Abstract

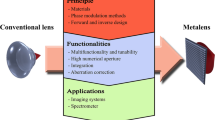

The development of optical elements has seen tremendous advances over the last few decades for a variety of applications, including displays, cameras, and microscopes. Various optical elements have been developed, ranging from refractive elements to diffractive elements. In recent years, metasurfaces have been in the spotlight to develop next-generation optical elements beyond existing refractive or diffractive optics. A metasurface is a two-dimensional metamaterial composed of subwavelength artificial structures and has been studied for the development of optical elements with the major advantage that the properties of light can be freely adjusted by a thin flat structure. Optical lenses using metasurfaces can be hundreds of times thinner than conventional lenses, while at the same time, provide excellent focusing performance. This suggests that they can be applied to mobile and high-performance imaging applications in the future. Here, we discuss developments of optical elements from refractive or diffractive optics to metasurface optics, including basic principles and properties, current issues, and future perspectives.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Lenses are optical elements that collect or spread light toward a focal point. They are one of the most important elements in imaging systems. Advances in conventional lenses, such as refractive or diffractive lenses, have led to the development of various imaging systems such as telescopes, cameras, and microscopes, and have also had a major impact on the development of mobile or wearable devices in recent years.1 Although research related to improving the performance of conventional lenses has continued, next-generation imaging systems demand performance improvements beyond what is achievable with conventional lenses, and further development of novel optical technologies for compact and high-performance lenses is required.

In recent years, metasurface optical elements have attracted much attention due to their great potential to advance photonics and optoelectronics. Metasurfaces are artificial photonic structures and are typically composed of two-dimensional arrays of subwavelength scatterers.2–7 The subwavelength scatterers, also called meta-atoms, are designed to have unique optical properties for spatial control of the amplitude, phase, polarization, or spectrum of light.8–18 The optical functions of metasurfaces are determined according to the geometry or material of meta-atoms, and they show unprecedented optical properties not generally found in natural materials such as dielectrics and metals. Various optical devices have been developed by using metasurfaces, and one of the most important applications is a metasurface lens (called metalens), which is considered a promising candidate for the next generation of optical elements.

In this article, we provide a brief overview of progress in the development of metalenses. We summarize basic principles and important features of metalenses along with their comparison with conventional lenses. We introduce several imaging applications using metalenses and discuss current issues and potential solutions. We conclude by providing an outlook and promising directions for further improvements.

Conventional lenses: Refractive or diffractive lens

The primary role of optical elements such as lenses is to modulate an incoming wavefront into an appropriate shape. From a device perspective, the ability to control phase information of light in the spatial domain is required to implement optical elements.

In this context, refractive lenses exploit refraction of light to implement a lens function (Figure 1a). Based on Snell’s Law of refraction, the lens curvature and composing material determine the direction of light at each part of the lens, and all of the rays transmitted through the lens propagate toward the focal point. Refractive lenses are useful for applications in imaging systems to date, but are relatively heavy, bulky, and expensive for high performance. In addition, higher-performance lenses with high numerical aperture and large size require longer phase delays, resulting in thicker and heavier lenses. To improve form factor, Fresnel lenses, which are compressions of refractive lenses according to the phase wrapping of the optical path length, leading to reduction in thickness, have been developed,19,20 but limited performance and high levels of distortion remain as challenges.

Diffractive optical elements (DOEs) are optical elements based on the diffraction of light for better performance and have a more compact form factor than refractive lenses.1,21–24 DOEs operate by interference of light transmitted through amplitude or phase masks, as shown in Figure lb. DOEs commonly consist of low-index dielectric materials such as polymers, and the thickness or period of the diffractive structures decides the transmitted wavefront shape. For example, increasing or decreasing the local period of the diffractive structure control effective refractive indices of the diffractive structures, which in turn, induces deflection of light with smaller or larger bending angles, respectively. Compared to refractive optics, DOEs have the advantage that they are thin regardless of focusing performance. Although various DOEs have been developed in the last few decades, DOEs still have issues of efficiency and low resolution. The diffractive structures are microscale, which is relatively large given that the wavelength of light in the visible spectrum is several hundred nanometers. This limits the range of spatial frequencies that the DOEs can provide for wavefront modulation, which leads to a drop in the efficiency of high-performance lenses in accordance with the Nyquist sampling theory, and stipulates a frequency condition to fully describe the desired signal.25,26

