Abstract

The polymerization of styrene in the presence of an organosilicon comb-shaped surfactant, α,ω‑bis(trimethylsiloxy)-oligodimethylmethyl-(10-carboxydecyl)siloxane, is studied. The reaction yields aggregatively stable polystyrene suspensions with a polymer content of up to 50%, a high surface concentration of carboxyl groups, and a particle diameter of up to 2.2 μm. A comparative analysis of the kinetic regularities of polymerization and the properties of polymer suspensions in the presence of the comblike, dimeric, and linear surfactants is carried out.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

INTRODUCTION

The use of water-insoluble surfactants as stabilizers of polymer suspensions makes it possible to carry out the synthesis at concentrations much lower than that in the presence of water-soluble hydrocarbon surfactants (1–2 and 4–5 wt % per monomer, respectively) [1–3]. Organosilicon compounds are promising water-insoluble surfactants. For example, in the presence of linear and dimeric surfactants [4–8], aggregatively stable polymer suspensions with particle diameters up to 1.0 µm were obtained. These suspensions with a narrow size distribution could not be obtained in the presence of water-soluble surfactants. It was also found that the structure of the organosilicon surfactant and its concentration affect the particle diameter of polystyrene suspensions. Apparently, this explains the fact that the sizes of particles of polystyrene suspensions synthesized in their presence are much larger than the sizes of particles isolated in the presence of water-soluble surfactants [1–3].

These results suggest that the use of comb-shaped organosilicon surfactant characterized by higher surface-active properties than dimeric and linear surfactants [9–14] will make it possible to obtain polystyrene suspensions with a large particle diameter directly during polymerization [15].

This work presents the data on the kinetic regularities of styrene polymerization in the presence of the comb-shaped surfactant containing 46 siloxane units and 14 carboxydecyl spacers, α,ω-bis(trimethylsiloxy)-oligodimethylmethyl-(10-carboxydecyl)siloxane (ODCS). The presented results are compared with the data on styrene polymerization under similar conditions but in the presence of the surfactants of the dimeric (with two carboxyl end groups) and linear (with one carboxyl group) structure.

EXPERIMENTAL

The surfactants used were water-insoluble carboxy-functional organosilicon oligomers of various structures (Table 1). They differ in the length of the dimethylsiloxane chain and the concentration of functional groups. The synthesis and properties of polydimethylsiloxanes are available in [6, 8, 16, 17].

The molecular weight of organosilicon compounds was determined by GPC; calibration was done against polystyrene. The density of the compounds was measured pycnometrically [18], and the refractive index was measured refractometrically on an Abbe Atago NAR-2T refractometer (Japan) [19] at a temperature of 20°C.

Styrene (Aldrich) with a basic substance content of ≥99% was used as a monomer, and potassium persulfate (PPS) (Sigma-Aldrich) with a basic substance content of 99.9% was used as an initiator. Styrene was distilled in vacuum to remove the stabilizer, and the initiator was used without further purification.

The interfacial tension was measured by the du Noüy ring method at the surfactant toluene solution/water interface using a K-9 tensiometer (KRUSS, Germany).

The synthesis of polymer suspensions and the kinetics of heterophase polymerization of styrene were studied by the dilatometric method [20]. Styrene polymerization was carried out at 80°C and different volume ratios of styrene : water (from 1 : 9 to 1 : 1). The initiator concentration was varied from 0.5 to 2.0 wt %, and the surfactant concentration was in the range from 0.25 to 3.0 wt % per monomer. The synthesis was carried out under constant stirring at 300 rpm.

The average diameter of polymer suspension particles was determined by dynamic light scattering using a Zetasizer Nano-ZS particle size analyzer (Malvern, United Kingdom) equipped with a helium-neon laser with a wavelength of 633 nm and a light source of 5 mW. The range of particle measurement was 0.6–6000 nm. The angle of detection of light scattering was 173°. The resulting dispersions were preliminarily diluted with water until a weak opalescence was reached. The measurements were carried out at room temperature according to the manufacturer recommended procedure in an automatic mode.

The particle size was also determined using a Motic B Series light microscope equipped with a KY‑F32 color optical camera. The suspension sample (0.1%) was applied on a glass slide and photographed with a light microscope. The particle diameter was determined from the obtained microphotographs using the program Image-Pro Plus 6.0 (Vtdia Cybernetics Inc.).

