Abstract

The results of a study of the adsorption of zinc(II) and chromium(III) ions by zeolites modified by HCl are presented. According to the data of elemental analysis and electron spectroscopy, the zeolites contain at least 75% heulandite in their composition. The removal of aluminum ions from the tetrahedral framework of the sorbent formed by AlO4 and SiO4 occurs upon modifying the zeolites by HCl. This leads to the destruction of the main component, heulandite, and compaction of the silicate layer. The time of establishment of adsorption equilibrium in the zeolite–aqueous solution system is 90 min. The isotherms of adsorption of zinc(II) ions are obtained in a temperature range 298–318 K at pH 5.6–5.8. It is shown that the adsorption of zinc(II) ions increases with growing temperature. The isotherms of adsorption of chromium(III) ions are obtained in a temperature range 298–318 K at pH 7.6–7.9. It is found that the adsorption of chromium(III) ions decreases with increasing temperature. The differential heats of adsorption are calculated based on the isosteres of adsorption. The increase in the adsorption of chromium(III) ions is accompanied by a decrease in the differential heat of adsorption from 36.9 to 26.8 kJ/mol. This may be associated with the nonuniformity of the surface of the adsorbent, due to what the metal ions are adsorbed on less active regions of the surface as far as the growth in the saturation of more active sites. The change in the differential heat of adsorption of zinc(II) ions with the growth in the degree of filling of the surface has a nonmonotone character. In the region of low degrees of filling of the surface, the differential heat of adsorption decreases, and then increases, which is probably determined by polymolecular adsorption presuming the presence of an adsorbate–adsorbate interaction. The efficiency of treatment of industrial wastewaters of the electroplating industry in the case of the use of the modified zeolites is over 97%.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

INTRODUCTION

It is known that zinc(II) and chromium(III) ions are toxic pollutants that have a negative effect on the environment [1]. When entering into water objects with the wastewaters of various industrial sectors such as metallurgical, chemical, and defense, these ions inflict irreparable damage to both individual ecosystems and nature as a whole. The use of state-of-the-art sewage treatment methods makes it possible to substantially decrease the concentration of toxic pollutants to the required water quality standards.

The toxic properties of zinc are mainly determined by ions and suspensions of hydroxides and carbonates. The intoxication induced by the toxicity of zinc(II) ions leads to anemia, growth inhibition, and infertility [2].

The adsorption of zinc(II) ions by synthetic X zeolites has been studied in [3]. The X zeolites were obtained from calcinated kaolin by the hydrothermal treatment in alkaline solutions. The SiO2/Al2O3 and K2O/Na2O molar ratios were 2.9 and 0.16, respectively. It has been shown that these ratios are required for obtaining the zeolite over the minimum reaction time. The authors of [4] studied the effect of pH and residence time on the adsorption capacity of a Dowex YCR S/S cation-exchange resin in respect of zinc(II) ions. Under optimum conditions, the efficiency of removal of the toxic ions is over 98%. The optimum parameters for the adsorption of zinc(II) ions by NaA and NaX zeolites during treatment of wastewaters from industrial zones of Algeria have been obtained in [5]. The authors of [6] synthesized hydroxysodalite–zeolite nanoparticles with various crystallites sizes (37.61–64.88 nm) by the hydrothermal method in the absence and presence of inexpensive aliphatic organic acids as the matrices. It has been found that the synthesized nanoparticles can be efficiently applied for the purification of water from zinc(II) ions; here, the maximum adsorption capacity was 8.53 mg/g. It has been shown that the value of adsorption of zinc(II) ions by a synthetic NaA zeolite obtained from ash reaches 47.78 mg/g [7].

It is known that chromium compounds have general toxic, irritating, cumulative, allergenic, carcinogenic, and mutagenic action on the living bodies [2].

