Abstract

This study explores the biodegradation potential of microbial isolates focusing on their ability to utilize biopolymers as sole carbon source. Previously described isolates have been investigated through agar-based screen for the ability to degrade plastic-related substrates in powder form, and four strains have been selected for further assessment. Polyhydroxybutyrate (PHB) films degradation was examined through liquid culture, soil burial, and respirometry assays. Structural and chemical alterations in PHB were analysed using scanning electron microscopy (SEM), Fourier-transform infrared spectroscopy (FTIR), and differential scanning calorimetry (DSC). The most successful strains were tested for the ability to degrade PHB/bacterial nanocellulose (BNC) blends. Bacillus sp. DG90 excelled in PHB degradation, achieving 60% weight loss in liquid culture, while Streptomyces sp. DG19 exhibited a notable degradation rate of 51 ± 1.7%. Soil burial assays underscored the impact of environmental factors on degradation rates, emphasizing the role of soil composition and nitrogen availability. In respirometry assay, PHB films were severely defragmented by Streptomyces sp. DG19 with overall weight loss of 83%, while for Bacillus sp. DG90, this percentage reached 39%. FTIR and DSC analyses suggested potential hydrolysis and structural alterations in treated samples. This study observed rapid PHB degradation (83% in 3 weeks) while, considering the complex composition of modern biomaterials, also showcased the potential of examined strains to degrade PHB-BNC blends up to 85%.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Introduction

Biopolymers are a class of polymers that are derived from renewable resources, such as plants, microorganisms, and agricultural waste. They are biodegradable and compostable, making them a sustainable alternative to traditional petroleum-based plastics [1]. Biopolymers are used in a variety of applications including food packaging [2], textiles [3], construction materials [4], medical devices [5], and electronics [6]. As the demand for sustainable materials continues to grow, biopolymers are likely to play an increasingly important role in our economy and environment.

The depletion of nonrenewable resources, coupled with greenhouse gas emissions, the lack of effective technologies for post-use circularity, and improper disposal of non-biodegradable materials are all contributing significantly to our environmental crisis. Biodegradable and environmentally sustainable biopolymers like polyhydroxyalkanoates (PHA) and its homopolymer, polyhydroxybutyrate (PHB), offer a promising alternative. They have the potential to replace the linear use and disposal practices of plastics with a fully circular life cycle [7, 8]. PHB materials, from a mechanical standpoint, are generally rigid and brittle, displaying low thermal stability and high crystallinity [9]. Renewable sources such as food waste can be used as feedstocks for PHB biopolymer production. These characteristics, combined with PHB’s biocompatibility and tendency to biodegrade in specific biological environments, position it as a prime alternative to synthetic polymers like polypropylene and polyethylene. Despite being extensively studied since its discovery in the 1920s [10], industrial-scale PHB production faces challenges. These include high production costs, low yields, susceptibility to degradation, and technological complexities such as extraction difficulties [11]. Unlike most conventional plastics, microbes frequently possess enzymes capable of degrading biodegradable polymers. For example, PHAs (polyhydroxyalkanoates) are naturally occurring microbial polyesters utilized as carbon and energy storage compounds, which have been commercially introduced as biodegradable plastics. Consequently, specific microbial lineages harbour a range of enzymes dedicated to processing PHAs [12]. PHA depolymerases, crucial in PHA degradation, belong to a diverse family of carboxylesterases within the α/β-hydrolase family. These depolymerases feature a catalytic triad consisting of serine (embedded in a GxSxG motif), a histidine, and an aspartic acid, with a conserved histidine near the oxyanion hole. These enzymes hydrolyze the solid PHA into the water-soluble monomer and oligomers [13]. In contrast, PLA (polylactic acid) is not a natural substrate for microorganisms, and organisms capable of degrading PLA through the process of ester groups’ hydrolysis into hydroxyl or carboxyl group seem to be less abundant compared to those that degrade PHA [14]. PLA-degrading enzymes exhibit relatively higher sequence diversity and are categorized as proteases, lipases, and esterases [15]. When it comes to starch, the breakdown occurs through enzymatic processes targeting the glucosidic bonds connecting sugar groups, facilitated by specific enzymes (glycoside hydrolases, transglycosidases, lyases, phosphatases, and lytic polysaccharide monooxygenases). This enzymatic action results in the shortening of polymer chains and the release of sugar units, such as monosaccharides, disaccharides, and oligosaccharides. These liberated sugars are easily assimilated into biochemical pathways [16].

Studies suggest that there are numerous microbial strains, including filamentous fungi, Bacillus species, and thermophilic actinomycetes, which can degrade PHB with varying degradation rates and patterns [17,18,19]. Studies are suggesting that microbial degradation of PHB can range from 21 h to 4 months, depending on factors such as microbe type, environmental conditions, and material composition [20, 21]. However, multiple studies are suggesting that limitations of microbial degradation of PHB include the lack of specific microorganisms and enzymes, incomplete degradation affecting biomass growth, and phosphorus availability [19, 22, 23]. Therefore, ongoing need to identify and characterize additional PHB-degrading bacteria is still persistent in scientific circles. By presenting effective solutions to disposal and enhancing biodegradation, the commercialization of PHB can be seamlessly facilitated.

