Abstract

The reaction of macromolecular cross-metathesis of polynorbornene and polydodecenamer catalyzed by the first-generation Grubbs Ru-carbene complex is studied for the first time. Polydodecenamer with high-molecular-weight characteristics (Mw = 406 × 103, Ð = 2.5) and a yield of 96% is synthesized by the ring-opening metathesis polymerization of cyclododecene mediated by the second-generation Grubbs catalyst. The polymer has a melting temperature of 62–83°C, depending on the content of trans double bonds, and shows poor solubility in organic solvents at room temperature. Its cross-metathesis with polynorbornene at 40°С gives rise to new statistical multiblock copolymers of norbornene and cyclododecene with different degree of blockiness. NMR, GPC, and DSC were used to investigate the effect of reaction conditions on the structure and thermal properties of the copolymers. At the initial step of the reaction, along with a high-molecular-weight peak, the GPC chromatograms exhibit a peak due to the low-molecular-weight fraction (M = (1–2) × 103), suggesting the formation of cyclooligomers. With increasing degree of interchain exchange, the proportion of the oligomeric fraction decreases appreciably. The kinetics of the cross-metathesis of polynorbornene with polydodecenamer and polyoctenamer at 40°С is studied by in situ 1Н NMR spectroscopy and ex situ 13С NMR spectroscopy. The rates of elementary reactions in these blends differ insignificantly, except for the conversion stage of the initial carbenes into polymer ones. The formation rate for carbene [Ru]=polyoctenamer is three times higher than the formation rate for the [Ru]=polydodecenamer carbene. In both cases, the fraction of Ru carbenes attached to norbornene units is extremely small throughout the process.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Cyclododecene (CDD) is one of the accessible cycloolefin petrochemicals [1]. The product of its metathesis polymerization—polydodecenamer (PCDD)—is an efficient additive to elastomers, which primarily increases the hardness of butadiene–styrene rubbers [2] and other vulcanizates.

A great deal of studies concern the ring-opening metathesis polymerization of CDD. This process was carried out using classical W-based catalytic systems combined with organoaluminum compounds and promotors (epichlorohydrin, chloranil) [3, 4], WCl6‒tetraphenylporphyrin [5], electrochemically reduced systems based on W and Mo [6], and Schrock catalysts W(=CH-t-Bu)-(OtBu)2(NAr), Mo(=CH-t-Bu)(OC(CH3)3)2(NAr), Mo(=CH-t-Bu) (OC(CH3)2CF3)2(NAr), and Mo(=CH-t-Bu)(OC(CH3)(CF3)2)2(NAr) [7, 8]. Detailed analysis of the microstructure of a polymer synthesized using Schrock catalysts [8] revealed that a high content of trans units (80–95%) responsible for crystallinity of the polymer is attained if the reaction is conducted in 3 М chloroform solution for 20 h at room temperature. It should be noted that the activity of the trans isomer of CDD is much higher than the cis isomer, which was demonstrated in the cross-metathesis of CDD with hexene-1 [9].

When the surface-initiated metathesis polymerization of CDD was carried out in the gas phase with the second-generation Grubbs Ru catalyst [10], the contribution of the chain-transfer reaction was reduced, but it was impossible to completely avoid this reaction because of the close proximity of molecules on the grafted surface. PCDD with fluoroalkyl end groups was prepared by polymerization of CDD catalyzed by WCl6/Bu4Sn in the presence of the chain-transfer agent C10F21(CH2)6CH=CH(CH2)6C10F21; these polymers possess low surface energy combined with chemical resistance and good mechanical properties [11]. The use of cis-1,4-diacetoxy-2-butene as a chain-transfer agent enabled the synthesis of PCDD with end acetoxy groups, which gave the polymer enhanced resistance against oxidation in air [12]. The postmodification of PCDD via the exhaustive hydroboration of double bonds followed by the oxidation of hydroborates afforded strictly linear copolymers of ethylene and vinyl alcohol with the predetermined distribution of alcohol units [7]. Using CDD in the ring-expansion metathesis reaction mediated by the second-generation Grubbs catalyst a number of macrocycles was isolated [13].

The synthesis of copolymers from CDD can be illustrated by only two examples. The copolymerization of CDD with 1,5-cyclooctadiene carried out in the presence of 1,4-diacetoxy-2-butene as a chain-transfer agent and the first-generation Grubbs catalyst leads to the synthesis of random copolymers with end acetoxy groups; upon removal of these groups, dihydroxy telechelics were obtained [12]. With the third-generation Grubbs catalyst, alternating metathesis copolymerization of CDD with a monomer containing a substituted cyclobutene moiety, bicyclo[4.2.0]oct-1(8)-ene-8-carboxamide, was achieved [14].

In this study, statistical multiblock copolymers of CDD and norbornene (NB) are synthesized for the first time and the kinetics of the process and main factors determining the structure of the product are explored. Interest in these copolymers is associated with their ability to combine the properties of corresponding homopolymers in a material while retaining performance characteristics typical for polymer blends and even for diblock copolymers with ease synthesis of irregular copolymers [15].

