Abstract

The authors perform a systematic study of the reaction of radical replacement of the dithiocarbonyl group of poly(methyl methacrylate) (PMMA) obtained by reversible addition–fragmentation chain transfer polymerization upon interaction with a radical azo initiator in an inert solvent at 80°C. It is shown that, for a polymer with a dithiobenzoate group, an increase in the molar ratio of the concentrations of the initiator and macromolecules with a terminal dithiobenzoate group to 100 equivalents promotes fast and quantitative replacement of the dithiobenzoate group by the initiator fragment and suppression of side chain termination reactions with the participation of radical intermediates. To replace the trithiocarbonate group, milder conditions are required, namely, a 20-fold molar excess of the initiator and a short reaction time of 2–5 h. The stability of the radical intermediates plays the decisive role in choosing the replacement reaction conditions. The reversible chain transfer agent formed during the replacement reactions, a low-molecular-weight compound containing a dithiocarbonyl fragment, can be repeatedly used for PMMA synthesis.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

INTRODUCTION

Reversible deactivation radical polymerization has been widely used in recent decades to synthesize macromolecules with a targeted molecular weight, structure, and nature of the RAFT agent architecture [1–5]. Reversible addition–fragmentation chain transfer (RAFT) polymerization, which is not only tolerant to the functional groups of monomers but which also yields polymers with the targeted functionality of the terminal groups [6–12], should be distinguished among its known versions. According to the RAFT polymerization mechanism [13–19], terminal α and ω groups in the macromolecules formed with an efficient RAFT agent under the condition [RAFT agent] : [initiator] \( \gg \) 1 are exclusively determined by the chemical R–S–C(=S)–Z and are the leaving group R and ‒S‒C(=S)–Z fragment of the RAFT agent, respectively; i.e., the structure of the macromolecules can be generally presented as R–Pn–S–C(=S)–Z.

As shown by multiple studies, the ω group is a convenient object for further modification that expands the potential application of the RAFT process in macromolecular design [5, 9, 10, 20]. Among the known techniques for modifying the dithiocarbonyl group summarized in a number of reviews and articles, the most commonly used in practice are thermolysis of the dithiocarbonyl group leading to the appearance of a terminal C=C multiple bond; interaction with nucleophiles and/or reducing agents, which results in the formation of a SH thiol group; and reaction with radical initiators which results in the replacement of a dithiocarbonyl group by the fragment of the initiator [19–37].

One convenient technique for removing the dithiocarbonyl group and its replacement by a different terminal functional group in a polymer is its treatment with an excess of a radical initiator in an inert solvent. In this case, radicals are formed upon decomposition of the initiator, which are added to the macromolecule via the C=S bond to form a radical intermediate. The fragmentation of the intermediate leads to the release of a macroradical that terminates on the radicals of the initiator under an excess of the radical initiator X–X, while in the presence of traps (H donors), it terminates on them:

The method of removing a terminal dithiocarbonyl group in PMMA (dithiobenzoate) and PC (dithiobenzoate and trithiocarbonate) using a radical azo initiator was described for the first time in [19]. The formation of a low-molecular-weight RAFT agent was chromatographically confirmed. The molecular weight distribution (MWD) of the polymer remains unchanged after the reaction, while according to the results of UV spectroscopy, absorption at 510 nm, which according to the authors corresponds to the dithiocarbonyl group is no longer recorded in the polymer. This reaction proceeds quantitatively over 2.5 h at 80°C and a molar ratio [initiator] : [RAFT] = 20. Here, the formation of the RAFT agent X‒SC(=S)Z takes place during the synthesis. The authors demonstrated a double RAFT agent regeneration cycle: synthesis of PMMA under the action of the X–SC(=S)Z RAFT agent—treatment of the polymer with a 20-fold excess of the initiator X–X—separation of the RAFT agent X–SC(=S)Z—synthesis of PMMA—etc.

Such a procedure was used to prepare telechelic PMMA with terminal –C(CH3)(CN)CH2CH2C (=O)OC6F5 pentafluorophenyl ester groups by the interaction of PMMA with a terminal dithiobenzoate group and a 20-fold excess of a suitable initiator [38].

