Abstract

Temperature dependences of dynamic modulus of elasticity and dynamic loss modulus of four compositions of epoxy polymers based on 2,2-di-(4-hydroxyphenyl) propane and a cycloaliphatic amine hardener in an initial state and after 3, 6, 9, and 12 months of exposure on an open bench under conditions of moderately warm climate of Gelendzhik. A glass transition temperature determined during a transition from a glassy state to a highly elastic one of epoxy polymers proved to be sensitive to the polymer composition, an amount of sorbed moisture and duration of exposure. Postcuring of polymers, masked by a plasticizing effect of moisture, is discovered. The glass transition temperature of exposed epoxy polymers changes unevenly across the thickness of specimens. Properties of a surface layer facing the sun (on the front side) change to the greatest extent. Methods of dynamic mechanical analysis have good sensitivity and informativeness for a study of non-uniformity of climatic aging across the thickness.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 INTRODUCTION

When there is the exposure of polymer and polymer composite materials (PCM) in natural climatic conditions, under the effect of temperature, humidity, precipitation, solar radiation and other climatic factors physicochemical and structural transformations occur, united by a term “climatic aging” [1–3]. To assess the climatic effect, the mechanical properties of the specimens cut from plates of the studied material are usually determined. Thus, it is used a concept of identification of integral effective physicochemical transformations in the material without taking into account unequal changes at different depths from the surface. Numerous experiments have proved that the aggressive climatic factors have their negative effect, mainly on the surface layer of the exposed specimens. As a result of exposure under the open climatic conditions, a stable gradient of parameters of the properties across the thickness of the specimens of PCM arises [2].

Experimental papers [4–12] convincingly prove urgency of systematic research of this general effect. Almost 40 years ago it was established that when there is the exposure of glass fiber reinforced plastic in a climatic zone of the Panama Canal the aging of the material occurs nonuniformly across the thickness of the specimen [4]. In the surface layer of the glass fiber reinforced plastic, the glass transition temperature of the epoxy matrix decreased much stronger than in an inner layer. In [5] the unidirectional glass fiber reinforced plastic based on a diglycidyl ether of bisphenol A (DGEBA) and the separately cured epoxy polymer were studied. These materials were subjected to thermal humid and light influence in a climate chamber and were exposed under the climatic conditions of Vietnam (Danang). Using the methods of differential scanning calorimetry and infrared Fourier spectroscopy, the effect of degradation in the surface layer of the epoxy polymer for the specimens exposed under the natural climatic conditions and subjected to ultraviolet irradiation in the climate chamber was revealed. Photodegradation of this polymer is confirmed by a decrease of the glass transition temperature and an increase of concentrations of amines, ketones and quinones in the surface layer.

Using a miniature device considered in [6], there is measured strength of thin films cut by a microtome at the different depths from the surface of the specimens of a copolymer of polypropylene and polyethylene after the UV irradiation in a Xenotest 1200 chamber. It is shown that after 300 h of irradiation in the surface layer of 250–300 μm thickness carbonyl groups accumulate. As a distance from the surface increases, the concentration of these groups decreases exponentially. In proportion to this decrease, tensile strength in microlayers of the polymer increases. Paper [6] is one of few examples showing that direct measurements can reveal a profile of UV degradation of the polymer across the thickness of the specimens. Similar results were obtained for the polyethylene exposed under UV irradiation in the Xenotest 1200 chamber and in the natural conditions of the temperate and subtropical climate [7]. At the same time, tensile strain, density of microtome films and a content of CH2=CH groups determined by the infrared spectroscopy method turned out to be sensitive characteristics of the degradation profile across the thickness of the polyethylene.

The IR spectroscopy method established an analogy of physicochemical transformations in an epoxy coating based on DGEBA under the artificial UV irradiation and exposure in the chamber under borosilicate glass under the climatic conditions of Maryland [8]. An increase of the content of C=O, –OH groups in infrared spectra, depending on the duration of the exposure, was determined only on the surface of the specimens. Similar studies for ethylenevinylacetate [9] have shown that the UV radiation is the dominant aging factor, but the temperature and relative air humidity have the synergistic effect.

According to data of [10], with identical doses of exposure to the UV radiation, the degradation of polycarbonate under the natural climatic conditions is less pronounced than in accelerated tests due to differences in the air temperature and distinctions between the spectra of real and artificial radiation. Using the example of specially formed gradient polymer systems on the basis of an epoxy resin and polyurethane, a possibility was shown to detect the differences in a structure and properties of polymers by the methods of dynamic mechanical analysis (DMA), differential scanning calorimetry (DSC), atomic force microscopy, and UV spectroscopy [11].

