as a function of Mg2+ concentration. The experimental extract groups resulted in similar cell numbers as the standards containing comparable concentrations of magnesium. *Significant difference between 100 mM and all other groups. Data are mean ± SD except for HA-coated and non-coated samples in (B), which are shown as individual data points.

Discussion

HA-coated magnesium may serve as an effective biodegradable material for temporary orthopedic implants, to provide an alternative to more permanent materials that can necessitate implant removal. Although seemingly idealistic, biodegradable materials, particularly magnesium, have their own set of limitations that accompany their fast degradation when placed within the physiological environment. These issues may be mitigated by implementing a biocompatible coating system, to reduce the adverse effects of metallic degradation and encourage integration of the implant with host tissue. This study investigated the utility of solution-deposited HA coating to limit the degradation rate and modify the surface properties of pure magnesium, with particular emphasis on surface roughness, morphology, and chemical composition. A hydrothermal solution deposition method was utilized, which is a practical, efficient, single-step coating technique that can be effectively applied to magnesium samples with unique geometries (i.e., screws, plates, and other orthopedic devices). The mechanism of this coating technique relies on initial corrosion of the magnesium substrate when placed in solution. This causes an increase in pH, which initiates the rapid nucleation of HA crystals and generates a protective coating of Mg(OH)2. Over the 24-h submersion time, corrosion of the magnesium is gradually halted, while additional HA crystals are deposited due to the ample supply of Ca2+ ions in solution. As shown through SEM and XRD analysis, this coating method produced a rod-like, crystalline HA structure, which has also been reported by others [22, 45, 49,50,51,52,53,54].

The solution-deposited HA coating was stable throughout the 30-day study, limiting the loss of material (mass), release of Mg2+ ions, and changes to surface chemical composition. Meanwhile, non-coated magnesium underwent significant changes in these properties, as well as an overall change in surface roughness and visual appearance. Mass change is one of the primary indicators of degradation, and the HA coating served to limit this effect of degradation. The mass loss data indicated that non-coated magnesium experienced a significant change in mass when compared to HA-coated magnesium over the 30-day period, although the incremental mass changes between each time point were not different for either group. A more indirect measurement of degradation is magnesium ion concentration in the immersion solution. A lower cumulative concentration of magnesium ions at all degradation time points for the HA-coated group indicated the degradation rate was lower compared to the non-coated group. Likely attributable to the protective HA coating hindering degradation of the magnesium substrate, the HA-coated group displayed a more gradual increase in magnesium concentration compared to the non-coated group, which exhibited a more sporadic release of magnesium ions. An orthopedic implant that quickly loses material mass after implantation in the body may not serve its mechanical function for a sufficient amount of time, thereby limiting its utility as a load-bearing implant. Here, minimal changes in mass and less magnesium in solution indicated the HA coating acted as a protective layer, slowing the breakdown of the base metal. As an implant material, this could allow native bone in the surrounding defect more time to regenerate and integrate with the implant. The pH values for the solution of the non-coated group were higher in general when compared to the HA-coated group, though this difference was significant only at day 30. In the in vivo environment, constant fluid filtration around the affected tissues and implant would likely modulate any significant pH changes, and our model here suggests that in a dynamic fluid environment, local pH near a magnesium implant may only slightly exceed physiological range (7.0–7.4). As expected, the pH and magnesium concentrations of the extract media for both coated and non-coated groups at all time points were non-toxic to MC3T3-E1 preosteoblasts. Others have reported a similar threshold pH (8.5) and magnesium concentration (10 mM) below which no cytotoxicity of MC3T3-E1 cells was observed at 1, 3, or 5 days [55]. Though an additional time point of 3 days may have elucidated any negative effects from the faster degrading non-coated samples, notably, 1 day was sufficient to demonstrate a cytotoxic effect from the 100 mM magnesium standard. Others have reported no differences in cytotoxicity of MC3T3-E1 cells as a function of culture duration (1, 3, or 5 days), with cells exposed to 0–100 mM magnesium concentrations [55]. The limitations of an in vitro model notwithstanding, these data suggest that even the faster degradation of uncoated pure magnesium may not pose biocompatibility issues when implanted.

SEM images revealed a delayed corrosion response in the HA-coated samples compared to the non-coated samples. Non-coated samples experienced cracking, a hallmark of magnesium degradation [10], starting at day 3 of immersion [12]. The behavior is believed to be the effect of intragranular corrosion, a phenomenon related to the localized degradation of grain boundaries resulting from immersion [56, 57]. The SEM images of the HA-coated group indicated that this intragranular cracking pattern began at day 20 and was less geometric and uniform than that of the non-coated group. This suggests the cracks occurred in an intermediate HA base coat rather than in exposed magnesium substrate, as also indicated by the lack of changes over time in elemental composition. Previous research suggests that water-soluble HA forms ceramic grain boundaries that can be prone to dissolution in aqueous solution, which may explain the cracking observed in this study [58]. Variability in the time required for the coating to erode was observed in the HA-coated group. Two of the five HA-coated samples showed significant pitting at day 20, while the other three samples demonstrated these features at day 30. Despite these differences in degradation rate at day 20, all HA-coated samples appeared nearly identical by day 30. Collectively, the SEM results indicated stability of the HA coating and protection of the underlying metal when compared to non-coated magnesium.