Copolymers CDD–NB were synthesized by the reaction of cross-metathesis between homopolymers polynorbornene (PNB) and PCDD. Macromolecular cross-metathesis is a poorly understood process, which is represented in the literature by reactions between polydienes and polyesters/polyurethanes synthesized via different mechanisms [16–18] and between polycyclooctenes with various substituents [19], reactive compatibilization of thermodynamically incompatible polymers [20], and cross-metathesis in the system PNB–polyoctenamer (PCO) [21–24]. We synthesized a number of copolymers that are hardly synthesized from monomers NB and cyclooctene (CO) and investigated their thermal and crystalline properties.

The reactivity of CDD in metathesis polymerization is lower than that of CO, and the cometathesis of CDD and NB is hindered because of the considerable difference in ring strain energies (27.2 kcal/mol for NB and 11.1 kcal/mol for CDD) [10, 25, 26]. To the best of our knowledge, this is why copolymers of NB with CDD have not been synthesized up to now. PCDD is distinguished by a higher degree of crystallinity and melting temperature compared with other polyalkenamers [27–30]; its copolymers and products of their subsequent modification via double bonds show promise as shape-memory materials having melting and glass transition temperatures in different ranges [31] and as components of general-purpose composites and materials with improved gas permeability [32].

EXPERIMENTAL

Reagents

All manipulations with air- and moisture-sensitive compounds were carried out on a standard vacuum setup and a Schlenk line in an argon atmosphere using dehydrated solvents. Monomer CDD (Aldrich) was dehydrated over CaH2. NB (Aldrich), which was dehydrated over sodium and used as 4.6 М solution in dehydrated chloroform was stored under argon. Grubbs catalysts of the first (G-1, Cl2(PCy3)2Ru=CHPh)

(Cy is cyclohexyl) and second (G-2, RuCl2(=CHPh)(H2IMes)(PCy3)), generation

where Mes  (Aldrich), were used as received in the form of 0.002–0.022 M solutions in dehydrated chloroform. Oxidation inhibitor 2,2'‑methylene-bis(6-tert-butyl-4-methylphenol) (Aldrich) was used as received. CDCl3 was dehydrated over СаН2. Other reagents and solvents (Aldrich) were purified and dried according to standard techniques.

(Aldrich), were used as received in the form of 0.002–0.022 M solutions in dehydrated chloroform. Oxidation inhibitor 2,2'‑methylene-bis(6-tert-butyl-4-methylphenol) (Aldrich) was used as received. CDCl3 was dehydrated over СаН2. Other reagents and solvents (Aldrich) were purified and dried according to standard techniques.

Analytical Methods

1Н and 13С{1H} NMR spectra were recorded on an Brucker AvanceTM 500 spectrometer operating at frequencies of 500.13 and 125.77 MHz, respectively. For the 13С{1H} NMR spectra, the acquisition parameters were as follows: 30° pulse (3 µs); acquisition time, 1.3 s; relaxation delay, 1.4 s; the FID size, 64 К, and the real spectrum size, 32 К. In 1Н NMR spectra chemical shifts (in parts per million relative to tetramethylsilane) were determined relative to the position of residual signals of a solvent (7.28 ppm); in 13C NMR spectra, relative to CDCl3 (77.23 ppm). According to 13С NMR data, the composition of the copolymer NB–CDD and the fraction of dyads of various types in it were estimated.

The molecular-weight characteristics were determined by GPC on a Waters liquid chromatograph equipped with a refractometric detector and a Waters Styragel HR 5E column (1–5 µm, 7.8 × 300 mm) at 40°C in THF. Calibration was done against PS standards (Polymer Labs).

The thermal properties were studied by DSC on a DSC823e calorimeter (Mettler Toledo). The samples were heated and cooled at a rate of 10°C/min in an argon atmosphere at a flow rate of 70 mL/min in the temperature range of –100 to +150°C. The results of measurements were processed using the STARe service program. The accuracy of temperature measurements was ±0.3°C; enthalpy measurements, ±1 J/g.

Polymer Synthesis Methods

All operations were carried out in an inert atmosphere (Ar) with the Schlenk vacuum technique.

Polydodecenamer. A 20-mL two-neck flask equipped with a magnetic stirrer was evacuated and filled with argon. The catalyst G-2 (1.9 mg, 0.0022 mmol) and 0.04 mL of dry CHCl3 and 422 mg (2.54 mmol) of CDD were added. After 25 min, the reaction mixture became fully immobile. After 24 h, the reaction mixture was heated to 40°C and 36 mL of CHCl3 and ethyl vinyl ether (500 mol/mol of G-2) as a stop agent were added. After 30 min, the oxidation inhibitor was added. PCDD was precipitated into methanol and dried in vacuum at room temperature (25°С) to a constant weight. The yield of the polymer was 406 mg (96%). The 1H NMR spectra corresponded to the published data [6, 8].

