Abstract

Carboxymethyl chitosan (CMC) was prepared using chitosan (CS) and chloroacetic acid, crosslinked carboxymethyl chitosan (CCMC) and its sodium salt (CCMC-Na) were synthesized by the compound crosslinking agent of glutaraldehyde and calcium chloride. The effect of the chloroacetic acid amount on the degree of substitution (DS) of CMC, the amount of glutaraldehyde on the water absorption of CCMC, DS on the water solubility of CMC, and the influencing factors of water (blood) absorption and coagulation performance of CCMC and CCMC-Na were systematically studied. The results indicated that the more chloroacetic acid is added, the higher the DS of CMC. When the volume fraction of glutaraldehyde is 6%, the water absorption rate of CCMC is the highest. When the DS is 0.62, the water and blood absorption rate of CCMC reaches the maximum of 1870 and 2790%, respectively. The results of vitro coagulation performance tests show that the coagulation time of CCMC is positively correlated with the water absorption rate, while the coagulation time of CCMC-Na is related to the DS. The greater the DS, the longer the coagulation time. The non-salted CCMC has a better coagulation effect, which may be widely used in new fast hemostatic materials.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

INTRODUCTION

Among the accidental injuries caused by emergencies, death caused by uncontrolled bleeding has always been a problem that needs to be solved urgently in wars and operations. How to solve the problem of bleeding has attracted more and more attention [1–3]. In the past few years, tremendous advances have been made in the development of advanced hemostatic products for use in traumatic bleeding. The most researched hemostatic materials mainly include alginates [4], oxidized regenerated cellulose [5], zeolites [6], chitosan [7], collagen [8], etc. The hemostatic mechanism of various materials is not the same, most of them have slow onset and cannot adapt to the sudden situation of emergency bleeding, or the exothermic reaction may cause tissue infection. Therefore, hemostatic materials with rapid hemostasis and good biocompatibility [9] are urgently needed.

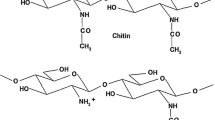

Chitosan (CS) has good biological functions such as hemostasis, bacteriostasis, healing promotion [10] and degradability. It is the only alkaline polysaccharide that exists in nature and has been widely used in the field of biomedicine [11]. Acidic CS and CS blended with other substances as hemostatic materials have been reported. Gu reported a nanofibrous hemostatic material of pure chitosan by electrospinning. Owing to the water-solubility of the resulting acidic chitosan nanofibers, an insoluble material could be achieved by neutralization reaction. After ultra-sonication treatment for 1 min, and the water absorption time decreased from 110 to 9 s. The blood clotting efficiency of the sonicated chitosan nanofiber mat was 1.35 and 3.41 fold better than that of the Surgicel® and chitosan sponge, respectively [12]. Wang developed chitosan/dopamine/diatom-biosilica composite beads (CDDs) for rapid hemostasis with good biocompatibility. CDDs were prepared by combining chitosan with diatom-biosilica using dopamine as bio-glue. The porous internal structure of CDDs led to rapid and large amount of water absorption, which contributed to the rapid hemostasis (83 s, 22% of the control group). The hemolyticrate of CDDs was less than 5% and cell viability was above 80%, confirming its good biocompatibility [13]. However, due to the strong intramolecular hydrogen bonding, chitosan can only be dissolved in dilute acid solutions, and not dissolved in water and other solvents, which greatly restricts its application [14, 15]. Therefore, various modification methods were used to increase its solubility, including acylation [16], carboxymethylation [17], sulfonation [18], quaternization [19], graft copolymerization [20], etc. Among them, the carboxymethyl chitosan had attracted wide attention for its excellent biological and chemical properties.

Carboxymethyl chitosan (CMC) as a derivative of CS, not only with the advantages of CS, but also with good solubility, good biodegradability, high moisture retention and non-toxicity [21, 22], is an amphoteric polyelectrolyte with both –NH2 and –COO– on the molecular chain. According to the different types of substitution, CMC can be divided into N-CMC, O-CMC and N, O-CMC. Among them, the amount of primary amino group playing a great role in pharmaceutical applications of O-CMC is highest, which has excellent application performance as a hemostatic material [23]. The amino group has a certain procoagulant effect. The positive charge carried by CMC reacts with the negative charge carried by the neuraminic acid residues on the surface of the red blood cell membrane [24], causing a large number of red blood cells to adhere on the wound and form a thrombus, thereby coagulating the blood [25, 26].

