Abstract

High-index ferroelectric thin films show excellent dielectricity, piezoelectricity and switching behaviors. Understanding the misfit strain relaxation behavior may prove beneficial to gaining insights into the high-quality growth of high-index ferroelectric films. In this study, ferroelectric PbTiO3 thin films were deposited on the (101)-oriented (La, Sr)(Al, Ta)O3 substrate by pulsed laser deposition and were investigated using (scanning) transmission electron microscopy. Two types of misfit dislocations with line directions of <111> and [010] were found at the interface. The <111> dislocation exhibited Burgers vectors of a [011] or [01\(\overline{1}\)1], while the [010] dislocation featured Burgers vectors of a[\(\overline{1}\)01]. The former might be generated by gliding, and the latter by climbing. We propose that the misfit strain relaxation in this film system basically results from the formation of dislocations and the residual misfit strain is relaxed via the formation of 90° ac domains.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

I. INTRODUCTION

Recently, perovskite oxide thin films have attracted much attention because of their potential applications in random access memories, thin-film capacitors, and field effect transistors, due to their excellent dielectric, piezoelectric, and ferroelectric properties.1–3 Elastic strains from lattice mismatch between substrates and stress-free films are generally used to tune the properties of perovskite oxide thin films, which is named “strain engineering.”4

In the past decades, many studies indicated that interfacial defects such as misfit dislocations (MDs) not only affect domain configurations,5–7 but also deteriorate the dielectric, piezoelectric, and ferroelectric properties of perovskite oxide thin films, such as pinning domain walls and reducing the local spontaneous polarization.8–11 Formation of interfacial MDs can relax the elastic strain when the film thickness exceeds the critical value in epitaxial thin films and then reduce the strain tuning ability of substrates.12 Besides, the threading dislocations in films are known to increase the surface roughness of thin films. Nevertheless, a recent study using phase-field simulations demonstrated a beneficial phenomenon that the proper dislocation intensity can reduce the coercive field and meanwhile enhance the remanent polarization of a ferroelectric single crystal.13 Experimentally, a periodic interfacial MD array in a BiFeO3/LaAlO3(001) nanostructure results in a giant strain gradient and consequently enhances the visible light absorption property.14 All these studies indicate that the effects of dislocations on physical properties of perovskite oxide thin films are not clarified so far. Thus, it is essential to systematically investigate the configuration of interfacial MDs and misfit strain relaxation behavior of perovskite ferroelectric thin films to better understand the effect of MDs on the physical properties of perovskite oxide thin films.

For decades, MDs in perovskite ferroelectric thin films have been widely studied. For example, Stemmer et al. observed MDs with Burgers vectors of 1/2a〈010〉 and a〈010〉 in (001)-oriented PbTiO3/MgO and PbTiO3/SrTiO3 thin films, respectively.15 Other researchers also found MDs with Burgers vectors of a〈010〉, threading dislocations with Burgers vectors of a〈110〉 in (001)-oriented BaTiO3/SrTiO3 thin films,16 and MDs with Burgers vectors of a〈110〉 and 1/2a〈110〉 in (001)-oriented Nb:SrTiO3/SrTiO3 thin films.17 Similar studies were performed in other (001)-oriented perovskite thin films, such as Pb(Zr, Ti)O3 and SrTiO3.8–10,18,19 Usually, in (001)-oriented perovskite thin films, the interfacial MDs exhibit Burgers vectors of a〈010〉, a〈110〉, 1/2a〈010〉, and 1/2a〈110〉, respectively. All of these dislocations have a line direction of 〈100〉, and they are usually formed by gliding, dislocation reaction, and dislocation half-loop mechanism.14–17 Nevertheless, so far, most of the studies have focused on the (001)-oriented epitaxial thin films. Experimental observations on MDs and misfit strain relaxation behavior in other oriented perovskite thin films have not been widely studied. Although several reports on the MD configuration and high-density stacking faults in (110)-oriented Nd0.45Sr0.55MnO3,20,21 interfacial MDs in (111)-oriented (Ba0.7Sr0.3)TiO3, and PbTiO3 thin films were published previously,22,23 the misfit strain relaxation behavior for {110}-oriented epitaxial thin films has still not been investigated. Especially, the complex domain structures in (101)-oriented tetragonal ferroelectric PbTiO3 and Pb(Zr0.2Ti0.8)O3 thin films complicate the misfit strain relaxation behavior in these thin films.24,25 Furthermore, theoretical simulations and experimental studies have shown that dielectric and piezoelectric responses are enhanced due to high domain wall density in (101)- and (111)-oriented tetragonal ferroelectric Pb(Zr0.2Ti0.8)O3 thin films.26–28

In this work, using transmission electron microscopy (TEM), including diffraction contrast analysis and aberration-corrected high-angle annular dark field (HAADF) scanning transmission electron microcopy (STEM), we investigate the interfacial MDs and misfit strain relaxation behavior of typical tetragonal ferroelectric PbTiO3 (PTO) thin films deposited on (101)-oriented (La, Sr)(Al, Ta)O3 (LSAT) substrates. Two types of MDs, named 〈111〉 MDs and [010] MDs, are observed. The former are mixed dislocations generated by gliding, and the latter are pure edge dislocations formed by climbing. Detailed analysis indicates that the lattice mismatch between strain-free PTO thin film and LSAT substrate is mainly relaxed by interfacial MDs and the residual misfit strain is relaxed by forming 90° ac domains.