The ξ potential of the particles was measured on a Zetasizer Nano ZS instrument (Malvern, United Kingdom) according to the standard procedure [21].

The viscosity average molecular weight of polymers [22] was calculated by the Mark–Kuhn–Houwink equation. Constants K and α for polystyrene in toluene at a temperature of 25°C were K = 7.5 × 103 and α = 0.75.

The concentration of functional groups on the surface of polymer particles was determined by X-ray photoelectron spectroscopy. The photoelectron spectra of the samples were measured on an ESCALAB MK-2 electronic spectrometer (VG Scientific, United Kingdom). The source was nonmonochromatized anode radiation MgKα with a photon energy of 1253.6 eV. The samples of polymer suspensions in the form of an aqueous solution were applied on a silicon substrate and dried in the input chamber of the spectrometer (pressure up to 4 × 10–2 mbar (~4 Pa)), the spectrometer preparation chamber, and the analysis chamber, and measurements were performed at a pressure of up to 5 × 10–9 mbar (5 × 10–7 Pa).

RESULTS AND DISCUSSION

The colloidal-chemical properties of surfactants significantly affect the mechanism of particle formation and the image of interfacial adsorption layers on their surface which determine the stability of the suspension. Figure 1 and Table 2 present the dependence of the interfacial tension on the concentration of ODCS and the colloidal-chemical characteristics of ODCS calculated from it according to the data from [9]. For comparison, the data for the surfactant of the dimeric (α,ω-bis(10-carboxydecyl)oligodimethylsiloxane (PDMS(COOH)) and linear structure (2-(carboxyethyl)–ω–(trimethylsiloxy)polydimethylsiloxane (PDS)) are given.

As can be seen from Table 2, the comb-shaped organosilicon surfactant features a higher surface activity (G = 4.9 mN m2/mol), forms interfacial layers of a greater thickness (δ = 18.4 nm) than dimeric and linear surfactants, and reduces the interfacial tension at the surfactant toluene solution/water interface to 18.5 mJ/m2 (σ1.2). The area occupied by the ODCS molecule is 0.44 nm2 (S0), and the maximum Gibbs adsorption (Гmax) is 3.8 × 10–6 mol/m2.

Figure 2 shows the kinetic curves in the coordinates conversion–time obtained in the presence of comb-shaped structure-surfactants at different volume ratios of monomer : water. It can be seen that the nature of the dependence is typical of heterophase polymerization [23–25]. Depending on the monomer content in the emulsion, the nonstationary section is from 10 to 25 min, the section of constant rate is from 60 to 80% conversion, and the complete conversion of styrene is achieved in 5.0–6.5 h. The characteristics of polystyrene suspensions stabilized with organosilicon surfactants are given in Table 3.

Thus, under the selected conditions in the presence of ODCS, the reaction system is stable during the synthesis and contains polymer particles with a narrow size distribution and an average diameter of 0.7 to 2.2 μm depending on the volume ratio of monomer : water. The molecular weight of the polymer depends on the volume ratio of the phases and varies in the range from 2.1 × 105 to 5.6 × 105.

Note that the stability of the reaction system during polymerization is retained up to the volume ratio monomer : aqueous phase = 1 : 4, respectively. This means that the comb-shaped surfactant at a concentration of 1 wt % does not ensure the stability of the reaction system at a monomer : water volume ratio above 1 : 4, just as in the presence of organosilicon linear and dimeric surfactants.

However, in contrast to these surfactants, the stability of the polymer suspension was increased by increasing the concentration of ODCS to 3 wt %. In this case, polymer suspensions with a particle diameter of 2.2 μm and a polymer content of 50% were synthesized. These results are unique, since suspensions with such a particle size cannot be obtained by heterophase polymerization; for this purpose, either the seed or dispersion polymerization of monomers in nonaqueous media is used [26–29].