Despite the apparent simplicity of this experiment, 100% replacement of a terminal dithiocarbonyl group in polymers does not always occur [21, 24, 28, 33–35]. Moreover, there are certain limitations even for PMMA. For example, the formation of a side product with a higher molecular weight (MW) is also possible in the case of a molar excess of the initiator in relation to the dithiobenzoate groups of the polymer [39]. Similar results were also obtained for poly(n-butyl acrylate) with a terminal dithiobenzoate group. Detailed analysis of the possible reactions showed that termination reactions with the participation of intermediates, macroradicals, and radicals of the initiator, may be the reason for it [40].

The results of such experiments for different polymers are systematized in several reviews [6–11]. More detailed studies of the reaction of the replacement of terminal dithiobenzoate and trithiocarbonate groups by a radical residue in polystyrene [33, 34] and poly(n-butyl acrylate) [33] demonstrated that, for them, the degree of replacement is far from 100%: 20 to 80% depending on the concentration of the initiator. The efficiency of the replacement reaction can be increased either by adding lauroyl peroxide or benzoyl peroxide to the azo initiator [33] or by introducing an H donor (e.g., toluene, isopropanol, tributyltin, silanes, or hypophosphites) [11, 21, 41]. The latter version was used for PMMA with a terminal trithiocarbonate group [21]; however, there is no published information on its direct reaction with an initiator without an H donor. Despite the multiple data on the replacement reaction of a dithiocarbonyl group in polymers, most studies are devoted to styrene and alkyl acrylates. Study [19], in which the behavior of PMMA with a dithiobenzoate group in a similar reaction is analyzed, is the solitary example, while there are no such data whatsoever for PMMA with a trithiocarbonate group. Earlier we showed by the example of a series of vinyl polymers that complete replacement of a trithiocarbonate group requires a higher concentration of the radical initiator and a longer reaction time [28, 42]. From our viewpoint, the question about the role of side processes in the replacement reaction in PMMA with a dithiobenzoate group remains open.

The aim of this study is systematic investigation of the influence of the molar ratio of the concentrations of the initiator and dithiocarbonyl groups in the polymer and reaction time on the efficiency of radical replacement in PMMA with two types of terminal groups, dithiobenzoate and trithiocarbonate. Based on the results of our previous studies and published data, we planned to determine the optimum reaction conditions. As expected, these conditions were different, determined by the stability of the radical intermediates formed in the first place.

EXPERIMENTAL

Methyl methacrylate (MMA) was distilled in vacuum prior to use. Azobis(isobutyronitrile) (AIBN) was recrystallized from methanol. 4-Cyanopentanoic acid 4-S-dithiobenzoate (CPADB) and 2-cyano-2-propyl dodecyl trithiocarbonate (CPDTC) (Aldrich) were used without additional purification. The solvents were purified according to standard procedures.

For the synthesis of poly(methyl methacrylate)dithiobenzoate (PMMA-B), the specified amounts of AIBN and CPADB were dissolved in freshly distilled MMA. The reaction mixture was poured into an ampoule, degassed to a residual pressure of ~5 × 10−3 mmHg, and sealed. The ampoule was placed in a thermostat at 80°C and polymerized for 24 h, cooled in liquid nitrogen, and opened; the formed polymer was precipitated into a tenfold excess of cold methanol and filtered off. Then the polymer was dissolved in a tenfold excess of benzene and lyophilized. According to the gel permeation chromato-graphy (GPC) data, Mn = 7.8 × 103 and Ð = 1.12.

The synthesis of poly(methyl methacrylate)trithiocarbonate (PMMA-C) was performed in a similar manner using CPDTC as a RAFT agent. According to the GPC data, Mn = 7.7 × 103 and Ð = 1.25.

To study the replacement reaction of a thiocarbonyl group by the cyanoisopropyl group of the initiator, AIBN, a solution of PMMA-B or PMMA-C and AIBN in benzene was prepared. The molar ratio of the concentrations of the initiator and thiocarbonyl terminal groups of the polymer was varied as 20 : 1, 40 : 1, and 100 : 1. The solution was poured in an ampoule and degassed; the ampoule was sealed and placed in a thermostat at 80°C for 2.5, 5, or 24 h. Upon completion of the experiment, the ampoule was cooled and the polymer was precipitated into a tenfold excess of cold hexane and centrifuged. The polymer precipitate was dissolved in a tenfold excess of benzene and lyophilized in vacuum. The polymer was dissolved in tetrahydrofuran (THF) and analyzed by UV spectro-scopy.

