Abstract

A systematic analysis was carried out to study the effect of shock waves on copper sulfate crystal in such a way that its optical properties and surface morphological properties were examined for different number of shock pulses (0, 1, 3, 5, and 7) with the constant Mach number 1.7. The test crystal of copper sulfate was grown by slow evaporation technique. The surface morphological and optical properties were scrutinized by optical microscope and ultraviolet–visible spectrometer, respectively. On exposing to shock waves, the optical transmission of the test crystal started increasing from the range of 35–45% with the increase of shock pulses and thereafter started decreasing to 25% for higher number of applied shocks. The optical band transition modes and optical band gap energies were calculated for pre- and post-shock wave loaded conditions. The experimentally obtained data prove that the optical constants such as absorption coefficient, extinction coefficient, skin depth, optical density, and optical conductivity are strongly altered, so also the optical transmission due to the impact of shock waves. Hence, shock wave induced high transmission test crystal can be used as an appropriate candidate for ultraviolet light filter applications.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Shock wave loading technique has emerged as one of the interesting and enlightening tools with which it is possible to tune and modify the properties of materials of either crystalline or non-crystalline or else nanocrystalline by choosing appropriate transient pressure and temperature of the shock wave. It provides with an alternate mechanism, so that a sample can be pressurized rapidly. Shock waves can enforce an influence on the sample, so that it attains a state wherein it can undergo property change with very high pressure, stress, tension and temperature conditions [1, 2, 3]. By utilizing this technique for materials in an experimental sequential analysis, it is possible to initiate thermochemical and thermophysical reactions and phase transitions and other physical properties, which are highly instrumental to understand the behavioral modifications of materials under deforming forces. This kind of shock wave impact study provides a new platform to learn more about the usual and unusual behaviors of crystalline and non-crystalline materials at extreme environmental conditions. Although the shock loading of these materials is performed at relatively low impact velocities (350–650 m/s), it is sufficient to enforce a number of changes such as local melting at the grain boundaries, crystalline plane orientation changes, electrical domain orientation changes, lattice strain crystal defects, and recrystallization [4, 5, 6]. These changes can lead to significant modifications in the crystal transport properties, such as thermal, electrical, and optical properties. The literature contains very little data on experimental work with respect to the impact of shock waves on materials compared with other studies like that of stress impact, gamma radiation, static pressure, and temperature conditions. Very few articles have been published so far in this area [5, 6, 7, 8, 9, 10], so that it provides an opportunity to explore the techno-oriented implications, which could be derived out of materials on encountering with shock waves in such a way that it can open the flood gates of a new dawn in research on the impact of shock waves on crystalline materials in bulk and nano size. Around the globe, few research groups have been continually working and carrying out experiments to understand the rich science behind shock wave impact conditions. In addition to that, it will pave the way to reveal the secrets of the impact of shock waves and explore the potential applications of relevant materials in various science branches. From the material science point of view, the structural, optical, electrical, and thermal properties are the basic building blocks for the material’s applicability for the diversified areas. In recent years, quite a number of research articles have been published containing the investigation of the impact of shock waves on structural and electrical properties of bulk crystals. But, very few articles are only available for understanding the optical properties, which encounter changes by the impact of shock waves [11, 12]. Conducting a number of shock wave recovery experiments is one of the best possible ways to understand the impact of shock waves on crystalline materials. As a follow up, the impact of shock waves on the structural, thermophysical, and electrical properties of technologically important crystals such as Ammonium dihydrogen phosphate (ADP) and potassium dihydrogen phosphate (KDP) crystals has been already reported [2, 4]. Interestingly, it has been recently reported that the optical transmittance is enhanced for the shock wave loaded benzil crystal due to the diffusion of internal grain boundaries [10].

