Abstract

The structure and sensing properties of SnO2–In2O3 composites synthesized by the impregnation method are studied. These composites consist of In2O3 nanocrystals comprising SnO2 nanoclusters with a size of 5–7 nm on their surface. Using energy-dispersive X-ray spectroscopy, it is found that the SnO2 nanoclusters contain indium ions, which provide an increase in the number of catalytically active oxygen vacancies in them. The maximum efficiency of the synthesized composites for hydrogen detection in air is achieved at a SnO2 content in the composite of about 40 wt %. In this case, the high sensor sensitivity of the composite is attributed to the catalytic activity of SnO2 clusters containing indium ions and the high specific surface area of SnO2 aggregates, which provide the conductivity of the composite.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

INTRODUCTION

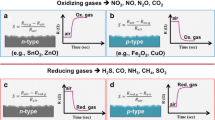

The ever-growing challenges associated with environmental pollution and safety show the necessity of real-time environmental monitoring. To this end, nanocrystalline semiconductor metal oxides, whose electrical conductivity varies depending on the composition of the surrounding gas atmosphere, are currently used as sensors to detect reducing gases, such as hydrogen, hydrocarbons, and carbon monoxide. The sensor effect is attributed to a change in the electrical conductivity of the sensor caused by the chemical (sensory) reaction of the gas with anionic oxygen centers on the surface of the sensor nanocrystals [1–3]. This reaction, which is accompanied by the release of trapped electrons and their transition into the conduction band of metal oxide, leads to an increase in the electrical conductivity of the sensor.

The sensing properties of a nanostructured metal oxide system are determined by its morphology, the electronic structure of the particles, and the interaction between them [4, 5]. In this context, new possible designs of efficient fast-response sensors are enabled by the use of composite systems consisting of metal oxides with different electronic and catalytic properties. Depending on the nature and content of components in this composite, the sensitivity and selectivity of the composite change as it detects different compounds (see, e.g., [6–8]).

Sensor effects in binary metal oxide systems are founded in the specific contacts between dissimilar metal oxide particles and the incorporation of ions of one metal oxide into the crystal lattice of the other, which can occur during the formation of the composite. Of particular importance for the sensing properties of a nanostructured metal oxide semiconductor composite is the morphology of the composite and in particular, the size of nanoparticles involved in the sensory process. A decrease in the size of the nanoparticle leads to an increase in the specific surface area of the sensitive layer of the sensor, resulting in an increase in the concentration of oxygen and analyte gas molecules chemisorbed in this layer, which leads to an enhancement of the sensor effect [9, 10]. It is particularly important that the characteristic structural flexibility of nanocrystalline metal oxide grains that are smaller than 10 nm under the action of stresses generated by the incorporation of foreign ions into their lattice opens up possibilities of the directed modification of nanoparticles to improve the sensitivity and selectivity of a sensor. In particular, it is shown that, in the case of doping of SnO2 with indium ions, their dissolution in the SnO2 lattice is observed only for SnO2 nanoparticles with a size of 5–10 nm [11].

The size of a nanoparticle in a nanostructured composite depends on the method of formation of the composite. It has been found that the impregnation of metal oxide nanocrystals with a metal salt solution and the subsequent heat treatment of the impregnated sample under certain conditions lead to the formation of another oxide with a size of up to 10 nm on the surface of matrix nanocrystals of metal oxide nanoclusters [12–15]. In this study, nanocomposites consisting of In2O3 nanocrystals with a size of 30–40 nm, which contain SnO2 nanoclusters with a size of 5–8 nm on their surface, are synthesized by the impregnation method. The structure, electrical conductivity, and sensing characteristics of the resulting nanocomposites for hydrogen detection are studied. It is shown that high sensor sensitivity is achieved in the case of a certain composition of the nanocomposite provided by its specific structure.