The mother liquor was decanted and evaporated on a rotary evaporator, the formed residue was dissolved in THF, and the UV spectrum was recorded. Then THF was evaporated to dryness. MMA was added to the dry residue obtained in the experiments with heating for 2.5 and 5 h, while MMA containing 10−3 mol/L AIBN was added to that obtained after heating for one day. The reaction mixtures were poured into ampoules, degassed to a residual pressure of ~5 × 10−3 mmHg via four freeze–thaw cycles, and sealed; the ampoules were placed into a thermostat and heated up to 80°C for 4 h. The mixtures were diluted with benzene, and the polymer was lyophilized and analyzed by GPC.

The concentration of dithiocarbonyl groups in the polymers was determined by UV spectroscopy using the values of the molar absorptivity coefficient for CPADB and CPDTC determined in [43]. The spectra of the polymers solutions in THF were recorded on a Unico 2804 spectrophotometer (United States).

The molecular weight characteristics of the polymers were analyzed by GPC in dimethylformamide (DMF) with 0.1 wt % LiBr at 50°C on a GPC-120 chromatograph (PolymerLabs) equipped with two PLgel 5 µm MIXED B (M = (5 × 102)–(1 × 107)) columns and a differential refractometer. Narrowly dispersed PMMA standards were used for calibration.

RESULTS AND DISCUSSION

Poly(methyl methacrylate) with a Terminal Dithiobenzoate Group

The heating of PMMA with a terminal dithiobenzoate group with a radical initiator in an inert solvent induces a chain of successive reactions.

According to Scheme 1, a radical intermediate Int-1• is formed by the interaction between the radical of initiator X• and the polymer. The intermediate can decompose with the elimination of a macroradical \({\text{P}}_{n}^{\centerdot }\) and formation of an X–SC(=S)Z RAFT agent (Z = Ph). At a ratio [initiator] : [RAFT] \( \gg \) 1, the radicals of the initiator are capable of capturing macroradicals \({\text{P}}_{n}^{\centerdot }\) and intermediates Int-1•, as well as dying upon interaction with each other. When intermediates accumulate in the system, they can participate in quadratic or crisscross termination with macroradicals. An increase in the concentration of the compound X–SC(=S)Z leads to its involvement in a similar chain of addition–fragmentation–termination reactions, during which a new intermediate Int-2• appears. Quadratic termination of macroradicals under these conditions is unlikely.

Scheme 1.

We performed a series of experiments in which PMMA-B (3.5 × 10−3 mol/L) was heated with a 20-, 40-, and 100-fold molar excess of AIBN in a solution in benzene at 80°C for 2.5, 5, and 24 h (τ1/2 = 90 min [44]). It should be noted that the color of the polymer isolated after reprecipitation changed from pink to white, and the higher the concentration of AIBN, the faster. The change in the color unambiguously indicates a decrease in the concentration of chromophore dithiobenzoate groups in the polymer.

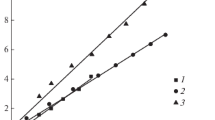

Figure 1 presents the GPC curves of the polymer before and after the reaction with AIBN normalized to the unit area. At [AIBN] : [PMMA-B] = 20 : 1, the GPC curves of the polymers become bimodal after the reaction with AIBN. The position of the MW in the maximum of the peak of mode 1 is almost the same as the MW in the maximum of the peak of PMMA-B; its slight shift to the region of high MWs is determined by insignificant losses during the precipitation of the polymer. The value of the MW in the maximum of the peak of mode 2 is twice as high when compared to PMMA-B. An increase in the duration of the reaction slightly affects the ratio of the intensities of these modes. With an increase in the [AIBN] : [PMMA-B] molar ratio to 40 : 1, the pattern is not qualitatively changed, but the ratio of the areas of the modes is noticeably changed; thus, the intensity of the peak of mode 2 decreases, and it continues to do so with an increase in the reaction time. Finally, at a 100-fold molar excess of AIBN over the polymer, the MWD of the polymer becomes unimodal. It should be noted that the used system of chromatographic columns cannot record low-molecular-weight reaction products with M < 500.