It is shown in [12] that in the unfilled amorphous and semicrystalline polymers, as a consequence of the climatic action, the surface layer is damaged to the depth of up to 200 μm, while the inner layers of these polymers retain their original properties. Formation of the thin damaged surface layer contributes to a reduction of the strength and toughness due to a modification of a character of fracture from viscous to brittle. It is suggested to consider the effects of climatic action with the help of methods of linear fracture mechanics [12].

Similar effects are observed in reinforced plastics. In [13], the measurements of ultimate interlaminar shear strength τz at the different depths from the surface were performed. For the specimens of the glass fiber reinforced plastic VPS-7 based on a binder EDT‑10 8 mm thick, in the initial state τz = 34 MPa at any depth from the surface. After 10 years of exposure of glass fiber reinforced plastic slabs on the open atmospheric bench under the conditions of the warm moist climate in the surface layers, this parameter decreases to 24 MPa, but remains practically unchanged at a depth of 3–5 mm. Under the same climatic conditions an organoplastic Organit 7T 5 mm thick was exposed, in which τz = 18 ± 2 MPa in the initial state. After 6 years of exposure in the surface layers of the organoplastic a value of τz decreases to 12 MPa when exposed under a canopy and to 8 MPa on the open atmospheric bench. In [14], a carbon fiber reinforced plastic KMU-9TK based on the epoxy resin matrix UDDF-4AP was studied after 10 years of exposure in the marine climate. The slabs of carbon fiber reinforced plastic 13 mm thick were studied. The effects of aging in this material at the different depths from the surface are varied. Under the action of solar radiation, temperature and moisture, the degradation of the binder on the side of the plate, which faced the Sun, occurs. In this layer, the glass transition temperature of the binder increases by 20°C. The non-uniformity of aging is accompanied by the formation of the significant gradient of strength with the interlayer compression from 5 MPa in the surface layers to 42 MPa in the center of the specimen.

The gradient of mechanical characteristics across the thickness of composite laminates after exposure to a Low Earth Orbit environment have been investigated [15]. Results on thin measurements of dynamic shear modulus, Young modulus, linear thermal expansion coefficient, glass transition temperature and microhardness of the carbon fiber reinforced plastics KMU‑31, KMU-41, and glass fiber reinforced plastic VPS-7V have been presented. The results show that thermal cycling of composite laminates in space, with a temperature difference of 200°C between the sunlit and back sides, generates the gradient of mechanical properties across the plate thickness. During the exposure to the space environment, this factor determines the depth and postcuring level, which influences the regularity of changes in their physical and mechanical properties.

One more example of detection of the gradient of mechanical properties across the thickness of PCM is the results of measurements of the dynamic shear modulus and loss modulus for the carbon fiber reinforced plastic KMU-41 during the transition from the glassy state to the highly elastic one of the epoxy matrix ENFB-2 of this carbon fiber reinforced plastic after the exposure during 12 years in outer space on the International Space Station [16]. The presented results of DMA studies of the carbon fiber reinforced plastic KMU-41 proved a dominant role of a process of postcuring of the epoxy matrix under the action of heat under the solar radiation. In all cases, the maximum transformations occur in the plates located in the upper layers of the exposed 8-layer packs. With the help of DMA measurements it was possible to determine at the reliable quantitative level a degree of weakening of the action of outer space factors on the properties of the material depending on the distance from the surface layer.

The given examples confirm the urgency of the problem of obtainment of new information on the formation of gradients of properties across the thickness of polymer plates exposed in the aggressive operating conditions. To solve this problem, it is necessary to choose such methods that would allow one not only to record differences in the values of mechanical parameters, but also to form conclusions about mechanisms of polymer aging at the different depths from the surface. Therefore, in this paper there are discussed the possibilities of dynamic mechanical analysis as one of the promising methods for an estimation of the aging of epoxy polymers across the thickness of specimens exposed under the open climatic conditions.

2 EXPERIMENT

2.1 Materials

The epoxy compositions of four compounds E-1, E-2, E-3, and E-4 (Table 1) were studied. The basis of all compositions was the epoxy resin of a brand ED-20 based on 2,2-di-(4-hydroxyphenyl) propane. The polymer E-1 was the resin ED-20 cured with the cycloaliphatic amine hardener Etal-45M [17].

where n = 1–4.