Huang synthesized benzaldehyde-terminated telechelic four-armed polyethylene glycol (PEG-BA) which crosslinked with CMC by Schiff base reaction to form dynamic hydrogels with strong mechanical performance. The gelation temperature and time, mechanical performance, and self-healing behavior are systematically investigated. The hydrogels have good storage modulus, excellent cytocompatibility and the cell viability. In vivo tests indicate that the hydrogels can effectively stop bleeding when the hydrogel is directly injected into a rabbit liver incision. The total blood loss is reduced from 0.65 ± 0.10 to 0.29 ± 0.11 g, and the hemostasis time is decreased from 167 ± 21 to 120 ± 10 s, when compared to a gauze treatment with physical compression [27]. Hu prepared composite hemostatic sponge by vacuum freeze-drying using carboxymethyl chitosan and sodium alginate as the main materials and CaCl2 as a crosslinking agent. On the basis of single factor experiments, an orthogonal experiment was carried out to optimize the preparation process of hemostatic sponge. The appearance, water absorption, porosity ratio, and in vitro hemostasis of the sponge were evaluated. Its water absorption and porosity ratio were 3050% and 67.23%, respectively. Meanwhile, the hemostatic sponges had significant in vitro procoagulant activity. Therefore, the hemostatic sponge is expected to be developed as a novel medical material [28].

In this paper, CS and chloroacetic acid are used to prepare CMC, glutaraldehyde and calcium chloride are used as compound crosslinking agents to obtain CCMC and CCMC-Na. The effect of the amount of chloroacetic acid on the degree of substitution (DS) of CMC, the effect of DS on the water solubility of CMC, and the effect of the amount of glutaraldehyde on the water absorption of CCMC were systematically studied. The influencing factors of water (blood) absorption and coagulation performance of CCMC and CCMC-Na are also discussed.

EXPERIMENTAL

Materials

Chitosan (molecular weight 100 kDa, deacetylation degree 90%) was purchased from Zhejiang Golden Shell Pharmaceutical Co., Ltd. Isopropanol (AR), sodium hydroxide (AR), chloroacetic acid (AR), calcium chloride (AR), glutaraldehyde (25% aqueous solution), acetic acid (AR) and hydrochloric acid (36.0~38.0%) were purchased from Sinopharm Chemical Reagent Co., Ltd. without any treatment before use.

Preparation of Carboxymethyl Chitosan

5 g of chitosan and 80 mL of isopropanol were added in a three-necked flask, stirred at room temperature for 30 min to make the chitosan uniformly dispersed in isopropanol, and then 40% sodium hydroxide solution was dropped. The mixture was stirred for 3 h to form an alkalization center, and 7 g of chloroacetic acid was added in batches to react for 4 h at 60°C. Then the mixture was cooled down at room temperature and stood, the supernatant was poured out after the solution was stratified, and the remaining yellow viscous substance was dissolved with 140 mL of distilled water. The resulting mixture was filtered to remove insoluble and adjusted to pH 7 with acetic acid, then washed repeatedly with 250 mL of ethanol to obtain 6 g yellow powder CMC.

Preparation of CCMC and CCMC-Na

0.2 g of CMC (CMC-Na) sample and deionized water were added in four beakers. The mixture was stirred until the solid completely dissolved, the value of pH was adjusted to 6–8 with hydrochloric acid, and then 2, 4, 6, and 8% volume fractions of glutaraldehyde aqueous solution were added, respectively. After being stirred for 10 min at room temperature, a 30% mass fraction CaCl2 solution 1 mL was added dropwise to crosslink for 2 h. The product was repeatedly washed with distilled water to remove excess unreacted materials, freeze-dried for 24 h to obtain 0.21 g of CCMC (CCMC-Na).

FTIR Characterization

The Fourier Transform Infrared Spectroscopy (FTIR) is measured in the range of 400–4000 cm−1 using the potassium bromide tablet method and the Fourier Transform Infrared Spectrometer (Shimadzu Model 8400S).

Measurement of the DS

Potentiometric titration was used to determine the DS of sample. An appropriate amount of sample was accurately weighed and dissolved in 0.1 mol/L hydrochloric acid aqueous solution, titrated with standard sodium hydroxide solution, and the pH value of the solution was measured with a pH meter. When pH 2.1 and pH 4.3, the volume of standard sodium hydroxide solution consumed was recorded as V1 and V2, respectively. The DS can be calculated by formula (1) and (2).