Although morphological changes were seen in the HA coating over time, HA remained on the magnesium surface for 30 days. Further, the HA coating maintained its rod-like, crystalline structure through day 10. At day 20, only a few rods were still distinguishable, and more spherical particles were apparent. These spherical particles were likely rod remnants that were being eroded during the degradation process. The crystalline structure of the HA base layer became more apparent at day 20, and smaller crystals were most prevalent, likely serving as the source of nucleation for larger crystals. Chemical analysis showed no significant change in any of the four elements measured for the HA-coated group across all time points (0, 3, 10, 20, and 30 days), suggesting the coating remained stable throughout the 30-day experiment. Of note, the EDS was set to measure only magnesium and oxygen for the non-coated samples, as previous work does not report measuring calcium or phosphorous for pure, non-coated magnesium, nor is it expected that non-coated magnesium would contain these elements even in trace amounts [59]. In the non-coated group, when the magnesium started degrading, the percentage of oxygen on the surface increased and the magnesium percentage decreased, both occurring by day 3. This is due to the formation of an oxide layer on the surface containing degradation products such as Mg(OH)2 and MgCO3 [48]. This increase in oxygen percentage and decrease in magnesium percentage were not seen on the HA-coated samples, showing that the HA coating delayed the degradation of the underlying magnesium. After the onset of degradation, the non-coated group showed stabilizing degradation from day 10 to day 30, as evidenced by the plateauing of oxygen and magnesium.

In addition to degradation rate, the surface roughness of an implant plays a key role in osseointegration and bone healing. Here, the surface roughness data showed a significant change in line roughness (Ra) over time for the non-coated group beginning at day 3. The HA-coated group experienced no significant change in Ra over time, although it underwent a gradual increase in Ra across the 30-day period. This supports the SEM findings, where the non-coated group showed significant cracking by day 3, while the HA-coated group showed a more gradual change in surface morphology. Osteoblasts, like many other cells, prefer a textured surface that facilitates attachment, a process required for cell growth and survival [60]. Successful attachment of osteoblasts on zirconia and titanium with Ra values in the range of 1–6 μm has been reported [61, 62]. Both HA-coated and non-coated groups saw a gradual increase in Ra over time, likely from the accumulation of degradation products such as Mg(OH)2 and MgCO3, and in the case of the HA-coated group, CaCO3 [63, 64]. The higher surface roughness (Sz, Sp, and Sv) values measured for the non-coated group, which indicate greater pit and peak heights along the surface, further highlight the accelerated degradation compared to the HA-coated group. Ra and Sa are root-mean-squared values representing the average intermediate distance between the deepest pit and highest peak. Sz, Sp, and Sv are dependent on only the pit depth, peak height, or total distance between the two, respectively. Ra and Sa were likely not different between the non-coated and HA-coated groups because both pit and peak heights were changing at similar rates. In contrast, Sz, Sp, and Sv are more representative of the localized surface characteristics, demonstrating that the non-coated group had higher peaks and deeper pits than the HA-coated group. Furthermore, heterogeneous degradation was observed in the non-coated group, evidenced by greater variability in surface roughness parameters, particularly Ra and Sa, as opposed to the more uniform response in the HA-coated group. Since the HA-coated group did not experience significantly lower Ra or Sa values when compared to the non-coated group, it would be expected that HA-coated implants could still provide an environment that facilitates osteoblast attachment, and over time would continue to encourage this process as the material roughens. Future work utilizing osteoblast and/or immune cell cultures grown in direct contact with HA-coated magnesium would more closely simulate the in vivo environment and allow for evaluation of biocompatibility.

Collectively, this work provides insight into the (short-term) longitudinal, degradation-mitigating effects of hydroxyapatite coating of pure magnesium via hydrothermal solution deposition. By thorough analyses of the physical and chemical properties of the surfaces, we demonstrated the stability of the HA coating over 30 days and the efficacy of HA in hindering the degradation of the magnesium substrate. The mass loss and magnesium concentration in solution indicated a lower degradation rate for the HA-coated magnesium compared to the non-coated group. Additionally, greater variation in surface cracking and pitting was observed in the non-coated group, while the HA-coated samples exhibited less surface variation, presumably due to a protective effect conferred by HA. Samples coated in HA also showed less elemental variation under EDS than the non-coated group, highlighting the stability of the HA-coated samples in aqueous solution. Additionally, extracts from hydroxyapatite-coated and non-coated pure magnesium were non-toxic to MC3T3-E1 preosteoblasts, further demonstrating the utility of magnesium as a biocompatible material.

Conclusion

Magnesium has been investigated as an advantageous material for biodegradable orthopedic implants for many years, but the rapid degradation rate of pure magnesium has slowed its clinical implementation. Coatings such as hydroxyapatite enable modulation of magnesium degradation and enhance its utility as a biomaterial. In this study, the degradation of pure magnesium was hindered using an insulating hydroxyapatite coating, applied via hydrothermal solution deposition, that effectively delayed degradation through the 30-day study. The HA coating remained stable for the duration of the study and prevented degradation of the magnesium substrate, as shown by consistent mass, elemental analysis, and surface roughness, along with reduced accumulation of magnesium ion degradation products. No cytotoxicity of preosteoblasts was observed from incubation with HA-coated or non-coated magnesium extracts. With this study, we provide a thorough analysis of the degradation process across many time points, rather than the limited “before and after” analysis more commonly reported. These results demonstrate the utility of HA coating to mitigate degradation and improve the surface properties of magnesium and its alloys for biodegradable orthopedic implants.

