Abstract

Special needs patients often require specific dental treatments and modified restorative materials that reduce clinical discomfort. Starting from glass ionomer cements (GICs), some different fillers were added to improve their mechanical and clinical performances. The effect of nanohydroxyapatite, antibiotic, and mucosal defensive agent on the mechanical and thermal properties of GICs was investigated. Compressive tests, calorimetric analysis, and morphological investigation were conducted. The middle percentages of fillers increased the elastic modulus while the highest decreases are recorded for highest percentages. Filler and environment also influence the compressive strengths and toughness. The introduction of fillers led to a reduction of the enthalpy with a maximum decrease with the middle percentage. The morphological characterization showed a good dispersion of the fillers. The filler percentages should be selected with a compromise between the elastic modulus, the compressive strength, and the curing time. Obtaining new materials with good clinical and mechanical properties can represent an innovative aspect of this work with positive implication in clinical practice, mainly in uncollaborative patients in which the use of traditional protocols is problematic.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

I. INTRODUCTION

Dental caries is one of the most important pathological processes in a human being with bacteria having a key role in their development.1,2

Some studies focus on the type of materials to use in conservative therapies and on the amount of damaged tissue that should be removed in the carious cavity. About restorative materials, in the last decades, the use of amalgam has been reduced due to its controversial safety and aesthetic properties. For these reasons, new restorative materials (tooth-colored) as composite resins have been introduced,3 even if doubts about secondary caries due to the poor adhesion and bisphenol A (and its components) estrogenicity were expressed.4–6

Among different conservative techniques, the atraumatic restorative treatment (ART) is an innovative dental treatment for special needs patients with an important impact on public health due also to the low cost factors.7 The main characteristic of the ART technique is the partial caries removal since in this way, only the softened (infected) dentine is removed from carious tissue.8 This partial removal is an acceptable procedure because the affected dentine still presents a remineralization capacity. Moreover, the total removal of carious tissue can increase the risk of pulp exposure in deep cavities and consequently endodontic treatments.9

Another important aspect of the ART technique is the use of manual instruments to make the procedure more comfortable for special needs patients. Consequently, cariogenic bacteria can survive under restorations and remain active even after two years, thus producing secondary caries.10

In these kinds of techniques, different materials have been proposed like glass ionomer cements (GICs) made of a glass powder (made of an acid degradable fluoroaluminosilicate) and an ionomer with carboxylic acids (usually a polyacrylic acid and copolymers of polyacrylic acid). In particular, they are the product of the reaction of liquid polyacid ionomer with the calcium released from the glass (forming insoluble polysalts)11,12 having good adhesion to bone, biocompatibility, and fluoride ion release (which is suitable for antibacterial activity of these materials).

GICs are usually adopted in pediatric dentistry for filling, particularly when micro-invasive strategies are chosen in place of traditional dental caries procedures also to reduce dental fear.7

GICs resulted in a mandatory choice for children caries treatment of primary teeth, due to the slow fluoride release ability of these cements. This ability in fact may endure residual decayed tissues when they resulted under-excavated after micro-invasive procedures.

Moreover, in pediatric dentistry, the use of GICs were often preferred to resin composite fillings (most usually used during adults’ treatment) because of their possibility to be used also in moist environment, without any rubber dam tooth isolation.12 As rubber dam use requires a stable tooth anchorage through a steel hook, this could represent a threatening instrument among young patients.7

However, the main disadvantages of these materials are the low mechanical properties (such as fracture toughness and wear resistance) and their propensity to dissolve in water with the consequent high risk of bacterial proliferation, secondary caries, and restoration failure.13

To overcome these limitations and improve mechanical and adhesive properties, numerous filler components have been added, including: silver amalgam particles, spherical silica, zirconia, glass fibers, hydroxyapatite (HA), and bioactive glass particles, as prereacted glass ionomer particles and antibiotics.