Polynorbornene. PNB was synthesized by ring-opening metathesis polymerization of bicyclo[2.2.1]hept-2-ene (norbornene) mediated by catalyst G-1. A 50-mL two-neck round-bottom flask equipped with a magnetic stirrer was filled with argon, and the catalyst (25.0 mg, 0.0304 mmol) and 26.6 mL of dry chloroform were loaded. To a catalyst solution cooled to 0°С 4.63 mL (21.3 mmol) of NB solution in chloroform was quickly added, and the cooling bath was removed. After 1 h, the reaction mixture was diluted with chloroform (23 mL) and ethyl vinyl ether (500 mol/mol of G-1), and in 30 min the oxidation inhibitor was added. The polymer was precipitated into ethanol and dried in vacuum at 25°С to a constant weight. The yield of PNB was 1.94 g (97%). Signals in the 1Н and 13С NMR spectra of PNB were assigned in accordance with [33, 34].

Cross-Metathesis between PNB and PCDD

Immediately prior to cross-metathesis experiments, the initial homopolymers were purified of the residual catalyst and inhibitor by passing their chloroform solutions through a column packed with silica gel (eluent, chloroform) and the purified polymer was precipitated into ethanol. The polymers were thoroughly dried in vacuum to a constant weight for no less than 2 days.

The polymer cross-metathesis technique is presented below for a molar ratio of [PNB] : [PCDD] : [G-1] = 50 : 50 : 1. Homopolymers PNB and PCDD (0.28 mmol each) were placed in a 10-mL two-neck round-bottom flask equipped with a magnetic stirrer, which was evacuated and filled with argon. Then, 0.7 mL of absolute chloroform was added and the polymers were dissolved for no less than 12 h. The resulting solution was degassed by three times via the freeze–pump–thaw cycles, and 0.35 mL (0.0061 mmol) of catalyst solution in chloroform (17.4 mmol/L) was added under constant stirring. The concentration of the homopolymers in solution was 5 wt %. The reaction was carried out at a temperature of 40°С. Ethyl vinyl ether as a stop agent was added at a molar ratio of ethyl vinyl ether : catalyst = 500 : 1. After 30 min, the oxidation inhibitor was added. The copolymers were precipitated into methanol and dried in vacuum to a constant weight. For spectral studies, the reaction mass was concentrated in vacuum and CDCl3 was added.

Spectral characteristics of multiblock copolymers:

1Н NMR (500 MHz, CDCl3): δ 5.39 (CH=CH, 1Н trans-PNB), 5.36 (CH=CH, 2Н, PCDD), 5.22 (СН=СН, 1Н, cis-PNB), 2.79 (br. s, 2Н1,4 PNB), 2.44 (br. s, 2Н1,4 PNB), 1.98 (4H, CH2), 1.86–1.76 (br. m, 3Н5a,6a,7a PNB), 1.44–1.25 (m, 2Н5c,6c PNB, 16H, CH2, PCDD), 1.10–1.04 (m, 1Н7c PNB) ppm.

13C NMR (126 MHz, CDCl3): δ 135.39, 135.36, 135.07, 134.91 (C=C, heterodyads NB–CDD), 134.12, 134.06, 133.89 (C=C, homodyads cis-NB–NB), 133.29, 133.17, 133.01 (C=C, homodyads trans-NB–NB), 130.51 (C=C, homodyads trans-CDD–CDD), 130.04 (C=C, homodyads cis-CDD–CDD), 128.8–128.56 (C=C, heterodyads CDD–NB), 43.56, 43.27 (С1,4 PNB), 42.89, 42.26, 41.54 (С7 PNB), 38.85, 38.60 (С1,4 PNB), 33.02 (С5,6, PNB), 33.11 (С5,6, PNB), 32.77 (trans-CH2 PCDD) 32.58 (С5,6, PNB), 32.42 (С7, PNB), 29.96, 29.85, 29.81, 29.74, 29.70, 29.50, 29.35 (8 CH2), 27.40 (cis-CH2 PCDD) ppm.

In Situ 1H NMR Monitoring of Cross-Metathesis between PNB and PCDD

Homopolymers PNB (20 mg, 0.213 mmol), PCDD (35.3 mg, 0.213 mmol), and CDCl3 (0.51 mL) were placed in a Young NMR tube (Aldrich), dissolved at 40°С for 2 h, and allowed to stay for a night. The resulting mixture was degassed three times, and a separately prepared 0.074 М solution of catalyst G-1 (17 mg, 0.021 mmol) in CDCl3 (0.28 mL) was added to the frozen polymer solution. The mixture was thawed, heated, stirred, and immediately placed in an NMR spectrometer. Spectra were taken at a temperature of 40°С, first after every 15–30 min and then every 3 h for one day.

1H NMR Monitoring of Interaction of Homopolymers with G-1

Homopolymer PCDD (35.3 mg, 0.21 mmol) and CDCl3 (0.53 mL) were placed in a Young NMR tube, and the polymer was dissolved overnight. The resulting mixture was degassed three times, and a separately prepared 0.055 М solution of catalyst G-1 (17.9 mg, 0.022 mmol) in CDCl3 (0.4 mL) was added to the frozen polymer solution. The mixture was thawed, heated, stirred, and immediately placed in an NMR spectrometer. Spectra were taken at a temperature of 40°С first after 5, 15–30 min and then every 3 h for one day. The interaction of PNB with G-1 was studied in a similar manner.

