Abstract

A series of recent instrumental advances have facilitated the application of atom probe tomography (APT) to the characterization of an increasingly wide range of materials and devices. Whereas APT was previously mostly limited to the analysis of alloys, advances in areas such as laser pulsing and detectors have enabled characterization of semiconductors and brittle materials. Most recently, ultraviolet laser pulsing has facilitated the analysis of materials previously considered not viable for the atom probe, such as minerals and large bandgap insulator materials. The development of in situ gas reaction cells fully integrated in atom probe instruments has enabled the characterization of surface reactions of materials exposed to highly controlled environments. Finally, current work toward an integrated cryo-transfer system is anticipated to create new directions for APT research.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The last decade has seen an unprecedented proliferation of the microscopy technique of atom probe tomography (APT). It is now considered an indispensable materials characterization tool in materials research labs around the world. A cursory survey of the literature shows that between 2005 and 2014, there was a tripling of the annual number of publications reporting work underpinned by APT characterization. Furthermore, over this same period, the yearly citation rate of APT-related articles increased by a factor of seven. This is a simple metric; however, it is indicative of the rapidly increasing impact of APT on an increasingly broad range of materials research.1

A number of factors have contrived to realize this increasing interest in the technique. However, key advances in instrumentation have been at the vanguard of what has been described as the “second revolution of atom probe.”2 Novel instrument design underpinned by maturation of electronics, computing, and laser technologies have led to instruments with increasing capabilities, and in turn, have rapidly widened the scope of applications.

Key advances in instrumental design

The key instrument advances that contributed to the initial renaissance in APT have been covered in more detail in previous reviews3,4 and recent books.5–7 However, given their enduring influence, they are introduced here in brief.

The advent of laser pulsing in the commercial atom probe is possibly the technique’s most influential instrumental advancement in the last decade. It has been the key to opening up APT to a much broader range of applications. Laser-pulsing technology has continued to develop, and in the process, has made the atom probe into an increasingly powerful characterization tool.

The overwhelming majority of atom probe instruments today are based on a local electrode geometry.8 In this configuration, the specimen is aligned in very close proximity to the counter electrode such that ions field-evaporated from the tip apex are projected directly through an aperture in the electrode and onto the position-sensitive detectors (PSDs). This design reduces the voltage required for the field evaporation of atoms and provides improved mass resolution and a wider field-of-view. Lower voltages also enable a significant increase in pulse repetition, and hence the rate of data that can be acquired.

The evolution of PSDs has been equally important not only for increasing the size of specimen volumes that can be sampled, but also, critically, to improve the accuracy of compositional analysis. PSDs for APT must be designed to meet a series of challenging criteria, including the capacity for highly accurate time and position measurements and capability to decipher multiple-hit events, which is closely related to minimizing dead times, the duration after each detected event for which the PSD is rendered inactive to the detection of subsequent incident ions. A microchannel plate coupled to a fast readout delay-line detector has proven to be the best approach to meet these requirements and has become the current standard in atom probe instruments.9 This technology continues to develop, and in particular, the introduction of larger PSDs for a much wider field-of-view has been significant not only for the amount of data that can be captured, but also for the increasing size of nanostructural features that can be imaged in their entirely.

Development of the reflectron lens is another compelling innovation, now incorporated in the majority of atom probe instruments. The reflectron is a time-focusing lens, effectively an electrostatic mirror extending or reducing ion trajectories to compensate for small variations in the energy acquired by each ion in the field evaporation process.10,11 Reflectron-fitted instruments operated in a high-voltage pulsing mode provide the highest mass resolution achievable by commercial atom probes. This capability has become critical to the analysis of complicated materials systems, such as superalloys and steels, to distinguish individual elements represented by closely occurring peaks when these elements have similar mass and various isotopes detected as higher charge-state ions.

These advances, each highly effective in their own right, have proven highly complementary and are most effective when combined together. Take, for example, the atom-by-atom imaging of an entire metal oxide semiconductor field-effect transistor.12 This was only enabled by wide field-of-view detectors with increased collection rates and multi-hit analysis capabilities in a system underpinned by laser pulsing to affect field evaporation for the analysis.