Apparently, it is impossible to distinguish macromolecules with a terminal cyanoisopropyl group, PMMA–C(CH3)2(CN), and an initial dithiobenzoate group which have close MWs by GPC. A similar problem also arises with the termination products of the intermediate Int-1• on the radicals of the initiator, PMMA–SC(C(CH3)2(CN))(Ph)S–C(CH3)2(CN). Macromolecules for which the MW is higher than that of the initial polymer can only form as a result of termination of the radical intermediates with each other or macroradicals. However, it seems impossible to directly record the termination products of the radical intermediates by either NMR or MALDI-TOF spectrometry [45].

UV spectroscopy was used to analyze the concentration of dithiobenzoate groups in the polymer before and after the reaction with AIBN. The preliminary estimate showed that PMMA-B contained almost 100% living chains with a terminal dithiobenzoate group. After the interaction with AIBN, the amount of living polymer chains will decrease and will be zero in the case of complete replacement of a dithiobenzoate group by a cyanoisopropyl group. Figure 2 shows the UV spectra of PMMA-B before and after the reaction with AIBN. At a ratio of [AIBN] : [PMMA-B] = 20 : 1 (Fig. 2a), the intensity of the absorption corresponding to the dithiobenzoate group in the polymer (λ = 302–310 nm, ε = (16.0 ± 0.3) × 103 mol L−1 cm−1 [43]) sharply decreases after 2.5 h of the reaction. Then it decreases about another twofold after 5 h of the reaction and changes slightly after this. Table 1 presents the results of calculation of the fraction of living chains in the polymer. It is seen that the absorption of the residual dithiobenzoate groups is recorded even 1 day after the onset of the reaction in the polymer. In the case of an increase in the concentration of the initiator to [AIBN] : [PMMA-B] = 40 : 1 (Fig. 2b), the concentration of living chains in the polymer decreases over the same reaction time and, finally, at [AIBN] : [PMMA-B] = 100 : 1 (Fig. 2c), no absorption of dithiobenzoate groups is recorded already after 2.5 h of the reaction.

By analyzing the obtained data, it can be assumed that increasing the concentration of AIBN relative to PMMA-B leads to inhibition of the side reactions of termination of macroradicals on radical intermediates. In other words, the radicals of the initiator manage to terminate the PMMA• radicals before their interaction with the Int-1• or Int-2• intermediates. Therefore, the higher the AIBN concentration, the more probable the reaction of the radicals of the initiator with the macroradicals and intermediate Int-1•. From this standpoint, a ratio of [AIBN] : [PMMA-B] = 100 : 1 and a relatively low absolute concentration of polymer chains preventing the formation of a noticeable concentration of intermediates are optimum.

In the case of precipitation of the polymer heated with AIBN into methanol, the mother liquor turns pink, which can only be associated with the formation of cyanoisopropyl dithiobenzoate (CPDB) PhC(=S)S–C(CH3)2(CN) containing a dithiobenzoate group. According to Scheme 1, no other products containing a dithiobenzoate group and absorbing at 302–310 nm can be formed in the system. However, the appearance of other low-molecular-weight compounds, products of termination with the participation of the radicals of the initiator and/or intermediate Int-2•, as well as residual initiator, cannot be ruled out. The supernatant was collected after precipitation of the polymer, the organic solvents were removed by evaporation in vacuum, and the dry residue was dissolved in THF and analyzed by UV spectroscopy (Fig. 3).

A clear correlation between the results in Figs. 2 and 3 is observed; thus, the intensity of the signal increases with the increase in the concentration of AIBN (i.e., more CPDB is formed). Therefore, the assumption that the growth in the concentration of AIBN leads to the inhibition of the side reaction of termination of macroradicals on the intermediate Int-1• was confirmed in an independent experiment. With the increase in the duration of the reaction, the intensity of the signal also increases.