II. RESULTS

A. General information

At room temperature, PTO is a typical tetragonal ferroelectric with the space group of P4mm and lattice parameters of a = b = 0.390 nm and c = 0.415 nm.29 LSAT is a cubic crystal with the space group of \(Fm\bar 3m\) and lattice parameters of a = b = c = 0.3868 nm.30 It is worthwhile to mention that LSAT(101) substrate has two different in-plane orthogonal axes of [010] and \(\left[ {\bar 101} \right]\), which are frequently used in TEM observations of (101)-oriented PTO thin films.

B. Microstructures of interfacial MDs

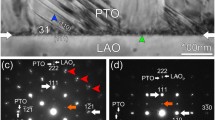

Figure 1(a) shows a cross-sectional bright-field image of [101]PTO thin films taken along the in-plane [010] zone axis of LSAT. The interface between PTO film and LSAT substrate is denoted by a pair of white arrows. The film thickness is about 35 nm. Many vertical stripe domains with alternately bright and dark contrast and a small number of inclined domains (denoted by red arrows) with an inclination angle of about 45° can be seen in the PTO thin film. These domains are 90° c1/c2 domains and 90° a/c domains, respectively, as observed in the previous studies.24,25 The 90° a/c domain wall is indistinct due to non-edge-on effect. Besides, as shown in Fig. 1(a), a high density of black dots appear at the PTO/LSAT(101) interface, which might be interfacial MDs. Figures 1(b) and 1(c) are two-beam dark-field images obtained near the in-plane [010] zone axis of LSAT taken with different reflections of g = 101c and \({\bf{g}} = \bar 1{01_{\rm{c}}}\), respectively, where the subscript “c” denotes cubic LSAT substrate. It is seen that the stripe domains are clearly visible when imaged with a reflection of g = 101c, while the stripe domains are invisible when imaged with a reflection of \({\bf{g}} = \bar 1{01_{\rm{c}}}\). This is because of the fact that the diffraction spots of 90° c1/c2 stripe domains split remarkably along the out-of-plane direction and slightly in the in-plane direction [Fig. 1(d)], which agrees well with our previous study.25 Meanwhile, the appearance of interfacial MDs shows a higher density when taken with reflection of \({\bf{g}} = \bar 1{01_{\rm{c}}}\), indicating that there are at least two types of MDs at the PTO/LSAT(101) interface. Figure 1(d) is a selected area electron diffraction (SAED) pattern taken along the [010] zone axis of the 35-nm-thick PTO film. The inset is the enlarged area of out-of-plane (101) diffraction spots corresponding to the white rectangular box in Fig. 1(d). As d110 = d101 = 0.274 nm for LSAT, and d110 = 0.276 nm and d101 = 0.284 nm for PTO, the relationship of \(d_{101}^{{\rm{LSAT}}} \approx d_{110}^{{\rm{PTO}}} < d_{101}^{{\rm{PTO}}}\) can be deduced. Therefore, in the inset, the above spot can be labeled as 101 of LSAT, while the other two spots are labeled as 101 and 011 of PTO, respectively. This indicates that the PTO film grown on LSAT(101) substrate is (101)-oriented.

Cross-sectional TEM images of 35-nm-thick PTO thin films on LSAT substrates. (a) Bright-field TEM image obtained near the [010] zone axis of LSAT. Some 90° a/c domains appear in PTO thin film as denoted by red arrows. (b) Two-beam dark-field image obtained near the [010] zone axis of LSAT taken with g = 101c. (c) Two-beam dark-field image obtained near the [010] zone axis of LSAT taken with \({\bf{g}} = \bar 1{01_{\rm{c}}}\). Note a high density of black dot-like defects is accumulated at the PTO/LSAT(101) interface as denoted by arrows. (d) SAED patterns taken along the [010] zone axis including the PTO film and LSAT substrate. The inset is the enlarged area corresponding to the white rectangular box in (d).

To accurately identify the line directions of the interfacial MDs, plane-view TEM observations are performed. Figure 2(a) is a plane-view bright-field image obtained near the out-of-plane [101] zone axis of LSAT. Three sets of dislocation lines along [010], \(\left[ {\bar 1\bar 11} \right]\), and \(\left[ {\bar 111} \right]\) directions of LSAT are seen, as marked with white arrows. The great majority of dislocation lines are along \(\left[ {\bar 1\bar 11} \right]\) and \(\left[ {\bar 111} \right]\) directions, while some dislocation lines (pointed by red arrows) are along the [010] direction. Besides, as shown in Fig. 2(a), the spaces of adjacent 〈111〉 dislocation lines in the areas labeled as green rectangles are several nanometers, while the spaces of adjacent 〈111〉 dislocation lines in the areas labeled as red circles are dozens of nanometers, which indicates that the spaces of 〈111〉 dislocation lines are inhomogeneous. This shows that the (101)-oriented PTO thin films grown on LSAT(101) substrates have asymmetric biaxial compressive strains,25 which might result in the inhomogeneous distributions of 〈111〉 dislocation lines. To analyze the types of dislocations with the dislocation lines along 〈111〉 directions, a two-beam bright-field image is obtained with a reflection of \({\bf{g}} = \bar 1\bar 11\), as shown in Fig. 2(b). The dislocation lines along the \(\left[ {\bar 111} \right]\) direction are invisible, while the dislocation lines along the \(\left[ {\bar 1\bar 11} \right]\) direction are still clearly visible. It is well known that dislocations with a Burgers vector b disappear in a two-beam bright-field image with a reflection of g when it satisfies the invisibility criterion: g ∣ b = 0.31 Thus, dislocations with dislocation lines \({{l}} = \left[ {\bar 1\bar 11} \right]\) do not satisfy the relationship: l ∣ b = 0. Meanwhile, taking into account the crystallographical equivalence between \(\left[ {\bar 1\bar 11} \right]\) and \(\left[ {\bar 111} \right]\) directions, we propose that MDs with dislocation lines along 〈111〉 directions are not pure edge dislocations.

