Abstract

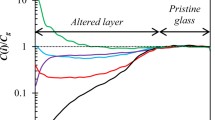

Since 1994, the KHNP has developed a vitrification technology to treat the LILW generated from Korean nuclear power plant. To vitrify the LILW including combustible Dry Active Waste (DAW) and Ion Exchange Resin (1ER) containing Zeolite, two borosilicate glasses are formulated. One of the formulated glass, DG2, is for the DAW vitrification solely and the other one, AG8W1, is for the blended wastes (DAW & 1ER) vitrification in a commercial vitrification facility in HanUl (former Ulchin) nuclear power plant. The physicochemical properties of the two glasses have been evaluated. To evaluate the processability of the glasses, the viscosities and electrical conductivities of the glass melts were measured in the laboratory within a temperature range between 950 and 1,350 degrees C, respectively. The liquidus temperatures of the glasses were evaluated using a gradient furnace for DG2 and data from heat treatment for AG8W1. The Mössbauer spectroscopy for AG8W1 was employed to evaluate the relations between the redox equilibria of iron. In addition, to verify the waste acceptance criteria for the final disposal of the vitrified forms, the compressive strengths of the vitrified forms were tested after an immersion test, a thermal cycling test, and an irradiation test. To verify the chemical durability of the glasses, several tests such as PCT, ISO, VHT, Soxhlet, MCC-1, and ANS16.1 were carried out. The PCT showed leach rates of B, Na, Li and Si were much less than those of the benchmark glass. The ISO test was performed at 90 degrees C for 1,022 days and Cumulative Fraction Leached of all elements in the glasses were analyzed. According to the VHT, the glasses had an outstanding chemical resistance under humid environment at 200 degrees C for 7 days. The Soxhlet leaching was performed on rectangular glass samples at 98 degrees C for 30 days. To analyze the forward dissolution rates of major glass elements, the MCC-1 was conducted at temperatures of 40, 70, and 90 degrees C for three weeks in pH buffer solutions ranging from pH 4to 11. The processability of the glasses was in the desired ranges. And the product quality of the glasses met all regulatory guidelines. Using two glasses, the CCIM commissioning tests in the UVF were successfully performed and they showed good workability.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.References

C. M. Jantzen, Ceramic Transactions, 23, 37–51 (1991).

D.F. Bickford, A. A. Ramsey, C.M. Jantzen, and K.G. Brown, J. Am. Ceram. Soc., 73(10), 2896–2902 (1990).

D.R. Uhlmann and N.J. Kreidl (Eds.), Glass Science and Technology, (Academic Press Inc., New York, 1986), pp. 233–270.

R Doremus., Glass Science, 2nd ed., (John Wiley & Sons Inc., New York, 1994), Ch. 6 & 15.

C.W. Kim, and D.E Day., J. Non-Cryst. Solids, 331, 20–31 (2003).

H.D. Schreiber, and A.L Hockman., J. Am. Ceram. Soc., 70(8), 591–594 (1987).

C.W. Kim, C.S. Ray, D. Zhu, D.E. Day, D. Gombert, A. Aloy, A Mogus-Milankovic. and M. Karabulut, J. Nuclear Materials, 322, 152–164 (2003).

US DOE, Design, Construction, Commissioning of the Hanford Tank Waste Treatment and Immobilization Plant, DOE Office of River Protection, Richland, WA, Contract No.: DE-AC27-01RV14136, (2001).

Personal communication with Siegfried Weisenburger at INE in Germany, (2005).

B.P McGrail, et al., “Measurement of kinetic rate low parameter on a Na-Ca-Al borosilicate glass for low-activity waste,” J. Nucl. Mater., 249, 175–189 (1997).

US DOE Argonne National Laboratory Report, ANL-05/43, 48–57 (2005).

US Department of Energy Report ANL–EBS-MD–000016, Rev. 00, ICN 01, Civilian Radioactive Waste Management System, Las Vegas, NV (2000).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Kim, CW., Lee, H., Jang, IS. et al. Physicochemical Properties of Vitrified Forms for LILW Generated From Korean Nuclear Power Plant. MRS Online Proceedings Library 1744, 211–216 (2014). https://doi.org/10.1557/opl.2015.474

Published:

Issue Date:

DOI: https://doi.org/10.1557/opl.2015.474