In this research article, we have chosen copper sulfate crystal for the investigation to understand the changes in optical properties due to the impact of shock waves. Since copper sulfate crystal can be grown easily and a very good material for ultraviolet (UV) and infrared (IR) band filters, this investigation would provide substantial insights into the crystal, so that it could be used much more effectively [13, 14]. These kinds of filters are majorly used in observatories in which climate changes are bound to happen, whereby enforcing considerable modifications in properties which are inevitable for the material because environmental conditions keep fluctuating vigorously in observatories. However, we need to understand whether the properties of the material are stable or any desirable changes occurred under extreme conditions of both low temperature and high temperature and pressure. Many researchers have already reported the growth and characterization of copper sulfate crystal [13, 14, 15, 16]. But ironically, there is no report available to understand the material properties under the shock wave impact conditions (extreme condition). On the other hand, the knowledge of optical properties of this material under rigorously changing environment is very much essential as it contributes to a considerable part for the UV band pass filters and related applications. Hence, we have focused on the optical property profiles of copper sulfate crystal under shock wave loaded conditions.

Results and discussion

Surface morphology studies

Optical microscope is a simple and an efficient tool to point out the micro- and macro-level surface defects present in the bulk crystalline materials, especially for optical transparent materials. For the experimental data, optical microscope (Weswox) was used to investigate the surface morphological changes in the test crystal due to the impact of shock waves. Figure 1 shows the surface morphologies of pre- and post-shock wave loaded copper sulfate crystal. Figure 1(a) shows the pre-shocked test crystal surface, which clearly exhibits that there are observable defects in the surface of the crystal. Figures 1(b)–1(i) represent the surfaces of shock wave loaded crystals with number of shocks 1, 2, 3, 4, 5, 6, 7, and 8, respectively. It clearly deliberates that up to 3rd shock there are no significant defects and even micro-level defects are not noticed. Moreover, the alignment of etch pits and surface flatness are relatively good till 3rd shock. It may be due to the recrystallization during the shock wave propagation in the crystal lattice. Since the test crystal has five H2O molecules with a couple of hydrogen bonds, they are easily diffused by even low impact shock waves. Moreover, the recrystallization mechanism may occur while shock wave propagates through the crystal. Furthermore, as and when the number of applied shock waves is increased, the crystallization region slowly undergoes to the state of surface defect region. In 5th and 7th shock wave loaded condition, micro-level defects like that of cracks and damages might have been generated on the surface of the crystal. Figures 1(g)–1(i) clearly show the surface defect formation by the applied shock waves.

Optical properties

UV–visible measurements

Optical transmittance of pre- and post-shocked copper sulfate crystal was measured at room temperature using Varian carry 5E spectrometer. The incident light was allowed to fall perpendicular to the shock wave induced plane of the test crystal. The cut and polished test sample was placed in the sample holder, and the measurements were recorded for the range of 200–800 nm. Air was kept as the standard reference during measurements. Optical properties of copper sulfate crystal play an outstanding role in the optoelectronic devices and filters as it gives the clear picture of the nature of the electronic spectrum. It is very well known that the number of material factors, such as crystalline nature, defect, and grain size, can significantly affect the optical properties of crystalline materials while light is passed through the crystals. It is worthwhile to investigate few prominent optical properties such as transmission, absorption, absorption coefficient, reflectance, refractive index, optical band gap energy, optical density, skin depth, optical polarization, and optical conductivity, so that the results can pave the way for possible applications [17, 18].