The authors of [8] studied the factors affecting the possibility of using modified zeolites in the removal of chromium(VI) ions. The adsorption has been studied under laboratory conditions depending on the pH, time, amount of the modified zeolites, and initial concentration of chromium(VI). It has been found that the sorption capacity of the modified zeolites depends on pH of the solution. The adsorption of chromium(VI) ions from aqueous solutions using modified natural zeolite materials from Zahedan (Iran) has been studied in [9]. It has been shown that the adsorption of chromium(VI) ions depends on the pH of the medium, while the maximum extraction of chromium(VI) ions occurs in an acidic medium at pH < 1.5. The adsorption of chromium(III) ions by an FCC catalyst transformed into a zeolite mixture has been studied in [10]. The effect of the conditions on the efficiency of adsorption has been studied. The authors of [11] have determined the optimum conditions for the removal of chromium on a modified surface of a zeolite—pH 8.8, a time of 55 min, temperature of 303.15 K, a weighed amount of the zeolite of 400 mg, and an initial concentration of chromium of 16.0 mg/L. The value of adsorption of chromium(III) ions by a synthetic NaA zeolite obtained from ash was 65.98 mg/g [7]. The adsorption of Cr(III) ions on a starch–graft-poly(acrylic acid)/organomodified 4A zeolite composite has been studied [12]. The results showed that the adsorption capacity of the synthesized composite can reach a very high value of 651.42 mg/g at an initial concentration of chromium(III) ions of 50 mmol/L.

In the case of treatment of the wastewaters of metallurgic, chemical, defense, and other industrial sectors, there is a problem associated with the completeness of removal of heavy metal ions including zinc(II) and chromium(III) ions using inexpensive and efficient sorption materials.

The development of effective wastewater treatment technologies is a priority task of electroplating industry acknowledged as one of environmentally damaging. The improvement of the wastewater treatment methods is required despite the development of new, less toxic electrolytes; new methods and schemes of rinsing of parts; and devices for the regeneration of solutions. Another, just as significant, problem associated with the processes of electroplating industry is the formation of highly concentrated and highly toxic spent solutions of electrolytes. The absence of due attention to this problem leads to the fact that toxic pollutants are discharged to the municipal sewage networks and then, through the municipal sewage treatment plants, to the surface watercourse at concentrations exceeding by tens and hundreds of times the concentrations allowable for the normal life of the fauna and flora of the aquatic environment.

One effective way to solve the above problems is the use of sorption technologies based on available adsorbents capable of providing the required depth of sewage treatment. Adsorption technologies utilizing synthetic, natural, and modified zeolites can be considered such methods [13, 14].

The aim of this work was the study the adsorption of zinc(II) and chromium(III) ions from aqueous solutions by zeolites modified by HCl, as well as the possibility of using the zeolites for treatment of wastewaters of the electroplating industry.

EXPERIMENTAL

Natural zeolites from the Kholinskoe deposit were used as the objects of study. A zeolite fraction with a size of 1.0 mm that had been preliminarily sifted on a sieve was used in the experiments.

Modification of the zeolites by HCl was executed in accordance with the following procedure: 10 g of aluminosilicates dried to a constant weight at 120–150°C were stirred for 24 h with 200 mL of a 12% solution of HCl in water. The suspension was then filtered and rinsed with distilled water to a neutral reaction. The obtained modified zeolites were dried to a constant weight and analyzed for the concertation of the major elements.

The adsorption was studied on the model solutions, for the preparation of which reagent grade ZnSO4 · 7H2O and Cr2(SO4)3 · 6H2O were used. The model solutions were prepared by dissolving the corresponding weighed amounts of the specified chemicals in distilled water. Here, the concentration of the heavy metal ions in the solutions corresponded to the real concentration of the pollutants at the outlet from an electroplating workshop. The concentrations of zinc(II) and chromium(III) ions in the solutions were determined by standard procedures [15, 16].

The investigation of the adsorption properties of the modified zeolites relative to zinc(II) and chromium(III) ions was performed under static conditions. The method of constant weighed amounts (1 g of the zeolites) and variable concentrations was used in the work to construct the isotherm of adsorption. The concentrations of zinc(II) and chromium(III) in the aqueous solutions were varied from 10 to 100 mg/L. The solutions under study were prepared with a volume of 0.1 dm3. The weight ratio of the liquid and solid phases was 1 : 100. The value of adsorption (A, mmol/g) was calculated by the formula

where C0 and Cequil are the initial and equilibrium concentrations of the metal in the solution, mmol/L; V is the volume of the solution, L; and m is the weight of the adsorbent, g.