After the recording of the UV spectra, THF was evaporated in vacuum and pure MMA was added to the dry residue, while MMA containing 10–3 mol/L AIBN was added to the residue isolated after 24 h. According to rough estimates, the concentration of CPDB in these experiments was 1.3–2.9 × 10–3 mol/L. The reaction mixtures were poured into ampoules, degassed, sealed, and placed into a thermostat at 80°C for 4 h. The obtained polymer was isolated and analyzed by GPC (Fig. 4, Table 1). All the formed polymers are characterized by a wide MWD. Within each series of experiments, the GPC curves of the postpolymerization products shift to the region of higher MWs with a reduction in the duration of the replacement reaction, i.e., with an increase in the concentration of CPDB, which is regenerating, and a decrease in the concentration of decomposed AIBN. Comparison with PMMA synthesized in the absence of CPDB reveals that the MWs of the polymers obtained in the above experiments are lower and the MWD is narrower. Conversely, PMMA synthesized in a control experiment with equimolar amounts of AIBN and CPDB is characterized by a narrower MWD and a higher MW than those for the polymers under discussion.

(1–3) GPC curves of the products of AIBN-initiated polymerization of MMA with the participation of CPDB isolated from experiments under heating with an excess of AIBN in benzene at 80°C for (1) 2.5, (2) 5, and (3) 24 h. [AIBN] : [PMMA-B] = (a) 20, (b) 40, and (c) 100. For comparison, Fig. 4a presents the GPC curves for PMMA obtained with (4) AIBN (10−3 ml/L) and (5) equimolar amounts of AIBN and CPDB (10−3 mol/L).

Apparently, the lower MWs and relatively wide MWD of the polymers obtained after the regeneration of CPDB can be determined by the high concentration of residual AIBN (Table 1). We used the idea described in [19] and introduced changes into the experiment: after the precipitation of the polymer, the mother liquor was collected and evaporated to dryness, after which the dry residue was heated in an oven at 95°C for 4 h. Almost no thermolysis of the RAFT agent occurs under these conditions [46]. We expected that residual AIBN would decompose as a result and the degree of control of the molecular weight characteristics of PMMA would increase.

The dry residues of the low-molecular-weight products isolated in the described experiments after the heating of PMMA-B for 2.5 h at a molar ratio of [AIBN] : [PMMA-B] = 20, 40, and 100 and after heating at 95°C were dissolved in THF and analyzed by UV spectroscopy. As is seen in the UV spectra (Fig. 5), the trend remains unchanged and the amount of regenerated CPDB grows with the increase in the initial concentration of AIBN.

Dry residues were dissolved in 2 mL of the monomer containing 10−3 mol/L AIBN, and the mixtures were poured into ampoules, degassed, and placed in a thermostat heated to 80°C for one day. The polymers were lyophilized from benzene and analyzed by GPC. As follows from Fig. 6, polymers with close MWs (Mn = 830–850 × 103 and Ð = 1.95–1.98, curves 1 and 2) are formed when 20- and 40-fold molar excesses of AIBN are used for the replacement of the dithiobenzoate group in PMMA-B and regeneration of CPDB, while its value is lower (Mn = 690 × 103, Ð = 1.99, curve 3) for a 100-fold excess of AIBN. This agrees with the UV spectroscopy data (Fig. 5): the CPDB concentration increases with an increase in the concentration of AIBN taken for the replacement, which is particularly what leads to the decrease in the MW of the postpolymer. Here, the MW of the polymers is higher than that in the previous experiments, which is related to the preliminary decomposition of AIBN upon heating of the dry residues and decrease in its contribution to the formation of chains. However, the MWD of the polymers is wider than that for the control sample obtained with CPDB and AIBN (curve 5) but is narrower than that for PMMA synthesized under the action of the same AIBN concentration (curve 4).

(1–3) GPC curves of the products of postpolymerization of MMA under the action of CPDB regenerated from PMMA-B at 80°C for 2.5 h. [AIBN] : [PMMA-B] = (1) 20, (2) 40, and (3) 100. For comparison, GPC curves for PMMA obtained with (4) AIBN (10−3 mol/L) and (5) equimolar amounts of AIBN and CPDB (10−3 mol/L).