EXPERIMENTAL

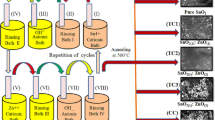

The SnO2–In2O3 composites were synthesized by impregnating In2O3 nanocrystals with an aqueous solution of SnCl4 and subsequently subjecting the impregnated samples to a heat treatment. Commercial In2O3 nanopowder samples (AnalaR grade, 99.5%, BDH/Merck Ltd., Lutterworth, Leicestershire, UK) were used. To prepare the samples, a suspension of In2O3 nanocrystals in an aqueous solution of SnCl4 was stirred for 24 h and then held for 24 h to provide a uniform penetration of the solution into all of the pores of the powder. The SnCl4 concentration in the solution was 0.014 mol/L. After that, water was evaporated in air at 70°С; the resulting impregnated powder was held at 100°С for 5 h and then heated in air at 500°С for 5 h. This heat treatment led to the hydrolysis of tin chloride and the subsequent formation of SnO2. The tin oxide content in the synthesized impregnated composite was calculated according to the amount of the salt added per gram of the In2O3 powder to the initial suspension.

To determine the conductivity and sensing properties of the synthesized materials, they were mixed with distilled and deionized water. The resulting paste was deposited on polycor plates and annealed at 550°C until a constant resistance of the resulting film was achieved.

The structure of the composites was determined by X-ray diffraction (XRD), transmission electron microscopy (TEM), and energy-dispersive X-ray (EDX) spectroscopy. The XRD spectra were recorded using a Rigaku Ultima IV X-ray diffractometer (CuKα radiation, λ = 0.154056 nm) that was equipped with a narrow slit analyzer providing an increase in the resolution of XRD patterns and a graphite monochromator providing the detection of weak peaks in XRD patterns.

Average nanoparticle size (D) was determined from XRD spectra in accordance with the Debye–Scherrer formula: D = 0.9λ/(β cos θ), where λ is the X-ray wavelength, β is the peak half-width, and θ is the diffraction angle corresponding to this peak. The relative position and contacts of particles in the composites were determined by TEM on a JEM-2100 instrument (Jeol, Japan). The EDX spectra, which characterize, in particular, the distribution of metal ions between the composite components, were recorded on a JOEL JSM-5610 instrument equipped with an Oxford Instruments X-MaxN 100TLE EDX microanalysis system.

The sensory activity of the composites in hydrogen detection was measured in a temperature range of 300–450°C. The temperature maintenance accuracy was ±1°C. Pure air or air containing 1100 ppm of hydrogen was pumped through a 1 cm3 measuring chamber with the sensor placed into it at a rate of 200 cm3/min. Sensor effect S was defined as S = (R0/Rg), where R0 and Rg are the resistance of the sensor film in pure air and in air containing the analyte gas, respectively.

RESULTS AND DISCUSSION

The initial In2O3 nanocrystals have a cubic structure with a lattice parameter of 1.012 nm. The XRD analysis data showed that, in the synthesized composites, this structure of In2O3 crystals is preserved, while SnO2 nanoclusters formed during impregnation have a tetragonal structure characteristic of SnO2 crystals. The XRD data are shown in Table 1 for the (110) and (400) peaks in the tetragonal lattice of SnO2 and in the cubic lattice of In2O3, respectively. These peaks were selected because they do not overlap other peaks in the spectrum of the composite even partially. The designations in Table 1 are given in accordance with the Debye–Scherrer formula. The average size D of the initial In2O3 nanocrystals, which was determined from the XRD data in accordance with the Debye–Scherrer formula, is 35 nm; it changes little during the formation of SnO2–In2O3 composites by the impregnation of the crystals (see Table 1).

At SnO2 concentrations of up to 10 wt %, only In2O3 crystals are detected in the composite. It is known that the dissolution of small amounts of SnO2 in In2O3 crystals hardly changes the crystal structure [16]. The increase in the conductivity of the composite compared with the conductivity of pure In2O3 (Fig. 1) confirms the formation of SnO2 solid solutions in In2O3 crystals. This effect is also observed in composites synthesized by codeposition of SnO2 and In2O3 from a solution of tin and indium salts [17]. The effect is attributed to the fact that an increase in the localized positive charge caused by the replacement of In3+ in the In2O3 lattice by Sn4+ ions is compensated for by the formation of negatively charged oxygen vacancies containing electrons weakly bound to the lattice. The transition of these electrons into the conduction band of In2O3 leads to an increase in the conductivity of the composite at low SnO2 concentrations, when the current paths in the composite are formed by In2O3 crystals. It is characteristic that the In2O3 particles observed under a transmission microscope (Fig. 2a) are apparently aggregates of crystals recorded by XRD.