Operating mechanisms of (a) refractive lens, (b) diffractive lens, and (c) metalens. The thickness t of the metalens is smaller than the wavelength of light. (a) Refractive lens composed of dielectric materials such as sapphire or plastics. The ray diagram describes a change of the ray direction through the refractive lens according to Snell’s Law. Any disparity of the refractive indices induces a change in direction of the light. (b) Diffractive lens with various structures having several Widths and heights that are composed of various dielectric materials. (c) Metalens with subwavelength structures composed of metal or dielectric materials.

Both refractive optical elements and diffractive optical elements have a common bottleneck for the tradeoff between miniaturization and high performance. In this context, a metasurface as a new kind of optical element appears to be a promising candidate to solve the problem of bulkiness of refractive optical elements and limited performance of DOEs.

Metalens

Recent advances in metasurfaces have enabled the local control of amplitude, phase, polarization, and the spectral range of light.8–18 In particular, the ability for phase control of metasurfaces has significant advantages; metasurfaces with subwavelength thickness and nanoscale unit cells can generate phase delays that cover the full range (from 0 to 2π). These advantages make it possible to implement a compact optical device with high performance well beyond conventional optical elements.

In order for an incident plane wave to form a focal point, most metalenses use a hyperbolic phase profile,

where f is the focal length of the designed lens, λis the wavelength, and r is radial coordinates with respect to the center of the metalens (r = 0). Equation 1 indicates the requirement that all rays have to reach the focus in phase, resulting in a diffraction-limited spot. The hyperbolic phase profile has been employed in most cases due to the diffraction-limited focal spot and the disappearance of spherical aberrations,27 but other phase profiles can also be used to apply different aberration characteristics in certain cases.28

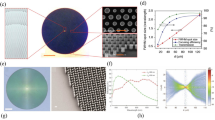

Yu et al. showed that V-shaped gold antennas with proper geometry and orientations can provide 2π phase coverage in the near-infrared (NIR) spectrum.29 The geometry and orientations of the V-shaped gold antennas determine the induced current distributions in the arms of the antennas, which can be used to control the phase of the scattered wave over the full range. Using the V-shaped antenna, metalenses were demonstrated in the NIR spectrum (Figure 2a).27For the visible spectrum, it was also reported that V-shaped apertures, which are the inverted version of the V-shaped antennas according to Babinet’s principle, can be used to implement a metalens operating in the visible spectrum.30

Another way to achieve full-range phase control is by using the Pancharatnam-Berry (PB) phase, also known as the geometric phase.31 The PB phase can be induced in anisotropic structures in which the phase delay is only determined by the rotation of the structures. In general, metasurfaces based on the PB phase are composed of asymmetric meta-atoms with identical sizes, but having different orientations.32 The advantage of the PB phase is that it is easy to uniformly maintain the amplitude according to the phase modulation. Various plasmonic metalenses based on the PB phase have been reported to provide diffraction-limited focusing as well as an anisotropic response.32–34

Examples of metalenses with various materials and principles. (a) Scanning electron microscope (SEM) images and phase profile of a plasmonic metalens composed of V-shaped gold antennas.27 (b) (i) Optical microscope image, (ii) schematic, and (iii, iv) SEM images of the dielectric metalens composed of amorphous silicon nanoposts.37 Scale bars = 100 μm in (i) and 1 μm in (iii, iv). (c) (Top) SEM image of the silicon metalens based on the Pancharatnam–Berry (PB) phase method where the inset represents the measured point spread functions. (Bottom) Measured intensity (I) distribution along the axial direction.38 (d) (Left) SEM image of a TiO2 metalens based on the PB phase method and (right) measured intensity distribution along the propagation direction.39 Scale bar = 300 nm.