Therefore, an increase in the molar ratio of the concentrations of AIBN and macromolecules with a terminal dithiobenzoate group up to 100 equivalents promotes fast and quantitative replacement of a dithiobenzoate group with the fragment of the initiator and inhibition of side reactions.

Poly(methyl methacrylate) with a Terminal Trithiocarbonate Group

The radical intermediates formed by trithiocarbonates are substantially less stable than those formed with the participation of dithiobenzoates [15]. It can be assumed that, under similar conditions, the probability of side reactions of termination of intermediates upon the interaction of PMMA-C with AIBN will be lower than that in the case of PMMA-B, and PMMA–C(CH3)2(CN) (Pn–X) and an unsymmetrical trithiocarbonate with cyanoisopropyl and dodecyl substituents X–SC(=S)S–C12H25 will mainly be formed (see Scheme 2).

Scheme 2.

Figure 7 shows the GPC curves of the polymer after interaction with AIBN normalized to the unit area. Irrespective of the [AIBN] : [PMMA-C] ratio and duration of the reaction, the GPC curves of the polymers remain unimodal and almost coincide with the curve of the initial polymer. Therefore, our assumption is confirmed: the probable formation of high-molecular-weight side termination products for PMMA with a trithiocarbonate group was substantially lower than for the dithiobenzoate groups.

Discoloration of the polymer is already observed after 2.5 h of the reaction with a 20-fold molar excess of the initiator. Figure 8 shows the UV spectra of the polymer purified of the low-molecular-weight reaction products via reprecipitation. The UV spectrum of the initial PMMA-C, for which the single absorption maximum at a wavelength λ = 309 nm (ε = 10.2 ± 0.9 × 103 mol L−1 cm−1) [43], which corresponds to a trithiocarbonate group, is characteristic, is presented for comparison. It is seen that a 20-fold molar excess of AIBN and 2.5 h of the reaction are sufficient for the almost complete replacement of the trithiocarbonate group in PMMA. Table 2 presents the results of calculating the fraction of living chains in PMMA-C. Comparison with the data for PMMA-B (Table 1) confirms that the rate of replacement of the trithiocarbonate group in PMMA is higher than for the dithiobenzoate group. This may be related to a higher fragmentation rate of trithiocarbonate intermediates than that for dithiobenzoate ones. Conversely, polymeric dithiobenzoate is more active in the addition reaction than similar trithiocarbonate [15, 40, 47].

The mother liquor obtained upon precipitation of the polymer heated with AIBN (20- and 40-fold molar excesses) into methanol was evaporated as described above, and the dry residue was analyzed. The yellowish color of the mother liquor is determined by the presence of S-(2-cyano-2-propyl)-S-dodecyl trithiocarbonate C12H25–SC(=S)S–C(CH3)2(CN) containing a chromophore trithiocarbonate group.

Figure 9 shows the UV spectra of the solutions of the low-molecular-weight products before and after heating of the residue at 95°C for 4 h. The intensity of absorption changes little with an increase in the duration of the reaction, which agrees with the above data on the almost complete replacement of the trithiocarbonate group already at a 20-fold molar excess of the initiator in the case of heating for 2.5 h.

UV spectra of THF solutions of the low-molecular-weight products of the reaction of PMMA-C with AIBN in benzene at 80°C for (1) 2.5, (2) 5, and (3) 24 h (a, b) isolated from the mother liquor after precipitation of the polymer and (c) additionally exposed at 95°C for 4 h. [AIBN] : [PMMA-C] = (a, c) 20 and (b) 40.

Therefore, as opposed to dithiobenzoate, the replacement reaction for trithiocarbonate requires milder conditions. To examine the possibility of regeneration of CPDTC under these conditions, a 10−3 mol/L solution of AIBN in 2 mL of MMA was added to the low-molecular-weight residue heated for 4 h at 95°C. The reaction mixture was polymerized at 80°C, and the polymer was isolated and analyzed by GPC. The obtained polymer is characterized by a wide MWD (Fig. 10, curve 1). However, its MW is lower than that for the control sample, i.e., PMMA obtained in the presence of 10−3 mol/L AIBN and in the absence of a RAFT agent.