Where A was the amount of carboxymethyl substances per gram of sample (mmol), 0.203 was the amount of substance per acetyl glucosamine residue (mmol), 0.058 was the mass of carboxymethyl per milligram equivalent, M was the concentration of sodium hydroxide standard solution and W was the net weight of the sample.

Determination of Water Absorption Rate

0.20 g CCMC sample was accurately weighed, then immersed in a petri dish filled with distilled water for 2 h. Then the sample was taken out of the water, removed excess water on the surface with filter paper, and weighed it again. Each group of samples is tested three times in parallel, and the average value was taken. The water absorption rate of the samples can be calculated by formula (3).

Where W0 and W1 were the mass of the sample before and after water absorption, respectively.

The determination of blood absorption rate is similar to that of water absorption.

In Vitro Coagulation Assays

1 mL blood of healthy adult females with anticoagulant was dropped into petri dishes containing 0.1 g sample. The petri dishes were tilted each 30 s, and the time used a stopwatch from the blood dripping to the sample no longer flowing under the action of gravity were recorded as coagulation time. And the coagulation status was observed. The group without sample was set as the blank control group.

RESULTS AND DISCUSSION

Synthesis and Characterization of Carboxymethyl Chitosan

The synthesis process of CMC is shown in Scheme 1. First, the CS powder in isopropanol was dispersed, then sodium hydroxide aqueous solution was added to form an alkalization center to ensure the substitution reaction is more likely to occur at the O position. And then chloroacetic acid was added to produce the substitution reaction to generate CMC-Na. Finally, the pH value was adjusted to 7 with acetic acid to prepare CMC.

FTIR Analysis

FTIR spectroscopy is an important analytical method in the study of polymer materials, which can directly and accurately characterize the structure and changes of materials. The FTIR spectra of CS and CMC are shown in Fig. 1. As can be seen from the CS spectrum (2), the characteristic broad peak at 3434 cm–1 belonged to the superposition of the stretching vibration of –OH and –NH bonds. The peak at 2866 cm–1 was the symmetric stretching vibration absorption peak of –CH bond, the peak at 1588 cm–1 was the asymmetric stretching vibration absorption band of the amide bond, the peak at 1380 cm–1 was the absorption band of the symmetric deformation vibration and bending vibration of the ‒CH bond, and the absorption peak at 1080 cm–1 was very wide, which was the –CO bond absorption band. Compared with CS, in the CMC spectrum (1), the absorption peaks at 1736 and 1343 cm–1 were caused by the asymmetric and symmetrical and symmetrical stretching vibrations of –COO–, which showed that the carboxymethylation reaction occurred in the CS molecule, and the CMC was successfully prepared.

The Effect of the Amount of Chloroacetic Acid Added on the DS of CMC

According to the literature [29], the amounts of NaOH and CS were fixed to study the effect of the amount of chloroacetic acid on the DS of CMC. The results were shown in Table 1. It can be seen that when the amount of chloroacetic acid was within a certain range, the DS of the product was increased with the addition of chloroacetic acid. If the amount was too low, the water solubility of product was poor, and the subsequent crosslink reaction could not be carried out. When the DS reached 0.92, the amount of chloroacetic acid continued to increase, the DS of the product did not change much. The reason may be that when the amount of chloroacetic acid added is low, the amount of introduced –COO– is low too, and the intramolecular and intermolecular hydrogen bonds formed by –OH and –NH2 in the CMC structure are large, making the product less hydrophilic. With the increase of the amount of chloroacetic acid, the collision probability of –OH on CMC and chloroacetic acid will increase, and the carboxymethylation reaction is more likely to occur. When more –COO– is introduced, the hydrophilicity of the product is improved. And when chloroacetic acid amount is too much, the entire reaction environment will be acidic, which is not conducive to the preparation of O-CMC.