Plane-view TEM images of 35-nm-thick PTO films on LSAT(101) substrates. (a) The bright field image obtained near the [101] zone axis of LSAT. The main two sets of dislocation lines with directions along \(\left[ {\bar 1\bar 11} \right]\) and \(\left[ {\bar 111} \right]\) were observed. Besides, the dislocation lines with directions along [010] are occasionally identified as denoted by white arrows. (b) Two-beam bright field image obtained near the [101] zone axis of LSAT taken with \({\bf{g}} = \bar 1\bar 11\). Note that the dislocation lines with directions along \(\left[ {\bar 111} \right]\) disappear, while the dislocation lines with directions along the \(\left[ {\bar 1\bar 11} \right]\) still exist.

C. Low-magnification HAADF-STEM imaging and strain field analysis of interfacial MDs

The HAADF-STEM imaging is used to investigate the details of interfacial MDs at atomic scale. Figure 3(a) shows a low-magnification HAADF-STEM image of 35-nm-thick PTO/LSAT(101) films taken along the in-plane [010] direction of LSAT. The intensity of HAADF-STEM image is approximately proportional to Z2, where Z denotes the atomic number of corresponding elements.32 The atomic numbers of heavy Pb (82) and light La (57) and Sr (38) atoms are remarkably different, so the interface between the PTO film and LSAT(101) substrate is clearly seen as labeled by a pair of opposite white arrows. An array of interfacial MDs is identified at the interface as denoted by yellow and red arrows, which reveal two different types of MDs. Geometric phase analysis (GPA) is performed to extract the unique strain distributions at the MD cores, which is an effective and accurate method to show complex strain distributions at a long range.33,34 Figures 3(b)–3(d) are in-plane strain (εxx), out-of-plane strain (εyy), and lattice rotation (Rx) maps corresponding to Fig. 3(a), respectively. As shown in Fig. 3(b), many bright dots labeled as both yellow and red arrows appear at the PTO/LSAT(101) interface, which are typical contrast of MDs. However, each MD labeled as a yellow arrow named type I shows two bright dots contrast, while each MD labeled as a red arrow named type II shows one bright dot contrast, which indicates that there are two types of MDs at PTO/LSAT(101) interfaces. The number of type I MDs is very low. Figures 3(c) and 3(d) demonstrate the difference. As shown in the figure, type I MDs lost the dots contrast in Figs. 3(c) and 3(d), while type II MDs still show an obvious dot contrast.

(a) Low-magnification HAADF-STEM image of 35-nm-thick PTO thin films grown on LSAT(101) substrates taken along the [010] direction of LSAT. A pair of horizontal arrows shows the PTO/LSAT(101) interface. Vertical red and yellow arrows indicate two different types of MDs. (b)–(d) GPA showing the strain distributions corresponding to (a). (b) In-plane strain (εxx), (c) out-of-plane strain (εyy), and (d) lattice rotation (Rx). Note the strain difference of the two types of dislocations.