According to [18], the solubility limit of SnO2 in In2O3 is 10–15 wt %, which corresponds to 5–7 at % Sn. With an increase in the SnO2 concentration above this limit, SnO2 nanoclusters are formed in the composite; according to XRD, the average size of these nanoclusters is about 5 nm (see Table 1).

As the SnO2 nanoclusters accumulate, low-resistance current paths consisting of In2O3 nanocrystals are broken by inclusions of SnO2 nanoclusters, whose resistance is three orders of magnitude greater than those of the In2O3 nanocrystals. Simultaneously, the formation and multiplication of current paths through aggregates of SnO2 nanoclusters are observed. All these factors lead to an increase in the resistance of the composite (Fig. 1). Owing to the small size of the SnO2 nanoclusters and, accordingly, the large width of their peaks in the XRD spectra, the resulting nanoclusters are clearly detected only at a total SnO2 concentration of about 40 wt %. In this case, assuming that approximately 10 wt % SnO2 is dissolved in In2O3, the concentration of SnO2 nanoclusters can be estimated at 30 wt %. In the synthesized nanostructured SnO2–In2O3 composites, the DIn/DSn ratio is ~7. Calculations based on the percolation theory [19] show that, at this DIn/DSn ratio, all current paths through In2O3 crystals are completely interrupted by SnO2 nanoclusters at their concentration in the composite of about 30%. Thus, the final percolation transition to conduction through SnO2 in our SnO2–In2O3 composites occurs at a total SnO2 concentration of about 40 wt %.

Sensor effect S in the studied SnO2–In2O3 nanocomposites, as well as in other nanostructured metal oxide sensors, varies with temperature and, at a certain temperature value Tmax, it achieves a maximum value Smax (Fig. 3). The dependence of Smax on the SnO2 concentration in the case of hydrogen detection by an impregnated SnO2–In2O3 composite sensor is shown in Fig. 4. Small SnO2 additives (up to 10 wt %), which dissolve in In2O3 crystals, lead simultaneously to an increase in the conductivity and a decrease in the sensor effect. Earlier, a decrease in S with an increase in the conductivity of the nanocrystalline sensor was found for SnO2 sensor films synthesized by the aerosol method [20].

At low SnO2 concentrations in SnO2–In2O3 composites, current flows through the In2O3 crystals. In this case, one possible cause of a decrease in the sensor effect is an increase in the conduction electron concentration nc upon the introduction of Sn ions into the In2O3 lattice. The S value is defined as the ratio of the rate of the reaction of the analyte reducing gas with oxygen anions O– (Vr) to the rate of the annihilation of these anions in the absence of the gas (VO) [1, 2]. The Vr/VO ratio is determined by the annihilation mechanism of O– in the absence of the gas.

In the case of monomolecular annihilation due to the electron detachment from the O– anion [1, 9], the Vr/VO = kr[A]/kO1 ratio does not depend on [O–]; here, kr is the rate constant for the reaction between O– and the adsorbed gas, [A] is the adsorbed gas concentration, and kO1 is the O– → O + e– reaction rate constant. In the case of annihilation of O– due to the bimolecular reaction 2O– → O2 + 2e– with rate constant kO2 [2], the Vr/VO ratio is determined by the following equation: Vr/VO = kr[A]/kO2 [O–]. An increase in nc unambiguously leads to an increase in [O–]; therefore, in this case, the Vr/VO ratio and, accordingly, the S value should decrease with increasing nc. Apparently, in the studied system, the annihilation of O– on the In2O3 surface occurs via the recombination of these radical anions; this factor is responsible for the decrease in S with an increase in nc, owing to the incorporation of Sn ions into the In2O3 lattice.

The percolation transition to conduction through SnO2, which is accompanied by an increase in the resistance of the composite, leads to a gradual increase in the sensor effect (Fig. 4). It is characteristic that the maximum value of the sensor effect is achieved at 40 wt % SnO2, when, in accordance with the percolation theory, the final percolation transition to conduction through SnO2 nanoclusters occurs in the composite.