The rest of this review focuses on a few of the more recent advances in instrumentation, including the further development of laser-pulsing technologies, the wider adoption of in situ reaction cells, and work toward cryogenic transfer of the specimen directly into the atom probe.

Ultraviolet laser pulsing

The implementation of laser pulsing to assist with field evaporation in APT13,14 greatly expanded its application to new areas of research, particularly to the characterization of less conductive materials. It also has the added benefit of reducing the necessary strength of the applied electric field, thus increasing the viability of brittle specimens or those featuring interfaces otherwise prone to fracturing due to field-induced stress during analysis. A compelling example is the groundbreaking characterization of the interface bonding between bone tissue and a titanium implant, shown in Figure 1.15 APT highlighted the direct contact between the titanium oxide surface of the implant and calcium of the bone mineral, supporting the theory of osseo-integration, atomic-scale continuum of bone mineral between the implant and the bone.

Scanning electron microscope (SEM) images of in vivo healing and of the tip geometry together with the atom probe tomography (APT) analysis for bonding between a titanium implant and human bone tissue. (a) Backscattered SEM image of the implant in bone. The arrow indicates the interface between the implant and the surrounding bone tissue from where the APT specimen was extracted. (b) SEM image of the sharpened APT specimen tip, together with the APT reconstruction, in which the Ti-containing ions are displayed in dark green, Ca-containing ions are gray, and C-containing ions are brown. Reproduced with permission from Reference 15. © 2014 American Chemical Society.

Recently, remarkable advances in the analysis of insulating materials have been achieved by a move to laser pulsing at ultraviolet (UV) wavelengths, in the range of 340–400 nm. Working at these wavelengths has directly enabled the characterization of bulk insulating oxides,16,17 mineral and geological materials,18,19 and biological materials.15,20 UV laser pulsing continues to enable APT applications that would have been unthinkable a decade ago.

Several articles have been published that comment on the broadening of APT applications using UV laser pulsing.21–23 However, the precise origins of the benefits of pulsing at these wavelengths remain a topic of current investigation. The drive to utilize shorter wavelengths was initially motivated by the notion that analyzing wide bandgap (WBG) materials necessitates a photon energy larger than the bandgap to create free carriers inside the materials and induce field evaporation by either a thermal24 or a resonant process.25 Nevertheless, it is also well documented that WBG materials, with a bandgap of 7–8 e V, such as MgO, Al2O3, and SiO2, have been readily analyzed using a lower photon energy of 3.2 eV.

In the case of semiconductors and insulators, the thermal energy supplied to the specimen cannot alone explain the facilitation of field evaporation. The physics is more complicated and must also take into account the effect of the intense electric field applied to the specimen. Recently, Kelly et al. ascribed two mechanisms to this process.26 The first, surface absorption, is induced by a combination of surface defects, such as those that might be created during focused ion beam (FIB)-based specimen preparation,17 and a high external electrostatic field that bends the electronic band structure, thus altering the optical properties of the specimen.27 The other mechanism is absorption in the volume of the specimen, which is enhanced through the excitation of resonant wave modes.28

It has been shown that the laser efficiency for APT analysis of WBG materials strongly depends on the electrostatic field applied to the sample.27 Many papers have reported the systematic deviation from stoichiometry of APT composition measurements of semiconductors and oxides when varying the applied laser conditions.29,30 Essentially, these studies demonstrate that electric fields can strongly affect the composition measurements. When the wavelength is shifted to the UV range, it becomes possible to explore a larger range of field values and hence to find optimal conditions for composition measurements. This is an advantage to gain further insights into the mechanisms behind field evaporation in these systems, to optimize experimental conditions to improve the accuracy of composition measurements, and to continue to open APT to an increasingly broader spectrum of materials.