Preparation and Properties of CCMC

Preparation of CCMC. Two strong hydrophilic groups –OH and –COO– were in the molecule of CMC, which made it have good water solubility. However, as a water-soluble linear polymer, it will dissolve in water instead of swelling. After being crosslinked, it can quickly swell after absorbing water without dissolving. And because water is wrapped in the inside of the gel-like molecular network structure, it is not easy to lose and volatilize under the action of liquid surface tension, and has certain mechanical strength [30]. Therefore, as a type of hemostatic material, CMC should be used after being crosslinked. At present, the commonly crosslinking used agents are calcium chloride and glutaraldehyde. The crosslinking mechanism of calcium chloride is the electrostatic interaction between Ca2+ and –COO– to form a crosslinked structure, and the microenvironment formed after being crosslinked is conducive to the fiber cell growth [31]. Glutaraldehyde is crosslinked through the formation of covalent bonds between aldehyde groups and amino groups to form Schiff bases. The crosslinking mechanism of the two is shown in Scheme 2.

The effects of calcium chloride and glutaraldehyde on the cross-linking effect of CMC when used alone or in combination were studied, respectively. Firstly, calcium chloride solutions with mass concentrations of 10, 20, and 30% were prepared, and crosslinked with CMC aqueous solution at room temperature. The resulting products had low crosslinking density and did not form gels. The reason is that the electrostatic interaction between the ion and the carboxylate ion is weak, and a tight crosslinked structure cannot be formed between the molecular chains. Then glutaraldehyde aqueous solutions with volume fractions of 2, 4, 6, and 8% were used alone as crosslinking agent, respectively. The crosslinked products with CMC were yellow gel, and as the volume fraction of glutaraldehyde increases, the gel strength increases. However, the product gradually began to dissolve in water during water absorption test for 2 h. The reason may be that the covalent bond formed between the aldehyde group and the amino group is not strong enough, resulting in insufficient crosslinking strength of the product. Based on the above research results, calcium chloride and glutaraldehyde were used as a compound crosslinking agent to crosslink CMC. And it was found that the products were elastic sponge. The shape, crosslinking density and mechanical strength were greatly improved, and the water (blood) absorption was also better. It can be seen that the crosslinked product obtained when the two were used as a compound crosslinking agent has better performance as a hemostatic material.

Determination of water absorption. CMC samples with different DS were crosslinked using different amounts of glutaraldehyde and fixing amount of calcium chloride as crosslinking agents to study the water absorption rate of the prepared CCMC. Figure 2 shows the water absorption rate change trend of a series of CCMC prepared by CMC with a DS of 0.92 in a 30% mass fraction of calcium chloride aqueous solution and a volume fraction of 2, 4, 6, and 8% glutaraldehyde aqueous solution. It can be seen that the water absorption of CCMC showed a trend of first increasing and then decreasing with the volume fraction of glutaraldehyde. And at 6%, the water absorption reached the maximum. The reason may be that when the volume fraction of glutaraldehyde is low, the crosslinking density is low. And the more the amount of crosslinking agent is added, the higher the crosslinking density is, and the more spatial network formed between the CMC molecular chains, which is more likely to swell and increase the water absorption. However, when the crosslinking density exceeds a certain level, although the dosage of the agent continues to increase, the molecular chain is too tightly entangled, the product swelling is poor, and the water absorption rate decreases accordingly.

The water and blood absorption performance tests of CCMC and CCMC-Na with different DS were carried out, the results are shown in Figs. 3 and 4. According to Table 1, the product was poor water solubility when the DS was less than 0.62, and subsequent crosslinking cannot be achieved. When the DS exceeded 0.92, the DS of the product did not change much with the increase of chloroacetic acid. So the water and blood absorption rate of CCMC-Na were studied when the DS was 0.62–0.92. It can be seen from Figs. 3 and 4 that the water and blood absorption rate of the products showed a trend of first decreasing and then increasing with the DS. When the DS was 0.62, the water and blood absorption rate all reached the highest value. The possible reason is that the water absorption performance of CCMC is related to the crosslinking density and the content of hydrophilic groups. In fact, there are not only chemical crosslink but also physical crosslink in CCMC. The –OH and ‒NH2 in the CMC structure formed strong intramolecular and intermolecular hydrogen bonds, which can form more physical crosslinking points to make the molecular structure tighter. When the DS of the product is low, the content of –OH and –NH2 in the CMC is high and the crosslink density is high. And the small amount of introduced –COO– makes the product poor hydrophilic and insolubility in water. When the DS reaches 0.62, on the one hand, the more introduction of –COO– improved the hydrophilicity of the product, on the other hand, the number of physical crosslinking points is moderate. And the product CCMC has the best water absorption performance. As the DS continues to increase, the amount of –COO– increases, but at the same time, the intermolecular hydrogen bond is destroyed and the physical crosslinking points decrease. The increase of hydrophilic groups is not enough to compensate for the impact of the decrease in crosslink density caused by the decrease of physical crosslinking points on the water absorption. Therefore, the water absorption rate decreases with the increase of the DS. When the DS continues to increase, the amount of introduced ‒COO– is larger, and the hydrophilic effect is greatly increased, which makes up for the impact of the reduction of physical crosslinking points on the water absorption, so the water absorption rate of the product is on the rise. Compared with CMC, CCMC-Na has a higher water (blood) absorption rate, indicating that CMC being salted has better performance. The reason may be that after CMC forms a salt, the carboxylic acid in its structure exists in the form of more hydrophilic –COO–, which makes CCMC-Na have better water absorption and blood absorption effect.