Study of the Stability of Catalyst G-1

Catalyst G-1 (17 mg, 0.21 mmol) was placed in a Young NMR tube and evacuated, 0.85 mL of CDCl3 was added, and the resulting mixture was stirred. The tube was immediately placed in the NMR spectrometer, and the spectra were taken at a temperature of 40°С first after 15–30 min and then every 3 h for one day.

RESULTS AND DISCUSSION

Synthesis of PCDD and PNB

PCDD and PNB homopolymers were prepared for macromolecular cross-metathesis experiments. The initial homopolymer PCDD was obtained by the ring-opening metathesis polymerization of CDD:

Commercial Ru-carbene complexes G-1 and G‑2 were used to initiate the polymerization of CDD. A polymerization technique was developed, and the conditions of CDD polymerization were chosen (Table 1). In the presence of catalyst G-1 the polymer was synthesized with a low yield and a small MW (experiment 1); it was poorly precipitated by alcohol. Catalyst G-2 turned out to be more efficient. Varying the reaction time and the monomer/catalyst molar ratio allowed us to choose the conditions of PCDD synthesis with high yield, MW, and content of trans-С=С units (experiment 3); this polymer was used in further cross-metathesis experiments. Table 1 shows the conditions of synthesis and characteristics of PCO (experiment 6) and PNB (experiments 4, 5), which were prepared by the metathesis polymerization of CO and NB mediated by catalyst G-1:

The reactivity of monomers in metathesis poly-merization is determined by the strain of the ring being opened; therefore, in the presence of catalyst G-1 the yield and Мw of the polymer decrease in the sequence PNB–PCO–PCDD.

Cross-Metathesis in the System PNB–PCDD–G-1

The reaction of interchain cross-metathesis between PNB and PCDD was carried out in chloroform solution using catalyst G-1:

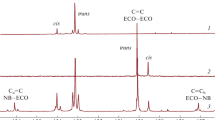

Prior to the reaction, the initial homopolymers were purified of residual catalyst and inhibitor. A high concentration of polymers in solution is a requirement for successful interchain exchange between homopolymers via the cross-metathesis scheme. Otherwise, the process of intrachain metathesis giving rise to cyclooligomers becomes competitive. In [21–24], chloroform was used as a solvent for the cross-metathesis of PNB and PCO, which made it possible to prepare quasi-homogeneous solutions of the homopolymer blend with a concentration of 6–8 wt %. At a higher concentration, aggregation of PCO chains occurred, as evidenced by dynamic light scattering [22]. The concentration of homopolymers [PNB + PCDD] in experiments was taken as 0.5 mol/L for comparison with the previously studied cross-metathesis between PNB and PCO under the same conditions. When the total concentration of homopolymers PNB and PCDD was increased to 1 mol/L, their mixture swelled but did not dissolve. It was found that PCDD is distinguished by higher Tm compared to PCO and limited solubility in chloroform at room temperature. The complete solubility of PCDD in chloroform was attained under heating to 40°С; therefore, the reaction mixture preparation, experiments and NMR spectra recording were performed for the most part at this temperature. When the solution of catalyst G-1 was added to the reaction mixture, the viscosity of the blend decreased due to reduction in the average MW of homopolymers because of interaction of the catalyst with polymer chains. After the specified time, the reaction was stopped by adding ethyl vinyl ether. The synthesized new copolymers NB–CDD were precipitated into methanol and characterized by NMR, DSC, and GPC (Table 2). The formation of copolymers is confirmed by the appearance of signals due to carbon in heterodyads in the region of double bonds in the NMR spectra (Fig. 1). Signals were assigned using the published data [34–36] and our previous results [21–24]: the signal of carbon at the double bond in the NB unit (Сa) of heterodyad NB–CDD is shifted to a weaker filed relative to position of the analogous signal in homodyad NB–NB (Сc,d), while the signal of carbon at the double bond in the CDD unit (Сb) of heterodyad CDD–NB is shifted to a stronger field relative to position of this signal in homodyad CDD–CDD (Сe,f).

Carrying out experiments with an increased content of the catalyst, in which the integral signals of heterodyads are more pronounced (Fig. 1, spectra 3, 4), and using a specially selected regime for recording 13С{1H} NMR spectra, we managed to more accurately assign signals in the region of double bonds which are presented in Experimental. As in [21, 23], the average blocks length in the copolymers was determined from the ratio of integral intensities of signals due to homodyads and heterodyads:

As follows from the NMR data, as a result of interaction between PNB and PCDD carried out at 40°С in the presence of 5 mol % G-1, already after 5 h, the blocks length reaches ≈2.5 units and then slowly decreases; after 24 h, it approaches the equilibrium value of two, which is typical of a completely random copolymer of equimolar composition (Table 2, experiments 3–5; Fig. 2).

With decreasing concentration of the catalyst, a multiblock copolymer with longer blocks formed within the predetermined time (Table 2, experiments 9, 14; Fig. 2).