In situ reaction cells

Efforts to incorporate additional capabilities into the vacuum chambers are also progressing. These are centered on the development of reaction cell systems fully integrated into the atom probe instrument. Such reaction cells are devised for exposing atom probe samples to carefully controlled environments. Most of these systems heat the samples to elevated temperatures under gaseous environments. After an initial surface cleaning through field evaporation in the atom probe, samples are transferred under vacuum to the in situ reaction cell. Following treatment, they are subsequently moved back to the analysis chamber for post-treatment examination. It remains important that samples are as clean as practically possible before such experiments; field evaporation only removes atoms from the tip, and any contaminants present on the shank may diffuse toward the tip during a subsequent reaction cell exposure.

Experiments of this type have particular relevance to heterogeneous catalysis applications, which has driven much of the developments to date. However, as the operating capabilities of both cells and APT instruments grow, this scope now also covers engineering alloys used in demanding environments, such as titanium alloys and nickel superalloys for gas-turbine engines.

Reaction cell development has its roots in the binary Pt-alloy surface segregation studies of Tsong et al.,31 who used a 1D atom probe equipped with a heating loop to rapidly heat samples. Heating a sample within the analysis chamber has also been extensively employed to study low pressure (~10–3 mbar or 100 Pa) surface restructuring reactions by a combination of field ion microscopy and a 1D atom probe.32 However, disrupting the analysis chamber vacuum for dedicated experiments is not desirable for APT.

Bagot et al.33 first proposed the idea of incorporating a separate reaction cell still contained within the overall vacuum system. This featured a cell mounted onto the buffer chamber of an Oxford Nanoscience 3DAP instrument, equipped with its own isolated vacuum pumping system and the potential to expose a single sample to a range of gases from a linked gas-dosing rig at up to 100 mbar/600°C (104 Pa/873K). This provided a range of insights into surface segregation in Pt-group alloys, showing the very sensitive nature of this phenomenon to alloy composition, surface crystallography, exposure temperature, and gas type.34,35

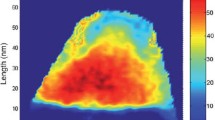

A number of research groups are currently developing in situ reaction cells for modern atom probe systems. A detailed schematic of one of the forerunners and how it is incorporated into the atom probe vacuum system is presented in Figure 2.36 Current developments are focused on increasing heat transfer to the sample tip in order to extend operating temperatures, widening the relevance of cells to materials science. In parallel, recent progress in operating at pressures up to 1 bar (105 Pa) has been achieved. Figure 3 shows details of preliminary experiments using the cell developed by Dumpala et al.36 These examples demonstrate that it is possible to distinguish between differences in oxidation levels down to the nanoscale for brief oxygen exposures in Al and Pt alloys; the aluminum sample revealed a relatively thicker (Al2O3) layer compared with the Rh-rich oxide on Pt-Rh-Ir, in agreement with known thermodynamics. These initial stages of reaction between gases and the alloy surface are poorly understood at present, despite their importance in catalysis and corrosion protection.

Atom maps of (a) an Al and (b) a Pt-Rh-Ir tip following oxidation in a reaction cell-equipped local electrode atom probe (LEAP) for 30 min in 2 × 104 Pa O2 at 450°C. Note the thicker Al2O3 layer compared with the Rh-rich oxide, in agreement with known thermodynamics. (c) Proxigram generated from an oxide-metal interface in a Pt-Rh-Ir alloy following oxidation in a reaction cell-equipped LEAP 3000 HR instrument for 30 min in 2 × 104 Pa O2 at 450°C. Depletion of Rh is apparent directly below the oxide. Adapted with permission from Reference 36. © 2014 Elsevier.

Cryogenic transfer

A further parallel theme has emerged: utilizing reaction cells that combine heating with the capability for cryogenic quenching. This has been driven by one of the ultimate challenges for advanced microscopy, the unambiguous detection of hydrogen. Unlike hydrogen, APT can accurately characterize the distribution of deuterium atoms within a material.37,38 However, any experiment of this kind is complicated by the fact that deuterium atoms in alloys such as steel can diffuse over significant distances even at room temperature. Hence it is critical that after the specimen has been charged with deuterium, it should be rapidly cooled to cryogenic levels (i.e., below 100K) and then held at this temperature while it is transferred to the analysis chamber within the atom probe. Takahashi et al.39 recently demonstrated this and successfully analyzed deuterium-charged steel specimens using APT. This is exemplified in Figure 4, in which the distribution of deuterium atoms in a TiC steel is strongly correlated to the presence of titanium carbides, confirming their potential to act as trapping sites within the microstructure.