More specifically, the PB phase has a relationship in which the sign of phase shifts is inverted according to the inversion of the incident circular polarization, and several studies have reported that a convex metalens based on the PB phase can be converted to a concave lens when the incident circular polarization is reversed.32 As will be discussed later, this characteristic can be applied in a variety of applications. Various plasmonic metalenses using metallic materials such as gold or silver have been explored, but they generally have the disadvantage of low efficiency due to metallic materials having high absorption in the visible spectrum. Various methods to improve the efficiency of plasmonic metasurfaces have been proposed, such as reflective metasurfaces that amplify their efficiency through metal–insulator–metal (MIM) resonators33 or metasurfaces that use relatively low-absorption metallic materials such as aluminum.34 Unfortunately, this has not been sufficient to realize a transmission-type plasmonic metalens with high efficiency in the visible spectrum.

Research for developing metalenses with dielectric materials such as silicon has been increasing recently. Dielectric metalenses are often more efficient in the visible spectrum since dielectric materials have relatively lower absorption than metallic materials. Due to fabrication compatibility and ease, silicon has been one of the most popular dielectric materials since the early development of dielectric metalenses.35,36 Arbabi et al. proposed a dielectric metalens using amorphous silicon (a-Si), as shown in Figure 2b.37 The proposed metalens is composed of cylindrical posts, which act as waveguides with low-quality resonance. The effective refractive index of each post changes with the radius, so one can control the phase of transmitted light by the radius of the post. It is notable that the absorption coefficient of a-Si in the NIR spectrum reaches near zero, and the efficiency can be maximized by the disappearance of absorption loss. The proposed dielectric metalens shows diffraction-limited focusing with high efficiency and polarization independency. Dielectric meta-atoms with anisotropic optical response can also be designed to provide the PB phase. Lin et al. reported that anisotropic silicon metaatoms with a thickness of 100 nm having different transmission coefficients for orthogonal polarizations can provide the PB phase where the orientation of the meta-atom is the only parameter to decide the phase profile of a metalens (Figure 2c).38 Polycrystalline silicon successfully achieves high efficiencies in the visible spectrum.

A wide variety of studies on materials for metalenses have been reported in the last few years. Khorasaninejad et al. found that titanium dioxide (TiO2) is a promising candidate to greatly improve the efficiency of a metalens (Figure 2d).39 As a low refractive index material, TiO2 has low absorption coefficients in the visible spectrum while the refractive index is sufficient to guide light in the subwavelength structure. The lower refractive index requires larger thickness of the meta-atoms of more than 500 nm, leading to higher fabrication difficulty. The authors solved this difficulty in fabrication by applying the atomic layer deposition (ALD) process during the electron beam (e-beam) lithography process. It has been demonstrated that a TiO2 metalens can have more than 66% efficiency in the visible spectrum while maintaining a diffraction-limited focal spot. More recently, in considering fabrication difficulties, several alternative low-index materials, including SiN and GaN, have also been suggested; these still provide high efficiency in the visible spectrum while simplifying the fabrication process compared to the ALD process for TiO2.40,41

Aberration issues in metalenses

One of the most important issues for metalenses is the correction of optical aberrations. Optical aberration refers to the phenomenon in which an image generated by optical systems (or a lens) is distorted rather than perfectly reproduced in the image plane. In general, optical aberrations for a lens can be divided into (1) monochromatic aberrations caused by the lens profile and (2) chromatic aberrations caused by the dispersive properties of the lens.