The hardener Etal-45M was also used in preparation of the compositions E-2–E-4. The reduction of viscosity of this resin was achieved by addition to the composition of an aliphatic diluent Etal-1 (an analog of the diluent diglycidyl ether of diethylene glycol DEG-1) in an amount of 10% (the polymer E-2) and 25% (the polymer E-3) of mass of the resin component.

The basis of the fourth studied composition E-4 was the epoxy resin Etal-247. The detailed information about chemical compositions and curing regime are published in [18, 19].

The cross-linked polymers prepared on the basis of ED-20 are moderately hydrophilic systems, since they are capable of sorbing up to 2–6% of moisture. The moisture plasticizes such epoxy polymers, causing not only a decrease of their glass transition temperature Tg and mechanical parameters, but also activating the postcuring and hydrolytic reactions of degradation [6].

The results of preliminary climatic tests of these materials are considered in [18, 19]. It is shown that a significant factor of the change of the color difference of Etal-247 is the dose of total and ultraviolet solar radiation during the exposure period. In the specimens of compositions of ED-20 + Etal-1, when they are exposed under the conditions of the moderately warm climate, 0.6–2% of moisture accumulates. The sorbed moisture has the plasticizing effect on these polymers. Plastification was revealed by the decrease of the glass transition temperature Tg and reduction of the dynamic shear modulus in the highly elastic state. When the specimens are exposed under the open climatic conditions, the moisture also activates the postcuring reactions.

2.2 Specimen Preparation

For the climatic tests, the specimens were prepared in a form of figure eights (the dog-bone specimens) (ASTM D638 Type 1) 4.7 mm thick. To assess the moisture content and determine the effect of the sorbed moisture in the initial state and after the exposure on the open atmospheric bench, the specimens were divided into 3 groups. The DMA measurements of the first group of the specimens were carried out within 1–4 h after the end of the exposure under the climatic conditions. The second group of the specimens was dried at a temperature of 60°C during 25–35 days to determine the amount of accumulated moisture and eliminate the plasticizing effect of moisture when determining the glass transition temperature of the polymers. The third group of the specimens was subjected to additional humidification in closed containers at a temperature of 60°C and a relative humidity of 98 ± 2% during 25–35 days before determining the parameters of the properties. It is assumed that when studying the specimens of this third group, it is possible to determine the properties of epoxy polymers when the maximum moisture saturation is achieved after the exposure under the open climatic conditions.

The dog-bone specimens in the initial condition and after the outdoor exposure were split into three sections (layers) to demonstrate the effect of weathering on the top (sun-facing), bottom, and interior regions, then they were submitted to the dynamic mechanical analysis to determine the glass transition temperature as a function of exposure time. To eliminate the influence of the reversible plasticizing effect of the sorbed moisture, the DMA measurements were performed after drying the specimens at 60°C till stabilization of the mass.

2.3 Environmental Conditions

To assess the effect of aggressive climate factors, the epoxy polymer specimens were exposed during 12 months on the open bench in the moderately warm climate of Gelendzhik (Russia).

The average monthly climatic parameters (Table 2) characterize aggressiveness of the Gelendzhik climate. The average annual air temperature in Gelendzhik is 14.8°C. The average monthly relative air humidity in Gelendzhik only in the summer months goes down to 57–67%. In the remaining months of the year this parameter exceeds 70%. During the year, there are 105 days with the precipitation, the level of which reaches almost 800 mm. During the year 275 sunny days are observed, for which the dose of total solar radiation falling on the horizontal surface reaches 5.0 GJ/m2. During the daylight hours under the action of solar radiation, the surface temperature of the specimens exceeds the air temperature by 20–30°C.

2.4 Testing Techniques

The DMA measurements of epoxy materials by a method of forced bending oscillations were performed on a Netzsch DMA 242D unit. The dynamic modulus of elasticity E ' and the dynamic loss modulus E '' were measured. Detailed description of measurement methodology, E ' and E '' values estimation can be found in [18].

where N is the axial force; L is the length of the sample; B is the width of the sample; H is the thickness of the sample; A is the amplitude of the oscillations; δ is the phase angle between stress and strain of the sample.