Three-dimensional elemental maps of (a) uncharged and (b) deuterium-charged TiC steel specimens with annealing. The bold arrow indicates the analysis direction in both (a) and (b). The arrow heads in (b) indicate smaller carbides with no associated deuterium atoms. Individual larger plate-shaped carbides acting as trapping sites are shown in two perspectives, as indicated by the arrows. Reproduced with permission from Reference 39. © 2010 Elsevier.

That work utilized a reaction cell attached to an atom probe instrument, such that the specimen was charged with deuterium and rapidly cooled, all in situ. Current research is also dedicated to the development of a cryo-transfer system in an atom probe to enable it to directly accept cryogenic specimens. However, there are numerous challenges still to be overcome. Strategies are being developed that either directly freeze the specimen into the required shape, or alternatively, utilize instrumental advances in cryogenic FIB instruments to fabricate appropriate geometries. Once fabricated, the specimen is prone to the formation of ice crystals and to attracting foreign contaminants. Hence the next significant challenge is transporting the sample between the specimen preparation instrumentation (e.g., a cryogenic FIB stage) and the atom probe, which requires maintaining both cryogenic temperatures and high-vacuum conditions.40 This can be achieved either by attaching additional chambers (with insulated sample transfer rods) to the atom probe vacuum chamber, or by sample shuttling systems, whereby a docking station is required for the accompanying hand-held cryo-vacuum chamber. These allow for the study of environmentally sensitive materials by avoiding oxidation or hydration modifications, since the high-vacuum transfer between, for example, a cryo-FIB/scanning electron microscope and the atom probe protects the exposed samples from destructive or phase-altering interactions.

The capacity to transfer rapidly quenched-in microstructures offers potential new insights into phases within materials at the very early stages of their formation. For example, applications include aluminum-based alloys used in the automobile industry that are designed for natural aging, where the alloy strengthens while being stored due to ambient-temperature bulk-diffusion processes.41 Similarly, amorphous phases that first form within certain bulk metallic glasses can be highly thermodynamically unstable, since energetically favorable crystalline phases have not yet had time to form.42

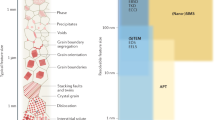

The capacity to maintain cryogenic temperatures as specimens are transferred to the atom probe and open up new opportunities. The APT analysis of samples of liquid origin or soft bio-organic matter has long been a far-reaching and sought-after goal. As demonstrated in Figure 5, recent developments in cryogenic instrumentation and preparation methods have offered the first experimental indications that aqueous solutions may represent a suitable matrix material for the analysis of soft organic materials, for nanoparticles, and for studying fine chemical gradients within frozen fluids.43,44

Freezing and atom probe tomography (APT) analysis of a water–ethanol solution. (Top) The atom map is an artificially extended representation of the ions detected, with the apex at the left and the substrate (W wire) at the right, yielding a (bottom) mass spectrum, where C-containing ions are from ethanol. The inset is a simplified ethanol molecule, indicating possible components of this molecule detected in the APT experiment, with the corresponding peaks (and colors) highlighted in the mass spectrum. The hydrogen ions are shown to primarily reside in the substrate. Nitrogen ions may be residual from plunge freezing in liquid N2. C2OH7+ is protonated ethanol.44

Summary

This article offers a brief overview of recent advances in atom probe technology through the continued enhancement of components fundamental to the instrument itself, as well as the emerging trend of the development of “addon” modules. The instrumentation advances, described herein, represent significant improvements in APT analysis. It should also be noted that significant projects are ongoing into the development of instruments directly combining atom probe with the capabilities of other characterization techniques, such as transmission electron microscopy.45 The impact of these developments is evident in the increasingly broad range of thematic areas to which APT is now applied, many that previously would have been considered too exotic for the technique. The drive to continue pushing the limits of what can be achieved with APT will continue motivating a vibrant area of research and instrument development.