CONCLUSIONS

It has been shown as a result of the systematic investigation of the radical replacement reaction by the example of PMMA with terminal dithiobenzoate and trithiocarbonate groups that, in the case of dithiobenzoate, the inhibition of the side termination reactions with the participation of radical intermediates occurs in the case of a hundredfold molar excess of the initiator relative to the dithiobenzoate groups. To replace a trithiocarbonate group, it is sufficient to use a 20-fold molar excess of the initiator. A low-molecular-weight RAFT agent forms during the replacement reactions, which can be repeatedly used for PMMA synthesis.

REFERENCES

D. A. Shipp, Polym. Rev. 51, 99 (2011).

Reversible Deactivation Radical Polymerization: Mechanisms and Synthetic Methodologies, Ed. by K. Matyjaszewski, H. Gao, B. S. Sumerlin, and N. V. Tsarevsky (ACS Symp. Ser., Washington, DC, 2018), Vol. 1284.

M. Destarac, Polym. Chem. 9, 4947 (2018).

B. Klumperman, in Encyclopedia of Polymer Science and Technology, Ed. by H. F. Mark (Wiley, New York, 2015), p. 1.

D. Vinciguerra, J. Tran, and J. Nicolas, Chem. Commun. 54, 228 (2018).

G. Moad, E. Rizzardo, and S. H. Thang, Polymer 49, 1079 (2008).

G. Moad, E. Rizzardo, and S. H. Thang, Aust. J. Chem. 62, 1402 (2009).

G. Moad, E. Rizzardo, and S. H. Thang, Polym. Int. 60, 9 (2011).

G. Moad, E. Rizzardo, and S. H. Thang, Aust. J. Chem. 65, 985 (2012).

H. Willcock and R. K. O’Reilly, Polym. Chem. 1, 149 (2010).

G. Moad, E. Rizzardo, and S. H. Thang, Polym. Int. 60, 9 (2011).

B. Chong, G. Moad, E. Rizzardo, M. Skidmore, and S. H. Thang, Aust. J. Chem. 59, 755 (2006).

Handbook of RAFT Polymerization, Ed. by C. Barner-Kowollik (Wiley-VCH, Weinheim, 2008).

C. Boyer, M. H. Stenzel, and T. P. Davis, J. Polym. Sci., Part A: Polym. Chem. 49, 551 (2011).

E. V. Chernikova and E. V. Sivtsov, Polym. Sci., Ser. B 59, 117 (2017).

G. Moad, Macromol. Chem. Phys. 215, 9 (2014).

J. Chiefari, Y. K. Chong, F. Ercole, J. Krstina, J. Jeffery, T. P. T. Le, R. T. A. Mayadunne, G. F. Meijs, C. L. Moad, G. Moad, E. Rizzardo, and S. H. Thang, Macromolecules 31, 5559 (1998).

C. Barner-Kowollik, M. Buback, B. Charleux, M. L. Coote, M. Drache, T. Fukuda, A. Goto, B. Klumperman, A. B. Lowe, J. B. McLeary, G. Moad, M. J. Monteiro, R. D. Sanderson, M. P. Tonge, and P. Vana, J. Polym. Sci., Part A: Polym. Chem. 44, 5809 (2006).