Recently, incorporation of HA and fluoroapatite nanobioceramics into conventional GICs also improved their mechanical properties and bond strength to dentine.4,14–17

HA is a calcium phosphate bioceramic [with formula Ca10(PO4)6OH2] with a calcium to phosphorus ratio (Ca/P) of 1.67 which can improve GIC biocompatibility since its composition and crystal structure are similar to the human dental apatite and bone tissue. HA in fact is the main mineral component of the enamel (more than 60 wt% of tooth dentine is HA). Recent studies also used nanohydroxyapatite to improve mechanical properties.18–20

Moreover, therapeutic benefit may be achieved by adding antibacterial agents to GIC materials (e.g., chlorhexidine,1,21,22 and antibiotics23–25) to increase its antibacterial effects. The type of antibacterial agent selected and its quantity are important factors to consider for antimicrobial properties and mechanical behavior of cements. The antibacterial effect on some cariogenic bacteria (Streptococcus mutans or Lactobacillus casei) can be used in the ART technique to reduce bacterial damage. Antibiotics (AB) like ciprofloxacin, minocycline, and metronidazole in different situations have been added directly to restorative materials.21,23

A mucosal defensive agent (MDA) may also have a positive effect on the prevention and repair of mucous membrane lesions (e.g., in orthodontic patients, or aphthosis lesions).26

The addition of all these fillers (HA, AB, and MDA) in a unique mixture to GICs could be important to enhance the clinical performance of the cement, providing each one a different pharmacological effect.

The aim of this study was the evaluation of the effect of different percentages of the HA, AB, and MDA on GICs on the mechanical and thermal properties along with the morphological dispersion of the fillers. The first null hypothesis was that no differences in mechanical properties were shown with the addition of the fillers to traditional GICs. The second null hypothesis was that no differences in thermal properties were shown with the addition of the fillers to traditional GICs. The third null hypothesis was that the different percentages of fillers do not modify the mechanical and thermal properties. The fourth null hypothesis was that the different filler concentrations do not change its dispersion into GIC.

II. MATERIALS AND METHODS

A. Materials and sample preparation

A commercially available glass ionomer cement (Fuji II, GC, Tokyo, Japan) has been chosen for this work. The reference cement (GIC) was prepared by mixing the polymeric liquid with the glass powder with a ratio of 1:2.7 according to the manufacturer’s instructions.

The powder is composed primarily of fluoroaluminosilicate glass and the liquids were polyacrylic acid and water.

Three different additives were selected for this study: nanohydroxyapatite, antibiotic, and MDA. Nanohydroxyapatite (Sealent®, Miromed S.r.l., Linate, Italy) was purchased from Mentadent, the antibiotic selected is ciprofloxacin (Ciproxin, Bayer S.p.A., Milan, Italy),10,27,28 and the MDA is zinc L-carnosine (Hepilor, Azienda Farmaceutica Italiana, Teramo, Italy).

The samples were obtained by replacing the liquid (L) or the solid phase, (P as powder) of the base GIC.

To prepare the experimental GIC groups, part of the powder was replaced by HA powder before the addition of liquid. A similar method was used to add antibiotic to the base GIC. Composite cements with anti-inflammatory were instead prepared by adding to the powder, the base liquid, and part of MDA, which is in liquid form. In this way for all samples, the P:L weight ratio was maintained at 2.7. All the formulations are shown in Table I. Each component was weighted on an analytical balance with ±0.1 mg precision (Mettler Toledo, type AB104-S, Greifensee, Switzerland).

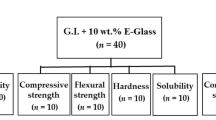

The GIC performance was evaluated after 7 days. In particular, after mixing, the wet paste was placed into silicon molds and left in air for 6 h, after which they were withdrawn from the mold and stored “dry” at room temperature or “wet” by immersion in water for setting and hardening. After 7 days, the hardened reference and cements (wet and dried) were tested. The weight percentages used were as follows: 2–4–6 wt% for HA and for AB, 1.5–3–4.5 wt% for MDA.

The materials were identified with GIC followed by the weight percentage of the material added and the letters identifying the material itself (i.e., GIC-2HA refers to GIC cement with 2 wt% of HA).

B. Calorimetric analysis

The fresh samples were subjected to differential scanning calorimetry (DSC) performed on a Mettler-Toledo DSC 822E/400. They were introduced in standard aluminum pans with lid and subjected to a heating cycle from 0 to 150 °C at a heating rate of 10 °C/min in nitrogen atmosphere.

The DSC thermograms were analyzed and the peak temperature was obtained using the software STARe. The same tests were performed on the base GIC and the thermal properties compared with those obtained for GIC and HA, AB, and MDA. In this way, the effect of the different additives was evaluated.