Materials and methods

Materials

For the hydrothermal solution deposition study, rods 6.35 mm in diameter of AZ31 were extruded using an Instron 8850 hydraulic testing system at the Center for Advanced Vehicular Systems at Mississippi State University. Samples were cut into disks 8 mm in length (Stuers Minitom Diamond Saw), mechanically polished (Stuers LaboPol-4 Polisher) using silicon carbide paper up to 4000 grit, and degreased by cleaning in 70% ethanol for 1 min followed by deionized water for 1 min. For the degradation study, rods 25.4 mm in diameter of pure magnesium (99.9% purity, 70 ppm Al, 20 ppm Cu, 280 ppm Fe, 170 ppm Mn, < 10 ppm Ni, 50 ppm Si, < 20 ppm Zn, Goodfellow Inc.) were cut into disks 8 mm in length, then polished and degreased using the same method.

Hydrothermal solution deposition of hydroxyapatite

Prior to the immersion degradation study, a study was conducted to identify appropriate solution deposition parameters. AZ31 was coated in HA via hydrothermal solution deposition, as described previously [22]. Briefly, solutions were prepared using calcium ethylenediaminetetraacetic acid (Ca-EDTA) and potassium dihydrogen phosphate (KH2PO4) (both ThermoFisher Scientific) in equal concentrations of 0.25 M using deionized water adjusted to a pH of 8.9. Incubation time in solution was 8, 16, or 24 h (n = 3) at 90 °C. To facilitate equal coating, samples were suspending in the coating solution using polyester netting. Sonication in ethanol (~ 10 min) of the 16 h, 0.25 M samples post-coating was performed to evaluate whether the coating was removed during this process. Attenuated total reflection Fourier transform infrared (ATR-FTIR) (Thermo Scientific Nicolet 6700) spectra were collected pre- and post-sonication (n = 1).

Confirmation of HA coating

Surface profilometry was measured using a Talysurf CLI 2000 non-contact laser gauge (Taylor Hobson) (n = 3). An area of 1 mm × 1 mm was raster scanned at a speed of 500 μm/s and at a spacing of 1 μm × 1 μm. After each scan, a 3-dimensional axonometric view of the surface was created (Fig. 1). From this, four profiles per sample were extracted [Fig. 1(A)], and line average roughness (Ra), the average of the height of the peaks and valleys for each profile, was calculated through an automated process. Ra was the parameter chosen to represent roughness, as it is one of the most commonly used roughness parameters [65]. Ra from each of the four profiles was averaged for each sample. FTIR spectroscopy was performed with a resolution of 8 cm−1 and 64 scans per sample to confirm the presence of HA on the surface (n = 1). Samples were imaged using scanning electron microscopy (SEM, Zeiss SUPRA 40) to visualize the deposited HA (n = 1). Conditions evaluated in FTIR and SEM were 8 h, 0.25 M; 16 h, 0.25 M; and 24 h, 0.25 M. Finally, X-ray diffraction (XRD) was utilized to further verify the presence of the HA coating on the magnesium surface. XRD was measured after the 16 h treatment time with a solute concentration of 0.25 M using a Rigaku SmartLab X-ray diffractometer (Cu Kα, 1.5406 Å), operating at 40 kV and 44 mA. 20–60° was scanned using a step size of 0.04° and a 2-s acquisition time.

Hydrothermal solution deposition of hydroxyapatite for immersion degradation

Pure magnesium samples for the immersion degradation experiment were coated for 16 h using a solute concentration of 0.25 M using the methods described above. After coating, samples were sonicated in 70% ethanol for 20 min to remove the unbound HA from the surface.

Immersion degradation

To investigate the effect of HA coating on the degradation behavior of pure magnesium, immersion degradation was performed in Dulbecco’s Modified Eagle Medium (DMEM, ThermoFisher, Cat. #31600083), due to the nutrient-rich composition similar to in vivo conditions [48]. Media was prepared to a pH of 6.9 before sterile filtration. Media was supplemented with 1% (v/v) penicillin/streptomycin, and all immersion experiments were performed using aseptic technique. Prior to immersion, samples (n = 5) were sterilized by immersion in 70% ethanol for a minimum of 8 h and flipped half-way through to ensure sterilization across the entire surface area. Samples were then suspended in 330 mL of media using polyester mesh netting to facilitate degradation of all sides of the samples. This volume conforms to ISO standards (ISO 10993-12), which states a minimum solution volume to sample surface area ratio of 0.2 mL/mm2 [48]. Media was used within one week of preparation to minimize changes in pH. Degradation conditions were maintained at 37 °C and 5% CO2. To simulate dynamic fluid flow, immersion was carried out on a shaker plate at 90 RPM.

Measurement of mass, solution pH, and magnesium ion release

At days 3, 10, 20, and 30 post-degradation, samples were removed from solution, and the extract media was collected and stored at 4 °C. Samples were sonicated in 70% ethanol for 5–10 min to remove any degradation products on the surface and then air dried for ~ 2 min with a heat gun to circulate air around the samples. The mass of each sample was recorded, as mass is the principal measure of corrosion (ASTM Standard G31, Standard Guide for Laboratory Immersion Corrosion Testing of Materials). Additionally, surfaces were analyzed for physical and chemical changes as described in detail below. Following surface analyses at each time point, samples were sterilized and placed back into fresh media to continue degradation.