The acidity of the model solutions was controlled using a pH-340 pH meter by a standard procedure [17]. The temperature was maintained using a UTU-4 thermostat; the studies were performed at 298, 318, and 338 K. The stirring was performed using a magnetic stirrer. The stirring conditions were maintained constant in all the experiments.

The possibility of practical application of the zeolites was considered by way of example of the wastewaters of electroplating industry, the main pollutants in which are heavy metal ions (Table 1).

As can be seen from the presented data (Table 1), it turns out to be impossible to decrease the concentration of heavy metal ions to the required limits for maximum allowable concentrations after the lime treatment of the wastewaters.

RESULTS AND DISCUSSION

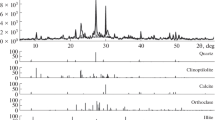

It has been found according to the results of X-ray phase analysis that natural zeolites contain calcium heulandite Ca[Al2Si7O18] ⋅ 6H2O as well as impurity rocks such as sanidine KAlSi3O8 and cristobalite SiO2 [18]. According to the data of elemental analysis and electron spectroscopy, the concentration of the zeolite in the tuff is at least 75 wt % [19]. The removal of aluminum ions from the infinite tetrahedral framework of the sorbent formed by AlO4 and SiO4 occurs during the modification of natural zeolites by HCl. This leads to the destruction of the main component—heulandite—and compaction of the silicate layer, as well as the improvement of the adsorption properties of the material [20].

The adsorption of zinc(II) and chromium(III) ions by zeolites modified by HCl has been studied. The adsorption equilibrium corresponding to the constancy of the composition of the concentrations of metal ions in the adsorbate–zeolite system was 90 min. The isotherms of adsorption of zinc(II) ions in a temperature range of 298–318 K at pH 5.6–5.8 (Fig. 1) have been obtained.

It is known that physical adsorption is an exothermal and reversible process, while increasing the temperature should lead to a decrease in the adsorption [21]. The decrease in the rate of adsorption with increasing temperature is associated with the weakening of the adsorption forces between the active sties of the adsorbent and adsorbate particles as well as between the adsorbed particles [22].

The obtained experimental data (Fig. 1) evidence that the value of adsorption of zinc(II) ions increases with growing temperature. It has been shown in [23–25] that the adsorption of heavy metal ions is an endothermic process, with its value increasing with increasing temperature. The increase in adsorption with growing temperature may be associated with the concept of activated adsorption [24]. In addition, this may result from the chemical interaction between the adsorbate and the adsorbent, creation of some new adsorption sites, or increase in the rate of intraparticle diffusion of the metal ions into the pores of the adsorbent at a higher temperature [23]. In the case of increasing temperature, hydrated metal ions are capable of dehydration, which favors adsorption and determines the endothermic character of the process [25].

The effect of temperature on the adsorption of chromium(III) ions has been studied. The obtained isotherms in a range of 298–318 K at pH 7.6–7.9 are presented in Fig. 2.

As is seen from the presented data (Fig. 2), the value of adsorption of chromium(III) ions decreases with increasing temperature, which confirms the exothermic character of the process under study. The metal ions adsorbed on the surface of aluminosilicate can be released into the aqueous solution in the case of increasing temperature. This is associated with the ascending trend to the desorption of the adsorbate ions from the interface into the solution with increasing temperature in the case of physical adsorption [26]. The inverse dependence of adsorption on temperature is characteristic for ion-exchange adsorbents, the degree of dissociation of the ionogenic groups of which increases with increasing temperature [27].

The isosteres of adsorption—the curves of the dependence of the concentration of the equilibrium phase on temperature at a constant value of adsorption (Figs. 3, 4)—play an important role in the thermodynamics of adsorption.