To correct monochromatic aberrations, a compound lens, made of multiple lenses mounted on a common axis, has been the traditional solution. There are tradeoff relationships among various monochromatic aberrations, including spherical aberration and comma aberration; therefore, options for reducing multiple aberrations within a single lens are limited. On the other hand, each lens constituting the compound lens cross-corrects each other’s aberrations, so compound lenses effectively reduce aberrations beyond the tradeoff relations. Arbabi et al. reported that a metalens doublet can effectively reduce monochromatic aberrations, especially in both comma and spherical aberration (Figure 3a) in a principle similar to that of compound lenses.42 The proposed doublet metalens is composed of two different metasurfaces where one is a focusing metalens with a spherical lens profile and the other is a correcting metasurface with a specific phase profile optimized to eliminate spherical aberration of the focusing metalens. Considering that the spherical lens has no comma aberration, it is apparent that both spherical and comma aberrations can be corrected by removing the spherical aberration through the correcting metalens. The authors demonstrated the doublet metalens and imaging performance in the NIR spectrum, showing its potential to be applied to a compact camera with nearly diffraction-limited image quality.42 Groever et al. also demonstrated the concept of doublet metalens in the visible spectrum, enabling diffraction-limited imaging for a large field of view more than 50° (Figure 3b).43

Conventional refractive optics have chromatic aberrations in which the wavelength and focal length are proportional to each other due to dispersion in materials in which the refractive index changes with wavelength. Normally, these aberrations can also be corrected by a compound lens composed of several lenses with different forms (shapes) or materials. Conversely, a metalens generally has chromatic aberration in which wavelength and focal length are in inverse proportion. This is because the phase profile of the metalens is related to the wavelength as given in Equation 1, and the encoded phase information of the metalens yields different focal lengths for different wavelengths due to phase-mismatch conditions. The ideal solution to solve chromatic aberration with a single metalens is to use a meta-atom capable of adequately providing different phase shifts for different wavelengths. This can be difficult, however, due to the limited degree of freedom in a single meta-atom. Early attempts for correcting chromatic aberration were based on the spatial multiplexing of meta-atoms to implement multiwavelength metalenses, which is aimed at reducing chromatic aberrations for a discrete set of wavelengths.44–46 For example, cascading several metalenses45 or spatially multiplexing several meta-atoms in a single device46 leads to improved achromatic behavior at specific wavelengths while each metalens or meta-atom is designed to be resonant at the specific wavelength.

For a broadband achromatic metalens, recent developments in dispersion-engineered metasurfaces have achieved achromatic focusing with continuous broadband.47,48 Khorasaninejad et al. designed coupled TiO2 nanofins as a meta-atom to implement a broadband achromatic metalens (Figure 3c).47 The designed meta-atom can control not only a phase delay, but also a group delay and its dispersion, providing adequate phase delays for different wavelengths (Equation 1). As a result, achromatic imaging from 470 to 670 nm was achieved with an achromatic metalens diameter of 220 urn and a numerical aperture of 0.02, requiring further improvements. Wang et al. proposed a broadband achromatic metalens composed of solid and inverse GaN nanopillars that can simultaneously control phase and dispersion of light, similar to the coupled TiO2 nanofins (Figure 3d).48 Using the GaN nanopillars, the broadband achromatic metalens with a 50-μm diameter and a numerical aperture of 0.106 achieves achromatic imaging over the entire visible spectrum. Both of these previously discussed works attempted to enhance dispersive properties of the nanostructures using multimode resonances, and successfully demonstrated the potential to realize dispersion engineered meta-atoms for broadband achromatic metalenses. However, it is notable that the size and numerical aperture of the achromatic metalenses are determined by the maximum phase compensation values, and for practical devices, a few hundred π of phase compensation is required, while current devices provide less than 10π. Therefore, further development of more resonant meta-atoms or other approaches to this problem are needed to implement a large-area broadband achromatic metalens.