References

T.F. Kelly, D.J. Larson, Annu. Rev. Mater. Res. 42, 1 (2012).

T.F. Kelly, D.J. Larson, MRS Bull. 37, 150 (2012).

T.F. Kelly, M.K. Miller, Rev. Sci. Instrum. 78, 031101 (2007).

D.N. Seidman, Annu. Rev. Mater. Res. 37, 127 (2007).

B. Gault, M.P. Moody, J.M. Cairney, S.P. Ringer, Atom Probe Microscopy (Springer, New York, 2012).

D.J. Larson, T. Prosa, R. Ulfig, B. Geiser, T. Kelly, Local Electrode Atom Probe Tomography (Springer, New York, 2014).

M.K. Miller, R.G. Forbes, Atom-Probe Tomography: The Local Electrode Atom Probe (Springer, New York, 2014).

T.F. Kelly, T.T. Gribb, J.D. Olson, R.L. Martens, J.D. Shepard, S.A. Wiener, T.C. Kunicki, R.M. Ulfig, D.R. Lenz, E.M. Strennen, E. Oltman, J.H. Bunton, D.R. Strait, Microsc. Microanal. 10, 373 (2004).

G. Da Costa, F. Vurpillot, A. Bostel, M. Bouet, B. Deconihout, Rev. Sci. Instrum. 76, 013304 (2004).

E. Bemont, A. Bostel, M. Bouet, G. Da Costa, S. Chambreland, B. Deconihout, K. Hono, Ultramicroscopy 95, 231 (2003).

A. Cerezo, T.J. Godfrey, S.J. Sijbrandij, G.D.W. Smith, P.J. Warren, Rev. Sci. Instrum. 69, 49 (1998).

K. Inoue, A.K. Kambham, D. Mangelinck, D. Lawrence, D.J. Larson, Microsc. Today 20, 38 (2012).

J.H. Bunton, J.D. Olson, D.R. Lenz, T.E. Kelly, Microsc. Microanal. 13, 418 (2007).

B. Gault, F. Vurpillot, A. Vella, M. Gilbert, A. Menand, D. Blavette, B. Deconihout, Rev. Sci. Instrum. 77, 043705 (2006).

J. Karlsson, G. Sundell, M. Thuvander, M. Andersson, Nano Lett. 14, 4220 (2014).

Y. Chen, R. Reed, E. Marquis, Scr. Mater. 67, 779 (2012).

E.A. Marquis, N.A. Yahya, D.J. Larson, M.K. Miller, R.I. Todd, Mater. Today 13, 34 (2010).

J.W. Valley, A.J. Cavosie, T. Ushikubo, D.A. Reinhard, D.F. Lawrence, D.J. Larson, P.H. Clifton, T.F. Kelly, S.A. Wilde, D.E. Moser, M.J. Spicuzza, Nat. Geosci. 7, 219 (2014).

D.E. Perea, I. Arslan, J. Liu, Z. Ristanovic, L. Kovarik, B.W. Arey, J.A. Lercher, S.R. Bare, B.M. Weckhuysen, Nat. Commun. 6, 7589 (2015).

L.M. Gordon, M.J. Cohen, K.W. MacRenaris, J.D. Pasteris, T. Seda, D. Joester, Science 347, 746 (2015).

B. Gault, Y.M. Chen, M.P. Moody, T. Ohkubo, K. Hono, S.P. Ringer, J. Appl. Phys. 110, 094901 (2011).

K. Hono, T. Ohkubo, Y.M. Chen, M. Kodzuka, K. Oh-ishi, H. Sepehri-Amin, F. Li, T. Kinno, S. Tomiya, Y. Kanitani, Ultramicroscopy 111, 576 (2011).