S. Perrier and P. Takolpuckdee, J. Polym. Sci., Part A: Polym. Chem. 43, 5347 (2005).

M. A. Harvison and A. B. Lowe, Macromol. Rapid Commun. 32, 779 (2011).

Y. K. Chong, G. Moad, E. Rizzardo, and S. Thang, Macromolecules 40, 4446 (2007).

C. W. Scales, A. J. Convertine, and C. L. McCormick, Biomacromolecules 7, 1389 (2006).

A. N. Zelikin, G. K. Such, A. Postma, and F. Caruso, Biomacromolecules 8, 2950 (2007).

G. Moad, Y. K. Chong, A. Postma, E. Rizzardo, and S. H. Thang, Polymer 46, 8458 (2005).

K. L. Heredia, G. N. Grover, L. Tao, and H. D. Maynard, Macromolecules 42, 2360 (2009).

A. J. Inglis, S. Sinnwell, T. P. Davis, C. Barner-Kowollik, and M. H. Stenzel, Macromolecules 41, 4120 (2008).

S. Sinnwell, A. J. Inglis, T. P. Davis, M. H. Stenzel, and C. Barner-Kowollik, Chem. Commun. 44, 2052 (2008).

E. V. Chernikova, A. V. Plutalova, E. S. Garina, and D. V. Vishnevetsky, Polym. Chem. 7, 3622 (2016).

J. M. Spruell, B. A. Levy, A. Sutherland, W. R. Dichtel, J. Y. Cheng, F. J. Stoddart, and A. Nelson, J. Polym. Sci., Part A: Polym. Chem. 47, 346 (2009).

G. N. Grover, S. N. S. Alconcel, N. M. Matsumoto, and H. D. Maynard, Macromolecules 42, 7657 (2009).

M. Li, P. De, S. R. Gondi, and B. S. Sumerlin, J. Polym. Sci., Part A: Polym. Chem. 46, 5093 (2008).

C. Boyer, V. Bulmus, and T. P. Davis, Macromol. Rapid Commun. 30, 493 (2009).

A. Postma, T. P. Davis, R. A. Evans, G. Li, G. Moad, and M. S. O’Shea, Macromolecules 36, 5293 (2006).

M. Chen, G. Moad, and E. Rizzardo, J. Polym. Sci., Part A: Polym. Chem. 47, 6704 (2009).

A. Postma, T. P. Davis, G. Moad, and M. S. O’Shea, Macromolecules 38, 5371 (2005).

V. Lima, H. Jiang, J. Brokken-Zijp, P. J. Schoenmakers, B. Klumperman, and R. V. D. Linde, J. Polym. Sci., Part A: Polym. Chem. 43, 959 (2005).

D. L. Patton, M. Mullings, T. Fulghum, and R. C. Advincula, Macromolecules 38, 8597 (2005).

P. J. Roth, K. T. Wiss, R. Zentel, and P. Theato, Macromolecules 41, 8513 (2008).

E. V. Chernikova, A. V. Tarasenko, E. S. Garina, and V. B. Golubev, Polym. Sci., Ser. A 50, 353 (2008).

E. V. Chernikova, V. B. Golubev, A. N. Filippov, and E. S. Garina, Polym. Sci., Ser. C 57, 94 (2015).

A. Studer and S. Amrein, Synthesis, No. 7, 835 (2002).

D. V. Vishnevetski, E. V. Chernikova, E. S. Garina, and E. V. Sivtsov, Polym. Sci., Ser. B 55, 515 (2013).

E. A. Litmanovich, M. Z. Bekanova, G. A. Shandryuk, E. V. Chernikova, and R. V. Talroze, Polymer 142, 1 (2018).

Polymer Handbook, Ed. by J. Brandrup, E. H. Immergut, and E. A. Grulke (Wiley, New York, 1999).

G. Moad, Macromol. Chem. Phys. 215, 9 (2014).

Y. Zhou, J. He, C. Li, L. Hong, and Y. Yang, Macromolecules 44, 8446 (2011).

V. B. Golubev, A. N. Filippov, E. V. Chernikova, M. L. Coote, C. Y. Lin, and G. Gryn’ova, Polym. Sci., Ser. C 53, 14 (2011).

Funding

The study was performed as part of the state task for the Topchiev Institute of Petrochemical Synthesis, Russian Academy of Sciences (investigation of the polymer with a dithiobenzoate group) and the state task for the Moscow State University for the topic no. AAAA-A16-116031050014-6 Modern Problems of Chemistry and Physics of High-Molecular-Weight Compounds (investigation of the polymer with a trithiocarbonate group).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by E. Boltukhina

Rights and permissions

About this article

Cite this article

Bekanova, M.Z., Neumolotov, N.K., Jablanovic, A.D. et al. Radical Substitution of the Dithiocarbonyl Group of Poly(methyl methacrylate) Obtained by Reversible Addition–Fragmentation Chain Transfer Polymerization. Polym. Sci. Ser. C 61, 186–197 (2019). https://doi.org/10.1134/S1811238219010028

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1811238219010028