C. Mechanical testing

Mechanical tests were performed on both dry and wet samples to determine the mechanical properties of the materials. The samples immersed in water were dried using filter paper just before the test. The top and bottom surfaces of all samples were lightly sanded using 600-grit sandpaper. Five samples of each material were tested in compression using a material testing machine (LR30K, Lloyd Instruments Ltd., Fareham, U.K.) at room temperature (25 °C) as per ISO 9917-1 (2007).

The samples were subjected to a compression force (F) perpendicular to the top surface at a constant crosshead speed of 0.5 mm/min until failure occurred. The load–deflection curves were recorded with PC-software (Nexygen, Lloyd Instruments Ltd., Fareham, U.K.). The ultimate compressive strength for all specimens (σc) was calculated by dividing the maximum force by the area of the specimen:

where Fmax is the applied load at the maximum of the curve (N) and d is the specimen diameter (mm). The diameter of each sample was measured with a digital caliper (Mitutoyo, Tokyo, Japan) before the test with 0.01 mm accuracy. The stiffness S of the materials was also calculated from the slope of the first linear part of the curve as S = F/D, where D is the deflection corresponding to load F at a point in the straight-line portion of the curve (N/m).

The elastic modulus from the compression test (Ec) was calculated using the following equation:

where l and A are the height (mm) and cross-sectional area of the sample, respectively, and S is the compression stiffness. In particular, the stress strain curve, expression of material reaction, presents a first peak load and then they show withstand other stresses with a next increase. The toughness of all cements was also evaluated from the stress–strain curves as the area under the curve up to the maximum load. In this way, both the elastic energy (i.e., reversible) and the plastic energy (i.e., irreversible) absorbed by the material prior to failure can be calculated.

D. Scanning electron microscopy

The samples were subjected to morphological analysis after DSC measurement. One specimen for each group was metallized with a thin layer of gold (15 nm, 99.99% of gold, 2 × 10−6 Torr) in a thermal evaporator (Sistec thin film equipment model GP 20 by Kenosistec Angelantoni Group, Massa Martana (PG), Italy) and then analyzed with a field emission scanning electron microscope (FESEM model SUPRA25, ZEISS, Oberkochen, Germany).

III. RESULTS

A. Calorimetric analysis

The DSC thermograms are shown in Fig. 1. The curves of the heat flow as a function of temperature show an exothermic peak at 48 °C. This exothermic reaction is related to the polymerization process of all the materials. Another endothermic peak was found for pure GIC and for GIC with HA and AB (especially for middle percentages) at about 100–110 °C.

According to Mueller,29 this peak can be attributed to loss of water of hydration contained in the components. For each sample, the polymerization enthalpy, the onset and endset temperatures, and the peak temperatures were evaluated and reported in Table II.

The results show that the introduction of different additives resulted in a reduction of the enthalpy with respect to the base material (showing a ΔH value of 43.85 J/g). The addition of 4% of HA results in a decrease of 19.5% with respect to the base GIC, the addition of 3% of AB shows a decrease of 63.7%, and 4% of MDA shows a decrease of 53.2%.

The temperature at which the polymerization reaction starts (Tonset) does not change significantly with the introduction of the additives. The only variation was detected with the middle percentage used with an increase of the Tonset of about 2–3 °C.

Moreover, the peak temperatures evaluated from the DSC curves showed similar values when HA and MDA were added to GIC while a slight increase of Tpeak was detected with the addition of AB (about 2–3 °C).

Finally, the evaluation of the temperature related to the end of the cure (Tendset) shows how only the addition of HA and MDA produce an early end of the curing process.

B. Mechanical testing

The stress–strain curves of all composites are shown in Fig. 2. The nature of materials and the sample production led to noisy stress–strain curves. In particular, their scattering, expression of materials reaction to the solicitation, after a first peak load they show the ability to withstand more stress so they load start to increase again. This aspect represents a good clinical behavior without undesirable sudden failure.

However it is important to highlight that Young’s modulus was calculated in the very first part of each curve (as for the definition of E itself) and in this part, the curves are linear. For this reason the sample stress curves did not modify the calculations.

The toughness was calculated as area under the curves with kaleidagraph up to the maximum load. Even the other parameters (stress and strain) were calculated at the maximum load and in general, the curves become more noisy after the peak.

The mechanical behavior of the materials showed by the stress–strain curves is very different from dry to wet samples. The GICs that absorbed water show a more extended plastic deformation for all the samples. Table III shows the mechanical results as the Young modulus (Ec), the compressive strength (σc), the strain related to the maximum strength (εc), and the toughness. The elastic modulus of the reference cement was 13.41 GPa in dry condition and decreased to 10.67 GPa in wet condition. The addition of HA resulted in a slight decrease of elastic modulus with all percentages used (in dry condition) while an opposite behavior was showed in the wet environment.