D. Atomic scale structures of the interfacial MDs

To accurately analyze the Burgers vectors and display the structural details of the interfacial MDs, the atomic scale high-resolution HAADF-STEM images corresponding to two white boxes labeled as “1” and “2” in Fig. 3(a) are obtained which are imaged along the in-plane [010] direction of LSAT, as shown in Figs. 4(a) and 4(b), respectively. As shown in Fig. 4(a), the dislocation core is very sharp, implying that the dislocation is observed in an edge-on condition, so this dislocation might possess a [010] line direction. By drawing a Burgers circuit surrounding this dislocation core, the Burgers vector b is determined to be \(a\left[ {\bar 101} \right]\). As mentioned above, MDs usually have perfect Burgers vectors a〈100〉 and a〈110〉 in perovskite thin films.16–19 Thus, in Fig. 4(a), the dislocation has a perfect Burgers vector of \(a\left[ {\bar 101} \right]\) and a dislocation line of [010] direction, which indicated that the type I MDs are pure edge dislocations. Similarly, the Burgers vector of the type II MD can be determined as a[001] by drawing a Burgers circuit as shown in Fig. 4(b). However, the Burgers vector obtained from the [010] direction could not be a real vector since the dislocations might be of mixed type. This Burgers vector of b = a[001] is possibly a projected component of a perfect Burgers vector on (010) plane. Based on this consideration, the perfect Burgers vector of this MD in Fig. 4(b) might be either \(a\left[ {0\bar 11} \right]\) or a[001], as illustrated (pink arrows) in the inset, which are two common perfect Burgers vectors in perovskite thin films. Furthermore, the dislocation core is a little blurred, which is likely because this image is obtained in a non-edge-on condition. Thus, the dislocation line of type II MDs in Fig. 3(a) is probably not along the [010] direction. Combined with the plane-view TEM images in Fig. 2, it is inferred that dislocation line of the type II MDs might be along 〈111〉 directions. Thus, the atomic scale HAADF-STEM images taken along in-plane 〈111〉 directions of LSAT should be performed as well. Figures 5(a) and 5(b) are atomic scale high-magnification HAADF-STEM images of MDs taken along the in-plane \(\left[ {\bar 1\bar 11} \right]\) direction of LSAT. By drawing Burgers circuits, the Burgers vectors is determined as a[011] and \(1/3a\left[ {2\bar 11} \right]\), respectively. In Fig. 5(a), the MD with a projected component b = a[011] on \(\left( {\bar 1\bar 11} \right)\) plane has only one perfect Burgers vector of b = a[011], as illustrated in the bottom schematics of Fig. 5(a). However, the MD in Fig. 5(b) with a projected component \(b = 1/3a\left[ {2\bar 11} \right]\) on \(\left( {\bar 1\bar 11} \right)\) plane has two possible perfect Burgers vectors, as illustrated in the bottom schematics of Fig. 5(b): \(1/3a\left[ {2\bar 11} \right]\) is denoted by a pink arrow in the left projected unit cell model viewed along the \(\left[ {\bar 1\bar 11} \right]\) direction of LSAT, and two possible perfect Burgers vectors of a[100] and \(a\left[ {0\bar 11} \right]\) are distinguished in the right 3D unit cell model, which have the projected component \(1/3a\left[ {2\bar 11} \right]\) on \(\left( {\bar 1\bar 11} \right)\) plane. To distinguish these two kinds of dislocations with perfect Burgers vectors of a[100] and \(a\left[ {0\bar 11} \right]\), the atomic scale HAADF-STEM imaging of the dislocation structure along the in-plane \(\left[ {\bar 101} \right]\) direction is performed. Along the \(\left[ {\bar 101} \right]\) direction, the former has a projected component b = 1/2a[101], while the latter has a projected component b = 1/2a[121]. Experimentally, many MDs with projected Burgers vector of b = 1/2a[121] are observed along the \(\left[ {\bar 101} \right]\) direction, one of which is shown in Fig. 5(c). It is noteworthy that MDs with projected Burgers vector of b = 1/2a[101] are not observed. Furthermore, the MD with a projected component b = 1/2a[121] from the \(\left[ {\bar 101} \right]\) direction has only one perfect Burgers vector of b = a[011], as illustrated in the bottom schematics of Fig. 5(c). Thus, the perfect Burgers vector of the MD in Fig. 5(b) is not a[100], but \(a\left[ {0\bar 11} \right]\). Besides, the dislocation core in Fig. 5(b) is very sharp, indicating that the dislocation is imaged in an edge-on condition. As a result, the dislocation line of the dislocations with a perfect Burgers vector of \(a\left[ {0\bar 11} \right]\) might be along the observed direction of \(\left[ {\bar 1\bar 11} \right]\), while the dislocation core in Fig. 5(a) looks blurred, indicating that \(\left[ {\bar 1\bar 11} \right]\) is not the dislocation line direction of the dislocation with Burgers vector of a[011]. According to the dislocation line patterns in Fig. 2(a), we propose that the MD with perfect Burgers vector of a[011] should have the dislocation line along the \(\left[ {\bar 111} \right]\) direction.

High-resolution HAADF-STEM images taken along the [010] direction of LSAT showing two types of dislocations corresponding to the white rectangular boxes labeled as “1” and “2” in Fig. 3(a). (a) The type I MD with Burgers vector of \(b = a\left[ {\bar 101} \right]\). (b) The type II MD with Burgers vector of b = a[001]. Note that the dislocation core is blurred due to non-edge-on effect.

(a) and (b) High-resolution HAADF-STEM images of MDs in Figs. 4(a) and 4(b) taken along the \(\left[ {\bar 1\bar 11} \right]\) direction of LSAT. (c) High-resolution HAADF-STEM image of MD taken along the [010] direction of LSAT. The bottom schematic diagrams illustrate the possible Burgers vectors.