Aggregates of SnO2 nanoclusters contacting each other, which form current paths in this composite, have an exceptionally high specific surface area. This factor is a cause of the enhancement of the sensor effect after the percolation transition to conduction in the composite through SnO2 because, according to theoretical analysis [9, 21] and experimental data [22], the sensor effect in a nanostructured system increases with an increase in the specific surface area of this system. Another cause is the structure of SnO2 particles contacting with In2O3 crystals. The EDX data (Fig. 2b) show that these particles contain In ions, due to the dissolution of In2O3 in SnO2.

The formation of a solid solution of In2O3 in SnO2 is facilitated for SnO2 nanoparticles, because they are more readily deformed upon the replacement of Sn4+ ions by the larger In3+ ions in the SnO2 lattice, so that, in small SnO2 particles, the fraction of dissolved In with respect to Sn in the nanoclusters can be up to 20% [11]. The dissolution of In2O3 in SnO2 can be represented by the following equation [23]:

where SnSn and OO are the Sn4+ and O2– ions in the SnO2 lattice, \({\text{In}}_{{{\text{Sn}}}}^{ - }\) is the In3+ ion that replaces Sn4+ in the SnO2 lattice and generates a localized negative charge in the lattice, and \({\text{V}}_{{\text{O}}}^{{ + + }}\) is the positively charged oxygen vacancy compensating for the negative charge at \({\text{In}}_{{{\text{Sn}}}}^{ - }.\) The formation of positively charged oxygen vacancies leads to a decrease in nc and, accordingly, the conductivity of the composite. In addition, these vacancies are centers of hydrogen adsorption to form H atoms [24]; therefore, they increase the catalytic activity of the composite in the sensory reaction of analyte hydrogen with O– radical anions on the surface of SnO2 nanoparticles.

It is characteristic that the sensor effect increases with an increase in the SnO2 concentration to 40 wt % and then decreases (Fig. 4). This result can be attributed to the fact that, in the In2O3–SnO2 composites, at a SnO2 content of 40 wt %, the concentration of SnO2 nanoclusters contacting with In2O3 crystals and containing indium ions, which increase the catalytic activity of these nanoparticles in the sensory reaction, apparently achieves a maximum.

Thus, the high sensor sensitivity of the composite is attributed to the following: the catalytic activity of SnO2 particles containing indium ions in the dissociative chemisorption of H2 and the small (5–7 nm) size of these particles, which, in accordance with the percolation theory, determine the conductivity of the composite at a SnO2 content of more than 30 wt %. In this case, the aggregates of SnO2 particles that form the current paths have a particularly high specific surface area, which increases the sensor response of the composite. Another factor that causes an increase in the sensor response of the composite under these conditions may be electron transfer from In2O3 to SnO2, which increases due to the sensor reaction. This conclusion follows from the results of studies of In2O3–SnO2 composites synthesized by mixing In2O3 and SnO2 nanopowders [7]. It is obvious that the degree of electron transfer between In2O3 and SnO2 is maximal if the concentration of SnO2 nanoparticles contacting with In2O3 crystals achieves a maximum value.

CONCLUSIONS

The structure and sensing properties of a SnO2–In2O3 composite synthesized by the impregnation of In2O3 nanocrystals with an aqueous solution of SnCl4 and the subsequent formation of SnO2 nanoclusters during the heat treatment of the impregnated samples have been studied. It has been shown that this method provides the formation of SnO2 nanoclusters with a size of 5–7 nm on the surface of In2O3 crystals. Using EDX spectroscopy, it has been found that these SnO2 nanoclusters contain indium ions; therefore, the number of catalytically active oxygen vacancies in the clusters increases.

The maximum efficiency of hydrogen detection in air by the synthesized SnO2–In2O3 composite sensors is achieved at a SnO2 content in the composite of about 40 wt %, when, according to the percolation theory, the current paths are aggregates of SnO2 clusters contacting with In2O3 crystals. In this case, the high sensor sensitivity of the composite is attributed to the catalytic activity of SnO2 clusters containing indium ions and the high specific surface area of SnO2 aggregates providing the conductivity of the composite.