A comparative analysis of the characteristics of polystyrene suspensions synthesized in the presence of organosilicon surfactants of various structures is shown in Table 2. In the presence of the linear surfactant, suspensions with a particle diameter of 0.43 to 0.70 μm were obtained; in the presence of the dimeric surfactant, suspensions with a particle diameter of 0.55 to 0.80 μm were obtained; in the presence of the comb-shaped surfactant, suspensions with a particle diameter of 0.7 to 2.2 μm were obtained. The effect of the structure of organosilicon surfactants on the diameter of polymer particles is clearly seen. The molecular weight of polymers decreases with an increase in the diameter of polymer particles; this dependence is observed for surfactants of various structures. The values of the ξ potential do not depend on the structure of the surfactant and are in the range from –21.5 to ‒36.7 mV.

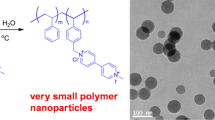

Figure 3 shows the photomicrographs of polystyrene suspensions obtained in the presence of ODCS.

The dependences of the polymerization rate and the molecular weight of the polymer on the initiator concentration are shown in Fig. 4. It can be seen that, with an increase in the potassium persulfate concentration, the rate of polymerization increases (to the power of 0.5) and the molecular weight decreases in inverse proportion to the power of 0.5. As the concentration of the initiator increases, there is an insignificant increase in the diameter of polymer particles of suspensions in the presence of both dimeric and comb-shaped surfactants (from 0.7 to 0.8 µm for ODCS and from 0.4 to 0.5 µm for PDMS(COOH)) (Figs. 5, 6). The photomicrographs of polystyrene particles show that the narrow particle size distribution remains at all values of the initiator concentration.

Dependences of (1) the rate of styrene polymerization and (2) MW of polymer on the concentration of PPS: (a) ODCS and (b) PDMS(COOH) at a volume ratio of monomer : water phases of 1 : 9; dashed lines denote theoretical dependences of the rate of polymerization and molecular weight to the power of 0.5 [24]. The surfactant concentration is 1 wt %; T = 80°C.

The effect of the concentration of the comb-shaped organosilicon surfactant on the kinetic regularities of polymerization was studied at the volume ratio of styrene : aqueous phase = 1 : 9, a PPS concentration of 1.0 wt % (per monomer), and a temperature of 80°C. The surfactant concentration was changed from 0.25 to 3.0 wt % (per monomer) (Table 4; Figs. 7, 8). Table 4 shows for comparison the data obtained in the presence of the dimeric surfactant under similar conditions.

Dependences of (1) the molecular weight of the polymer at 100% monomer conversion and (2) the rate of styrene polymerization at a monomer conversion from 10 to 50% on the concentration of (a) ODCS and (b) PDMS(COOH) obtained at a monomer : water volume ratio of 1 : 9 and a concentration of surfactants and PPS of 1 wt % (per monomer).

With a change in the concentration of surfactants (ODCS and PDMS(COOH)), the narrow particle size distribution remains. The particle diameter is almost independent of the concentration of oligodimethylsiloxanes. This finding differs from the results observed in the case of water-soluble surfactants, in the presence of which the particle size decreases with an increase in the surfactant concentration [3]. The molecular weight of the polymer increases with increasing surfactant concentration and ranges from 5.3 × 105 to 6.5 × 105 for ODCS and from 3.1 × 105 to 5.6 × 105 for PDMS(COOH). It can be assumed that formation of a high molecular weight polymer during polymerization in the presence of organosilicon surfactants is associated with an increased viscosity of the reaction medium containing a surfactant dissolved in the monomer and a decrease in the role of the chain termination reaction.

A feature of the polymerization of monomers in the presence of water-insoluble surfactants is that the formation of polymer-monomer particles is influenced by the efficiency of dispersion, the process of Ostwald ripening, and the polymerization initiation, which occur simultaneously. The dispersion of the monomer is defined by the rate of stirring of the emulsion and increases with the acceleration of the initiation of polymerization [20]. The Ostwald ripening occurs only up to a certain degree of monomer conversion [30, 31]. The influence of these processes on the diameter of particles and their size distribution was studied in detail at the volume ratio of styrene : aqueous phase = 1 : 2, respectively, and a surfactant concentration of 2.0 wt % (Fig. 9, Table 5). The data presented clearly illustrate the change in the particle diameter at the initial stage of polymerization (up to 30% conversion) and the narrowing of the particle size distribution. These results indicate that the Ostwald ripening process proceeds over time up to 20% conversion, after which polymer suspensions are characterized by a narrow particle size distribution until the end of polymerization. One should note the high aggregative stability of polystyrene suspensions starting from early degrees of conversion (6% conversion), as indicated by the absence of coagulum.