Optical transmission

Figures 2(a) and 2(b) show the optical transmission of pre- and post-shocked crystal with respect to incident wavelength and number of shock, respectively. The attained optical transmission profiles clearly indicate that the transmission percentage of the test crystal appreciably increases as the number of shock pulses is increased, and thereafter, it starts decreasing significantly on increasing the number of shock pulses. For better understanding, the obtained optical transmission profiles could be divided into three regions: (i) first region of zero transmission, which is the region of wavelength <280 nm; (ii) a rapid increment for the transmission range of 280–490 nm and exponential decrement for 490–600 nm; and (iii) second zero transmission region range for >600 nm. Pre-shock wave loaded copper sulfate crystal exhibits the transparent region only in UV and visible region of 280–550 nm, which is due to the natural color effect (blue) of the crystal. This is the prime reason for the crystal to be used in observatories [13]. The grown copper sulfate crystal shows relatively good optical transmission (35%) at 480 nm. Furthermore, shock wave loaded test crystal for 1st and 3rd shocks shows the linear increment of optical transmission as 40% and 45%, respectively. The rapid enrichment of optical transmission of test crystal may be due to the diffusion of internal grain boundaries and improvement of crystalline nature. Moreover, the optical transmission enrichment may be also due to the dynamic recrystallization mechanism, which may occur while shock waves pass through the crystal. A large number of research articles are available to provide substantial evidence of dynamic recrystallization occurring during the shock wave loaded conditions, and it is well associated with the nature of the materials [2, 19, 20]. In the present case, the test crystal has five water molecules and a couple of hydrogen bonds. The hydrogen bond may induce recrystallization of the crystal under the influence of the shock waves. As the number of applied shock waves is increased further, the transmissions range is reduced from 45 to 25%. The diffusion of the grains continues up to the 3rd shock, and the size of the grains becomes bigger, and while exposing the 4th shock, the bigger grains would have started to break into smaller ones, which could be one of the reasons for the decrement of transmission. Also, it is very clear from Figs. 1(f)–1(i) that the surface of the crystal gets damaged after 4th shock. The presence of the defects at the surface of the crystal significantly traps the incident light and also it enhances the scattering of light [21]. Hence, the net transmittance of the crystal is decreased. The creation of defects and enhancement of defect concentration is evidently identified in the optical microscopic studies. Figure 2(b) shows the transmission range of pre- and post-shock wave loaded copper sulfate crystal with respect to the number of shock waves. The Gaussian single curve fitting method is used to find the band area of the test crystal to understand the shock wave impact better.

As it is already discussed, during the shock wave loaded condition, the optical transmission range increases and then decreases so that the transmission band width also changes with respect to shock number. Full width half maximum (FWHM) and area under the band values of pre- and post-shock wave loaded test crystal are presented in Table I. It is very well evident that the 3rd shock wave loaded test crystal has high FWHM and high transmission band area compared with other cases, and this kind of FWHM is favorable for transmitter and filter applications at a particular region of wavelength.

Optical absorption and absorption coefficient

At ambient condition, the optical absorption and absorption coefficient profiles of pre- and post-shock wave loaded copper sulfate crystal are shown in Fig. 3. The attained data show relatively low absorption values in the visible region. The values of absorption and optical transmission change only in visible region under shock wave loaded condition, whereas there is no change occurred in the UV and near IR (NIR) regions. The absorption coefficient profile shows similar trend as that of optical absorption of the test samples. The computed absorption coefficient values are utilized to calculate the optical band gap energy and other optical constants.

Optical band gap energy

Figure 4 illustrates the Tauc plot of copper sulfate crystal under pre- and post-shock wave loaded conditions. The test sample obeys the indirect transition mode (n = 2), which is dependent on the nature of the material either crystalline or non-crystalline. For this experiment, the mode of n = 2 is used for calculating the band gap energy of the control and shock wave loaded test crystal. As a result of plotting (αhγ)2 versus the incident photon energy (hγ), the straight line fitting curve in the particular region is obtained, as witnessed in Fig. 4. The extrapolation of the tangent line intercepting the value (hγ) in x-axis gives the direct band gap energy of the test crystal. The calculated optical band gap energy of the pre-shock wave loaded copper sulfate crystal is 4.45 eV and shock loaded crystal also gives the identical value of optical band gap energy, which clearly reflects that the absorption edges and transition mode of the crystal are not affected by the shock waves.

Optical constants: extinction coefficient, optical density, skin depth, and reflectance

The extinction coefficient provides significant data in calculating the optical constants such as optical conductivity and refractive index. Extinction coefficient provides fraction of light loss, which is due the absorption and scattering per unit distance in the given medium. The typical extinction coefficient profile of pre- and post-shock wave loaded crystal is shown in Fig. 5(a), which shows the similar trend as that of absorption coefficient for the control and shock wave loaded condition.