The pH of extract media was measured via a Thermo Scientific™ Orion™ 2-Star Benchtop pH Meter. The concentration of magnesium ions (Mg2+) in extract media from each time point was measured using a magnesium assay kit (RayBio® Magnesium Assay Kit, Cat#:68-Mag-S100). The magnesium concentration in each extract sample was compared to concentrations of magnesium standards included in the kit, according to the manufacturer’s protocol. Sample solutions were diluted between 10 and × 20 to allow solutions to fall within the suggested standard curve range of the kit.

Chemical microanalysis (EDS)

Samples (n = 5) were imaged using scanning electron microscopy (SEM, Zeiss SUPRA 40) prior to immersion (day 0), and at days 3, 10, 20, and 30. Images were taken at × 250 and × 1000 magnification for global and microstructural scale observations, respectively. Energy-dispersive X-ray spectroscopy (EDS) was performed using EDAX Genesis (EDAX-Ametex). Elemental peaks were identified and quantified for each sample. The range of elements detected was manually set to magnesium, oxygen, calcium, and phosphorus for the HA-coated group, and only magnesium and oxygen for the non-coated group, to narrow the detection range and limit background signal. Scans were performed at × 250 (~ 0.03% of one circular face area).

Surface profilometry

Surface profilometry, as described above, was measured using a Talysurf CLI 2000 non-contact laser gauge (Taylor Hobson) of samples (n = 5) at days 0, 3, 10, 20, and 30. Ra from each of the four profiles was averaged for each sample [Fig. 1(A)]. Additionally, more extensive profilometry was performed using a Keyence VR-5000 3D Optical Profilometer on post-degradation day 30 samples (n = 5), as well as one representative day 0 sample from each group. Scans were completed at × 40 magnification (~ 8.4% of one circular face area), and Ra values were extracted as averages over 60 scan lines for each sample. Three-dimensional surface renderings were produced by the software from images scanned two-dimensionally. Arithmetical mean height (Sa), maximum peak-to-pit height (Sz), maximum peak height (Sp), and maximum pit depth (Sv) values were also extracted from the two-dimensional profiles. Additionally, a Keyence VK-X1000 3D Laser Scanning Confocal Microscope was used to scan the entirety of the surface of one representative sample from HA-coated and non-coated groups at day 30. Three-dimensional surface renderings were constructed from these scans, and approximate coating thickness was extracted for one HA-coated sample at day 0 and day 30.

Cytotoxicity assay

Mouse preosteoblast cells (MC3T3-E1 Subclone 4, ATCC®) were used to evaluate the cytotoxicity of extracts from degrading HA-coated and non-coated pure magnesium samples in DMEM collected at days 3, 10, 20, and 30 using an extraction method (ISO 10993-5). The cells were cultured in minimum essential medium (α-MEM, Gibco), supplemented with 10% fetal bovine serum and 1% penicillin–streptomycin and incubated at 37 °C in a humidified atmosphere with 5% CO2. Samples collected from immersion degradation were sterile filtered with a 0.2 µm filter. Cells were seeded in 96-well plate at a density of 5000 cells per well and incubated for 20 h to allow attachment. The medium in the experimental wells (n = 4–5) was replaced with 100 µL of extract solutions from degraded HA-coated and non-coated samples. Extract solutions were supplemented with 10% fetal bovine serum and an additional 1% penicillin–streptomycin. The medium in the standard (control) wells (n = 5) was replaced with 100 µL of a 0–100 mM MgCl2 solution made with DMEM supplemented with 10% fetal bovine serum and 1% penicillin–streptomycin. After incubation for an additional 24 h, the media were removed and 10 µL of CCK-8 solution (Sigma-Aldrich) and 90 µL of α-MEM were added to each well, according to the manufacturer’s protocol. The well plate was incubated for 1 h, and optical density (OD) was evaluated at 450 nm, with a reference wavelength of 650 nm.

Statistical analyses

Talysurf surface profilometry data from the hydrothermal solution deposition study were analyzed using a one-way ANOVA with Tukey’s multiple comparisons. Mass, solution pH, magnesium ion concentration, and Talysurf surface profilometry data over time were analyzed using two-way, repeated-measures ANOVAs with Sidak’s multiple comparisons. VR-5000 profilometry data were analyzed using Mann–Whitney non-parametric t-tests. Elemental composition was analyzed using two-way ANOVAs with Sidak’s multiple comparisons for the magnesium and oxygen data, and one-way ANOVAs with Tukey’s multiple comparisons for the calcium and phosphorous data. Cytotoxicity assays were analyzed using one-way ANOVAs with Tukey’s multiple comparisons. All data were analyzed using GraphPad Prism 8 (GraphPad Software, Inc.) and are presented as mean ± standard deviation. An alpha value of 0.05 was used for all statistical analyses.

Data availability

The data that support the findings of this study are available from the corresponding author, Lauren B. Priddy, upon reasonable request.