III. DISCUSSION

A. MD formation mechanisms in the PTO/LSAT(101) film system

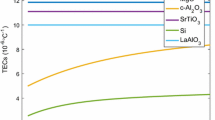

For the ferroelectric PTO/LSAT(101) thin film system at room temperature, the lattice mismatches along in-plane [010] and \(\left[ {\bar 101} \right]\) directions are −0.8% and −4.1%, respectively, which indicates that it has a large lattice mismatch along the \(\left[ {\bar 101} \right]\) direction.25 However, taking into account the lattice expansion of PTO and LSAT at deposition temperature of 700 °C, the lattice mismatch values can be calculated to be approximately −1.85% along both in-plane [010] and \(\left[ {\bar 101} \right]\) directions.35,36 To offset the misfit difference, the formation of either domains or MDs or both is believed to be a main mechanism depending on the film system itself. In the present study, formation of high-density MDs should be a main contributor to relieve the misfit strains.25

As mentioned above, MDs in PTO/LSAT(101) thin films have Burgers vectors of \(a\left[ {\bar 101} \right]\), a[011], and \(a\left[ {0\bar 11} \right]\), whose line directions are along [010], \(\left[ {\bar 111} \right]\), and \(\left[ {\bar 1\bar 11} \right]\), respectively. Dislocation with Burgers vector of \(a\left[ {\bar 101} \right]\) is a pure edge dislocation, while the rest are mixed dislocations. As reported previously, MDs in perovskite film systems could mainly originate from the film by gliding, climbing, dislocation reaction, or nucleating during the beginning of film growth.14–17,20,23 For 〈111〉 MDs (the dislocation lines is along \(\left[ {\bar 111} \right]\) and \(\left[ {\bar 1\bar 11} \right]\)) in this PTO/LSAT(101) thin film system, they should be formed through gliding. Two reasons should be taken into account to interpret this phenomenon. On the one hand, dislocation movements by gliding may form a projected Burgers vector b of \(1/3a\langle 2\bar 11\rangle \), while the dislocation movement by climbing leads to a projected Burgers vector b of a〈110〉 when observed along dislocation line directions of 〈111〉.20 On the other hand, it is generally believed that gliding is easier than climbing because of a lower driving force needed. For [010] MDs (the dislocation line is along [010]), the direction of Burgers vector \(b = a\left[ {\bar 101} \right]\) is along the in-plane \(\left[ {\bar 101} \right]\) direction of LSAT, so the slip plane for this MDs is parallel to the PTO/LSAT(101) interface. Based on this consideration, gliding is impossible to result in [010] MDs. Besides, dislocation formation during the deposition of films occurs only when the lattice mismatch is very large. Formation of [010] MDs is almost impossible during film deposition because the lattice misfit is relatively small (about −1.8%) at the deposition temperature of 700 °C.23 Thus, climbing is probably the only way to form the [010] MDs. Meanwhile, formation of 〈111〉 and [010] MDs might occur at the stage of cooling. Configuration and forming mechanisms of MDs in the present film system agree well with those of our previous study in (110)-oriented Nd0.45Sr0.55MnO3 film,20 which indicates that formation mechanism of MDs has universal relevance for {110}-oriented perovskite thin films.

Why are there a small number of [010] MDs? It can be understood from two aspects. One is that [010] MDs formed through climbing need a larger driving force and more energy than gliding. Climbing generally occurs with thermal diffusion at high temperature.37 This is the reason why we have observed a low density of [010] MDs. The other lies in the difference in strain energy. According to the dislocation theory, dislocation strain energy Ed of the mixed dislocation per unit length can be calculated via the following formulas12:

where G is the shear modulus of elasticity, b is the norm of the Burgers vector, ν is the Poisson’s ratio, h is the thickness of the film, ρc is the dislocation core parameter, and β is the intersection angle between dislocation line and Burgers vector. For [010] or 〈111〉 MDs in PTO thin films, only β is different. For the former β = 90°, and for the latter 0° < β < 90°. It can be deduced that the dislocation strain energy of [010] MDs is larger than that of the 〈111〉 MDs, which prevents the formation of a large amount [010] MDs in the present thin film system.

B. Misfit strain relaxation of the PTO/LSAT(101) film systems

The importance of MD is well known, through which misfit strain is relaxed in perovskite thin films. In the present thin film system, two types of MDs, named [010] MDs and 〈111〉 MDs, are observed. Both of these MDs have the Burgers vector of a〈110〉. Since the two types of MDs have different characteristics, the misfit strain relaxation contributed by MDs should be discussed separately. First, for [010] MDs, the Burgers vector of \(b = a\left[ {\bar 101} \right]\) is along the in-plane \(\left[ {\bar 101} \right]\) direction, which is parallel to the PTO/LSAT(101) interface and has no perpendicular component along the interface. Besides, [010] MDs have no components along the in-plane [010] direction. Thus, [010] MDs can only relax the in-plane \(\left[ {\bar 101} \right]\) directional misfit strain and cannot relax the in-plane [010] directional misfit strain. Next, for 〈111〉 MDs, misfit strain relaxation is very complicated because Burgers vectors of b = a[011] or \(b = a\left[ {0\bar 11} \right]\) are inclined to the interface. Taking the MD with Burgers vector of b = a[011] and line direction of \(\left[ {\bar 111} \right]\) for example, to better understand its contributions to the misfit strain relaxation, the perfect Burgers vector of b = a[011] should be decomposed into several components, as illustrated in Fig. 6. The red arrow denotes the perfect Burgers vector of b = a[011], which is decomposed into two components (denoted by blue arrows) according to the following formula:

where \(1/2a\left[ {\bar 101} \right]\) is parallel to the PTO/LSAT(101) interface, which relaxes the in-plane \(\left[ {\bar 101} \right]\) directional misfit strain. The 1/2a[121] component can be further decomposed into two components (denoted by yellow arrows) as shown in the following formula:

The a[010] component is also parallel to the PTO/LSAT(101) interface and can relax the in-plane [010] directional misfit strain, while the 1/2a[101] component is perpendicular to the PTO/LSAT(101) interface, which could relax shear strains resulting from large lattice rotations between the neighboring 90° domains.23 Thus, 〈111〉 MDs not only relax the misfit strains of both in-plane \(\left[ {\bar 101} \right]\) and [010] directions, but also relax the shear strain in neighboring domains.