To determine the glass transition temperature Tg of epoxy polymers by the DMA methods the approach is used, in which the values of this parameter were determined from the dependences of the minimum of the temperature derivative dE '/dT and the maximum of the dynamic loss modulus E ''(T), approximated by the Gaussian distribution function of the form

where y denotes the experimental values of the temperature dependence dE '/dT and E '', x denotes the temperature values, xc is the position of the extremum of the distribution on the temperature curve, and σ is the half-width of the distribution. The values of the glass transition temperature, determined from the position of E ''(T) and according to the minimum of dE '/dT, coincide with an accuracy of ±1°C.

To determine the moisture content of epoxy polymers in the initial state and after 3, 6, 9, and 12 months of the climatic exposure, the mass of flat rectangular coupons with the dimensions of 40 × 8 × 4.7 mm and 40 × 8 × 0.6 mm, cut from the top (sun-facing), bottom and interior regions when drying at a temperature of 60°C. The periodic measurements of the mass of the specimens were carried out on analytical scales with an accuracy of 10–4 g. During drying, the change of the geometric dimensions of the specimens was controlled with an accuracy of 0.001 mm.

3 RESULTS AND DISCUSSION

When the epoxy polymers are exposed under the natural climatic conditions, the moisture accumulates in the specimens, the amount of which is determined by drying (Table 3).

After completion of the tests in the summer and autumn periods (after 6 and 9 months of exposure), there is less water by a factor of 1.5–2.5 in the polymer specimens than after the completion of the tests in the winter and spring periods (Table 3). This result is logical: in the drier time of the year less water is accumulated in the epoxy polymers.

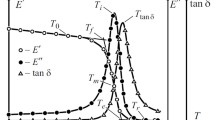

First of all, the dynamic mechanical analysis of the specimens was performed without division into layers. The integral estimation of the transition of polymers from the vitreous state to the highly elastic one is obtained taking into account the moisture content. The characteristics of the plasticizing effect of moisture on the results of DMA can conveniently be considered using the example of the polymer E-4. In Fig. 1 there are shown the temperature dependences of the dynamic modulus of elasticity E ', the temperature derivative of the dynamic modulus of elasticity dE '/dT, and the dynamic loss modulus E '' of the composition of the epoxy resin Etal-247 cured by the Etal-45M product, in the initial state with the moisture content of 0.25% and also after drying. The DMA method makes it possible to study in detail the transition of the cured epoxy cross-linked polymer from the vitreous state to the highly elastic one (the α-transition), in which segmental mobility of macromolecules becomes “unfrozen”. The regularities of this relaxation transition are studied in detail in papers [1–5, 12, 15, 16]. The glass transition temperature of the epoxy polymer Tg is established according to the dE '/dT minimum temperature. A physical meaning of Tg determined in this way is that at a point of minimum of the dE '/dT temperature curve, the rate of the α-transition is maximum. According to the DMA data, the glass transition temperature of E-4 is Tg = 49.0°C for the specimens with the initial moisture content of 0.25%. With an accuracy of ±1°C, it coincides with the temperature of the maximum peak of the dynamic loss modulus E '' (Fig. 1). Reliability of this method of determination of Tg of the epoxy polymers is proved by the results of similar torsion pendulum measurements [12, 15, 16].

After drying, the effect of the reversible plasticizing action of moisture [1–3, 12] is clearly revealed, with which the dynamic modulus of elasticity and the glass transition temperature of the cross-linked epoxy polymer increase. For the dry specimens of E-4 in the initial state, Tg is 58°C. The mechanism of the plasticizing action of moderately hydrophilic epoxy polymers consists in the fact that the molecular-condensed moisture forms hydrogen bonds with the active groups of macromolecules, weakens efficiency of intermolecular interaction, increases the mobility and flexibility of macrochain fragments between the crosslink nodes, lowers the glass transition temperature, reduces the strength characteristics and elastic moduli of the compounds in the highly elastic state [12]. In the vitreous state, the moisture also weakens the intermolecular interaction and reduces the values of mechanical parameters.

Similarly, the plasticizing effect of moisture is also discovered after the exposure of the polymer E-4 under the open climatic conditions. It follows from Fig. 2 that Tg of the specimens exposed during 12 months and containing 2.1% of moisture is 47 ± 1°C. After drying, the glass transition temperature increases to 60 ± 1°C.