The ratio of average lengths of NB and CDD blocks in the copolymer can be controlled by varying the composition of the initial blend (experiments 15, 16). As the fraction of PNB in the initial blend increases at fixed concentrations of the homopolymers and catalyst, cross-metathesis proceeds more intensively (experiment 15): the degree of blockiness increases, while the average blocks length and the MW of the copolymer, on the contrary, decrease compared with the reaction in the equimolar initial blend (experiments 12, 13). A similar behavior was observed earlier for the PNB–PCO blend. This result agrees with the kinetic study of evolution in the concentration of active centers of reaction—Ru-carbene complexes [22]. At the initial cross-metathesis stage, Ru=PCO complexes are formed via the interaction of G-1 with PCO. Subsequently, the limiting stage is the interaction of Ru=PCO with PNB macromolecules; therefore, an increase in the concentration of PNB entails a rise in the total rate of the process.

It is interesting that the GPC chromatograms of NB–CDD copolymers isolated by concentration of the reaction mixture in vacuum show two peaks corresponding to high-molecular-weight and low-weight-molecular reaction products (Table 2, Fig. 3). Upon precipitation into alcohol, the fraction of the low-molecular-weight product decreases appreciably (Table 2, experiment 7).

It is known that in metathesis polymerization, CDD shows a tendency towards cyclization during intramolecular metathesis: in the case of classical W-containing catalysts, cyclooligomers consisting of two to seven units are formed [34, 37–39] and chromatography–mass spectrometry studies reveal the formation of even cathenanes—interlocked chemically unbound cyclic molecules [40]. For the detected low-molecular-weight peak Мw≈ (1–2) × 103 and the MW of the monomer unit of CDD is 166; hence, the low-molecular-weight fraction can consist of molecules containing four to six CDD units. This agrees with the published data presented above. The proportion of the low-molecular-weight fraction depends on catalyst concentration and reaction time (Figs. 3, 4).

At a high concentration of the catalyst (Fig. 4, curve 1), the low-molecular-weight products form very rapidly and already after 1.5 h, their proportion reaches 50% of the total amount of reaction products. Subsequently, the proportion of the oligomer fraction decreases to 17% (Table 2, experiment 5). The decrease is especially pronounced at the late stages of the process, when the average blocks length is ≈2 units. It can be assumed that initially cyclooligomers are formed via intramolecular metathesis involving flexible PCDD chains. During cross-metathesis more rigid NB units, which, as is known, hamper the formation of cycles with a small number of units [34], are involved in the structure of oligomers. As a result, the proportion of the low-molecular-weight fraction decreases in the course of time. As the amount of the added catalyst is decreased, the concentration of active centers declines while the average MW of the polymer increases. For this reason, both the rate of formation and the proportion of oligomers in the reaction products become much smaller (Fig. 4, curves 2, 3).

When cross-metathesis between PNB and PCO was studied at room temperature, no low-molecular-weight products were observed on the GPC chromatograms (Table 2, experiment 22) [22]. However, in this study, at 40°С products with a molecular weight close to the MW of CDD oligomers corresponding to ≈10 CO units appeared (experiment 17). According to [39, 41–45], CO can give rise to cyclooligomers with a number of units from 2 to 12. It appears that the increasing temperature increases the flexibility of PCO chains. As a consequence, the contribution of intramolecular reaction to the initial stages of cross-metathesis increases and the formation of cyclooligomers intensifies. The degree of blockiness of the CO‒NB copolymers synthesized over the desired time also increases with temperature (cf. experiments 17 and 18 and 21 and 22 in Table 2).

Comparison of the average blocks length in the copolymers that formed at 40°С in PNB blends with PCO and PCDD implies that in the first case, cross-metathesis occurs at a higher rate. The difference in the reactivities of PCO and PCDD in cross-metathesis with PNB is more distinct at a lower concentration of the catalyst. In accordance with Table 2, for [G‑1] = 0.33 mol %, the average blocks length is 18–20 in the copolymer NB–CO (experiment 21) and 49–50 in the copolymer NB–CDD (experiment 13). In our opinion, this difference may be explained by a longer methylene sequence in the CDD unit, which can decrease the polarity of the polymer and worsen its affinity for the polar solvent (chloroform). Therefore, the number of interchain contacts in the PCDD–PNB blend is smaller than that in the PCO–PNB blend, as evidenced by a higher melting temperature of PCDD compared with PCO, and the rate of reaction declines. With increasing catalyst concentration a marked amount of oligomers is formed, the solution becomes more homogeneous, and, as a result, the average blocks length in the copolymers NB–CO and NB–CDD takes similar values.

Interestingly, at room temperature, despite limited solubility in chloroform, PCDD is also involved in cross-metathesis with PNB in the presence of G-1 (Table 3), as indicated by the appearance of signals due to heterodyads in the 13С NMR spectra. At the same time, a broad MWD and thermal properties close to the properties of PCDD may provide evidence that the reaction products contain a considerable amount of unreacted homopolymers.

Comparison of the behavior of PCO and PCDD in the reaction with PNB suggests that PCO soluble at room temperature reacts with PNB without heating more actively than PCDD and forms multiblock copolymers NB–CO with shorter blocks (Table 3, experiments 2, 3).