Following up on our previous study where microorganisms isolated from plastic polluted environments were examined for the ability to degrade substrates related to conventional plastic materials [24], further research was directed towards biopolymers. Overall, this study delved into the ability of selected strains to degrade PHB as a sole carbon and energy source in several experimental setups. Additionally, we monitored changes in chemical and thermal properties of PHB, which demonstrated the effective biodegradation activity of selected bacterial strain.

Materials and methods

Polyhydroxybutyrate (PHB Biomer P226E) in powder form used for this research was purchased from Biomer (Krailling, Germany). Glucose (dextrose), Luria Broth (LB), agar bacteriological N.1, and tryptone soy broth (TSB) were purchased from Neogen (USA). Other compounds, CaCl2 × 2H2O (calcium chloride dihydrate), MgSO4 × 7H2O (magnesium sulphate heptahydrate), Fe (III)NH4-citrate, EDTA, FeCl3, ZnCl2, CuCl2 × 2H2O, CoCl2 × 6H2O, MnCl2 × 6H2O, H3BO3, N-Z-Amine® A and other salts, and Na2HPO4 × 12H2O (sodium phosphate dibasic dodecahydrate), and KH2PO4 (potassium phosphate monobasic), were obtained from Sigma Aldrich (Hamburg, Germany). Bacterial strains were previously isolated, identified, and analysed for plastic-related substrates utilization [24]. GenBank accession numbers of selected isolates are listed in Table 1.

Bacterial precultures preparation

A total of 10 μL of glycerol stocks from selected isolated strains (Table 1) were plated in Luria Broth agar (LA) (Luria Broth (LB), Lennox, Neogen (NaCl 5 g/l, enzymatic digest of casein, 10 g/L, yeast Bertani extract, 5 g/L)), agar bacteriological, and Neogen (15 g/L) and incubated at 30 °C, 36 h. Using single colony method, a loopful of the plated strains was used to inoculate 15 mL of Tryptone Soy Broth (TSB) medium (enzymatic digest of casein 17 g/L, enzymatic digest of soybean 3.0 g/L, NaCl 5.0 g/L, K2 HPO4 2.5 g/L, glucose monohydrate 2.5 g/L) and incubated for 48 h (180 rpm, 30 °C).

Preparation of PHB films

PHB films were prepared by blow film extrusion. The film blowing was conducted with a blown film extrusion machine (CMG 40, Euro Machinery, Vissenbjerg, Denmark) with a screw diameter of screw diam.: 40 mm–30 (length/diameter). The PHB pellets were fed into the machine with a temperature profile of 163 °C at the feeding zone and 170 °C at the metering zone. The screw speed of 28–31 rpm and nip roll speed of 2.5–3.0 rpm were maintained to form a tubular film. PHB films were cut into squares of 2 cm × 2 cm, then soaked in 70% isopropanol for 30 min, sterilized by ultraviolet (UV) lamp for 30 min, and left to dry in 60 °C for 24 h.

Preparation of PHB/BNC films

Preculture of Komagataeibacter medelinensis ID13488 was prepared in Hestrin-Schramm medium (HS; 0.5% peptone, 0.5% yeast extract, 0.27% Na2HPO4, 0.15% citric acid, 2% glucose; w/v) for 4 days at 30 ℃, 180 rpm. This strain was previously described as bacterial nanocellulose (BNC) producer by Castro et al. [25], and 10% inoculum was used for 2-L fermentation in Bionet F2–3 twin bioreactor system (Bionet, Fuente Alamo, Spain) equipped with a double-wall tank which allows control over the inner chamber temperature and with an airflow rate control [26]. Temperature has been kept constant at 30 ± 1 and pH 5.5 ± 1 under static conditions. The process was monitored using ROSITA software [27]. After cultivation, BNC membranes were taken from the containers and washed with 2-M sodium hydroxide (20 min, 80 ℃), neutralized with distilled water, and left for a room-temperature drying process for 48 to 72 h followed by the measurement of the dried mass [26, 28] and disintegration into powder by a laboratory blender at 18,000 rpm for two cycles of 5 min (Waring 8011S, USA). PHB/BC blends in the form of films were prepared by dissolving 1 g of BNC powder in a solution of PHB and glacial acetic acid to achieve a 2% PHB final composition [29]. The solution was then homogenized using a high-shear mixer (HG-15D, Witeg, Wertheim, Germany) at 21,000 rpm for 60 min. The mixture was then spread onto glass 100 mm × 15 mm petri dishes and subjected to oven drying at 30 °C overnight, resulting in flat opaque film.

Biodegradation assays

Agar-based screening methodology

The ability of bacterial strains listed in Table 1 to utilize different biopolymers (thermoplastic starch (TPS), polylactic acid (PLA) and PHB) as a sole carbon and energy source was investigated using mineral salt medium agar plates (MSM): 15 g/L agar, 9 g/L Na2HPO4 × 12H2O, 1.5 g/L KH2PO4, 1 g/L NH4Cl, 0.2 g/L MgSO4 × 7H2O, 0.2 g/L CaCl2 × 2H2O, 0.1% trace elements solution, 0.025% N-Z amine, and carbon source 3 g/L. Biopolymer powders were used as a sole carbon source: TPS (Rodenburg Biopolymers, Oosterhout, The Netherlands), PLA (Hisun Biomaterials Co., Ltd., Zhejiang, China), and PHB (Sigma Aldrich, London, UK). The applied method is based on the combination of several references and previous experience [30,31,32]. A total of 100 μL of preculture was transferred to pierced-double-layer agar plates: The top layer consisting of 10 mL of mineral salt medium agar without carbon source supplemented with PHB solution (3 g/L). The bottom layer consisted of 20 mL of MSM medium without glucose. Clear zone formation was used as confirmation of PHB depolymerase activity.