In dry condition, the antibiotic seems to increase the elastic modulus of GICs mainly at low concentration (16.74 GPa) while the other percentages does not change this property; in wet condition, an increase of the elastic modulus can be detected for 1.5 and 3% of AB added and no change for high percentage.

A similar trend was recorded with the addition of MDA with the highest decrease of E for GIC-6MDA (9.48 GPa for dry samples) and an increase for low and middle percentages (both for dry and wet environments). The compressive strength of the pure GIC dried samples was higher (36.6 ± 6.9 MPa) than that of the wet ones (28.1 ± 6.8 MPa) (Fig. 3). Among the GICs doped with HA, a general decrease of the compressive strengths was observed for all the dry samples mainly with the addition of 6%. On the contrary, when the samples are kept in wet environment, higher compressive strength with respect to pure GIC was obtained with the addition of 2 wt% of HA (36.5 MPa) and with 4 wt% (36.4 MPa). On the contrary, the addition of 6 wt% of HA decreased the compressive stress of GIC.

The samples with 1.5 wt% of antibiotic left in air showed a higher compressive strength in respect of those left in water and in respect to pure GIC. The addition of 3 wt% of antibiotic does not seem to sensibly affect the compressive strength of the GIC neither in dry nor in wet condition. In wet conditions, higher percentage (4.5 wt%) led to an increase of compressive strength.

The addition of MDA on GIC resulted in an increase of compressive strength with 4 wt% (the other percentage produced almost no effect on this property). A similar trend was detected in wet conditions. It can be observed that the environmental condition (dry versus wet) does not affect the GIC behavior in terms of toughness (Fig. 4). In GIC-HA samples, the addition of HA led to a reduction of toughness for dry samples while for wet samples, the addition of only 6 wt% led to a reduction of this property.

The addition of AB to GIC samples left in air resulted in a decrease with the low and middle AB concentrations and a decrease with the highest concentration in respect to the base GIC. On the contrary, in wet samples only with the addition of 4.5% of AB, it is possible to observe an important increase in toughness (up to 868 kJ/m3).

The most evident change of toughness level caused by the addition of MDA can be found for 4 wt% with an increase of about 25% for wet samples.

The mechanical data were subjected to two-way ANOVA (SPSS10 Inc, Chicago, IL) to determine the statistical significance of the results obtained: the values differed from one another with a significance level of P < 0.05.

C. Scanning electron microscopy

The morphology of GIC as prepared following the manufacturer’s instructions after fracture and the different solid additives were subjected to SEM analysis to highlight their morphology to verify their presence in the samples produced (Fig. 5).

Figures 5(a) and 5(b) show the morphology of GIC as prepared following the manufacturer’s instructions after fracture. The gray areas visible in Fig. 5(a) represent the spherical morphology of the cement fillers. On the contrary, the dark areas are voids in the cement structures due to the manual mixing and production of the samples. Figure 5(b) at higher magnification (10,000×) shows the fracture surface of GIC.

Figures 5(c) and 5(d) show the typical crystalline morphology of HA nanoparticles; in particular, agglomerates of nanoparticles with the dimension of 1–2 µm can be detected.

Figures 5(e) and 5(f) show, as expected, the spherical particles of antibiotic with an average diameter of 200 µm.

The SEM images of the samples GIC-2HA, GIC-4HA, and GIC-6HA are reported in Figs. 6(a)–6(c). As it can be noted in Fig. 6(c), a higher distribution of HA is shown due to the high percentage of HA added. The decrease of mechanical properties recorded by GIC samples with 6 wt% of HA can be attributed to a reduction of matrix content with respect to the filler. In Figs. 6(d)–6(f) (related to GIC + AB), it is possible to detect the different distribution of spherical AB particles (gray round zones) into the polymeric matrix from the lowest [Fig. 6(d)] to the highest percentage added [Fig. 6(f)].

SEM micrographs of GIC with (a) 2 wt% HA; (b) 4 wt% HA; (c) 6 wt% HA. The circles indicate some of the zones with HA nanoparticles (10,000×). SEM micrographs of GIC with (d) 1.5 wt% AB; (e) 3 wt% AB; (f) 4.5 wt% AB (100×). SEM micrographs of GIC with (g) 2 wt% MDA; (h) 4 wt% MDA; (i) 6 wt% MDA (10,000×).