Aberration correction of metalenses. (a) Doublet metalens for correction of monochromatic aberration in the near-infrared spectrum.42 (Left) Schematic illustrations and (right) focal plane intensity profiles of (i) the singlet metalens and (ii) the doublet metalens for different incident angles (0). The doublet metalens in (ii) can correct monochromatic aberrations more than singlet metalens shown in (i). Scale bars = 2 µm. (b) (Top) A schematic illustration of the doublet metalens for correction of monochromatic aberration in the visible spectrum. The doublet metalens can correct monochromatic aberrations for tilted angles of incidence above 25°.43 (Bottom) Measured focal plane intensity profiles for incident angles (left to right) 0°, 6°, 12°, 18°, and 25°. Scale bar= 1.1 μm (c). Broadband achromatic metalenses using coupled TiO2 nanofins.47 (i) A schematic illustration of the designed nanofin. (ii) Scanning electron microscope (SEM) image of a portion of the achromatic metalens. Scale bar = 500 nm. (iii) Measured intensity profiles for the achromatic metalens at several wavelengths. The white dashed line indicates the position of the focal plane, (d) Broadband achromatic metalens composed of GaN nanopillars in the visible spectrum.48 (i) Optical microscope image and (ii, iii) SEM images of the achromatic metalens from the blue and green boxes, respectively, in (i). Scale bars = 10 μm for (i) and 5 μm for (ii and iii). (iv) Measured intensity profiles for the achromatic metalens at several wavelengths (X); the white dashed line indicates the position of the focal plane. Note: TE, transverse electric polarization; TM, transverse magnetic polarization.

Imaging applications with metasurface optics

Recent research on metalens applications has attracted much interest mainly due to the unique optical properties of the metalens not seen in conventional optical lenses. This section addresses several representative applications using metalenses for imaging. Compared to conventional lenses, a metalens has the advantages of being ultrathin and lightweight. Also, a variety of functionalities that are not possible in conventional devices are now becoming possible with metalenses.

By virtue of the compactness and high performance of metalenses, they can improve optical systems by replacing existing lenses. For example, a metalens can replace a graded-index lens in an endoscope to improve imaging performance (Figure 4a).49 Current endoscope systems based on graded-index lenses show deterioration of image quality due to aberrations such as astigmatism. Metalenses were shown to improve both transverse resolution and depth of focus, and provide diffraction-limited image quality, which cannot be achieved with conventional graded-index lenses. Figure 4b shows a metalens array composed of broadband achromatic metalenses that can be applied for light-field imaging, which is an optical technology that records not only the intensity profile, but also the direction of light at each position.50 Current light-field imaging systems are composed of bulky and heavy lenses, and the compact size and light weight of the metalens array show potential for future development of mobile and wearable devices.

Various applications using metalenses. (a) Nano-optic endoscope for high-resolution optical coherence tomography in vivo.49 (i) A schematic illustration and (ii) photographic image of the nano-optic endoscope system, (iii) Scanning electron microscope (SEM) images of a portion of the metalens. (b) Achromatic metalens array for full-color light-field imaging with extended depth of focus.50 (i) Schematic diagram of light-field imaging with a metalens array and the rendered images, (ii–iv) SEM images of a portion of the metalens array sample. (c) Metasurface eyepiece for ultrawide augmented reality imaging.51 (i) Schematic illustration representing the operating mechanism of the metasurface eyepiece for augmented reality imaging, (ii) Optical microscope image and (iii) SEM image of the see-through metalens that has a diameter of 2 cm. (d) Compact folded metasurface spectrometer.52 (i) (Left) Ray tracing analysis results at three wavelengths and (right) the optimized phase profiles of the metasurfaces. (ii) SEM image of a portion of the metasurface. Scale bar = 1 μm. (iii) Spatial intensity profiles for several wavelengths with (top) TE and (bottom) TM modes. Note: TE, transverse electric polarization; TM, transverse magnetic polarization; LCR left-handed circular polarization.