References

M. Navarro, A. Michiardi, O. Castaño, J.A. Planell, Biomaterials in orthopaedics. J. R. Soc. Interface. 5, 1137–1158 (2008). https://doi.org/10.1098/rsif.2008.0151

M. Niinomi, M. Nakai, Titanium-based biomaterials for preventing stress shielding between implant devices and bone. Int. J. Biomater. (2011). https://doi.org/10.1155/2011/836587

D.L. Millis, Responses of musculoskeletal tissues to disuse and remobilization. Canine Rehabil. Phys. Ther. (2013). https://doi.org/10.1016/B978-1-4377-0309-2.00007-7

I.I. Onche, O.E. Osagie, S. Inuhu, Removal of orthopaedic implants: indications, outcome and economic implications. J. West Afr. Coll. Surg. 1, 101–112 (2011)

F. Witte, H. Ulrich, C. Palm, E. Willbold, Biodegradable magnesium scaffolds: Part II: Peri-implant bone remodeling. J. Biomed. Mater. Res. Part A 81A, 757–765 (2007). https://doi.org/10.1002/jbm.a.31293

B.D. Hahn, D.S. Park, J.J. Choi, J. Ryu, W.H. Yoon, J.H. Choi, H.E. Kim, S.G. Kim, Aerosol deposition of hydroxyapatite–chitosan composite coatings on biodegradable magnesium alloy. Surf. Coatings Technol. 205, 3112–3118 (2011). https://doi.org/10.1016/j.surfcoat.2010.11.029

J.C. Middleton, A.J. Tipton, Synthetic biodegradable polymers as orthopedic devices. Biomaterials 21, 2335–2346 (2000). https://doi.org/10.1016/S0142-9612(00)00101-0

J.W. Lee, H.S. Han, K.J. Han, J. Park, H. Jeon, M.R. Ok, H.K. Seok, J.P. Ahn, K.E. Lee, D.H. Lee, S.J. Yang, S.Y. Cho, P.R. Cha, H. Kwon, T.H. Nam, J.H. Lo Han, H.J. Rho, K.S. Lee, Y.C. Kim, D. Mantovani, Long-term clinical study and multiscale analysis of in vivo biodegradation mechanism of Mg alloy. Proc. Natl. Acad. Sci. USA 113, 716–721 (2016). https://doi.org/10.1073/pnas.1518238113

F. Mammoli, S. Castiglioni, S. Parenti, C. Cappadone, G. Farruggia, S. Iotti, P. Davalli, J.A.M. Maier, A. Grande, C. Frassineti, Magnesium is a key regulator of the balance between osteoclast and osteoblast differentiation in the presence of vitamin D3. Int. J. Mol. Sci. (2019). https://doi.org/10.3390/ijms20020385

I. Marco, A. Myrissa, E. Martinelli, F. Feyerabend, R. Willumeit-Römer, A.M. Weinberg, O. VanderBiest, In vivo and in vitro degradation comparison of pure MG, MG-10GD and MG-2AG: A short term study. Eur. Cells Mater. 33, 90–104 (2017). https://doi.org/10.22203/eCM.v033a07

F. Witte, V. Kaese, H. Haferkamp, E. Switzer, A. Meyer-Lindenberg, C.J. Wirth, H. Windhagen, In vivo corrosion of four magnesium alloys and the associated bone response. Biomaterials 26, 3557–3563 (2005). https://doi.org/10.1016/j.biomaterials.2004.09.049

Y.K. Kim, K.B. Lee, S.Y. Kim, K. Bode, Y.S. Jang, T.Y. Kwon, M.H. Jeon, M.H. Lee, Gas formation and biological effects of biodegradable magnesium in a preclinical and clinical observation. Sci. Technol. Adv. Mater. 19, 324–335 (2018). https://doi.org/10.1080/14686996.2018.1451717

R. Radha, D. Sreekanth, Insight of magnesium alloys and composites for orthopedic implant applications—A review. J. Magnes. Alloy 5, 286–312 (2017). https://doi.org/10.1016/j.jma.2017.08.003

R. Marsell, T.A. Einhorn, The biology of fracture healing. Injury 42, 551–555 (2011). https://doi.org/10.1016/j.injury.2011.03.031

M.S. Ghiasi, J. Chen, A. Vaziri, E.K. Rodriguez, A. Nazarian, Bone fracture healing in mechanobiological modeling: A review of principles and methods. Bone Reports. 6, 87–100 (2017). https://doi.org/10.1016/j.bonr.2017.03.002

M. Thomann, C. Krause, D. Bormann, N. Von Der Höh, H. Windhagen, A. Meyer-Lindenberg, Comparison of the resorbable magnesium alloys LAE442 und MgCa0.8 concerning their mechanical properties, their progress of degradation and the bone-implant-contact after 12 months implantation duration in a rabbit model. Materwiss. Werksttech. 40, 82–87 (2009). https://doi.org/10.1002/mawe.200800412

E. Bütev Öcal, Z. Esen, K. Aydınol, A.F. Dericioğlu, Comparison of the short and long-term degradation behaviors of as-cast pure Mg, AZ91 and WE43 alloys. Mater. Chem. Phys. 241, 122350 (2020). https://doi.org/10.1016/j.matchemphys.2019.122350

R. Walter, M.B. Kannan, In-vitro degradation behaviour of WE54 magnesium alloy in simulated body fluid. Mater. Lett. 65, 748–750 (2011). https://doi.org/10.1016/j.matlet.2010.11.051

C. Liu, Z. Ren, Y. Xu, S. Pang, X. Zhao, Y. Zhao, biodegradable magnesium alloys developed as bone repair materials: A review. Scanning (2018). https://doi.org/10.1155/2018/9216314