The effect of the duration of exposure under the climatic conditions on the glass transition temperature of epoxy polymers of four compositions, taking into account the drying, is presented in Table 4. After removal of the moisture, the irreversible changes of this parameter are detected. In the polymers E-1 and E-4, Tg did not change or increased by 2–4°C during 12 months of exposure. In the compositions E-2 and E-3, Tg increases during this period by 8–15°C. It can be concluded that in these polymers in the process of climatic action the moisture activates the postcuring process (the cross-link of polymer chains) [3, 12]. The effect of the postcuring of epoxy polymers is not so obvious if the results of DMA specimens containing moisture are considered (Table 4).

To achieve the main objective of this study, the specimens with the dimensions of 40 × 8 × 0.6 mm from the front, back and center layers were made from the original and exposed during 12 months specimens-blades of the polymer E-4 with a thickness of 4.7 mm similarly to [4]. The prepared specimens were dried during 2 weeks till the stabilization of the mass at a temperature of 60°C. It is found that the atmospheric moisture sorbed by the specimens under the exposure in the climatic conditions is unevenly distributed across the thickness of the specimens. After 12 months of exposure, 1.8–2.0% of moisture was accumulated in the central layer, 2.6–2.8% in the face layer, and 2.0–2.2% in the layer cut from the back side. After drying the exposed specimens 4.7 mm thick, not subjected to separation, the moisture content was 2.1%.

In Fig. 3 there are shown the temperature dependences E ', dE '/dT and E '' of the dried initial specimens of E-4 cut from the front, back, and central layers. It is seen that a location of the layer, from which the specimens are cut out, does not practically affect the results of dynamic mechanical measurements. The same measurements are made for the dried specimens cut from the different layers of E-4 after 12 months of exposure (Fig. 4). In the inner layer and on the back side, Tg was the same and amounted to 58–60°C, whereas on the front side Tg = 74°C. In Table 5 there are shown the results of determination of Tg according to two criteria for three parallel specimens taken from each layer and from the specimen without the separation into layers. A good reproducibility of the results is seen, proving that after 12 months of exposure of the polymer E-4 under the direct solar radiation, in the surface layer more postcuring is achieved than in the inner layers and the back side.

In Fig. 5 there are shown the results of dynamic mechanical analysis of layers of the polymer E-2 after 12 months of exposure. A shift of Tg with the postcuring of the polymer on the front exposed side is 10°C compared to the central layer. The differences in the temperature of the α-transition of the front, back sides and the central layer after the exposure of epoxy polymers under the climatic conditions are similar, but depend on the polymer composition (Table 6).

4 CONCLUSIONS

When there is the exposure of polymer and polymer composite materials in the open climatic conditions, the processes of degradation and various physicochemical transformations take place unequally across the thickness of the specimens. The properties of the surface layer facing the sun (on the front side) change to the maximum extent.

The methods of dynamic mechanical analysis have the good sensitivity and informativeness for the study of the non-uniformity of climatic aging across the thickness. On the example of four compositions of epoxy polymers based on 2,2-di-(4-hydroxyphenyl) propane and the cycloaliphatic amine hardener, there are studied the temperature dependences of the dynamic modulus of elasticity and dynamic loss modulus in the initial state and after 3, 6, 9, and 12 months of exposure on the open bench under the conditions of the moderately warm climate of Gelendzhik.

The glass transition temperature determined during the transition from the glassy state to the highly elastic one of epoxy polymers proved to be sensitive to the polymer composition, the amount of sorbed moisture and the duration of exposure.

The postcuring of polymers, masked by the plasticizing effect of moisture, is discovered. To find the differences in the layers of exposed polymers after the action of the aggressive factors of external environment, it is necessary to use the dried specimens for the DMA measurements.

The gradient of the glass transition temperature across the thickness of the exposed specimens depends on the polymer composition and reaches 10–16°C after 12 months of exposure.

REFERENCES

E. N. Kablov, O. V. Startsev, A. S. Krotov, and V. N. Kirillov, “Climatic aging of composite materials: 1. Aging mechanisms,” Russ. Metall. 2011 (10), 993–1000 (2011).

E. N. Kablov, O. V. Startsev, A. S. Krotov, and V. N. Kirillov, “Climatic aging of composite aviation materials: 2. Relaxation of the initial structural nenequilibrium and through thickness gradient of properties,” Russ. Metall. 2011 (10), 1001–1007.

E. N. Kablov, O. V. Startsev, A. S. Krotov, and V. N. Kirillov, “Climatic aging of composite aviation materials: 3. Significant aging factors,” Russ. Metall. 2012 (4), 323–329 (2012).