The extraordinary optical properties of metalenses often generate new kinds of optical components to advance optical systems. For example, anisotropic optical response of metalenses can be applied for multifunctional optical devices. Lee et al. proposed a see-through metalens with engineered anisotropic properties for compact augmented reality near-eye display with an ultrawide viewing angle (Figure 4c).51 As a new type of eyepiece, the proposed metalens operates as an imaging lens for virtual information or a transparent glass for real-world scenes. This enables the metalens eyepiece to be positioned right in front of a user’s eye, resulting in a wide field of view reaching 100°; current typical augmented reality systems can only provide about 40°. In addition, metalenses can be applied to compact spectrometers with novel system configurations. Figure 4d shows a compact metasurface spectrometer with a light-path folding configuration.52 Whereas conventional spectrometers occupy a large form factor to secure propagation space for sufficient dispersion of light, the metalens minimizes the system configuration size by enabling light propagation in a concentrated space.

Summary and outlook

Although a variety of novel metalens technologies have been developed, and related application studies are actively underway, some challenges remain to be explored and solved. Further development of chromatic aberration correction of metalenses is required for overcoming current limitations on the size and numerical aperture of broadband achromatic metalenses. In addition, based on the techniques for correcting each aberration, further research toward an aberration-free metalens correcting both chromatic and monochromatic aberrations is needed to further development in imaging applications.

In considering the commercialization of metalenses for practical products, further research for materials and related fabrications optimized to implement practical metalenses is required. State-of-the-art metalenses employ low refractive index dielectric materials (such as SiN and TiO2) with low absorption in the visible spectrum to improve efficiency. For commercialization, it may be necessary to place thin films around the metalenses to prevent physical or chemical damage and increase durability. In that case, however, the refractive index contrast between metalens and the protective film must be relatively small; and the performance will then be expected to decrease. Further study is needed on materials and the commercialization process that can improve efficiency and ensure adequate index contrast with protective films. For commercialization, it is also necessary to mass-produce a metalens. Most metalenses thus far have been fabricated using e-beam lithography. In this regard, several mass-production technologies using nanoimprinting or ultraviolet lithography have recently been reported,51,53,54 which are expected to be a cornerstone for future metalens development.

In summary, metalenses have shown their capability to replace and complement conventional lenses. The clear advantages of metalenses, including subwavelength thickness, lightweight, high focusing ability, and unprecedented optical functions, highlight its differentiation from conventional optical elements and present the unlimited potential of future imaging applications. Considering the extraordinary optics realized by ultracompact and multifunctional light modulation, metalenses are expected to revolutionize optical engineering and optoelectronics in the near future.

References

M. Born, E. Wolf, Principle of Optics, 7th ed. (Cambridge University, Cambridge, UK, 1999).

N. Yu, F. Capasso, Nat. Mater. 13, 139 (2014).

N. Meinzer, W.L. Barnes, I.R. Hooper, Nat. Photonics 8, 889 (2014).

A.I. Kuznetsov, A.E. Miroshnichenko, M.L. Brongersma, Y.S. Kivshar, B. Luk’yanchuk, Science 354, aag2472 (2016).

S. Jahani, Z. Jacob, Nat. Nanotechnol. 11, 23 (2016).

S. Kruk, Y. Kivshar, ACS Photonics 4, 2638 (2017).

P. Genevet, F. Capasso, F. Aieta, M. Khorasaninejad, R. Devlin, Optica 4, 139 (2017).

S.M. Kamali, E. Arbabi, A. Arbabi, A. Faraon, Nanophotonics 7, 1041 (2018).

G.-Y. Lee, G. Yoon, S.Y. Lee, H. Yun, J. Cho, K. Lee, H. Kim, J. Rho, B. Lee, Nanoscale 10, 4237 (2018).

A. Arbabi, Y. Horie, M. Bagheri, A. Faraon, Nat. Nanotechnol. 10, 937 (2015).

J.P. Balthasar Mueller, N.A. Rubin, R.C. Devlin, B. Groever, F. Capasso, Phys. Rev. Lett. 118, 113901 (2017).