The shape of the obtained isosteres (Fig. 3) confirms the occurrence of activated adsorption of zinc(II) ions. The linearity of the presented isosteres (Fig. 4) evidences the constancy of the physical process of adsorption with growing temperature. The presented experimental data were used for the calculation of the differential heats of adsorption by the Clausius–Clapeyron equation:

where Q is the isosteric heat of adsorption, kJ/mol, and R is the universal constant, J mol−1 K−1. The differential heat of adsorption was calculated by the values of the slope angles of the isosteres in accordance with the Clausius–Clapeyron equation; the obtained results are presented in Fig. 5.

The increase in the adsorption of chromium(III) ions is accompanied by a decrease in the differential heat of adsorption from 36.9 to 26.8 kJ/mol (Fig. 5). This may be associated with the nonuniformity of the surface of the adsorbent, due to what the metal ions are adsorbed on less active regions of the surface as far as the saturation of more active sites [28].

The change in the differential heat of adsorption of zinc(II) ions with the growth in the degree of filling of the surface has a nonmonotone character (Fig. 5). In the region of low degrees of filling of the surface, the differential heat of adsorption decreases, and then increases, which is probably determined by polymolecular adsorption that presumes the presence of an adsorbate–adsorbate interaction [29, 30].

The zeolites modified by HCl were used in the sorption treatment of the wastewaters of electroplating industry. The obtained results are presented in Table 2.

The use of the zeolites for the sorption treatment of the industrial wastewaters of electroplating industry made it possible to decrease the concentration of zinc(II) ions to 0.02 mg/L and that of chromium(III) to 0.03 mg/L. Here, the efficiency of the treatment was over 97%.

CONCLUSIONS

1. The effect of temperature on the adsorption of zinc(II) and chromium(III) ions by the zeolites modified by HCl has been studied. It has been shown that the adsorption of zinc(II) ions increases with increasing temperature, while the adsorption of chromium(III) ions decreases.

2. The isosteres of adsorption of zinc(II) and chromium(III) have been obtained. The differential heats of adsorption have been calculated. A decrease in the differential heat of adsorption from 36.9 to 26.8 kJ/mol is observed in the case of adsorption of chromium(III) ions. The change in the differential heat of adsorption of zinc(II) ions with the growth in the degree of filling of the surface has a nonmonotone character. In the region of low degrees of filling of the surface, the differential heat of adsorption decreases and then increases, which is probably due to polymolecular adsorption presuming the presence of an adsorbate–adsorbate interaction.

3. The use of modified zeolites for afterpurification of industrial wastewaters of the electroplating industry has made it possible to decrease the concentration of zinc(II) ions to 0.02 mg/L and that of chromium(III) to 0.03 mg/L. Here, the efficiency of the treatment is over 97%.

REFERENCES

Hall, J.L., J. Exp. Bot., 2002, vol. 53, no. 366, p. 1.

Korte, F., Bahadir, M., Klein, W.W., Lay, J.P., Parlar, H., und Scheunert, I., Ökologische Chemie. Grundlagen und Konzepte für die ökologische Beurteilung von Chemikalien, Korte, F., Hrsg., Stuttgart, New York: Georg Thieme Verlag, 1987.

Ismael, I.S., Chin. J. Geochem., 2010, vol. 29, no. 2, p. 130.

Alyuz, B. and Veli, S., J. Hazard. Mater., 2009, vol. 167, nos. 1–3, p. 482.

Nibou, D., Mekatel, H., Amokrane, S., Barkat, M., and Trari, M., J. Hazard. Mater., 2010, vol. 173, nos. 1–3, p. 637.

Abdelrahman, E.A., Tolan, D.A., and Nassar, M.Y., J. Inorg. Organomet. Polym., Mater., 2019, vol. 29, no. 1, p. 229.

Nibou, D., Amokrane, S., Mekatel, H., and Lebaili, N., Phys. Procedia, 2009, vol. 2, no. 3, p. 1433.

Shi, H.S. and Liu, Y.H., Jianzhu Cailiao Xuebao/J.Build. Mater. (Shanghai, China), 2006, vol. 9, no. 4, p. 408.

Noroozifar, M., Khorasani-Motlagh, M., Gorgij, M.N., and Naderpour, H.R., J. Hazard. Mater., 2008, vol. 155, no. 3, p. 566.

Gonzalez, M.R., Pereyra, A.M., Torres Sanchez, R.M., and Basaldella, E.L., J. Colloid Interface Sci., 2013, vol. 408, p. 21.