Liquid culture assay

MSM medium with PHB films as a sole carbon source was used to estimate performance of selected strains to degrade PHB in liquid culture. A total of 100-mL flasks were inoculated (1%) with precultures prepared as explained in the previous section (the “Bacterial precultures preparation” section). The inoculated flasks were incubated for 2 weeks at 30 °C and 180 rpm to evaluate whether any of the strains exhibited rapid degradation of PHB as per Cho et al. Following cultivation, PHB films were washed and weighed to assess efficiency of biodegradation.

Soil Burial Method (SBM)

Samples were cut to 2 cm × 1.5 cm, sterilized (IPA 70%, UV 30 min, 24 h 60 ℃), labelled, and weighed. A total of 100 g of previously autoclaved commercial soil (carbon: nitrogen ratio < 17:1, total organic matter 10–35%, total nitrogen 1–2%, sulphide 0 ppm, ammonium 0 per trace, pH 6.5–8.5; Verve, Kingfisher International UK) (121 ℃, 15 min) in 10 × 8 cm petri dishes (Sigma Aldrich) was inoculated with 10 mL of each preculture Streptomyces sp. DG19 (0.38 × 108 CFU/mL), Streptomyces sp. DG25 (0.298 × 108 CFU/mL), Streptomyces sp. DG89 (0.32 108 CFU/mL), and Bacillus sp. DG90 (0.336 × 108 CFU/mL) after 2 days in TSB medium (30 ℃, 180 rpm). Accession numbers of the strains used in this experiment are listed in Table 1. Samples were placed at a depth of 1–2 cm in the middle of the plate, and the burial site of each sample was marked. Control samples were treated as mentioned above and buried in sterile non-inoculated soil. The samples in the soil were incubated for 3 weeks at 30 ℃. The tests were established under sterile conditions in a biosafety cabinet. All assays were performed in duplicate. The samples were extracted after 2, 3, and 4 weeks, washed (dH2O, 70% IPA), and dried (24 h, 60 ℃), and the level of degradation was estimated by recording their weight loss in comparison to the initial weight. The degradation percentage was analysed using Minitab software. Soil burial method was used to assess the ability of selected strains to degrade PHB/BNC blends using same protocol.

Respirometry assay

Respirometry test was designed and performed according to the ISO 14852 [33]. A total of 300 mL of MSM was prepared per a bottle (1L). A total of 1 g of PHB films previously sterilised was added to bottles. As per ISO protocol, 3.5% of inoculum was used to inoculate bottles according to experiment design. Bottles were labelled and connected in the channels in the chamber set in the respirometer (ECHO Instruments, Zeče, Slovenia). Total organic carbon (TOC) was calculated from chemical formula, following ISO 17556 [34]. Cultures were kept at 30 ℃, for 21 days. Biodegradation % was calculated based on the CO2 production, calculated according to ISO 14852 [33]. Following respirometry assays, PHB films were washed and dried, and their weight was recorded prior to their further chemical and thermal analysis.

Scanning Electron Microscopy (SEM)

Scanning electron microscopy (SEM) was used to analyse the surface of the samples. Specifically, the Mira XMU SEM (Tescan™, Brno, Czech Republic) was employed to capture back-scattered electron mode images with the accelerating voltage of 20 kV. Samples were prepared on an aluminium stub and coated with a thin layer of gold using Baltec SCD 005 (Schalksmühle, Germany). The sputtering process lasted 110 s and was performed under a vacuum pressure of 0.1 mbar.

Fourier-transform infrared spectroscopy (FTIR)

A Perkin-Elmer Spectrum One FTIR spectrometer (Perkin Elmer Inc., WA, USA) equipped with a universal ATR sampling accessory and Perkin Elmer software was employed to capture the spectra of dried PHB films in order to detect changes in the typically found functional groups present in its structure. The spectral resolution was set at 4 cm−1, and each spectrum was obtained by performing 16 scans in the range of 4000–650 cm−1.

Differential Scanning Calorimetry (DSC)

Differential scanning calorimetry (DSC) measurements were conducted on a differential scanning calorimeter (TA Instruments, Q20, USA) under nitrogen flow (50 mL/min). To achieve the same thermal history before measurements, each sample was first heated at a scanning rate of 50 °C/min to 200 °C and was maintained at 200 °C for 5 min and then immediately quenched to 5 °C at the same scanning rate and maintained at 5 °C for 5 min. The second heating scan was run from 5 to 250 pristine at a scanning rate of 5 °C/min to record the glass-transition temperature (Tg).