Furthermore, skin depth is the quantity of diffusion of electromagnetic radiation into a material. The obtained skin depth profile for pre- and post-shock wave loaded crystal is shown in Fig. 5(b), which evidently shows that the skin depth values are enhanced for the 1st and 3rd shock, but it starts decreasing for 5th and 7th shock wave loaded condition. The skin depth profile perfectly matches with the transmission profile of the test crystal. It clearly shows that the high skin depth value of the test material has high optical transmission due the large amount of light diffusion. The observed optical density profiles of pre- and post-shock wave loaded copper sulfate crystal are shown in Fig. 5(c). It clearly shows that the optical density is directly proportional to the absorption behavior of the control and shock wave loaded sample. Reflectance is one of the most prominent properties of optical materials that enable to find the refractive index of the materials. Generally, high transmission materials have low reflectance and low absorption values and vice versa. The test crystal of copper sulfate also obeys the natural law of the optical behavior in such a way that it has low reflectance values in the visible region and high in the UV and NIR regions. The obtained profiles of reflectance for control and shock wave loaded test crystal are shown in Fig. 5(d).

Refractive index and dielectric constant

Refractive index is one of the most important optical constants for all kind of materials and especially for optically transparent materials [22]. It reflects the electronic and optical polarization of the ions and local electrical field inside the material. So, the determination of refractive index of the materials has significant impact toward the industrial applications. The obtained refractive index profiles with respect to wavelength for pre- and post-shock wave loaded copper sulfate crystal are shown in Fig. 6(a). In UV and IR regions, the values of refractive index are very low, which may be due to the strong absorption, reflection, and dispersion. In visible region, the refractive index is low for pre-shocked test crystal for which the refractive index is found to be 1.01 at 480 nm. In case of shock number 1 and 3, the refractive index is slightly reduced and again on increasing the number of shocks, the refractive index increases to 1.09 at 480 nm. The number of factors such as crystallization rate and defect has an effect on the changes occurring in the value of refractive index.

The real and imaginary part of dielectric constant provides significant representation of speed of refracted light and the absorption energy form of the electric field, which is due to the dipole dislocation of the crystal [22, 23]. Hence, calculation of the dielectric constant is highly essential for the characterization of materials. The complex dielectric constant is well associated with electronic band structure and dipole orientation of the materials. These properties of materials can push them toward optical device fabrications. The obtained dielectric constant of copper sulfate crystal for the pre-and post-shock wave loaded condition can be noted from Fig. 6(b). The real and imaginary dielectric constants are closely related to the optical transmission trend observed for control and shock wave loaded conditions.

Dissipation factor, surface energy loss, and volume energy loss

The observed dissipation factor profiles of control and shock wave loaded copper sulfate crystal are shown in Fig. 7(a). In both pre- and post-loaded cases, the dissipation factor profile trend is similar, whereas the quantity of the loss factor is found to be low, which is followed by the dielectric constant as well. Moreover, low loss factor obtained for 1st and 3rd shock wave loaded crystals is considerably decreased further by the impact of more number of shock waves. It is attributed to the lower scattering of the incident light radiation. The surface energy loss and volume energy loss can be alternative data to understand the rate of energy loss for inelastic scattering of electrons passing through the surface of the materials. Moreover, these two energy losses are reciprocal of the dielectric constant properties. The attained surface energy loss and volume energy loss profiles are shown in Figs. 7(b) and 7(c), respectively. As per the formulations, the trends of the volume energy loss and surface energy loss are inversely proportional to each other, which are observed for both pre- and post-shock wave loaded test crystals that is also similar to transmission trend observed. From the observed results, it is clearly known that the volume energy loss is quite large compared with surface energy loss throughout UV-visible spectrum for both pre- and post-shock wave loaded test crystals.

Other optical constants

Electrical conductivity, optical conductivity, optical polarization, and optical susceptibility are strongly dependent on many parameters such as extinction coefficient, optical absorption coefficient, refractive index, and incident photon wavelength. The obtained pre- and post-shocked values of optical constants, namely, electrical conductivity, optical conductivity, optical polarization, and optical susceptibility of copper sulfate crystal could be observed from Fig. 8, and the identified values are similar to the trend observed in reflective index profile for all the four optical constants for both the cases of pre- and post-loaded condition.