M. Braic, A. Vladescu, T.M. Mukhametkaliyev, I. Pana, C.M. Cotrut, M. Dinu, M. Mueller, M.D. Vranceanu, M.A. Surmeneva, R.A. Surmenev, A biodegradable AZ91 magnesium alloy coated with a thin nanostructured hydroxyapatite for improving the corrosion resistance. Mater. Sci. Eng. C 75, 95–103 (2017). https://doi.org/10.1016/j.msec.2017.02.033

S. Hiromoto, M. Inoue, T. Taguchi, M. Yamane, N. Ohtsu, In vitro and in vivo biocompatibility and corrosion behaviour of a bioabsorbable magnesium alloy coated with octacalcium phosphate and hydroxyapatite. Acta Biomater. 11, 520–530 (2015). https://doi.org/10.1016/j.actbio.2014.09.026

S. Hiromoto, A. Yamamoto, High corrosion resistance of magnesium coated with hydroxyapatite directly synthesized in an aqueous solution. Electrochim. Acta. 54, 7085–7093 (2009). https://doi.org/10.1016/J.ELECTACTA.2009.07.033

R.R. Kottuparambil, S. Bontha, R.M. Rangarasaiah, S.B. Arya, A. Jana, M. Das, V.K. Balla, S. Amrithalingam, T.R. Prabhu, Effect of zinc and rare-earth element addition on mechanical, corrosion, and biological properties of magnesium. J. Mater. Res. 2018(33), 3466–3478 (2018). https://doi.org/10.1557/JMR.2018.311

J. Wang, J. Tang, P. Zhang, Y. Li, J. Wang, Y. Lai, L. Qin, Surface modification of magnesium alloys developed for bioabsorbable orthopedic implants: A general review. J. Biomed. Mater. Res. Part B 100, 1691–1701 (2012). https://doi.org/10.1002/jbm.b.32707

F. Zhang, S. Cai, G. Xu, S. Shen, Y. Li, M. Zhang, X. Wu, Corrosion behavior of mesoporous bioglass-ceramic coated magnesium alloy under applied forces. J. Mech. Behav. Biomed. Mater. 56, 146–155 (2016). https://doi.org/10.1016/j.jmbbm.2015.11.029

Y.K. Kim, K.B. Lee, S.Y. Kim, Y.S. Jang, J.H. Kim, M.H. Lee, Improvement of osteogenesis by a uniform PCL coating on a magnesium screw for biodegradable applications. Sci. Rep. (2018). https://doi.org/10.1038/s41598-018-31359-9

L. Xu, A. Yamamoto, Characteristics and cytocompatibility of biodegradable polymer film on magnesium by spin coating. Colloids Surf. B 93, 67–74 (2012). https://doi.org/10.1016/j.colsurfb.2011.12.009

A. Drynda, T. Hassel, R. Hoehn, A. Perz, F.-W. Bach, M. Peuster, Development and biocompatibility of a novel corrodible fluoride-coated magnesium-calcium alloy with improved degradation kinetics and adequate mechanical properties for cardiovascular applications. J. Biomed. Mater. Res. Part A (2009). https://doi.org/10.1002/jbm.a.32582

P. Sikder, Y. Ren, S.B. Bhaduri, Synthesis and evaluation of protective poly(lactic acid) and fluorine-doped hydroxyapatite–based composite coatings on AZ31 magnesium alloy. J. Mater. Res. 2019(34), 3766–3776 (2019). https://doi.org/10.1557/JMR.2019.317

A. Zomorodian, M.P. Garcia, T. Moura E Silva, J.C.S. Fernandes, M.H. Fernandes, M.F. Montemor, Biofunctional composite coating architectures based on polycaprolactone and nanohydroxyapatite for controlled corrosion activity and enhanced biocompatibility of magnesium AZ31 alloy. Mater. Sci. Eng. C. 48, 434–443 (2015). https://doi.org/10.1016/j.msec.2014.12.027

Y. Jiang, L. Zhu, S. Cai, S. Shen, Y. Li, S. Jiang, Y. Lin, S. Hua, R. Ling, G. Xu, Corrosion-resistant fluoridated Ca–Mg–P composite coating on magnesium alloys prepared via hydrothermal assisted sol–gel process. J. Mater. Res. 2018(33), 3793–3800 (2018). https://doi.org/10.1557/JMR.2018.270

J.L. Merlo, R. Detsch, S. Ceré, A.R. Boccaccini, J. Ballarre, Degradable magnesium implants: Improving bioactive and antibacterial performance by designed hybrid coatings. J. Mater. Res. 2021(36), 443–458 (2021). https://doi.org/10.1557/S43578-020-00099-W

X. Zhang, X.W. Li, J.G. Li, X.D. Sun, Preparation and characterizations of bioglass ceramic cement/ca-p coating on pure magnesium for biomedical applications. ACS Appl. Mater. Interfaces 6, 513–525 (2014). https://doi.org/10.1021/am404574t

M. Alizadeh-Osgouei, Y. Li, C. Wen, A comprehensive review of biodegradable synthetic polymer–ceramic composites and their manufacture for biomedical applications. Bioact. Mater. 4, 22–36 (2019). https://doi.org/10.1016/j.bioactmat.2018.11.003

W. Kozuma, K. Kon, S. Kawakami, A. Bobothike, H. Iijima, M. Shiota, S. Kasugai, Osteoconductive potential of a hydroxyapatite fiber material with magnesium: In vitro and in vivo studies. Dent. Mater. J. 38, 771–778 (2019). https://doi.org/10.4012/dmj.2018-333