Results and discussion

Our previous study [24] delved into the microbial diversity of plastic-polluted sites, exploring their proficiency in degrading various plastic-related substrates as sole carbon and energy sources. Following up on that work, 20 isolates were tested for the ability to use biopolymers such as TPS, PLA, and PHB as a sole carbon and energy source. Results presented in Fig. 1 are implying that 35% of examined strains have the ability to grow on all examined biopolymers as a sole carbon source with visible halo zones on agar plates. When it comes to PHB, all strains were able to grow in some extant: 30% with moderate growth and 35% with poor growth. Most of these strains belong to Streptomyces spp. which is in compliance with reported studies on enzymatic toolbox these microbes possess [35]. The presence of various enzymes that can be linked with biopolymer degradation in these species is widely studied and discussed in the literature [36,37,38,39,40]. Overall, thanks to significant amount of information on genome data, streptomycetes have been widely employed for the production of valuable enzymes [36]. Their cellulases are reported to have high thermostability and alkaline pH optimum [37]. Streptomyces coelicolor CH13 was able to completely degrade blends of cassava starch foam and natural rubber latex [38], while many of them have been reported as PHB degraders even in acidic environments [39, 40]. In case of PLA, percentages are similar: 35% of isolates were able to consume this substrate with excellent, 35% with moderate, 25% with poor growth, while only one strain was not capable of utilizing PLA under examined conditions. Excellent growth was detected for isolates belonging mostly to the Bacillus spp. and Enterococcus spp. Bacillus genus is well known for its ability to generate substantial amounts of both secreted and surface-associated enzymes. The ability of specific Bacillus strains to generate and release substantial amounts (20–25 g/L) of extracellular enzymes has positioned them as key players in industrial enzyme production. A diverse range of their proteases and lipases are responsible for catalyzing the degradation of PLA, resulting in the formation of lactic acid [41, 42]. Significant number of Bacillus spp. is already proven to possess the ability to degrade PLA [43], while Enterococcus are found to form biofilms easily on the surface of these materials [44].

Ability of isolates to degrade biopolymers in agar-based screen (the full names of the isolates are provided in Table 1)

The same experiment on TPS as a sole carbon source has resulted with 35% excellent, 25% moderate, and 30% poor growth, while two isolates (both Enterococcus spp.) were not able to grow in these conditions. Bacillus spp. were once again the most successful, which was expected since this genus is well known as a producer of raw starch-degrading amylases [45].

To enable additional analysis of PHB material after microbial attack, the degradation test was conducted in liquid media. Based on agar-based screening results, four strains exhibiting the fastest growth on PHB as a sole carbon source (Fig. 2A) have been selected for further assessment in liquid culture. As presented in the Fig. 2B after 2 weeks of incubation in MSM media supplemented with PHB films as a sole carbon source, the most significant weight reduction (up to 60%) has been detected in the presence of Bacillus sp. DG90 strain. Streptomycetes spp. have shown similar performance, with strain DG19 exhibiting the best degradation rate up to 40%. Strain Streptomyces sp. DG89 degradation rate was not significant in comparison to the negative control; hence, this strain was not included in further experiments.

Degradation rates were also assessed in soil burial assay (Fig. 3). Results are partially in the accordance with previous experiments, with Bacillus sp. showing the best performance. It was interesting to note that PHB degradation by Streptomyces sp. DG25 stops after the first week for all examined replicates at ~ 19% of weight loss. In comparison to the liquid assay results, degradation rates were significantly lower in this experiment presumably due to the nature of selected soil (green compost) and the amount of nitrogen (carbon–nitrogen ratio < 17:1, total nitrogen 1–2%, w/w). In most of the cases, PHB is used as a carbon source under conditions where nitrogen sources are limited [46]. It is important to highlight that the examined films showed degradation in samples lacking microbial presence (negative control). This degradation could potentially arise from external contamination introduced during handling or processing procedures. Alternatively, it may be attributed to the inherent hydrolytic degradation properties of the tested materials, wherein exposure to environmental factors such as moisture and temperature leads to chemical breakdown over time.

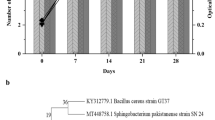

The most important drawback of the available standards for biodegradation of plastics in soil is weak reproducibility due to the possible soil compositions (e.g. round robin tests reported in ISO 17556–12 [34]). Hence, respirometry assay in liquid culture was conducted for two best-performing strains: Streptomyces sp. DG19 and Bacillus sp. DG90. According to calculations based on CO2 generated, the degradation rate of PHB for Streptomyces sp. DG19 has reached 51 ± 1.7% (Fig. 4, B1–3). The lag phase persisted for approximately 10 days, after which the degradation percentage began to exhibit exponential growth pattern. The presence of lag phase is in accordance with previously described liquid culture assay where Bacillus strain exhibited better performance then Streptomyces sp. after 10 days of cultivation. The biodegradation curves for PHB films degraded by Bacillus sp. DG90 were normal (Fig. 4, B4–6), and the material started undergoing degradation almost immediately upon the experiment initiation with no lag phase observed which indicates good polymer utilization by examined strain [47]. Under these conditions, PHB exhibited moderate degradation rate, achieving 23 ± 2.04% mineralization within 3 weeks.

After 3 weeks in respirometry assay, leftover PHB films were further weighted, and their properties were examined. In case of Streptomyces sp. DG19, PHB films were severely defragmented with overall weight loss of 83%, while for Bacillus sp. DG90, this percentage reached only 39% (Fig. 5). SEM analysis has confirmed material surface deterioration and roughness for both microbial treatments (Fig. 6). The difference between samples could be detected with bare eye, as shown in Fig. 6. The films had acquired a milky appearance presumably due to the metabolite’s excretion from 3-hydroxybutyric acid [48].