As mentioned above, the lattice mismatch along the in-plane \(\left[ {\bar 101} \right]\) direction can be calculated to be −4.1%. Thus, the theoretical spacing (S) of 〈111〉 MDs along \(\left[ {\bar 101} \right]\) can be derived from the following equation16:

where b is the magnitude of projected Burgers vectors on (010) plane of 〈111〉 MDs and f is the lattice mismatch value between the stress-free thin film and substrate. Thus, the theoretical spacing of 〈111〉 MDs along \(\left[ {\bar 101} \right]\) is about 7 nm. However, the average dislocation spacing (D) between adjacent dislocations is measured to be approximately 10.9 nm, which is obtained statistically from numerous cross-sectional high-resolution HAADF-STEM images. The contributed extent (R) of lattice misfit relaxation along \(\left[ {\bar 101} \right]\) only by the formation of interfacial MDs can be calculated according to the following equation16:

R is calculated to be about 64%, which means that only about 64% misfit strain is relieved by the formation of interfacial MDs. In the present PTO/LSAT(101) film system, stripe 90° c1/c2 domains and some 90° a/c domains are observed in the PTO films as shown in Fig. 1. As proposed previously, formation of stripe 90° c1/c2 domains can hardly relax the in-plane \(\left[ {\bar 101} \right]\) directional misfit strain.25 Instead, the residual misfit strain could be relaxed by the formation of 90° a/c domains.

Geometrically, 〈111〉 MDs with an average dislocation spacing of 10.9 nm along the \(\left[ {\bar 101} \right]\) direction also have an average dislocation spacing of 7.8 nm along the in-plane [010] direction, which can relax the in-plane [010] directional misfit strain up to 5.0%. However, at room temperature, the lattice mismatch calculated along the in-plane [010] direction is only about −0.8%. So the tensile stress occurs along the in-plane [010] direction in PTO films, which promotes the nucleation of a domains to compensate the tensile strain field in the [010] direction. This is the reason why there are some 90° a/c domains in this film system. As discussed above, both the interfacial MDs and 90° a/c domains contribute to the misfit strain relaxation along both the in-plane \(\left[ {\bar 101} \right]\) and [010] directions, and also they remarkably interact, which indicates a big difference in strain relaxation mechanisms between the (101)- and (001)-oriented ferroelectric PTO films. Furthermore, the strain relaxation behavior and the formation of a/c domains in (101)-oriented ferroelectric PTO films may also work for the (101)-oriented tetragonal Pb(Zr, Ti)O3 thin films.

IV. CONCLUSION

In this study, we investigate the interfacial MDs and misfit strain relaxation behavior of (101)-oriented ferroelectric PTO epitaxial thin films grown on LSAT(101) substrates using TEM approaches. We find two types of MDs at the interface, which have the majority of contribution to the misfit strain relaxation. One is formed by gliding with the Burgers vectors of a[011] or \(a\left[ {0\bar 11} \right]\) and line direction of 〈111〉, which not only simultaneously relaxes the misfit strain of both in-plane \(\left[ {\bar 101} \right]\) and [010] directions, but also relaxes the shear strain in adjacent domains. The other is formed by climbing with the Burgers vectors of \(a\left[ {\bar 101} \right]\) and line direction of [010], which only relaxes the misfit strain of \(\left[ {\bar 101} \right]\) direction. The residual misfit strains are relaxed by the formation of 90° a/c domains. These results may shed some light on the understanding of asymmetric strain relaxation in (101)-oriented perovskite thin films and provide useful information for the growth of the (101)-oriented perovskite thin films.

V. EXPERIMENTAL

The PTO thin films were deposited on single-crystal LSAT(101) substrates by pulsed laser deposition (PLD), using a Coherent ComPexPRO 201FKrF (λ = 248 nm) excimer laser. A sintered PTO target (3 mol% Pb-enriched) was used. Before deposition, the substrate was preheated to 800 °C for 5 min to clean the substrate surface and then cooled down to film-growing temperature. During deposition, an oxygen pressure of 10 Pa, laser energy density of 2 J/cm2, growing temperature of 700 °C, and a repetition rate of 4 Hz were used. After deposition, the film was annealed at 700 °C for 5 min in an oxygen pressure of 3 × 104 Pa and then cooled down to room temperature at a rate of 5 °C/min.

Cross-sectional and plane-view TEM samples for TEM and STEM observations were prepared by slicing, mechanical grinding, dimpling, and finally ion milling by Gatan 691 PIPS (Gatan Inc., Pleasanton, California). Before ion milling, the samples were dimpled down to about 10 µm. The final voltage of milling was less than 0.5 kV for 10 min to reduce the ion beam damage. Plane-view TEM samples were grinded, dimpled, and finally ion-milled only from the substrate side. Bright-field and dark-field TEM images were recorded by Tecnai G2 F30 transmission electron microscope (FEI, Hillsboro, Oregon). All HAADF-STEM images were acquired by aberration-corrected (scanning) transmission electron microscope (Titan G2 60-300 kV microscope (FEI) equipped with double aberration correctors from CEOS and a monochromator operating at 300 kV). Large-scale strain field was extracted by using GPA, carried out using Gatan Digital Micrograph software (Gatan Inc.).