Kinetic Studies

An advantage of Ru-containing catalytic systems, along with stability in air and tolerance to many functional groups, is that the signal due to the proton of carbene Сl2(PCy3)2Ru=СН–Ph (20 ppm) can be observed in the 1Н NMR spectrum. This makes it possible to monitor the active centers of the metathesis reaction. We developed the technique for studying the transformations of Ru-carbene complexes during the cross-metathesis of polymers using 1Н NMR monitoring [22]. Taking into account the experimental data we advanced the kinetic scheme to quantitatively describe cross-metathesis in the system PNB–PCO–G-1 at room temperature as a set of elementary reactions of transformation of the initial carbene into the polymer one via chain break up and addition of the active center to the end group, decay of carbenes, and interchain exchange involving end groups of the polymer carrying carbenes [22].

In this study, this approach was applied to investigate cross-metathesis in the PNB–PCDD–G-1 system. Because of the limited solubility of PCDD in chloroform at room temperature, kinetic studies with this polymer were performed at 40°С. For comparison, similar measurements at this temperature were also carried out for the PNB–PCO–G-1 system.

Initially, the stability of the G-1 solution in СDCl3 was studied (Fig. 5). The catalyst is stable at 25°С for one day; however, at 40°С, the amount of active centers decreases by 15% within the first 2 h and in one day ≈50% of these centers is lost. Using the data in Fig. 5 and assuming that the decomposition of the catalyst is the first-order reaction, we find that its rate constant is kd = 5.4 × 10–6 s–1.

Next we studied the interaction of catalyst G-1 with homopolymers PCDD and PNB separately:

In the PCDD–G-1 system, at the early stage, the initial carbene of the catalyst is almost completely transformed into [Ru]=PCDD, the concentration of which then gradually decreases and after 20 h it is 50% of the maximum value (Fig. 6а). The interaction of PNB with G-1 (40°С) proceeds much more slowly, because the stages of formation of polymer carbene [Ru]=PNB and the decay of carbenes overlap in time (Fig. 6b). With increase in temperature from 25 to 40°С, the rate of all elementary reactions grows. A comparison of Figs. 6а and 6b suggests that at 40°С carbene [Ru]=PNB is decayed more rapidly than [Ru]=PCDD. Because the polymers are present, as a minimum, in a 20-fold excess with respect to the catalyst, it can be assumed that the transformation of the initial carbene [Ru]=CHPh into the polymer carbene is the first-order irreversible reaction as well as the decay of carbenes of any type. An analysis of the kinetic data makes it possible to calculate rate constants for the formation of polymer carbenes k1 and k2 and their decay k1d and k2d (Table 4).

The equation expressing the concentration с0 of initial carbenes can be written as dc0/dt = \( - {{k}_{1}}{{c}_{{\text{p}}}}{{c}_{0}}\) – \({{k}_{{\text{d}}}}{{c}_{0}}\), where the first term in the right-hand side describes transformation of the initial carbene [Ru]=CHPh to the polymer one, the second term describes its decay, and cp is the polymer concentration. Because in experiments with PCDD kd = 5.4 × 10–6 s–1\( \ll \)k1cp ≈ 9.5 × 10–3 L/(mol s) × 0.5 mol/L ≈ 5 × 10–3 s–1, the spontaneous decomposition of catalyst G-1 can be neglected.

In the solution of the PNB–PCDD–G-1 blend, polymer carbenes can enter into exchange reactions with С=С bonds in units of different type, which leads first to the formation of copolymers and then to an increase in their degree of blockiness:

These reversible elementary reactions are characterized by the rate constants k122, k212, k211, and k112. A system of kinetic equations describing evolution of the system in terms of concentrations of carbenes and the proportion of heterodyads in the copolymer is presented in [22].

According to 1Н NMR monitoring (Fig. 7), except for the initial stage of reaction, mostly carbenes [Ru]=PCDD and, to a much lesser concentration, carbenes [Ru]=PNB and initial carbenes [Ru]=СНРh are present in the PNB–PCDD–G-1 system (Fig. 8). Despite the fact that, according to the 13С NMR data, the copolymer NB–CDD is formed in the blend, the fraction of heterodyads in it approaches 0.5 within one day. As mentioned in [22], this behavior is possible if the rate of the elementary reaction k211 between the carbene [Ru]=PNB and С=С bond in the CDD unit is much higher (by two orders of magnitude) than the rate of reaction k122 between the carbene [Ru]=CDD and double bond in the NB unit. This observation may be explained by steric factors and requires further studies.

(Color online) Kinetics of carbene fractions: (1) [Ru]=СНРh, (2) [Ru]=PCDD, and (3) [Ru]=PNB and (4) heterodyads NB–CDD during cross-metathesis between PNB and PCDD. The molar ratio of [PNB] : [PCDD] : [G-1] = 10 : 10 : 1, cp = 0.5 mol/L, and Т = 40°С. Figures refer to the experimental data, and curves refer to calculations according to the kinetic model developed in [22].