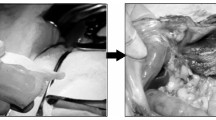

In vitro coagulation assays. CCMC and CCMC-Na samples with the DS of 0.62, 0.70, 0.80, and 0.92 were placed in a petri dish, respectively, dripped an appropriate amount of anticoagulated blood, and the group without hemostatic samples was as the control group. When the blood dripped into the sample surface was started time with a stopwatch, and when the blood formed a clot and the petri dish did not flow when tilted was stopped time. And the morphological changes on the surface of the blood drop were observed during this time. The results are shown in Table 2, Figs. 5, 6, and 7. The coagulation time of the blank group was 60 min, and the coagulation time was significantly shortened after adding the hemostatic material, indicating that the material has a very good coagulation effect.

Figure 5 shows a photograph of the sample when the coagulation test was performed for 60 s. It can be seen that CCMC-2, CCMC-4 and CCMC-2-Na had solidified, while other samples had fluidity under the action of gravity, and the blank sample had the best fluidity.

The coagulation time of CCMC was positively correlated with the water absorption rate (Fig. 6). The higher the water absorption rate, the shorter the coagulation time. The reason is that the greater the water absorption rate, the less water content in the blood, the slower the blood fluidity, and the faster it is to coagulate. The coagulation time of CCMC-Na is related to the DS. The smaller the DS, the shorter the coagulation time. The reason is that the greater the DS, the more –COO– is introduced, and the more likely it is to reject negatively charged red blood cells, which is not conducive to blood coagulation (Fig. 7). The coagulation time of CCMC is shorter than that of CCMC-Na. Although the blood absorption rate of CCMC-Na is higher than that of CCMC, the negative charge on CCMC-Na has greater negative impact on the coagulation effect. Therefore, CCMC that does not form salt has a better coagulation effect.

CONCLUSIONS

In this paper, CMC was successfully prepared using CS and chloroacetic acid, CCMC and CCMC-Na were synthesized by crosslink. The results indicate that the DS of CMC increased with the amount of chloroacetic acid. When the DS is 0.62, the water and blood absorption rate of CCMC reached the maximum of 1870 and 2790%, respectively. And the water and blood absorption performance of CCMC-Na was better than CCMC. The coagulation time of CCMC is positively correlated with the water absorption rate, while the coagulation time of CCMC-Na became longer with the increase of the DS. The former has a better coagulation effect than the latter, and the non-salted CCMC is more suitable as a fast hemostatic material.

REFERENCES

M. Harris, R. Baba, R. Nahouraii, and P. Gould, Mil. Med. 177, 928 (2012).

L. F. Littlejohn, J. J. Devlin, S. S. Kircher, R. Lueken, M. R. Melia, and A. S. Johnson, Acad. Emerg. Med. 18, 340 (2011).

M. B. Rahmany, R. R. Hantgan, and M. Van Dyke, Biomaterials 34, 2492 (2013).

C. Liu, Z. Shi, H. Sun, C. J. Mujuni, L. Zhao, X. Wang, and F. Huang, Carbohydr. Polym. 249, 116860 (2020).

Y. G. Zhuo, J. Liu, Q. S. Li, G. Z. Xing, and W. F. Lv, Integr. Ferroelectr. 167, 199 (2015).

Y. Zhang, C. Xu, Y. He, X. Wang, F. Xing, H. Qiu, Y. Liu, D. Ma, T. Lin, and J. Gao, J. Biomater. Sci., Polym. Ed. 22, 809 (2011).