Conclusion

The optical properties of control and shock wave loaded copper sulfate crystal were investigated and demonstrated for different number of shock pulses with the constant Mach number of 1.7. The observed optical data clearly show that during the shock wave loaded condition, there is no significant defect noticed up to 3rd shock, whereas on increasing the number of shocks, the formation of surface defects starts and the defects increase on further increasing the number of shocks, which is due to the instability of the test material. Interestingly, the optical transmission is increased from 35 to 45% for the shock wave loaded sample, and this enhancement may be due to the recrystallization and reduction of internal grain boundaries. The values of optical band gap energies were calculated for the direct allowed transition, and the observed values show that there is no change occurred due to the effect of shock waves, which facilitates the stability of optical bands of the test crystal. As followed by optical transmission, the optical constants are also significantly altered by the impact of shock waves. High transmission copper sulfate crystals are suggested for UV–NIR band pass filter applications. From this experiment, the authors suggest that the optical properties of the copper sulfate crystal can be tuned by shock waves, which does not require addition of any dopants or adapting various crystal growth methods.

Experimental section

Crystal growth

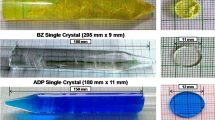

CuSO4·5H2O powder (Sigma-Aldrich Company) was used to grow copper sulfate crystals by slow evaporation method and water was used as the solvent. The mixture of distilled water and copper sulfate pentahydrate salt was mixed up well to get saturated condition. Thereafter, the obtained saturated solution was filtered using a filter paper and allowed for slow evaporation at ambient condition. A good quality and defect-free copper sulfate crystal was harvested after 25 days with the dimension of 14 × 12 × 3 mm3. The grown copper sulfate crystal is shown in Fig. 9(a). This crystal was subjected to shock wave recovery experiment. Shock wave loaded crystal does not undergo any visible changes in size, color, damages, etc., as shown in Figs. 9(b)–9(e). Both the crystals look alike, but the optical properties of both the crystals drastically differ from each other, which are due to the influence of shock waves.

Shock wave loading

For the experiment, a pressure-driven shock tube was utilized for launching the shock waves on the crystal surface. The shock tube has three sections, namely, driver, diaphragm, and driven sections. Atmospheric gas is used as the test gas in the driver section to produce shock waves. The schematic diagram and working principle of the shock tube have been clearly discussed in our previous research articles [2, 3]. The cut and polished test material of copper sulfate crystal was tightly fixed in the sample holder and loading of the shock waves with Mach number 1.7 was enabled in such a way that shock pulses of 1, 3, 5, and 7 were applied periodically. The applied shock wave has the transient pressure and temperature of 1.048 MPa and 644 K, respectively. The optical transmission of the test crystal was recorded before loading the shock wave. After every shock wave loading, the test crystal’s optical transmission was recorded. The acoustical pressure profile of the applied shock wave is presented in Fig. S1.

References

V. Jayaram and K.P.J. Reddy: Experimental study of the effect of strong shock heated test gases with cubic zirconia. Adv. Mater. Lett. 7, 100 (2016).

A. Sivakumar, S. Suresh, S. Balachandar, J. Thirupathy, J. Kalyana Sundar, and S.A. Martin Britto Dhas: Effect of shock waves on thermophysical properties of ADP and KDP crystals. Opt. Laser Technol. 111, 284 (2019).

S. Kalaiarasi, A. Sivakumar, S.A. Martin Britto Dhas, and M. Jose: Shock wave induced anatase to rutile TiO2 phase transition using pressure driven shock tube. Mater. Lett. 219, 72 (2018).

A. Sivakumar, S. Suresh, J. Anto Pradeep, S. Balachandar, and S.A. Martin Britto Dhas: Effect of shock waves on dielectric properties of KDP crystal. J. Electron. Mater. 47, 4831 (2018).

Y. Meshcheyakov, S. Atroshenko, A. Divakov, and N. Naumova: The conditions for dynamic recrystallization of metals in shock waves. AIP Conf. Proc. 1426, 1367 (2012).

G. Xiao, X. Yang, X. Zhang, K. Wang, X. Huang, Z. Ding, Y. Ma, G. Zou, and B. Zou: A protocol to fabricate nanostructured new phase: B31-type MnS synthesized under high pressure. J. Am. Chem. Soc. 137, 10297–10303 (2015).

G. Xiao, Y. Wang, D. Han, K. Li, X. Feng, P. Lv, K. Wang, L. Liu, S.A.T. Redfern, and B. Zou: Pressure-induced large emission enhancements of cadmium selenide nanocrystals. J. Am. Chem. Soc. 140, 13970–13975 (2018).