The results obtained prove that polymer suspensions obtained in the presence of the comb-shaped surfactant possess high aggregative stability starting with low monomer conversions and at low surfactant concentrations (less than 1 wt %). This can be only if a strong interfacial adsorption layer is formed on the surface of polymer-monomer particles even at the initial stages of polymerization. The mechanism for the formation of the interfacial adsorption layer was proposed in [32]. It assumes the joint participation of the polymer formed during the initiation of polymerization and the surfactant adsorbed from the monomer phase in the formation of a strong interfacial layer. An important role in its formation is played by the incompatibility of the polymer and oligodimethylsiloxanes, which in the process of polymerization leads to the forced displacement of surfactant molecules to the interface [33, 34]. In this case, surfactant molecules form a shell on the surface of polymer-monomeric particles orienting themselves by functional groups to the aqueous phase. This structure of polymer particles opens up the possibility of their use for biotechnology, for example, for replacing biocarriers with polymer particles in the preparation of diagnostic test systems.

Using X-ray photoelectron spectroscopy, the concentration of carboxyl groups on the surface of polystyrene particles synthesized in the presence of the carboxyl-containing ODCS at a concentration of 2 wt % and a monomer : water volume ratio of 1 : 2, respectively, was determined. According to the XPS data, the surface of the polystyrene particles contains 16.4 at % oxygen, 16.7 at % silicon, and 66.9 at % carbon, of which 72 at % of carbon occurs in carboxyl groups, 24 at % occurs in aliphatic carbon, and 4 at % occurs in carbon in the ether group. The appearance of ether groups can be associated with the residues of trimethylsilyl protective groups used in the synthesis of organosilicon surfactants. The absence of signals due to the initiator sulfo groups is probably related to the fact that their concentration is at the accuracy limit of the instrument (~0.5–1.0 at %). The absence of hydrophilic sulfo groups on the surface can be attributed to their orientation toward the substrate or to a “random” orientation inside the polymer particle.

REFERENCES

L. I. Ronco, R. J. Minari, and L. M. Gugliotta, Braz. J. Chem. Eng. 32, 191 (2015).

U. Yildiz and I. Capek, Polymer 44, 2193 (2003).

A. Yu. Men’shikova, T. G. Evseeva, B. M. Shabsel’s, I. V. Balanina, A. K. Sirotkin, and S. S. Ivanchev, Russ. J. Appl. Chem. 78, 1008 (2005).

A. I. Kadantseva, I. A. Gritskova, and I. G. Krasheninnikova, Plast. Massy 8, 26 (2012).

I. A. Gritskova, V. S. Papkov, I. G. Krasheninnikova, and A. M. Evtushenko, Polym. Sci., Ser. A 49, 235 (2007).

I. A. Gritskova, D. I. Shragin, S. M. Levachev, A. A. Ezhova, E. V. Milushkova, V. M. Kopylov, S. A. Gusev, N. I. Prokopov, and N. A. Lobanova, Fine Chem. Technol. 11, 5 (2016).

E. N. Levshenko, I. A. Gritskova, S. A. Gusev, A. A. Gusev, and E. A. Volkova, Biotekhnologiya 29, 65 (2013).

D. I. Shragin, I. A. Gritskova, V. V. Kopylov, E. M. Milushkova, L. A. Zlydneva, and S. M. Levachev, Silicon 7, 217 (2015).

I. A. Gritskova, A. A. Ezhova, A. E. Chalikh, S. M. Levachev, and S. N. Chvalun, Russ. Chem. Bull. 68, 132 (2019).

A. A. Ezhova, I. A. Gritskova, A. E. Chalykh, S. M. Levachev, D. I. Shragin, S. N. Chvalun, Yu. N. Malakhova, and A. M. Muzafarov, Polym. Sci., Ser. A 61, 149 (2019).

S. C. Mehta, P. Somasundaran, C. Maldarelli, and R. Kulkarni, Langmuir 22, 9566 (2006).

Yu. N. Malakhova, A. I. Buzin, and S. N. Chvalun, J. Surf. Invest.: X-ray, Synchrothron Neutron Tech. 12, 339 (2018).