E.-Y. Song, G.-Y. Lee, H. Park, K. Lee, J. Kim, J. Hong, H. Kim, B. Lee, Adv. Opt. Mater. 5, 1601028 (2017).

J. Sung, G.-Y. Lee, B. Lee, Nanophotonics 8, 1701 (2019).

J. Sung, G.-Y. Lee, C. Choi, J. Hong, B. Lee, Adv. Opt. Mater. 7, 1801748 (2019).

I. Kim, G. Yoon, J. Jang, P. Genevet, K.T. Nam, J. Rho, ACS Photonics 5, 3876 (2018).

G.-Y. Lee, J. Sung, B. Lee, ETRI J. 41, 10 (2019).

X. Ni, A.V. Kildishev, V.M. Shalaev, Nat. Commun. 4, 2807 (2013).

S.-E. Mun, H. Yun, C. Choi, S.-J. Kim, B. Lee, Adv. Opt. Mater. 6, 1800545 (2018).

K. Miyamoto, J. Opt. Soc. Am. A Opt. Image Sci. Vis. 51, 17 (1961).

T. Fujita, H. Nishihara, J. Koyama, Opt. Lett. 7, 578 (1982).

D.C. O’Shea, T.J. Suleski, A.D. Kathman, D.W. Prather, Diffractive Optics: Design, Fabrication, and Test, Vol. 62 (Spie Press, Bellingham, WA, 2004).

M.B. Fleming, M.C. Hutley, Appl. Opt. 36, 4635 (1997).

D.W. Sweeney, G.E. Sommargren, Appl. Opt. 34, 2469 (1995).

G. Kim, J.A. Domínguez-Caballero, R. Menon, Opt. Express 20, 2814 (2012).

C.E. Shannon, Proc. IRE 37, 10 (1949).

S.-Y. Lee, K. Kim, S.-J. Kim, H. Park, K.-Y. Kim, B. Lee, Optica 2, 6 (2015).

F. Aieta, P. Genevet, M.A. Kats, N. Yu, R. Blanchard, Z. Gaburro, F. Capasso, Nano Lett. 12, 4932 (2012).

C. Chen, W. Song, J.-W. Chen, J.-H. Wang, Y.H. Chen, B. Xu, M.-K. Chen, H. Li, B. Fang, J. Chen, H.Y Kuo, S. Wang, D.P Tsai, S. Zhu, T. Li, Light Sci. Appl. 8, 99 (2019).

N. Yu, P. Genevet, M.A. Kats, F. Aieta, J.-P. Tetienne, F. Capasso, Z. Gaburro, Science 334, 333 (2011).

X. Ni, S. Ishii, A.V. Kildishev, V.M. Shalaev, Light Sci. Appl. 2, e72 (2013).

M.V Berry, J. Mod. Opt. 34, 1401 (1987).

X. Chen, L. Huang, H. Mühlenbernd, G. Li, B. Bai, Q. Tan, G. Jin, C.-W. Qiu, S. Zhang, T. Zentgraf, Nat. Commun. 3, 1198 (2012).

G. Zheng, H. Mühlenbernd, M. Kenney, G. Li, T. Zentgraf, S. Zhang, Nat. Nanotechnol. 10, 308 (2015).

Y.-W. Huang, W.T. Chen, W.-Y Tsai, P.C. Wu, C.-M. Wang, G. Sun, D.P. Tsai, Nano Lett. 15, 3122 (2015).

M.L. Tseng, H.-H. Hsiao, C.H. Chu, M.K. Chen, G. Sun, A.-Q. Liu, D.P. Tsai, Adv. Opt. Mater. 6, 1800554 (2018).