D. Roylance and M. Roylance, “Weathering of fiber-reinforced epoxy composites,” Polym. Eng. Sci. 18, 249–254 (1978).

L. Belec, T. H. Nguyen, D. L. Nguyen, and J. F. Chailan, “Comparative effects of humid tropical weathering and artificial ageing on a model composite properties from nano- to macro-scale,” Compos. Part A 68, 235–241 (2015).

J. C. M. de Bruijn and H. D. F. Meijer, “The design and application of a microfoil tensile test apparatus for monitoring the degree of ultraviolet degradation of polymers,” Rev. Sci. Instrum. 62 1620–1623 (1991).

J. C. M. de Bruijn, “Degradation profiles of thick high-density polyethylene samples after outdoor and artificial weathering,” in Polym. Durab. Degrad. Stab. Lifetime Predict., Ed. by L. Clough, N. C. Billingham, and K. T. Gillen, 1996, pp. 599–620.

X. Gu, B. Dickens, D. Stanley, W. E. Byrd, T. Nguyen, I. Vaca-Trigo, W. Q. Meeker, J. Chin, and J. W. Martin, “Linking accelerating laboratory test with outdoor performance results for a model epoxy coating system,” Iowa State Univ., Stat. Prepr. 30, 1–47 (2008).

X. Gu, Y. Pang, C.-C. Lin, K. Liu, T. Nguyen, and J. W. Chin, “Linking accelerated laboratory and outdoor exposure results for PV polymeric materials: A mechanistic study of EVA,” in SPIE 8825, Reliab. Photovolt. Cells, Modul. Components, Syst. VI, 88250L (2013), pp. 1–15.

M. Diepens and P. Gijsman, “Outdoor and accelerated weathering studies of bisphenol A polycarbonate,” Polym. Degrad. Stab. 96 (4), 649–652 (2011).

X. Lv, Z. Huang, M. Shi, Y. Fan, and G. Gao, “Composition distribution, damping and thermal properties of the thickness-continuous gradient epoxy/polyurethane interpenetrating polymer networks,” Appl. Sci. 7 (2), 135 (2017).

O. V. Startsev, Doctoral Dissertation in Engineering (Moscow, 1990).

O. V. Startsev, A. S. Krotov, and L. T. Startseva, “Interlayer shear strength of polymer composite materials during long term climatic ageing,” Polym. Degrad. Stab. 63, 183–186 (1999).

V. O. Startsev, “Across-the-thickness gradient of the interlaminar shear strength of a CFRP after its long-term exposure to a marine climate,” Mech. Compos. Mater. 52 (2), 171–176 (2016). https://doi.org/10.1007/s11029-016-9570-7

O. V. Startsev, V. V. Isupov, and E. F. Nikishin, “The gradient of mechanical characteristics across the thickness of composite laminates after exposure to a low Earth orbit environment,” Polym. Compos. 19, 65–70 (1998).

O. V. Startsev, À. Y. Makhonkov, I. S. Deev, and E. F. Nikishin, “Dynamic mechanical analysis of KMU-4L carbon fiber reinforced plastic after 12 years of exposure to space environment. 2. Factor of specimens position in multilayer exposed stack,” Vopr. Materialoved., No. 4, 61–68 (2013).

B. D. Man, Development of Composite Materias Based on Epoxyurethane Oligomers with Improved Performance Qualities (D. I. Mendeleev Univ. Chem. Technol. Russ., 2014).

V. O. Startsev, M. P. Lebedev, K. A. Khrulev, M. V. Molokov, A. S. Frolov, and T. A. Nizina, “Effect of outdoor exposure on the moisture diffusion and mechanical properties of epoxy polymers,” Polym. Test. 65 (2018). https://doi.org/10.1016/j.polymertesting.2017.12.007

V. O. Startsev, T. A. Nizina, and O. V. Startsev, “A colour criterion of the climatic ageing of an epoxy polymer,” Int. Polym. Sci. Technol. 43, 45–48 (2016).

Funding

The reported study was funded by RFBR according to the research project no. 18-29-18029.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Startsev, V.O., Lebedev, M.P., Molokov, M.V. et al. The Gradient of Dynamic Mechanical Characteristics across the Thickness of Epoxy Polymers during Environmental Exposure. Polym. Sci. Ser. D 12, 381–391 (2019). https://doi.org/10.1134/S1995421219040154

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1995421219040154