References

J.F. Scott: Applications of modern ferroelectrics. Science 315, 954 (2007).

N. Setter, D. Damjanovic, L. Eng, G. Fox, S. Gevorgian, S. Hong, A. Kingon, H. Kohlstedt, N.Y. Park, G.B. Stephenson, I. Stolitchnov, A.K. Taganstev, D.V. Taylor, T. Yamada, and S. Streiffer: Ferroelectric thin films: Review of materials, properties, and applications. J. Appl. Phys. 100, 051606 (2006).

L.W. Martin and A.M. Rappe: Thin-film ferroelectric materials and their applications. Nat. Rev. Mater. 2, 1 (2016).

D.G. Schlom, L.Q. Chen, C.J. Fennie, V. Gopalan, D.A. Muller, X.Q. Pan, R. Ramesh, and R. Uecker: Elastic strain engineering of ferroic oxides. MRS Bull. 39, 118 (2014).

S.Y. Hu, Y.L. Li, and L.Q. Chen: Effect of interfacial dislocations on ferroelectric phase stability and domain morphology in a thin film—A phase-field model. J. Appl. Phys. 94, 2542 (2003).

D. Su, Q. Meng, C.A.F. Vaz, M-G. Han, Y. Segal, F.J. Walker, M. Sawicki, C. Broadbridge, and C.H. Ahn: Origin of 90° domain wall pinning in Pb(Zr0.2Ti0.8)O3 heteroepitaxial thin films. Appl. Phys. Lett. 99, 102902 (2011).

Y. Liu, Y.L. Tang, Y.L. Zhu, W.Y. Wang, and X.L. Ma: Spatial coupling of ferroelectric domain walls and crystallographic defects in the PbTiO3 films. Adv. Mater. Interfaces 3, 1600342 (2016).

M.W. Chu, I. Szafraniak, R. Scholz, C. Harnagea, D. Hesse, M. Alexe, and U. Gosele: Impact of misfit dislocations on the polarization instability of epitaxial nanostructured ferroelectric perovskites. Nat. Mater. 3, 87 (2004).

V. Nagarajan, C.L. Jia, H. Kohlstedt, R. Waser, I.B. Misirlioglu, S.P. Alpay, and R. Ramesh: Misfit dislocations in nanoscale ferroelectric heterostructures. Appl. Phys. Lett. 86, 192910 (2005).

C.L. Jia, S.B. Mi, K. Urban, I. Vrejoiu, M. Alexe, and D. Hesse: Effect of a single dislocation in a heterostructure layer on the local polarization of a ferroelectric layer. Phys. Rev. Lett. 102, 117601 (2009).

P. Gao, C.T. Nelson, J.R. Jokisaari, S.H. Baek, C.W. Bark, Y. Zhang, E. Wang, D.G. Schlom, C.B. Eom, and X.Q. Pan: Revealing the role of defects in ferroelectric switching with atomic resolution. Nat. Commun. 2, 591 (2011).

S.C. Jain, A.H. Harker, and R.A. Cowley: Misfit strain and misfit dislocations in lattice mismatched epitaxial layers and other systems. Philos. Mag. A 75, 1461 (1997).

H.H. Wu, J. Wang, S.G. Cao, and T.Y. Zhang: Effect of dislocation walls on the polarization switching of a ferroelectric single crystal. Appl. Phys. Lett. 102, 232904 (2013).

Y.L. Tang, Y.L. Zhu, Y. Liu, Y.J. Wang, and X.L. Ma: Giant linear strain gradient with extremely low elastic energy in a perovskite nanostructure array. Nat. Commun. 8, 15994 (2017).

S. Stemmer, S.K. Streiffer, F. Ernst, and M. Ruhle: Dislocations in PbTiO3 thin films. Phys. Status Solidi A 147, 135 (1995).

T. Suzuki, Y. Nishi, and M. Fujimoto: Analysis of misfit relaxation in heteroepitaxial BaTiO3 thin films. Philos. Mag. A 79, 2461 (1999).

Y.L. Zhu, X.L. Ma, D.X. Li, H.B. Lu, Z.H. Chen, and G.Z. Yang: Microstructural analyses of a highly conductive Nb-doped SrTiO3 film. Acta Mater. 53, 1277 (2005).

I.B. Misirlioglu, A.L. Vasiliev, S.P. Alpay, M. Aindow, and R. Ramesh: Defect microstructures in epitaxial PbZr0.2Ti0.8O3 films grown on (001) SrTiO3 by pulsed laser deposition. J. Mater. Sci. 41, 697 (2006).

Y.L. Qin, C.L. Jia, K. Urban, J.H. Hao, and X.X. Xi: Dislocations in SrTiO3 thin films grown on LaAlO3 substrates. J. Mater. Res. 17, 3117 (2011).