GIC samples with different percentages of MDA are also reported in Figs. 6(g)–6(i) at 10,000× The highest compressive strength shown by GIC with 4 wt% of MDA is confirmed by the morphology of the matrix after fracture [Fig. 6(h)]. However, even GIC with 6 wt% of MDA could be selected for potential similar properties (the high standard deviation of 4 wt% makes it close to 6 wt%).

Moreover, for GIC with AB, the SEM analysis was made at higher magnification for each percentage to analyze the morphology and structure of a single AB particle. In particular, Fig. 7 reports the magnification of GIC samples with 4.5 wt% AB [Fig. 7(a)]. At 1000×, an individual AB particle can be seen with an external shell surrounding the active substance [Fig. 7(b)]. This image confirms the dimensions of AB particle (around 200 µm). In Fig. 7(c), the internal component of the AB particle was presented at 10,000×.

IV. DISCUSSION

To preserve a larger amount of natural tooth structure, the use of a new dental practice (called minimal intervention dentistry) which allows partial removal of the soft demineralized carious tooth tissue and restoration of the cavity with an adhesive dental material10 is increasing. Moreover, after partial caries removal, it is possible to note the persistence of residual bacteria under restorations for long time (up to years).30–32

Different fillers added to conventional GICs were used in the past years. Among them, the effect of antibiotic,21,23–25, chlorhexidine,1,21,22 quaternary ammonium compounds,33,34 nanoparticles,35,36 and some different pharmacological components was studied.23,27

According to data found in our study, Chae and coworkers indicated in their literature review that how the antibacterial molecules added to GIC did not impair their mechanical caries properties.17 In addition, it was shown that the antibacterial molecules make a synergic intervention in stopping caries with the GICs releasing fluoride ions enough to induce a certain degree of dentine remineralization.17

HA was also found in the literature as an antibacterial agent. Particularly, in one study, (in vitro) several hydroxyapatite samples were found more effective than composite or GIC in reducing the concentration of the cariogenic Streptococcus mutans. Conversely, the hydroxyapatite was found to be a growth favoring factor (through its buffering features) for specific noncariogenic batteries, such as the Streptococcus sanguinis, in the aqueous solution (simulating oral environment) where the microorganisms were cultured.19 These results support our choice in adding GIC with hydroxyapatite for both its mechanical and antibacterial features.

Finally, the literature also supports the use of L-carnitine added to glass ionomer for its preventive role in oral mucositis.21 Glass ionomer dental restore might be considered also a specific type of slow release drug source, such as L-carnosine, particularly useful in special need subjects where adequate oral hygiene procedure is not easy to obtain and, therefore, inflammatory affections show a most frequent prevalence.22

In this work, three different fillers were added to GIC: nanoparticles of HA for its higher mechanical and biological properties, antibiotic for its antimicrobial properties, and MDA agent for prevention and therapy of oral mucositis.

In this work, the introduction of these fillers to GICs led to a general reduction of the enthalpy; this reduction can be considered a positive effect since the exothermic reaction releases a smaller amount of heat with consequent lower risk of thermal stresses. In particular, the middle percentage of each additive used seems to give an important reduction of the glass ionomer enthalpy. Moreover, the introduction of HA shifts the peak of the polymerization curve (Tpeak) to lower temperatures, thus producing a positive effect on the percentage of cured material at oral temperatures. From the point of view of the start of the cure, the addition of middle percentages should be avoided for all fillers since the Tonset increases.

The mechanical characterization showed that a reduction of Young modulus (as an increase of plastic deformation) produces a positive effect on the elasticity of the material, especially when used in partially removed caries in ART technique. A more elastic material in the early stages of the procedure represents a clinical advantage in low collaborative patients for higher adhesion and moldability.

For this reason, if only the elastic modulus is taken into account, the fillers should be added at their highest concentration to avoid an excessive reduction of the cements’ elasticity. It should be pointed out that these considerations are made by considering the behavior of wet samples. In fact, it represents the condition closest to the real one in oral cavities.

However, a reduction of Young’s modulus was also observed in dry condition with the addition of a high percentage of MDA. This could be explained by considering that being MDA in liquid form, it may decrease the rigidity of GIC and this effect is greater when all the other components are in dry state. This could explain the fact that in wet condition, a similar decrease was not observed.