The values of the rate constants of exchange and other elementary reactions listed in Table 4 make it possible to satisfactorily describe the experimental data on a change in the fraction of carbenes of various types and heterodyads in the copolymer NB–CDD for the system PNB–PCDD–G-1 using the kinetic model, which was previously developed for the system PNB–PCO–G-1 (Fig. 8).

To correctly compare the intensities of cross-metathesis in PNB blends with PCO and PCDD, the kinetics of transformation of Ru-carbene complexes in the PNB–PCO–G-1 system at 40°С was investigated and compared with the data obtained at 25°С [21]. Using 1Н NMR monitoring, we first studied the interaction of G-1 with homopolymers PNB and PCO separately and then with the blend of these polymers according to the above-described technique. For the blend, the 13С NMR data on the change in fraction of heterodyads in the copolymer NB–CO formed during cross-metathesis were also used. As follows from Fig. 9, our kinetic model can describe in a unified way the experimental data obtained for the PNB–PCO–G-1 system both at 25 and 40°С. The rate constants of elementary reactions used for this are given in Table 4.

(Color online) Kinetics of carbene fractions (1) [Ru]=СНРh, (2) [Ru]=PCO, and (3) [Ru]=PNB and (4) heterodyads NB–CO during cross-metathesis in the system PCO–PNB–G-1 at 25 (open figures) and 40°С (closed figures). The molar ratio of [PNB] : [PCDD] : [G-1] = 10 : 10 : 1. Figures—refer to the experimental data, and curves refer to calculations according to the kinetic model developed in [22].

It is seen that an increase in the temperature of reaction by 15°С causes an increase in the formation rate of polymer carbenes [Ru]=PCO (k1) by an order of magnitude. The decay rate of carbenes (k1d, k2d) increases by ≈30 times, and the rate of interchain exchange (k211, k122) increases by ≈8 times. It is significant that an increase by ≈40 times is observed for the formation rate of polymer carbenes [Ru]=PNB from [Ru]=CHPh (k2); however, it still remains an order of magnitude lower than that of carbenes [Ru]=PCO.

Note also that at 40°С and an initial concentration of G-1 of 5 mol %, the rates of all elementary reactions for PNB blends with PCO and PCDD differ insignificantly, except for the reaction of transformation of initial carbenes into polymer ones, where Ru=[PCO] is formed at a rate three times higher than for Ru=[PCDD]. This is apparently due to the higher thermodynamic affinity between PCO and chloroform.

In this study, the reaction of macromolecular cross-metathesis mediated by the first-generation Grubbs catalyst in the chloroform solution of the polynorbornene–polydodecenamer blend was investigated in greater detail. The main specific features of this system compared with the polynorbornene–polyoctenamer pair are related to the greater length of the methylene sequence in the PCDD unit, which is responsible for worse quality of the solvent for this polymer. Multiblock copolymers of norbornene and cyclododecene were synthesized for the first time. The thermal and crystalline properties of these copolymers will be the subject of a separate publication.

REFERENCES

V. Sh. Fel’dblyum, Synthesis and Application of Unsaturated Cyclic Hydrocarbons (Khimiya, Moscow, 1982) [in Russian].

US Patent No. 4.048.262 (1977).

L. M. Vardanyan, Y. V. Korshak, M. P. Peterina, and B. A. Dolgoplosk, Dokl. Akad. Nauk SSSR 207, 345 (1972).

E. Ceausescu, A. Cornilescu, E. Nicolescu, M. Popescu, S. Coca, M. Cuzmici, and V. Dragutan, J. Mol. Catal. 46, 415 (1988).

S. Coca, M. Dimonie, V. Dragutan, R. Ion, L. Popescu, M. Teodorescu, F. Moise, and A. Vasilescu, J. Mol. Catal. 90, 101 (1994).