Y.L. Tang, Y.L. Zhu, H. Meng, Y.Q. Zhang, and X.L. Ma: Misfit dislocations of anisotropic magnetoresistant Nd0.45Sr0.55MnO3 thin films grown on SrTiO3 (110) substrates. Acta Mater. 60, 5975 (2012).

Y.L. Tang, Y.L. Zhu, Y.Q. Zhang, Z.D. Zhang, and X.L. Ma: Nanostructured Nd0.45Sr0.55MnO3 films grown on SrTiO3 (110). J. Mater. Res. 28, 1692 (2013).

X. Shen, T. Yamada, R. Lin, T. Kamo, H. Funakubo, D. Wu, H.L. Xin, and D. Su: Interfacial dislocations in (111) oriented (Ba0.7Sr0.3)TiO3 films on SrTiO3 single crystal. Appl. Phys. Lett. 107, 141605 (2015).

Y.B. Xu, Y.L. Tang, Y.L. Zhu, Y. Liu, S. Li, S.R. Zhang, and X.L. Ma: Misfit strain relaxation of ferroelectric PbTiO3/LaAlO3 (111) thin film system. Sci. Rep. 6, 35172 (2016).

M. Mtebwa, A. Mazzalai, C.S. Sandu, A. Crassous, and N. Setter: Engineered a / c domain patterns in multilayer (110) epitaxial Pb(Zr, Ti)O3 thin films: Impact on domain compliance and piezoelectric properties. AIP Adv. 6, 055104 (2016).

Y.P. Feng, Y.L. Tang, D.S. Ma, Y.L. Zhu, M.J. Zou, M.J. Han, J.Y. Ma, and X.L. Ma: Thickness-dependent evolution of piezoresponses and stripe 90° domains in (101)-oriented ferroelectric PbTiO3 thin films. ACS Appl. Mater. Interfaces 10, 24627 (2018).

R.J. Xu, J. Karthik, A.R. Damodaran, and L.W. Martin: Stationary domain wall contribution to enhanced ferroelectric susceptibility. Nat. Commun. 5, 3120 (2014).

R.J. Xu, S. Liu, I. Grinberg, J. Karthik, A.R. Damodaran, A.M. Rappe, and L.W. Martin: Ferroelectric polarization reversal via successive ferroelastic transitions. Nat. Mater. 14, 79 (2015).

W. Zhang, H. Cheng, Q. Yang, F. Hu, and J. Ouyang: Crystallographic orientation dependent dielectric properties of epitaxial BaTiO3 thin films. Ceram. Int. 42, 4400 (2016).

A.M. Glazer and S.A. Mabud: Powder profile refinement of lead zirconate titanate at several temperatures. II. Pure PbTiO3. Acta Crystallogr., Sect. B: Struct. Crystallogr. Cryst. Chem. 34, 1065 (1978).

D. Mateika, H. Kohler, H. Laudan, and E. Volkel: Mixed-perovskite substrates for high-Tc superconductors. J. Cryst. Growth 109, 447 (1991).

D.B. Williams and C.B. Carter: Transmission Electron Microscopy, 2nd ed. (Springer, New York, 2009); p. 445.

S.J. Pennycook and D.E. Jesson: High-resolution Z-contrast imaging of crystals. Ultramicroscopy 37, 14 (1991).

M.J. Hytch, E. Snoeck, and R. Kilaas: Quantitative measurement of displacement and strain fields from HREM micrographs. Ultramicroscopy 74, 131 (1998).

Y.L. Tang, Y.L. Zhu, and X.L. Ma: On the benefit of aberration-corrected HAADF-STEM for strain determination and its application to tailoring ferroelectric domain patterns. Ultramicroscopy 160, 57 (2016).

G. Shirane, S. Hoshino, and K. Suzuki: X-ray study of the phase transition in lead titanate. Phys. Rev. 80, 1105 (1950).

B.C. Chakoumakos, D.G. Schlom, M. Urbanik, and J. Luine: Thermal expansion of LaAlO3 and (La, Sr)(Al, Ta)O3, substrate materials for superconducting thin-film device applications. J. Appl. Phys. 83, 1979 (1998).

P.A. Langjahr, F.F. Lange, T. Wagner, and M. Ruhle: Lattice mismatch accommodation in perovskite films on perovskite substrates. Acta Mater. 46, 773 (1998).

ACKNOWLEDGMENTS

This work is supported by the National Natural Science Foundation of China (Nos. 51571197, 51501194, and 51671194), National Basic Research Program of China (2014CB921002), and the Key Research Program of Frontier Sciences CAS (QYZDJ-SSW-JSC010). Y.L.T. acknowledges the IMR SYNL-T.S. Kê Research Fellowship and the Youth Innovation Promotion Association CAS (No. 2016177). The authors are grateful to Mr. B. Wu and Mr. L.X. Yang for their technical support on the Titan platform of G2 60-300 kV aberration-corrected scanning transmission electron microscope.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Feng, Y., Tang, Y., Zhu, Y. et al. Misfit strain relaxations of (101)-oriented ferroelectric PbTiO3/(La, Sr)(Al, Ta)O3 thin film systems. Journal of Materials Research 33, 4156–4164 (2018). https://doi.org/10.1557/jmr.2018.422

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2018.422