K. Stiller, L. Viskari, G. Sundell, F. Liu, M. Thuvander, H.-O. Andrén, D.J. Larson, T. Prosa, D. Reinhard, Oxid. Met. 79, 227 (2013).

A. Vella, B. Mazumder, G. Da Costa, B. Deconihout, J. Appl. Phys. 110, 044321 (2011).

H. Tamura, M. Tsukada, K.P. McKenna, A.L. Shluger, T. Ohkubo, K. Hono, Phys. Rev. B Condens. Matter 86, 195430 (2012).

T.F. Kelly, A. Vella, J.H. Bunton, J. Houard, E.P. Silaeva, J. Bogdanowicz, W. Vandervorst, Curr. Opin. Solid State Mater. Sci. 18, 81 (2014).

E.P. Silaeva, L. Arnoldi, M.L. Karahka, B. Deconihout, A. Menand, H.J. Kreuzer, A. Vella, Nano Lett. 14, 6066 (2014).

J. Bogdanowicz, M. Gilbert, N. Innocenti, S. Koelling, B. Vanderheyden, W. Vandervorst, Opt. Express 21, 3891 (2013).

L. Mancini, N. Amirifar, D. Shinde, I. Blum, M. Gilbert, A. Vella, F.O. Vurpillot, W. Lefebvre, R. Lardé, E. Talbot, J. Phys. Chem. C 118, 24136 (2014).

D.R. Diercks, B.P. Gorman, R. Kirchhofer, N. Sanford, K. Bertness, M. Brubaker, J. Appl. Phys. 114, 184903 (2013).

M. Ahmad, T.T. Tsong, Appl. Phys. Lett. 44, 40 (1984).

C. Barroo, S.V. Lambeets, F. Devred, T.D. Chau, N. Kruse, Y. De Deckerb, T.V. de Bocarme, New J. Chem. 38, 2090 (2014).

P.A.J. Bagot, T.V. de Bocarme, A. Cerezo, G.D.W. Smith, Surf. Sci. 600, 3028 (2006).

P.A.J. Bagot, A. Cerezo, G.D.W. Smith, Surf. Sci. 601, 2245 (2007).

P.A.J. Bagot, A. Cerezo, G.D.W. Smith, Surf. Sci. 602, 1381 (2008).

S. Dumpala, S.R. Broderick, P.A.J. Bagot, K. Rajan, Ultramicroscopy 141, 16 (2014).

R. Gemma, T. Al-Kassab, R. Kirchheim, A. Pundt, Ultramicroscopy 109, 631 (2009).

D. Haley, S.V. Merzlikin, P. Choi, D. Raabe, Int. J. Hydrogen Energy 39, 12221 (2014).

J. Takahashi, K. Kawakami, Y. Kobayashi, T. Tarui, Scr. Mater. 63, 261 (2010).

J. Panitz, J. Vac. Sci. Technol. A 7, 2850 (1989).

S. Pogatscher, H. Antrekowitsch, M. Werinos, F. Moszner, S. Gerstl, M. Francis, W. Curtin, J. Löffler, P. Uggowitzer, Phys. Rev. Lett. 112, 225701 (2014).

A. Celarek, T. Kraus, E.K. Tschegg, S.F. Fischerauer, S. Stanzl-Tschegg, P.J. Uggowitzer, A.M. Weinberg, Mater. Sci. Eng. C 32, 1503 (2012).

S.S.A. Gerstl, R. Wepf, Microsc. Microanal. 21, 517 (2015).

S.S.A. Gerstl, B. Scherrer, J.M. Cairney, R. Spolenak, R. Wepf, AVS 62nd International Symposium & Exhibition (2015).

T.F. Kelly, M.K. Miller, K. Rajan, S.P. Ringer, Microsc. Microanal. 19, 652 (2013).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Moody, M.P., Vella, A., Gerstl, S.S.A. et al. Advances in atom probe tomography instrumentation: Implications for materials research. MRS Bulletin 41, 40–45 (2016). https://doi.org/10.1557/mrs.2015.311

Published:

Issue Date:

DOI: https://doi.org/10.1557/mrs.2015.311