C. Kim, M. C. Gurau, P. S. Cremer, and H. Yu, Langmuir 24, 10155 (2008).

A. R. Esker and H. Yu, “Langmuir Monolayers of Siloxanes and Silsesquioxanes,” in Silicone Surface Science, Ed. by M. J. Owen and P. R. Dvornic (Springer, Netherlands, 2012), Chap. 7, pp. 195–228.

I. A. Gritskova, V. G. Lakhtin, D. I. Shragin, A. A. Ezhova, I. B. Sokolskaya, I. N. Krizhanovsky, P. A. Storozhenko, and A. M. Muzafarov, Russ. Chem. Bull. 67, 1908 (2018).

V. V. Gorodov, S. A. Milenin, N. V. Demchenko, and A. M. Muzafarov, INEOS OPEN 3, 43 (2020).

V. V. Gorodov, N. V. Demchenko, M. I. Buzin, V. G. Vasil’ev, D. I. Shragin, V. S. Papkov, and A. M. Muzafarov, Russ. Chem. Bull. 66, 1290 (2017).

GOST (State Standard) 53654.1-2009M: Paint Materials. Method for Determination of Density, 2010.

B. V. Ioffe, Refractometric Methods in Chemistry (Khimiya, Leningrad, 1974) [in Russian].

A. A. Ezhova, Candidate’s Dissertation in Chemistry (RTU-MIREA, Moscow, 2019).

GOST (State Standard) 18249-72: Plastics. Methods for Viscosity Dtermination of Diluted Polymer Solution, 2000.

D. Braun, H. Cherdron, M. Rehahn, H. Ritter, and B. Voit, Polymer Synthesis: Theory and Practice (Springer-Verlag, Berlin; Heidelberg, 2013).

C. S. Chern, Prog. Polym. Sci. 31, 443 (2006).

W. D. Harkins, J. Chem. Phys. 13, 381 (1945).

H. Macková and D. Horák, J. Polym. Sci., Part A: Polym. Chem. 44, 968 (2006).

H. S. Hwang, Y.-S. Gal, K. P. Johnston, and K. T. Lim, Macromol. Rapid Commun. 27, 121 (2006).

Z.-S. Xu, Z.-W. Deng, X.-X. Hu, L. Li, and C.-F. Yi, J. Polym. Sci., Part A; Polym. Chem. 43, 2368 (2005).

N. N. Shevchenko, T. G. Evseeva, D. I. Shevaldysheva, G. A. Pankova, B. M. Shabsel’s, and A. Yu. Men’shikova, Colloid J. 75, 460 (2013).

D. Wang, V. L. Dimonie, E. D. Sudol, and M. S. El-Aasser, J. Appl. Polym. Sci. 84, 2710 (2002).

A. S. Kabal’nov, Kolloidn. Zh. 47, 1048 (1985).

A. S. Kabal’nov, Kolloidn. Zh. 46, 1108 (1984).

A. E. Chalykh, V. K. Gerasimov, U. V. Nikulova, A. A. Ezhova, and I. A. Gritskova, Russ. Chem. Bull. 68, 1735 (2019).

A. A. Poteryaev, A. E. Chalykh, O. V. Stoyanov, and E. V. Surovyatkina, Vestn. Tekhnol. Univ. 18 (8), 62 (2015).

A. E. Chalykh, V. K. Gerasimov, and O. V. Stoyanov, Vestn. Tekhnol. Univ. 21 (7), 25 (2018).

ACKNOWLEDGMENTS

This work was performed using the equipment of the Collaborative Access Center for Polymer Research, Enikolopov Institute of Synthetic Polymer Materials, Russian Academy of Sciences.

Funding

This work was supported by the Russian Foundation for Basic Research, project no. 19-33-60053, and the Ministry of Science and Higher Education of the Russian Federation.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ezhova, A.A., Gritskova, I.A., Gusev, S.A. et al. Organosilicon Comb-Shaped Surfactants for the Synthesis of Polymer Suspensions with a Narrow Particle Size Distribution. Polym. Sci. Ser. B 63, 209–217 (2021). https://doi.org/10.1134/S1560090421030052

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1560090421030052