In any case, other properties have to be considered and the choice of each percentage should be made as a general consideration of all properties.

The evaluation of the compressive strength is also an important factor because an excessive reduction of this property can induce to a higher risk of failure of the restoration under normal masticatory forces. Moreover, physical disabilities are associated with anomalous masticatory actions and parafunctions that can lead to an increase in the failure percentage. The results showed that the compressive strength of all dry GICs with additives is always higher than wet samples. The reduction of compressive strength of GIC cements followed by water absorption can be attributed to the weight loss and ionic release.

In particular, the strength of dry GIC + HA samples (which is the filler with a greater influence on this property) reduced with increasing HA percentage while in water, it increased. This suggests that HA is participating in chemical changes that are taking place during the setting of the cement.37 The reaction mechanism between HA and GIC is similar to the mechanism of adhesion of GIC to enamel and dentin. The apatite of the tooth structure may interact with the polyacrylic acid of GIC, thus producing polyacrylate ions; these ions then form strong ionic bonds.4

The addition of AB to GIC does not seem to greatly affect the value of compressive strength (especially in water) and 1.5 wt% could be preferred for the increase recorded in dry condition.

Moreover, the compression test results indicate that the addition of 4% MDA reinforces GIC in dry condition. A similar trend was recorded for wet samples with any percentage used. The difference in mechanical behavior between wet and dry samples was not associated to a macroscopic physical change of the materials: neither visible dehydration of dry samples (with consequence brittleness) nor swelling of wet samples was detected in this work.

The fracture toughness is a better indicator of clinical strength rather than average stress-based tests. Particularly, it may be a more reliable parameter to predict clinical performance than compressive stress evaluation.4 In this study, the toughness of GIC cements with filler results were lower than the pure GIC for all percentages and fillers used when the samples are kept in air. In SEM micrographs, the cleavage surfaces also show fracture areas with fracture borders in evidence. In particular, GIC with 6 wt% of HA shows cleavage surfaces with smaller fracture areas, indicating an increased brittleness of the samples confirmed by the highest reduction of the deformation (εc).

This trend is not followed for all samples when maintained in water. In particular, the dramatic decrease of the toughness showed with 6 wt% of HA (both for dry and wet samples) can be attributed to the excessive presence of HA nanoparticles. In this way, the addition of HA results in a decay of the ability of the GIC to resist catastrophic failure.

This aspect can be related to the specific nanomorphology of HA particles that, beyond a concentration percentage, which in this study seems to be 4%, led to a dramatic toughness reduction and mechanical performances.

A similar reduction of toughness was observed also with high percentage of MDA.

In this case, the wet environment is generally a disadvantageous condition for high concentrations of liquid filler with a general reduction of strain, modulus, and strength. Since the toughness is strictly related to these properties, a low value of both stress and strain gives a toughness reduction.

V. CONCLUSIONS

In this study, the effect of different percentages of HA, antibiotic, and MDA on GICs was evaluated. In the mechanical characteristics (elastic modulus, compressive strength, and toughness), the addition of all the fillers changed the material properties significantly. For these reasons not only the type of filler is important but also the concentration used. The thermal properties were also changed after the addition of the fillers with a reduction of the enthalpy (with all fillers) and of the peak of the polymerization curve (with HA).

The morphological characterization showed a good dispersion of the fillers.

By considering both the mechanical and the thermal properties of the cements with the three fillers, it can be concluded that the percentages should be selected for the particular clinical use with a compromise between the elastic modulus, the compressive strength, and the curing time. In particular, one of the possible mix concentrations could be 4% HA, 1.5% AB, and 6% MDA taking into consideration, the overall thermal and mechanical properties of modified GICs. The fourth null hypothesis can be rejected.

References

M. Deepalakshmi, S. Poorni, R. Migliani, R. Rajamani, and S. Ramachandran: Evaluation of the antibacterial and physical properties of glass ionomer cements containing chlorhexidine and cetrimide: An in vitro study. Indian J. Dent. Res. 21, 552 (2010).

J. Frencken and W. van Amerongen: The Atraumatic Restorative Treatment Approach, Dental Caries: The Disease and its Clinical Management (Blackwell Munksgaard, Oxford, 2008); p. 427.

M. Chieruzzi, S. Pagano, S. Moretti, R. Pinna, E. Milia, L. Torre, and S. Eramo: Nanomaterials for tissue engineering in dentistry. Nanomaterials 6, 134 (2016).