M. Khorasaninejad, F. Capasso, Science 358, eaam8100 (2017).

A. Arbabi, Y. Horie, A.J. Ball, M. Bagheri, A. Faraon, Nat. Commun. 6, 7069 (2015).

D. Lin, P. Fan, E. Hasman, M.L. Brongersma, Science 345, 298 (2014).

M. Khorasaninejad, W.T. Chen, R.C. Devlin, J. Oh, A.Y. Zhu, F. Capasso, Science 352, 1190 (2016).

A. Zhan, S. Colburn, C.M. Dodson, A. Majumdar, Sci. Rep. 7, 1673 (2017).

B.H. Chen, P.C. Wu, V.-C. Su, Y.-C. Lai, C.H. Chu, I.C. Lee, J.-W. Chen, Y.H. Chen, Y.-C. Lan, C.-H. Kuan, D.P. Tsai, Nano Lett. 17, 6345 (2017).

A. Arbabi, E. Arbabi, S.M. Kamali, Y. Horie, S. Han, A. Faraon, Nat. Commun. 7, 13682 (2016).

B. Groever, W.T. Chen, F. Capasso, Nano Lett. 17, 4902 (2017).

M. Khorasaninejad, F. Aieta, P. Kanhaiya, M.A. Kats, P. Genevet, D. Rousso, F. Capasso, Nano Lett. 15, 5358 (2015).

O. Avayu, E. Almeida, Y. Prior, T. Ellenbogen, Nat. Commun. 8, 14992 (2017).

E. Arbabi, A. Arbabi, S.M. Kamali, Y. Horie, A. Faraon, Optica 3, 628 (2016).

W.T. Chen, A.Y. Zhu, V. Sanjeev, M. Khorasaninejad, Z. Shi, E. Lee, F. Capasso, Nat. Nanotechnol. 13, 220 (2018).

S. Wang, P.C. Wu, V.C. Su, Y.C. Lai, M.K. Chen, H.Y. Kuo, B.H. Chen, Y.H. Chen, T.T. Huang, J.H. Wang, R.M. Lin, C.H. Kuan, T. Li, Z. Wang, S. Zhu, D.P. Tsai, Nat. Nanotechnol. 13, 227 (2018).

H. Pahlevaninezhad, M. Khorasaninejad, Y.-W. Huang, Z. Shi, L.P. Hariri, D.C. Adams, V. Ding, A. Zhu, C.-W. Qiu, F. Capasso, M.J. Suter, Nat. Photonics 12, 540 (2018).

R.J. Lin, V.C. Su, S. Wang, M.K. Chen, T.L. Chung, Y.H. Chen, H.Y. Kuo, J.W. Chen, J. Chen, Y.T. Huang, J.H. Wang, C.H. Chu, P.C. Wu, T. Li, Z. Wang, S. Zhu, D.P. Tsai, Nat. Nanotechnol. 14, 227 (2019).

G.-Y Lee, J.-Y. Hong, S. Hwang, S. Moon, H. Kang, S. Jeon, H. Kim, J.-H. Jeong, B. Lee, Nat. Commun. 9, 4562 (2018).

M. Faraji-Dana, E. Arbabi, A. Arbabi, S.M. Kamali, H. Kwon, A. Faraon, Nat. Commun. 9, 4196 (2018).

S.H. Hwang, J. Cho, S. Jeon, H.-J. Kang, Z.-J. Zhao, S. Park, Y. Lee, J. Lee, M. Kim, J. Hahn, B. Lee, J.H. Jeong, H. Kim, J.R. Youn, Sci. Rep. 9, 3051 (2019).

J.-S. Park, S. Zhang, A. She, W.T. Chen, P. Lin, K.M.A. Yousef, J.-X. Cheng, F. Capasso, (2019) Nano Lett., doi:10.1021/acs.nanolett.9b03333.

Acknowledgments

This research was supported by the Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Science and ICT (2017R1A2B2006676).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Lee, GY., Sung, J. & Lee, B. Metasurface optics for imaging applications. MRS Bulletin 45, 202–209 (2020). https://doi.org/10.1557/mrs.2020.64

Published:

Issue Date:

DOI: https://doi.org/10.1557/mrs.2020.64