All FTIR spectra exhibited marker characteristic peaks of PHB (Fig. 7), specifically the carbonyl group C = O at 1721 cm−1 and the methyl group − CH at 1276 cm−1 [49]. Interestingly, these peaks exhibited significant differences in intensity, as evidenced by increased percent transmittance (%T) values. For the carbonyl group (1721 cm−1), %T values were 37% and 32% for Streptomyces sp. DG19 and Bacillus sp. DG90, respectively, compared to 24% for pristine PHB. Similarly, for the methyl group (1276 cm−1), %T values were 59% and 55% for Streptomyces sp. DG19 and Bacillus sp. DG90, respectively, compared to 36% for pristine PHB. These observations suggest the possibility of hydrolysis and polymer degradation in the bacterial-derived samples [50]. The emergence of a new peak around 3439 cm−1 in the Streptomyces sp. DG19-treated samples provides further evidence of biodegradation. This peak, attributed to terminal hydroxyl (− OH) groups [51], could arise through hydrolysis since these terminal hydroxyl groups are possibly a direct byproduct of hydrolysis. Additionally, distinct peaks at 2975 and 2933 cm−1, corresponding to the asymmetric and symmetric stretching vibrations of methyl (CH3) and methylene (CH2) groups [49], respectively, were observed in pristine PHB. These peaks exhibited alterations in bacterial-treated samples, suggesting potential structural changes.

Based on the DSC data, a peak in the glass transition temperature (Tg) can be observed at 58.88 °C in the pristine PHB (represented as a purple line in Fig. 8). This parameter slightly decreased after treatment with Bacillus sp. DG90 and Streptomyces sp. DG19, reaching 56.26 °C and 56.32 °C, respectively. However, the difference was only 2 °C and might be insufficient to infer relevant changes. On the other hand, from the provided data, it is evident that there is a decrease in the melting temperature (Tm) across the samples compared to the pristine (untreated) PHB. The pristine PHB exhibited the highest melting temperature at 173.98 °C, in accordance with literature data [52], while the samples treated with bacteria (Streptomyces sp. DG19 and Bacillus sp. DG90) showed reduced melting temperatures of 167.59 °C and 164.87 °C, respectively. Therefore, the lower melting temperature observed in the bacterial-treated PHB samples aligns with the previous FTIR findings, suggesting possible degradation and structural alterations. The decrease in Tm could be attributed to changes in molecular arrangement or structural disruptions caused by the biodegradation and potential hydrolysis effects initiated by Streptomyces sp. DG19 and Bacillus sp. DG90 treatments on the PHB material [53].

Literature is suggesting that the abiotic degradation of PHB materials under conditions relevant to the environment, typically not surpassing a temperature of 30 °C, is exceptionally slow and requires several months [54, 55]. However, our results are implying that this does not have to be the case. Without any additional optimization, PHB with our isolate has reached 83% of weight loss after only 3 weeks of incubation.

Taking into consideration that modern biomaterials consist of additional compounds (other biopolymers, additives, stabilizers), we have additionally assessed the ability of herein presented strains to degrade PHB-BC blends in soil burial assay. After 2 weeks in examined conditions, PHB-BNC blends have lost 85% of weight in the presence of Streptomyces sp. DG19, while this percentage goes down to 40% for Bacillus sp. DG90 (Fig. 9). This increase in degradation rates could be attributed to the synergistic effects between the two materials, potentially providing a more conducive environment for microbial activity and enzymatic breakdown, thus accelerating the degradation process. Previous studies have shown that increase of the BNC content in the blend leads to the increase of their degradation in in vitro studies [56]. Similar results were achieved in a study with biocomposites prepared by reinforcing nanocellulose in a matrix of polyvinyl alcohol in soil burial assay [57]. Results obtained in this study are suggesting that these strains can potentially be utilized for complex materials breakdown which will be evaluated in our further studies where additives and plasticizers will be involved in the mix.

Conclusion

This study has demonstrated the capability of microbial isolates to utilize biopolymers such as TPS, PLA, and PHB as sole carbon and energy sources. This ability, tested on powder samples and confirmed by visible halo zones on agar plates, highlights the potential of these microorganisms for biodegradation applications. Analysis on film samples has shown that Streptomyces spp. and Bacillus spp. strains exhibit notable growth on PHB films, with varying degrees of efficiency. Bacillus sp. DG90 demonstrated the highest weight reduction (up to 60%) in liquid culture, emphasizing its proficiency in PHB degradation. Streptomyces sp. DG19 also exhibited significant degradation, reaching a rate of 51 ± 1.7%. Soil burial assays revealed that Bacillus sp. showed superior performance in degrading PHB under soil conditions. However, the presence of nitrogen and soil composition influenced degradation rates, indicating the need for considering environmental factors in assessing biodegradation. Respirometry assays confirmed effectiveness of selected isolates in PHB degradation with 83% of weight loss when Streptomyces sp. DG19 was employed. Analysis of residual PHB films indicated substantial material changes, including a milky appearance and surface roughness. SEM analysis confirmed material surface deterioration and roughness, supporting the visual observations. The study’s findings challenge the conventional understanding that the abiotic degradation of PHB is exceptionally slow. The rapid weight loss observed (83% in 3 weeks) highlights the potential of Streptomyces sp. DG19 for accelerating PHB degradation, even without additional optimization. Furthermore, the ability of Streptomyces sp. DG19 and Bacillus sp. DG90 to degrade PHB/BNC blends suggests their potential utility in breaking down complex biomaterials, providing avenues for further exploration in future studies.