M.E. Lucas, K. Arita, and M. Nishino: Toughness, bonding and fluoride-release properties of hydroxyapatite-added glass ionomer cement. Biomaterials 24, 3787 (2003).

Y. Weng, X. Guo, V. Chong, L. Howard, R. Gregory, and D. Xie: Synthesis and evaluation of a novel antibacterial dental resin composite with quaternary ammonium salts. J. Biomed. Sci. Eng. 4, 147 (2011).

V. Deligeorgi, N.H.F. Wilson, and I.A. Mjor: An overview of reasons for the placement and replacement of restorations. J. Dent. Res. 77, 714 (1998).

L. Marti, M. Lata, B. Ferraz-Santos, E. Azevedo, E. Giro, and A. Zuanon: Addition of chlorhexidine gluconate to a glass ionomer cement as study on mechanical, physcial and antibacterial properties. Braz. Dent. J. 25, 33 (2014).

A.R.F. de Castilho, C. Duque, T.D. Negrini, N.T. Sacono, A.B. de Paula, C.A.D. Costa, D.M.P. Spolidorio, and R.M. Puppin-Rontani: In vitro and in vivo investigation of the biological and mechanical behaviour of resin-modified glass-ionomer cement containing chlorhexidine. J. Dent. 41, 155 (2013).

M. Chieruzzi, S. Pagano, C. De Carolis, S. Eramo, and J.M. Kenny: Scanning electron microscopy evaluation of dental root resorption associated with granuloma. Microsc. Microanal. 21, 1264 (2015).

S. Mittal, H. Soni, D. Sharma, K. Mittal, V. Pathania, and S. Sharma: Comparative evaluation of the antibacterial and physical properties of conventional glass ionomer cement containing chlorhexidine and antibiotics. J. Int. Soc. Prev. Community Dent. 5, 268 (2015).

S. Goenka, R. Balu, and T.S.S. Kumar: Effects of nanocrystalline calcium deficient hydroxyapatite incorporation in glass ionomer cements. J. Mech. Behav. Biomed. Mater. 7, 69 (2012).

Y.W. Gu, A.U.J. Yap, P. Cheang, and K.A. Khor: Effects of incorporation of HA/ZrO2 into glass ionomer cement (GIC). Biomaterials 26, 713 (2005).

R. Garcia-Contreras, R.J. Scougall-Vilchis, R. Contreras-Bulnes, H. Sakagami, R.A. Morales-Luckie, and H. Nakajima: Mechanical, antibacterial and bond strength properties of nano-titanium-enriched glass ionomer cement. J. Appl. Oral Sci. 23, 321 (2015).

J.W. Nicholson, S.J. Hawkins, and J.E. Smith: The incorporation of hydroxyapatite into glass-polyalkenoate (glass-ionomer) cements—A preliminary-study. J. Mater. Sci.: Mater. Med. 4, 418 (1993).

A.U.J. Yap, Y.S. Pek, R.A. Kumar, P. Cheang, and K.A. Khor: Experimental studies on a new bioactive material: HA ionomer cements. Biomaterials 23, 955 (2002).

K. Arita, M.E. Lucas, and M. Nishino: The effect of adding hydroxyapatite on the flexural strength of glass ionomer cement. Dent. Mater. J. 22, 126 (2003).

M.H. Chae, Y.K. Lee, K.N. Kim, J.H. Lee, B.J. Choi, H.J. Choi, and K.T. Park: The effect of hydroxyapatite on bonding strength in light curing glass ionomer dental cementKey Engin. Mater. 309–311, 881–884 (2006).

A. Moshaverinia, S. Ansari, M. Moshaverinia, N. Roohpour, J.A. Darr, and I.U. Rehman: Effects of incorporation of hydroxyapatite and fluoroapatite nanobioceramics into conventional glass ionomer cements (GIC). Acta Biomater. 4, 432 (2008).

A. Moshaverinia, S. Ansari, Z. Movasaghi, R.W. Billington, J.A. Darr, and I.U. Rehman: Modification of conventional glass-ionomer cements with N-vinylpyrrolidone containing polyacids, nano-hydroxy and fluoroapatite to improve mechanical properties. Dent. Mater. 24, 1381 (2008).

Y. Mu, G. Zang, H. Sun, and C. Wang: Effect of nano-hydroxyapatite to glass ionomer cement. Hua xi kou qiang yi xue za zhi 25, 544 (2007).