S.-M. Kim, J.-H. Jo, S.-M. Lee, M.-H. Kang, H.-E. Kim, Y. Estrin, J.-H. Lee, J.-W. Lee, Y.-H. Koh, Hydroxyapatite-coated magnesium implants with improved in vitro and in vivo biocorrosion, biocompatibility, and bone response. J. Biomed. Mater. Res. Part A 102, 429–441 (2014). https://doi.org/10.1002/jbm.a.34718

A.F. Mavrogenis, R. Dimitriou, J. Parvizi, G.C. Babis, Biology of implant osseointegration. J. Musculoskelet. Neuronal Interact. 9, 61–71 (2009)

S.A. Salman, K. Kuroda, M. Okido, Preparation and characterization of hydroxyapatite coating on AZ31 Mg alloy for implant applications. Bioinorg. Chem. Appl. 13, 175756 (2013). https://doi.org/10.1155/2013/175756

M.M. Hassan, Antimicrobial Coatings for Textiles (Elsevier, Amsterdam, 2017), pp. 321–355

J.A. Juhasz, S.M. Best, Surface modification of biomaterials by calcium phosphate deposition. Surf. Modif. Biomater. Methods Anal. Appl. (2011). https://doi.org/10.1533/9780857090768.1.143

J. Chen, Y. Yang, I.P. Etim, L. Tan, K. Yang, R.D.K. Misra, J. Wang, X. Su, A. Sorrentino, Recent advances on development of hydroxyapatite coating on biodegradable magnesium alloys: A review. Materials (2021). https://doi.org/10.3390/ma14195550

Preparation and corrosion behaviors of calcium phosphate conversion coating on magnesium alloy | Elsevier Enhanced Reader, (n.d.). https://reader.elsevier.com/reader/sd/pii/S0257897216308192?token=933915B4BEF1BC66EC389883C265907A14E82379C4C55DDFF2EEAFF3864180ED5422E9C8358C027DE801685E1CB14A15&originRegion=us-east-1&originCreation=20220104173616 (accessed January 4, 2022).

Solution Deposition of Hydroxyapatite on a Highly Porous Titanium Surface Enhances Osseointegration - Google Search, (n.d.). https://www.google.com/search?q=Solution+Deposition+of+Hydroxyapatite+on+a+Highly+Porous+Titanium+Surface+Enhances+Osseointegration&rlz=1C1CHBF_enUS904US906&oq=Solution+Deposition+of+Hydroxyapatite+on+a+Highly+Porous+Titanium+Surface+Enhances+Osseointegration&aqs=chrome..69i57.378j0j9&sourceid=chrome&ie=UTF-8 (accessed January 6, 2022).

R.A. Lindtner, C. Castellani, S. Tangl, G. Zanoni, P. Hausbrandt, E.K. Tschegg, S.E. Stanzl-Tschegg, A.M. Weinberg, Comparative biomechanical and radiological characterization of osseointegration of a biodegradable magnesium alloy pin and a copolymeric control for osteosynthesis. J. Mech. Behav. Biomed. Mater. 28, 232–243 (2013). https://doi.org/10.1016/J.JMBBM.2013.08.008

S. Hiromoto, M. Tomozawa, Hydroxyapatite coating of AZ31 magnesium alloy by a solution treatment and its corrosion behavior in NaCl solution. Surf. Coatings Technol. 205, 4711–4719 (2011). https://doi.org/10.1016/J.SURFCOAT.2011.04.036

I. Rehm, W. Bonfield, Characterization of hydroxyapatite and carbonated apatite by photo acoustic FTIR spectroscopy, 1997.

M. Pogorielov, E. Husak, A. Solodivnik, S. Zhdanov, Magnesium-based biodegradable alloys: Degradation, application, and alloying elements. Interv. Med. Appl. Sci. 9, 27–38 (2017). https://doi.org/10.1556/1646.9.2017.1.04

J. Gonzalez, R.Q. Hou, E.P.S. Nidadavolu, R. Willumeit-Römer, F. Feyerabend, Magnesium degradation under physiological conditions – Best practice. Bioact. Mater. 3, 174–185 (2018). https://doi.org/10.1016/j.bioactmat.2018.01.003

M. Tomozawa, S. Hiromoto, Growth mechanism of hydroxyapatite-coatings formed on pure magnesium and corrosion behavior of the coated magnesium. Appl. Surf. Sci. 257, 8253–8257 (2011). https://doi.org/10.1016/j.apsusc.2011.04.087

S. Wen, X. Liu, J. Ding, Y. Liu, Z. Lan, Z. Zhang, G. Chen, Hydrothermal synthesis of hydroxyapatite coating on the surface of medical magnesium alloy and its corrosion resistance. Prog. Nat. Sci. Mater. Int. 31, 324–333 (2021). https://doi.org/10.1016/J.PNSC.2020.12.013

T.T. Li, L. Ling, M.C. Lin, Q. Jiang, Q. Lin, J.H. Lin, C.W. Lou, Properties and mechanism of hydroxyapatite coating prepared by electrodeposition on a braid for biodegradable bone scaffolds. Nanomaterials (2019). https://doi.org/10.3390/nano9050679

T.T. Hoai, N.K. Nga, L.T. Giang, T. QuangHuy, P. Nguyen, M. Tuan, B. Thi, T. Binh, Hydrothermal synthesis of hydroxyapatite nanorods for rapid formation of bone-like mineralization. J. Electr. Mater. 46(8), 5064–5072 (2017). https://doi.org/10.1007/s11664-017-5509-6