A. Sivakumar and S.A. Martin Britto Dhas: Shock-wave-induced nucleation leading to crystallization in water. J. Appl. Crystallogr. 52, 1016–1021 (2019).

L. Zhang, C. Liu, L. Wang, C. Liu, K. Wang, and B. Zou: Pressure-induced emission enhancement, band-gap narrowing, and metallization of halide perovskite Cs3Bi2I9. Angew. Chem., Int. Ed. 57, 1–6 (2018).

A. Sivakumar, A. Saranraj, S. Sahaya Jude Dhas, and S.A. Martin Britto Dhas: Shock wave induced enhancement of optical properties of benzil crystal. Mater. Res. Express 6, 046205 (2019).

P.A. Urtiew: Effect of shock loading on transparency of sapphire crystals. J. Appl. Phys. 45, 3490 (1974).

O.V. Fatyanov, R.L. Webb, and Y.M. Gupta: Optical transmission through inelastically deformed shocked sapphire: Stress and crystal orientation effects. J. Appl. Phys. 97, 123529 (2005).

N.A. Bakr, T.A. Al-Dhahir, and S.B. Mohammad: Growth of copper sulfate pentahydrate single crystals by slow evaporation technique. J. Appl. Phys. 13, 4651 (2017).

F.S. Williamson: Basic copper sulphate. J. Phys. Chem. 27, 380 (1923).

R.C. Zumstein and R.W. Rousseau Anomalous: Anomalous growth of large and small copper sulfate pentahydrate crystals. Ind. Eng. Chem. Res. 28, 289 (1989).

R. Manimekalai and C. Ramachandra Raja: EDTA effect on copper sulphate penta hydrate-A NLO material. Int. Res. J. Pure Appl. Chem. 3, 391 (2013).

A. Saranraj, S. Sahaya Jude Dhas, G. Vinitha, and S.A. Martin Britto Dhas: Third harmonic generation and thermo-physical properties of benzophenone single crystal for photonic applications. Mater. Res. Express 4, 106204 (2017).

M. Kladkaew, N. Samranlertrit, V. Vailikhit, P. Teesetsopon, and A. Tubtimtae: Effect of annealing process on the properties of undoped and manganese2+-doped co-binary copper telluride and tin telluride thin films. Ceram. Interfaces 44, 7186 (2018).

Y.I. Meshcheryakov, A.K. Divakov, S.A. Atroshenko, and N.S. Naumova: Effect of velocity nonuniformity on the dynamic recrystallization of metals in shock waves. Tech. Phys. Lett. 36, 1125 (2010).

A.E. Gleason, C.A. Bolme, H.J. Lee, B. Nagler, E. Galtier, D. Milathianaki, J. Hawreliak, R.G. Kraus, J.H. Eggert, D.E. Fratanduono, G.W. Collins, R. Sandberg, W. Yang, and W.L. Mao: Ultrafast visualization of crystallization and grain growth in shock-compressed SiO2. Nat. Commun. 6, 8191 (2015).

M.A. Gaffar and A. Abu El-Fadl: Effect of doping and irradiation on optical parameters of triglycine sulphate single crystals. Cryst. Res. Technol. 34, 915 (1999).

A.S. Hassanien and A.A. Akl: Influence of composition on optical and dispersion parameters of thermally evaporated non-crystalline Cd50S50−xSex thin films. J. Alloys Compd. 648, 280 (2015).

A. Sivakumar, A. Saranraj, S. Sahaya Jude Dhas, M. Jose, and S.A. Martin Britto Dhas: Shock wave-induced defect engineering for investigation on optical properties of triglycine sulfate crystal. Opt. Eng. 58, 077104 (2019).

Acknowledgment

The authors thank the management of Sacred Heart College for the financial support through Don Bosco Research Grant (SHC/DB Grant/2017/01).

Author information

Authors and Affiliations

Corresponding author

Supplementary Material

Rights and permissions

About this article

Cite this article

Sivakumar, A., Sarumathi, M., Sahaya Jude Dhas, S. et al. Enhancement of the optical properties of copper sulfate crystal by the influence of shock waves. Journal of Materials Research 35, 391–400 (2020). https://doi.org/10.1557/jmr.2019.383

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2019.383