Y. Takahashi, S. Imazato, A.V. Kaneshiro, S. Ebisu, J.E. Frencken, and F.R. Tay: Antibacterial effects and physical properties of glass-ionomer cements containing chlorhexidine for the ART approach. Dent. Mater. 22, 647 (2006).

B.J. Sanders, R.L. Gregory, K. Moore, and D.R. Avery: Antibacterial and physical properties of resin modified glass-ionomers combined with chlorhexidine. J. Oral Rehabil. 29, 553 (2002).

C. Yesilyurt, K. Er, T. Tasdemir, K. Buruk, and D. Celik: Antibacterial activity and physical properties of glass-ionomer cements containing antibiotics. Oper. Dent. 34, 18 (2009).

S.L. Pinheiro, M.R.L. Simionato, J.C.P. Imparato, and M. Oda: Antibacterial activity of glass-ionomer cement containing antibiotics on caries lesion microorganisms. Am. J. Dent. 18, 261 (2005).

J. Ferreira, S. Pinheiro, F. Sampaio, and V. Menezes: Use of glass ionomer cement containing antibiotics to seal off infected dentin: A randomized clinical trial. Braz. Dent. J. 24, 68 (2013).

S. Katayama, K. Nishizawa, M. Hirano, S. Yamamura, and Y. Momose: Effect of polaprezinc on heating of acetic acid-induced stomatitis in hamsters. J. Pharm. Pharmaceut. Sci. 3, 113 (2000).

C. Farrugia and J. Camilleri: Antimicrobial properties of conventional restorative filling materials and advances in antimicrobial properties of composite resins and glass ionomer cements—A literature review. Dent. Mater. 31, E89 (2015).

M.G. Botelho: Inhibitory effects on selected oral bacteria of antibacterial agents incorporated in a glass ionomer cement. Caries Res. 37, 108 (2003).

H.J. Mueller, M.S. Bapna, and P.L. Fan: Heats of reactions between dentin bonding agents and tooth components. J. Oral Rehabil. 21, 699 (1994).

L. Bjorndal and T. Larsen: Changes in the cultivable flora in deep carious lesions following a stepwise excavation procedure. Caries Res. 34, 502 (2000).

C. Duque, T.D. Negrini, N.T. Sacono, D.M.P. Spolidorio, C.A.D. Costa, and J. Hebling: Clinical and microbiological performance of resin-modified glass-ionomer liners after incomplete dentine caries removal. Clin. Oral Invest. 13, 465 (2009).

A.S. Pinto, F.B. de Araujo, R. Franzon, M.C. Figueiredo, S. Henz, F. Garcia-Godoy, and M. Maltz: Clinical and microbiological effect of calcium hydroxide protection in indirect pulp capping in primary teeth. Am. J. Dent. 19, 382 (2006).

C. Poggio, C.R. Arciola, S. Cepurnykh, M. Chiesa, A. Scribante, L. Selan, M. Imbriani, and L. Visai: In vitro antibacterial activity of different self-etch adhesives. Int. J. Artif. Organs 35, 487 (2012).

S. Imazato, A. Kuramoto, Y. Takahashi, S. Ebisu, and M.C. Peters: In vitro antibacterial effects of the dentin primer of Clearfil Protect Bond. Dent. Mater. 22, 527 (2006).

N. Beyth, I. Yudovin-Farber, R. Bahir, A.J. Domb, and E. Weissa: Antibacterial activity of dental composites containing quaternary ammonium polyethylenimine nanoparticles against streptococcus mutans. Biomaterials 27, 3995 (2006).

M.A.S. Melo, S.F.F. Guedes, H.H.K. Xu, and L.K.A. Rodrigues: Nanotechnology-based restorative materials for dental caries management. Trends Biotechnol. 31, 459 (2013).

K. Choudhary and B. Nandhal: Comparative evaluation of shear bond strength of nano-hydroxyapatite incorporated glass ionomer cement and conventional glass ionomer cement on dense synthetic hydroxyapatite disk: An in vitro study. Indian J. Dent. Res. 26, 170 (2015).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chieruzzi, M., Pagano, S., Lombardo, G. et al. Effect of nanohydroxyapatite, antibiotic, and mucosal defensive agent on the mechanical and thermal properties of glass ionomer cements for special needs patients. Journal of Materials Research 33, 638–649 (2018). https://doi.org/10.1557/jmr.2018.36

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2018.36