Aljerf, L., J. Environ. Manage., 2018, vol. 225, p. 120.

Ma, K., Zhao, L., Jiang, Z., Huang, Y.Y., and Sun, X.P., Polym. Compos., 2018, vol. 39, no. 4, p. 1223.

Pomazkina, O.I., Filatova, E.G., Lebedeva, O.V., and Pozhidaev, Yu.N., Prot. Met. Phys. Chem. Surf., 2018, vol. 54, no. 4, p. 582.

Filatova, E.G., Pozhidaev, Yu.N., and Pomazkina, O.I., Prot. Met. Phys. Chem. Surf., 2019, vol. 55, no. 5, p. 858.

Lur’e, Yu.Yu. and Rybnikova, A.I., Khimicheskii analiz proizvodstvennykh stochnykh vod (Chemical Analysis for Industrial Waste Waters), Moscow: Khimiya, 1974.

Marczenko, Z., Spectrophotometric Determination of the Elements, Ellis Horwood Series in Analytical Chemistry, New York: John Wiley and Sons, 1976.

Vasil’ev, V.P., Analiticheskaya khimiya (Analytical Chemistry), Moscow: Drofa, 2004, part 1 and part 2.

Filatova, E.G., Pozhidaev, Yu.N., and Pomazkina, O.I., Prot. Met. Phys. Chem. Surf., 2016, vol. 52, no. 3, p. 438.

Pomazkina, O.I., Filatova, E.G., and Pozhidaev, Yu.N., Prot. Met. Phys. Chem. Surf., 2015, vol. 51, no. 4, p. 518.

Filatova, E.G., Pomazkina, O.I., and Pozhidaev, Yu.N., Prot. Met. Phys. Chem. Surf., 2017, vol. 53, no. 6, p. 999.

Tsivadze, A.Yu., Rusanov, A.I., Fomkin, A.A., et al., Fizicheskaya khimiya adsorbtsionnykh yavlenii (Physical Chemistry of Adsorption Phenomena), Moscow: Granitsa, 2011.

Sheela, T., Nayaka, Y.A., Viswanatha, R., Basavanna, S., and Venkatesha, T.G., Powder Technol., 2012, vol. 217, p. 163.

Al-Othman, Z.A. and Naushad, M., Chem. Eng. J., 2012, vol. 184, p. 238.

Frolov, Yu.G., Kurs kolloidnoi khimii (Course of Colloid Chemistry), Moscow: Khimiya, 1982.

Zhao, G., Li, J., Ren, X., Chen, C., and Wang, X., Environ. Sci. Technol., 2011, vol. 45, no. 24, p. 10454.

Kubilay, S., Gurkan, R., Savran, A., and Sahan, T., Adsorption, 2007, vol. 13, p. 41.

Gode, F. and Pehlivan, E., J. Hazard. Mater., 2006, vol. 136, p. 330.

Potapov, S.V., Fomkin, A.A., Sinitsyn, V.A., and Shkolin, A.V., Vestn. Mosk. Gos. Tekh. Univ. im. N. E. Baumana, Ser. “Mashinostr.”, 2010, vol. 2010, no. k, p. 178.

Muminov, S.Z. and Khandamov, D.A., Sorbtsionnye Khromatogr.Protsessy, 2010, vol. 10, no. 5, p. 669.

Makarevich, N.A. and Bogdanovich, N.I., Teoreticheskie osnovy adsorbtsii (Theoretical Fundamentals for Adsorption), Arkhangelsk: Northern (Arctic) Federal Univ. Named after M.V. Lomonosov, 2015.

Funding

This work was financially supported by the Russian Foundation for Basic Research, project 18-08-00718.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by E. Boltukhina

Rights and permissions

About this article

Cite this article

Filatova, E.G., Pozhidaev, Y.N. & Pomazkina, O.I. Adsorption of Zinc(II) and Chromium(III) Ions by Modified Zeolites. Prot Met Phys Chem Surf 56, 911–916 (2020). https://doi.org/10.1134/S2070205120050123

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2070205120050123