Availability of data and materials

No datasets were generated or analysed during the current study.

References

George A, Sanjay MR, Srisuk R, Parameswaranpillai J, Siengchin S. A comprehensive review on chemical properties and applications of biopolymers and their composites. Int J Biol Macromol. 2020;154:329–38. https://doi.org/10.1016/j.ijbiomac.2020.03.120.

Bajpai P. Biobased polymers in packaging. In: Biobased polymers. Elsevier; 2019. p. 129–38. https://doi.org/10.1016/B978-0-12-818404-2.00005-9.

Shahid-ul-Islam, Shahid M, Mohammad F. Green chemistry approaches to develop antimicrobial textiles based on sustainable biopolymers—a review. Ind Eng Chem Res. 2013;52(15):5245–60. https://doi.org/10.1021/ie303627x.

Niaounakis M . Building and construction applications. In: Biopolymers: applications and trends. Elsevier; 2015. p. 445–505. https://doi.org/10.1016/B978-0-323-35399-1.00010-7.

Baranwal J, Barse B, Fais A, Delogu GL, Kumar A. Biopolymer: a sustainable material for food and medical applications. Polymers (Basel). 2022;14(5):983. https://doi.org/10.3390/polym14050983.

Mohiuddin M, Kumar B, Haque S. Biopolymer composites in photovoltaics and photodetectors. In: Biopolymer composites in electronics. Elsevier; 2017. p. 459–86. https://doi.org/10.1016/B978-0-12-809261-3.00017-6.

McAdam B, Fournet MB, McDonald P, Mojicevic M. Production of polyhydroxybutyrate (PHB) and factors impacting its chemical and mechanical characteristics. Polymers (Basel). 2020;12(12). https://doi.org/10.3390/polym12122908.

Israni N, Shivakumar S. Polyhydroxybutyrate. In: Materials for Biomedical Engineering. Elsevier; 2019. p. 405–444. https://doi.org/10.1016/B978-0-12-816872-1.00014-5.

Grigore ME, Grigorescu RM, Iancu L, Ion R-M, Zaharia C, Andrei ER. Methods of synthesis, properties and biomedical applications of polyhydroxyalkanoates: a review. J Biomater Sci Polym Ed. 2019;30(9):695–712. https://doi.org/10.1080/09205063.2019.1605866.

Foreword. In: monomers, polymers and composites from renewable resources. Elsevier; 2008. p. v–vi. https://doi.org/10.1016/B978-008045316-3.00026-0.

Pernicova I, et al. Introducing the newly isolated bacterium Aneurinibacillus sp. H1 as an auspicious thermophilic producer of various polyhydroxyalkanoates (PHA) copolymers–1. Isolation and characterization of the bacterium. Polymers (Basel). 2020;12(6):1235. https://doi.org/10.3390/polym12061235.

Jendrossek D, Handrick R. Microbial degradation of polyhydroxyalkanoates. Annu Rev Microbiol. 2002;56(1):403–32. https://doi.org/10.1146/annurev.micro.56.012302.160838.

Knoll M, Hamm TM, Wagner F, Martinez V, Pleiss J. The PHA Depolymerase Engineering Database: a systematic analysis tool for the diverse family of polyhydroxyalkanoate (PHA) depolymerases. BMC Bioinformatics. 2009;10(1):89. https://doi.org/10.1186/1471-2105-10-89.

Tokiwa Y, Calabia B, Ugwu C, Aiba S. Biodegradability of plastics. Int J Mol Sci. 2009;10(9):3722–42. https://doi.org/10.3390/ijms10093722.

Mayumi D, Akutsu-Shigeno Y, Uchiyama H, Nomura N, Nakajima-Kambe T. Identification and characterization of novel poly(dl-lactic acid) depolymerases from metagenome. Appl Microbiol Biotechnol. 2008;79(5):743–50. https://doi.org/10.1007/s00253-008-1477-3.

Møller MS, Svensson B. Structural biology of starch-degrading enzymes and their regulation. Curr Opin Struct Biol. 2016;40:33–42. https://doi.org/10.1016/j.sbi.2016.07.006.

Di Y, et al. “Biodegradation of polyhydroxybutyrate by Pseudomonas sp. DSDY0501 and purification and characterization of polyhydroxybutyrate depolymerase. 3 Biotech. 2019;9(10):359. https://doi.org/10.1007/s13205-019-1871-9.

Tseng M, Hoang K-C, Yang M-K, Yang S-F, Chu WS. Polyester-degrading thermophilic actinomycetes isolated from different environment in Taiwan. Biodegradation. 2007;18(5):579–83. https://doi.org/10.1007/s10532-006-9089-z.

Amir M, et al. Isolation and optimization of extracellular PHB depolymerase producer Aeromonas caviae Kuk1-(34) for sustainable solid waste management of biodegradable polymers. PLoS ONE. 2022;17(4):e0264207. https://doi.org/10.1371/journal.pone.0264207.

Doyle C, Tanner ET, Bonfield W. In vitro and in vivo evaluation of polyhydroxybutyrate and of polyhydroxybutyrate reinforced with hydroxyapatite. Biomaterials. 1991;12(9):841–7. https://doi.org/10.1016/0142-9612(91)90072-I.