H. Yang, K. Xia, T. Wang, J. Niu, Y. Song, Z. Xiong, K. Zheng, S. Wei, W. Lu, Growth, in vitro biodegradation and cytocompatibility properties of nano-hydroxyapatite coatings on biodegradable magnesium alloys. J. Alloys Compd. 672, 366–373 (2016). https://doi.org/10.1016/J.JALLCOM.2016.02.156

S. Jafari, R.K. Singh Raman, In-vitro biodegradation and corrosion-assisted cracking of a coated magnesium alloy in modified-simulated body fluid. Mater. Sci. Eng. C 78, 278–287 (2017). https://doi.org/10.1016/J.MSEC.2017.04.079

J. Wang, F. Witte, T. Xi, Y. Zheng, K. Yang, Y. Yang, D. Zhao, J. Meng, Y. Li, W. Li, K. Chan, L. Qin, Recommendation for modifying current cytotoxicity testing standards for biodegradable magnesium-based materials. Acta Biomater. 21, 237–249 (2015). https://doi.org/10.1016/J.ACTBIO.2015.04.011

A.S. Hamdy Makhlouf, intelligent stannate-based coatings of self-healing functionality for magnesium alloys. Intell. Coatings Corros. Control (2015). https://doi.org/10.1016/B978-0-12-411467-8.00015-5

W. Aperador, A. Delgado, F. Franco, Improved resistance to intergranular corrosion in the AZ31B magnesium alloy by friction stir welding, 2013.

S. Raynaud, E. Champ Ion, D. Bernache-Assolant, D. Tet, Dynamic fatigue and degradation in solution of hydroxyapatite ceramics, 1998.

M.E. Iskandar, A. Aslani, H. Liu, The effects of nanostructured hydroxyapatite coating on the biodegradation and cytocompatibility of magnesium implants. J. Biomed. Mater. Res. Part A 101, 2340–2354 (2013). https://doi.org/10.1002/jbm.a.34530

V. Grigoriou, I.M. Shapiro, E.A. Cavalcanti-Adam, R.J. Composto, P. Ducheyne, C.S. Adams, Apoptosis and survival of osteoblast-like cells are regulated by surface attachment. J. Biol. Chem. 280, 1733–1739 (2005). https://doi.org/10.1074/jbc.M402550200

D. Yamashita, M. Machigashira, M. Miyamoto, H. Takeuchi, K. Noguchi, Y. Izumi, S. Ban, Effect of surface roughness on initial responses of osteoblast-like cells on two types of zirconia. Dent. Mater. J. 28, 461–470 (2009). https://doi.org/10.4012/dmj.28.461

P.M. Brett, J. Harle, V. Salih, R. Mihoc, I. Olsen, F.H. Jones, M. Tonetti, Roughness response genes in osteoblasts. Bone 35, 124–133 (2004). https://doi.org/10.1016/j.bone.2004.03.009

H. Liu, Z.S. Dunn, A. Tsanhani, Q. Tian, A. Rodriguez, L. Rivera-Castaneda, A. Aslani, J. Lin, Nano-to-submicron hydroxyapatite coatings for magnesium-based bioresorbable implants—Deposition, characterization, degradation, mechanical properties, and cytocompatibility. Sci. Rep. 9, 1–27 (2019). https://doi.org/10.1038/s41598-018-37123-3

Y. Xin, K. Huo, T. Hu, G. Tang, P.K. Chu, Corrosion products on biomedical magnesium alloy soaked in simulated body fluids. J. Mater. Res. 2009(24), 2711–2719 (2009). https://doi.org/10.1557/JMR.2009.0323

T. Hobson, Exploring surface texture, 7th edition, 2011.

Acknowledgments

This work was supported by the Bagley College of Engineering, the Office of Research and Economic Development, and the Institute for Imaging and Analytical Technologies at Mississippi State University. L. Priddy is supported by an NIH Center of Biomedical Research Excellence Grant (P20GM103646-07). We would like to thank Goodfellow Inc. for their generous donation of the pure magnesium used in this study. We would also like to thank the Center for Advanced Vehicular Systems at Mississippi State University for providing AZ31 for the hydrothermal solution deposition study and access to equipment throughout the entirety of the work. Additionally, we would like to thank Evan Eltinge and Skyler Beck of Keyence Corporation of America for assisting with scans and data collection using the VR-5000 and VK-X1000 instruments. We would also like to acknowledge Weitong Chen, Adam Vitale, RoobanVenkatesh Kulandaivelu Govindarajulu Thirumali, and Stephen Horstemeyer for their assistance and guidance.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no conflict of interest to declare.

Supplementary Information

Below is the link to the electronic supplementary material.

Supplementary file1 (DOCX 1884 KB)

Supplemental Figure 1. (A) XRD analysis of HA-coated magnesium confirming the presence of HA. (B) Higher magnification SEM of HA-coated magnesium at Day 0 (pre-degradation). Crystals are shown as clusters of rod-like structures covering a particulate, crystalline base layer.

Rights and permissions

About this article

Cite this article

Rourke, A.S., Beard, M.C., Jones, S.E. et al. Hydroxyapatite coating promotes stable physicochemical properties of pure magnesium in a longitudinal degradation study. Journal of Materials Research 37, 1231–1245 (2022). https://doi.org/10.1557/s43578-022-00523-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43578-022-00523-3