REFERENCES

N. Barsan and U. Weimar, J. Electroceram. 7, 143 (2001).

N. Yamazoe and K. Shimanoe, Sens. Actuators, B 128, 566 (2008).

G. N. Gerasimov, V. F. Gromov, O. J. Ilegbusi, and L. I. Trakhtenberg, Sens. Actuators, B 240, 613 (2017).

V. Brinzari, I. Damaskin, L. Trakhtenberg, et al., Thin Solid Films 552, 225 (2014).

L. I. Trakhtenberg, G. N. Gerasimov, L. N. Aleksandrova, and V. K. Potapov, Radiat. Phys. Chem. 65, 479 (2002).

W. J. Moon, J. H. Yu, and C. G. Man, Sens. Actuators, B 87, 464 (2002).

L. I. Trakhtenberg, G. N. Gerasimov, V. F. Gromov, et al., Sens. Actuators, B 169, 32 (2012).

K.-W. Kim, P.-S. Cho, S.-J. Kim, et al., Sens. Actuators, B 123, 318 (2007).

M. A. Kozhushner, L. I. Trakhtenberg, V. L. Bodneva, et al., J. Phys. Chem. C 118, 11440 (2014).

G. Korotcenkov, S.-D. Han, B. K. Cho, and V. Brinzari, Crit. Rev. Solid State Mater. Sci. 34, 1 (2009).

K. I. Gnanasekar, X. Jiang, J. C. Jiang, et al., J. Nanosci. Nanotechnol. 2, 189 (2002).

M. M. Natile and A. Glisenti, J. Phys. Chem. B 110, 2515 (2006).

G. N. Gerasimov, M. I. Ikim, P. S. Timashev, V. F. Gromov, T. V. Belysheva, E. Yu. Spiridonova, V. N. Bagratashvili, and L. I. Trakhtenberg, Russ. J. Phys. Chem. A 89, 1059 (2015).

V. F. Gromov, G. N. Gerasimov, T. V. Belysheva, M. I. Ikim, E. Yu. Spiridonova, M. M. Grekhov, R. A. Ali-zade, and L. I. Trakhtenberg, Russ. J. Phys. Chem. B 12, 129 (2018).

G. N. Gerasimov, M. M. Grekhov, V. F. Gromov, M. I. Ikim, E. Yu. Spiridonova, and L. I. Trakhtenberg, Russ. J. Phys. Chem. B 12, 709 (2018).

H. Kim, C. M. Gilmore, A. Piqué, et al., J. Appl. Phys. 86, 6451 (1999).

S. J. Wen, G. Coutirier, J. P. Chaminade, et al., J. Solid State Chem. 101, 203 (1992).

H. Enoki, J. Echigoya, and H. Suto, J. Mater. Sci. 26, 4110 (1991).

N. Savage, B. Chwieroth, A. Ginwalla, et al., Sens. Actuators, B 79, 17 (2001).

G. Korotcenkov, V. Brinzari, J. Schwank, et al., Sens. Actuators, B 77, 244 (2001).

M. A. Kozhushner, L. I. Trakhtenberg, A. C. Landerville, et al., J. Phys. Chem. C 117, 11562 (2013).

G. J. Li, X. H. Zhang, and S. Kawi, Sens. Actuators, B 60, 64 (1999).

J. Maier and W. Gopel, J. Solid State Chem. 72, 293 (1988).

W. Gopel, G. Rocker, and R. Feierabend, Phys. Rev. B 28, 3427 (1983).

Funding

This work was performed under a state task to Semenov Institute of Chemical Physics of the Russian Academy of Sciences (project 45.22 no. 0082-2018-0003 “Fundamentals of Designing New-Generation Nanostructured Systems with Unique Performance Characteristics” (AAAA-A18-118012390045-2)) and supported by the Russian Foundation for Basic Research (project nos. 17-07-00131a, 18-07-00551a, 19-07-00141a, and 19-07-00251a).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by M. Timoshinina

Rights and permissions

About this article

Cite this article

Gerasimov, G.N., Gromov, V.F., Ikim, M.I. et al. Structure and Sensing Properties of Nanostructured SnO2–In2O3 Composites Synthesized by the Impregnation Method. Russ. J. Phys. Chem. B 13, 763–768 (2019). https://doi.org/10.1134/S1990793119050154

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1990793119050154