Park SL, et al. Isolation of Microbulbifer sp. SOL66 with high polyhydroxyalkanoate-degrading activity from the marine environment. Polymers (Basel). 2021;13(23):4257. https://doi.org/10.3390/polym13234257.

Cavaillé L, et al. Understanding of polyhydroxybutyrate production under carbon and phosphorus-limited growth conditions in non-axenic continuous culture. Bioresour Technol. 2016;201:65–73. https://doi.org/10.1016/j.biortech.2015.11.003.

Tokiwa Y, Calabia BP. Review degradation of microbial polyesters. Biotechnol Lett. 2004;26(15):1181–9. https://doi.org/10.1023/B:BILE.0000036599.15302.e5.

Herrera DAG, et al. Exploring microorganisms from plastic-polluted sites: unveiling plastic degradation and PHA production potential. Microorganisms. 2023;11(12):2914. https://doi.org/10.3390/microorganisms11122914.

Castro C, et al. Gluconacetobacter medellinensis sp. nov., cellulose- and non-cellulose-producing acetic acid bacteria isolated from vinegar. Int J Syst Evol Microbiol. 2013;63(Pt_3):1119–25. https://doi.org/10.1099/ijs.0.043414-0.

Pereira EHDS, et al. Boosting bacterial nanocellulose production from chemically recycled post-consumer polyethylene terephthalate. Sustain Mater Technol. 2024;39:e00784. https://doi.org/10.1016/j.susmat.2023.e00784.

Bionet©. ROSITA. Available: https://bionet.com/technology/rosita/. Accessed 19 May 2023.

Costa AFS, Almeida FCG, Vinhas GM, Sarubbo LA. Production of bacterial cellulose by Gluconacetobacter hansenii using corn steep liquor as nutrient sources. Front Microbiol. 2017;8. https://doi.org/10.3389/fmicb.2017.02027.

Anbukarasu P, Sauvageau D, Elias A. Tuning the properties of polyhydroxybutyrate films using acetic acid via solvent casting. Sci Rep. 2015;5(1):17884. https://doi.org/10.1038/srep17884.

Álvarez-Barragán J, Domínguez-Malfavón L, Vargas-Suárez M, González-Hernández R, Aguilar-Osorio G, Loza-Tavera H. Biodegradative activities of selected environmental fungi on a polyester polyurethane varnish and polyether polyurethane foams. Appl Environ Microbiol. 2016;82(17):5225–35. https://doi.org/10.1128/AEM.01344-16.

Ibrahim MHA, Willems A, Steinbüchel A. Isolation and characterization of new poly(3HB)-accumulating star-shaped cell-aggregates-forming thermophilic bacteria. J Appl Microbiol. 2010. https://doi.org/10.1111/j.1365-2672.2010.04786.x.

Molitor R, Bollinger A, Kubicki S, Loeschcke A, Jaeger K, Thies S. Agar plate-based screening methods for the identification of polyester hydrolysis by Pseudomonas species. Microb Biotechnol. 2020;13(1):274–84. https://doi.org/10.1111/1751-7915.13418.

ISO. 14852. Available: https://www.iso.org/standard/72051.html. Accessed: 22 Nov 2023.

ISO. 17556. Available: https://www.iso.org/standard/74993.html. Accessed: 20 Nov 2023.

Spasic J, Mandic M, Djokic L, Nikodinovic-Runic J. Streptomyces spp. in the biocatalysis toolbox. Appl Microbiol Biotechnol. 2018;102(8):3513–36. https://doi.org/10.1007/s00253-018-8884-x.

Prakash D, et al. Actinomycetes: a repertory of green catalysts with a potential revenue resource. Biomed Res Int. 2013;2013:1–8. https://doi.org/10.1155/2013/264020.

Jang H-D, Chang K-S. Thermostable cellulases from Streptomycessp.: scale-up production in a 50-l fermenter. Biotechnol Lett. 2005;27(4):239–42. https://doi.org/10.1007/s10529-004-8356-5.

Watcharakul S, Umsakul K, Hodgson B, Chumeka W, Tanrattanakul V. Biodegradation of a blended starch/natural rubber foam biopolymer and rubber gloves by Streptomyces coelicolor CH13. Electron J Biotechnol. 2012;15(1). https://doi.org/10.2225/vol15-issue1-fulltext-10.

García-Hidalgo J, Hormigo D, Arroyo M, de la Mata I. Novel extracellular PHB depolymerase from Streptomyces ascomycinicus: PHB copolymers degradation in acidic conditions. PLoS ONE. 2013;8(8):e71699. https://doi.org/10.1371/journal.pone.0071699.

Mergaert J, Webb A, Anderson C, Wouters A, Swings J. Microbial degradation of poly(3-hydroxybutyrate) and poly(3-hydroxybutyrate-co-3-hydroxyvalerate) in soils. Appl Environ Microbiol. 1993;59(10):3233–8. https://doi.org/10.1128/aem.59.10.3233-3238.1993.

Schallmey M, Singh A, Ward OP. Developments in the use of Bacillus species for industrial production. Can J Microbiol. 2004;50(1):1–17. https://doi.org/10.1139/w03-076.

Hanphakphoom S, Maneewong N, Sukkhum S, Tokuyama S, Kitpreechavanich V. Characterization of poly(L-lactide)-degrading enzyme produced by thermophilic filamentous bacteria Laceyella sacchari LP175. J Gen Appl Microbiol. 2014;60(1):13–22. https://doi.org/10.2323/jgam.60.13.