K. Kalantari, A. M. Afifi, H. Jahangirian, and T. J. Webster, Carbohydr. Polym. 207, 588 (2019).

L. Sun, B. Li, D. Jiang, and H. Hou, Colloids Surf., B 159, 89 (2017).

J. Granville-Chapman, N. Jacobs, and M. J. Midwinter, Injury 42, 447 (2011).

S. K. Nandi, B. Kundu, and D. Basu, Mater. Sci. Eng., C. 33, 1267 (2013).

M. Rinaudo, Prog. Polym. Sci. 31, 603 (2006).

B. K. Gu, S. J. Park, M. S. Kim, C. M. Kang, J. Il Kim, and C. H. Kim, Carbohydr. Polym. 97, 65 (2013).

Y. Wang, Y. Fu, J. Li, Y. Mu, X. Zhang, K. Zhang, M. Liang, C. Feng, and F. Chen, Carbohydr. Polym. 200, 6 (2018).

I. M. Van der Lubben, J. C. Verhoef, G. Borchard, and H. E. Junginger, Eur. J. Pharm. Sci. 14, 201 (2001).

C. M. Valmikinathan, V. J. Mukhatyar, A. Jain, L. Karumbaiah, M. Dasari, and R. V. Bellamkonda, Soft Matter 8, 1964 (2012).

A. A. Golyshev, Y. E. Moskalenko, and Y. A. Skorik, Russ. Chem. Bull. 64, 1168 (2015).

Y. Qin, H. Hu, A. Luo, Y. Wang, X. Huang, and P. Song, J. Appl. Polym. Sci. 99, 3110 (2006).

Z. Yang, H. Peng, W. Wang, and T. Liu, J. Appl. Polym. Sci. 116, 2658 (2010).

S. Wei, X. Liu, J. Zhou, J. Zhang, A. Dong, P. Huang, W. Wang, and L. Deng, Int. J. Biol. Macromol. 155, 153 (2020).

K. El-Tahlawy and S. M. Hudson, J. Appl. Polym. Sci. 82, 683 (2001).

H. Tu, G. Wu, Y. Yi, M. Huang, R. Liu, X. Shi, and H. Deng, Carbohydr. Polym. 210, 9 (2019).

M. A. Zarandi, P. Zahedi, I. Rezaeian, A. Salehpour, M. Gholami, and B. Motealleh, IET Nanobiotechnol. 9, 191 (2015).

M. Prabaharan, R. L. Reis, and J. F. Mano, React. Funct. Polym. 67, 43 (2007).

A. E. Pusateri, J. B. Holcomb, B. S. Kheirabadi, H. B. Alam, C. E. Wade, and K. L. Ryan, J. Trauma: Inj., Infect., Crit. Care 60, 674 (2006).

Q. Zeng, J. Qin, X. Yin, H. Liu, L. Zhu, W. Dong, and S. Zhang, J. Appl. Polym. Sci. 133, 2 (2016).

P. R. Klokkevold, H. Fukayama, E. C. Sung, and C. N. Bertolami, J. Oral Maxillofac. Surg. 57, 49 (1999).

W. Huang, Y. Wang, Y. Chen, Y. Zhao, Q. Zhang, X. Zheng, L. Chen, and L. Zhang, Adv. Healthcare Mater. 5, 2813 (2016).

Z. Hu, Q. Q. Ouyang, Y. Chen, P. Z. Hong, M. N. Liao, F. J. Chen, S. D. Li, IOP Conf. Ser.: Mater. Sci. Eng. 213, 1 (2017).

M. Kurniasih, Purwati, T. Cahyati, and R. S. Dewi, Int. J. Biol. Macromol. 119, 166 (2018).

H. Li, J. Yang, X. Hu, J. Liang, Y. Fan, and X. Zhang, J. Biomed. Mater. Res., Part A 98, 31 (2011).

C. P. Fall and J. P. Bennett, Biochim. Biophys. Acta, Bioenerg. 1410, 77(1999).

Funding

We acknowledge financial support from Natural Science Foundation of Shandong (ZR2019MEM010).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Rights and permissions

About this article

Cite this article

Qian Sun, Zhang, K., Bai, X. et al. Study on the Preparation and Properties of Carboxymethyl Chitosan as Fast Hemostatic Material. Polym. Sci. Ser. B 63, 843–852 (2021). https://doi.org/10.1134/S1560090421060270

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1560090421060270