S. Karabulut, S. Çetinkaya, B. Düz, and Y. Imamoğlu, Appl. Organomet. Chem. 18, 375 (2004).

S. Ramakrishnan, Macromolecules 24, 3753 (1991).

W. Panagiotis Dounis, J. Feast, and A. M. Kenwright, Polymer 36, 2787 (1995).

V. I. Bykov, B. A. Belyaev, T. A. Butenko, and E. Sh. Finkel’shtein, Pet. Chem. 56, 62 (2016).

M. F. Z. Lerum and W. Chen, Langmuir 27, 5403 (2011).

S. J. McLain, B. B. Sauer, and L. E. Firment, Macromolecules 29, 8211 (1996).

C. Gascon, F. Lucas, S. Carlotti, and A. Deffieux, J. Appl. Polym. Sci. 118, 1830 (2010).

C. W. Lee, T.-L. Choi, and R. H. Grubbs, J. Am. Chem. Soc. 124, 3224 (2002).

J. Zhang, G. Li, and N. S. Sampson, ACS Macro Lett. 7, 1068 (2018).

M. L. Gringolts, Y. I. Denisova, E. Sh. Finkelshtein, and Y. V. Kudryavtsev, Beilstein J. Org. Chem. 15, 218 (2019).

H. Otsuka, T. Muta, M. Sakada, T. Maeda, and A. Takahara, Chem. Commun. 2009, 1073 (2009).

T. Maeda, S. Kamimura, T. Ohishi, A. Takahara, and H. Otsuka, Polymer 55, 6245 (2014).

T. Ohishi, K. Suyama, S. Kamimura, M. Sakada, K. Imato, S. Kawahara, A. Takahara, and H. Otsuka, Polymer 78, 145 (2015).

M. R. Radlauer, M. E. Matta, and M. A. Hillmyer, Polym. Chem. 7 (40), 6269 (2016).

C. Descour, T. Macko, I. Schreur-Piet, M. P. F. Pepels, and R. Duchateau, RSC Adv. 5, 9658 (2015).

M. L. Gringolts, Yu. I. Denisova, G. A. Shandryuk, L. B. Krentsel, A. D. Litmanovich, E. S. Finkelshtein, and Y. V. Kudryavtsev, RSC Adv. 5, 316 (2015).

Yu. I. Denisova, M. L. Gringolts, A. S. Peregudov, L. B. Krentsel, E. A. Litmanovich, A. D. Litmanovich, E. Sh. Finkelshtein, and Y. V. Kudryavtsev, Beilstein J. Org. Chem. 11, 1796 (2015).

Yu. I. Denisova, M. L. Gringolts, L. B. Krentsel’, G. A. Shandryuk, A. D. Litmanovich, E. Sh. Finkelshtein, and Y. V. Kudryavtsev, Polym. Sci., Ser. B 58, 292 (2016).

G. A. Shandryuk, Yu. I. Denisova, M. L. Gringolts, L. B. Krentsel, A. D. Litmanovich, E. Sh. Finkelshtein, and Y. V. Kudryavtsev, Eur. Polym. J. 86, 143 (2017).

R. Walker, R. M. Conrad, and R. H. Grubbs, Macromolecules 42, 599 (2009).

P. V. R. Schleyer, J. E. Williams, and K. R. Blanchard, J. Am. Chem. Soc. 92, 2377 (1970).

A. Keller and E. Martuscelli, Makromol. Chem. 141, 189 (1971).

A. Keller and E. Martuscelli, Makromol. Chem. 151, 169 (1972).

E. Martuscelli and V. Vittoria, Polymer 13, 360 (1972).

K. V. Werden and K. Holland-Moritz, Colloid Polym. Sci. 259, 731 (1981).

C. Liu, H. Qin, and P. T. Mather, J. Mater. Chem. 17, 1543 (2007).

E. S. Finkelshtein, M. V. Bermeshev, M. L. Gringolts, L. E. Starannikova, and Y. P. Yampolskii, Russ. Chem. Rev. 80, 341 (2011).

G. Floros, N. Saragas, P. Paraskevopoulou, N. Psaroudakis, S. Koinis, M. Pitsikalis, N. Hadjichristidis, and K. Mertis, Polymers 4, 1657 (2012).

K. J. Ivin and J. C. Mol, Olefin Metathesis and Metathesis Polymerization (Acad. Press, London, 1997).

M. Lichtenheldt, D. Wang, K. Vehlow, I. Reinhardt, C. Kuhnel, U. Decker, S. Blechert, and M. R. Buchmeiser, Chem.-Eur. J. 15, 9451 (2009).

V. Amir-Ebrahimi and J. J. Rooney, J. Mol. Catal. A: Chem. 208, 115 (2004).

R. Wolovsky, J. Am. Chem. Soc. 92, 2132 (1970).

V. M. Kuteinikov, Yu. V. Korshak, and B. A. Dolgoplosk, Tr. Mosk. Khim.-Tekhnol. Inst. 86, 117 (1975).

H. Höcker, W. Reimann, K. Riebel, and Z. Szentivanyi, Makromol. Chem. 177, 1707 (1976).

D. A. Ben-Efraim and C. Batich, J. Am. Chem. Soc. 92, 2133 (1970).

H. Höcker and R. Müsch, Macromol. Chem. 157, 201 (1972).

H. Höcker and R. Müsch, Macromol. Chem. 175, 1395 (1974).

H. Höcker, L. Reif, W. Reinmann, and K. Riebel, Recl. Trav. Chim. Pays-Bas 96, M47 (1977).

H. Höcker, J. Mol. Catal. 65, 95 (1991).

L. Reif and H. Höcker, Macromolecules 17, 952 (1984).

ACKNOWLEDGMENTS

The structure of the synthesized compounds was studied using equipment of the Shared Research Center of the Topchiev Institute of Petrochemical Synthesis, Russian Academy of Sciences, and the Center for Molecular Composition Studies of the Nesmeyanov Institute of Organoelement Compounds, Russian Academy of Sciences.

Funding

This study was supported by the Russian Science Foundation (project no. 17-73-10450).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by T. Soboleva

Rights and permissions

About this article

Cite this article

Denisova, Y.I., Zhigarev, V.A., Gringolts, M.L. et al. Cyclododecene in Olefin Metathesis: Polymerization and Macromolecular Cross-Metathesis with Polynorbornene. Polym. Sci. Ser. C 61, 120–133 (2019). https://doi.org/10.1134/S1811238219010053

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1811238219010053