Wang Y, et al. Biodegradation of polylactic acid by a mesophilic bacteria Bacillus safensis. Chemosphere. 2023;318:137991. https://doi.org/10.1016/j.chemosphere.2023.137991.

Hchaichi I, Bandini F, Spini G, Banni M, Cocconcelli PS, Puglisi E. Enterococcus faecalis and Vibrio harveyi colonize low-density polyethylene and biodegradable plastics under marine conditions. FEMS Microbiol Lett. 2020;367(15). https://doi.org/10.1093/femsle/fnaa125.

Shofiyah SS, et al. Isolation, expression, and characterization of raw starch degrading α-amylase from a marine lake Bacillus megaterium NL3. Heliyon. 2020;6(12):e05796. https://doi.org/10.1016/j.heliyon.2020.e05796.

Jeon Y, et al. Poly(3-hydroxybutyrate) degradation by Bacillus infantis sp. isolated from soil and identification of phaZ and bdhA expressing PHB depolymerase. J Microbiol Biotechnol. 2023;33(8):1076–83. https://doi.org/10.4014/jmb.2303.03013.

Julinová M, et al. Comprehensive biodegradation analysis of chemically modified poly(3-hydroxybutyrate) materials with different crystal structures. Biomacromol. 2023;24(11):4939–57. https://doi.org/10.1021/acs.biomac.3c00623.

Gangurde N, Patil Y, Jain R, Sayyed R. Poly-β-hydroxybutyrate biodegradation by mixed culture population vis-à-vis single culture population under varying environmental conditions: a new approach. Indian J Exp Biol. 2017;55:311–20.

Trakunjae C, et al. Enhanced polyhydroxybutyrate (PHB) production by newly isolated rare actinomycetes Rhodococcus sp. strain BSRT1–1 using response surface methodology. Sci Rep. 2021;11(1):1896. https://doi.org/10.1038/s41598-021-81386-2.

Gasparyan KG, Tyubaeva PM, Varyan IA, Vetcher AA, Popov AA. Assessing the biodegradability of PHB-based materials with different surface areas: a comparative study on soil exposure of films and electrospun materials. Polymers (Basel). 2023;15(9):2042. https://doi.org/10.3390/polym15092042.

Gumel AM, Annuar MSM, Heidelberg T. Biosynthesis and characterization of polyhydroxyalkanoates copolymers produced by Pseudomonas putida Bet001 isolated from palm oil mill effluent. PLoS ONE. 2012;7(9):e45214. https://doi.org/10.1371/journal.pone.0045214.

Zhuikov V, et al. The growth of 3T3 fibroblasts on PHB, PLA and PHB/PLA blend films at different stages of their biodegradation in vitro. Polymers (Basel). 2020;13(1):108. https://doi.org/10.3390/polym13010108.

Kim J, et al. Biodegradation studies of polyhydroxybutyrate and polyhydroxybutyrate-co-polyhydroxyvalerate films in soil. Int J Mol Sci. 2023;24(8):7638. https://doi.org/10.3390/ijms24087638.

Tarazona NA, Machatschek R, Lendlein A. Unraveling the interplay between abiotic hydrolytic degradation and crystallization of bacterial polyesters comprising short and medium side-chain-length polyhydroxyalkanoates. Biomacromol. 2020;21(2):761–71. https://doi.org/10.1021/acs.biomac.9b01458.

Pei R, Tarek-Bahgat N, Van Loosdrecht MCM, Kleerebezem R, Werker AG. Influence of environmental conditions on accumulated polyhydroxybutyrate in municipal activated sludge. Water Res. 2023;232: 119653. https://doi.org/10.1016/j.watres.2023.119653.

Râpă M, et al. In vitro degradation of PHB/bacterial cellulose biocomposite scaffolds. Int J Polym Sci. 2021;2021:1–8. https://doi.org/10.1155/2021/3820364.

Islam N, Proma S, Rahman A, Chakraborty A. Preparation and biodegradation of nanocellulose reinforced polyvinyl alcohol blend films in bioenvironmental media. Chem Sci Int J. 2017;19(3):1–8. https://doi.org/10.9734/CSJI/2017/32570.

Funding

This research was funded by the Technological University of The Shannon through the President Seed Fund (Government of Ireland International Education Scholarship 2020/2021), the European Union’s Horizon 2020 Research and Innovation programme (grant number: 870292 (BioICEP)), and European Union’s Horizon Europe EIC Pathfinder programme (grant number: 101046758 (EcoPlastiC)).

Author information

Authors and Affiliations

Contributions

Methodology, investigation, data curation, formal analysis D.A.G.H.; Conceptualization, validation, resources, writing, visualization, supervision M.M.; Methodology, investigation, data curation, formal analysis, C.V.; Methodology, investigation, data curation, formal analysis, writing, E.H.P.; Supervision, resources, funding acquisition, M.B.F. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Herrera, D.A.G., Mojicevic, M., Venkatesh, C. et al. Unveiling the potential of bacterial isolates from plastic-polluted environments: enhancement of polyhydroxybutyrate biodegradation. Biotechnol Environ 1, 9 (2024). https://doi.org/10.1186/s44314-024-00009-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s44314-024-00009-y