Abstract

2-Formyl pyrrole polymerizes in alcoholic solution by hydrochloric acid as a catalyst. The polymeric product was characterized by FTIR, XPS, and EDX techniques, which confirmed that polymerization occurred through aldehyde group. Kinetics of the reaction was studied by UV–Vis absorption spectroscopy at 475 nm. It was found that reaction occurred according to an accelerated chain polymerization mechanism via two stages. Firstly, active centers are formed. Then the chain growth occurs. The reaction order with respect to monomer and catalyst concentration as well as reaction rate coefficients were determined on both stages. Suggested reaction mechanism is consistent with experimental data.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

INTRODUCTION

Synthesis of conductive polymers from hetero aromatic rings have been widely studied recently due to their wide range of applications [1]. Conductive polymers are used in optical displays [2], light emitting diodes [3], solar cells [4], as rechargeable batteries [5], sensors [6], enzyme immobilization matrices [7], membranes [8], gas separation membranes [9], and electrochromic devices [10]. Pyrrole, thiophene, furane, selenophene [11] and aniline are used to synthesize conductive polymers [12, 13]. Polypyrrole (PPy) and its derivatives have been studied more than other moieties as building blocks for conductive polymers due to easy oxidizability and good solubility in water [14], and also for good properties of their polymers such as high electrical conductivity, good electrochemical properties, thermal stability [15] and possibility of synthesis by both chemical and electrochemical methods [16]. A copolymer was prepared from 2-formyl pyrrole and pyrrole in chloroform by trichloroacetic acid as catalyst [17], 2-formyl pyrrole was polymerized by effect of thionyl chloride in its solution in carbon tetrachloride [18].

Properties and applications of the conductive polymers depend on the polymer structure and method of synthesis [19]. Polymerization kinetics study is used to determine suitable conditions to obtain polymers with desired properties [20]. In this paper, we present a new method for preparing and diagnosing an innovative polymer. 2-Formyl pyrrole is polymerized by acid catalyst in water–alcohol mixture in the absence of oxidizing agent. Poly(2-formyl pyrrole) was characterized by FT/IR, XPS and EDX. We also present a comprehensive kinetic study and suggest a suitable mechanism for the polymerization reaction.

EXPERIMENTAL

Materials

2-Formyl pyrrole, 98% (Sigma, Germany), hydrochloric acid (Sigma Germany), ethanol, 98% (Sigma, Germany), sodium hydroxide, 99% (Sigma, Germany) and distilled water were used as received.

Characterization

UV spectra were recorded by Optizen OUV322 spectrophotometer (Optizen lab Co., Korea) in the range of 380–800 nm. FTIR spectra were recorded in KBr disks by JASCO FTIR spectrometer, M4100 model (Jasco Co., Japan) in the range of 4000–400 cm–1. Surface morphologies were examined with SEM, EDS and XPS by TESCAN scanning electron microscope, MIRA3 model (Tescan Co., Czech).

Synthesis

2-Formyl pyrrole (9.5 g, 100 mmol) was dissolved in 50 mL of water-ethanol mixture (v/v 60/40) and added to 10 mL of concentrated hydrochloric acid (35.5%). The solution became yellow then dark. Solvent was evaporated under gas puller at temperature 55°C for 24 h. The resulted blackish green precipitate was washed several times with aqueous sodium hydroxide solution (0.1 M), distilled water, and then pure alcohol. Precipitate was dried at 105°C resulting in fine green powder, which undergoes degradation at more than 300°C.

Kinetic Study

Reaction was repeated at different concentrations of 2-formyl pyrrole (0.1, 0.075, 0.05, 0.025, 0.01 M) in alcohol 40% solution and acid concentration 5 M. Absorbance of the reaction mixture was measured by time. Measurements were repeated with 0.1 M monomer and 10 and 1.5 M acid concentrations. Data from absorbance measurements were used in the kinetics study.

RESULTS AND DISCUSSION

Characterization of Poly(formyl pyrrole)

To determine the proceeding of the reaction, FTIR spectra of monomer and polymer were recorded (Fig. 1). For monomer the following bands are observed: at 3441 cm–1 (N‒H in pyrrole range), 3230 cm–1 (C‒H aromatic), 2857 cm–1 (C‒H aliphatic), 1667 cm–1 (C=O aldehyde), bands between 1500 and 1000 cm–1 (C=C pyrrole range and C–H out of plane). The band at 3500 cm–1 (H2O in the polymer structure), and weak band at 1667 cm–1 (C=O aldehyde) prove that polymerization reaction happened via aldehyde group.

Then polymer was submitted to irradiation by high energy source. X-ray penetrates between 1–10 nm under the surface (depending on the tilting angle of sample) enhancing surface analysis. As an atom absorbs X-radiation, absorbed energy will eject electron from 1sc orbital. Ejected electron has kinetic energy related to incident beam energy, electron binding energy is specific for element [21]. Figure 2a shows X-ray photoelectron spectrum of the polymer containing three peaks, first at 534.6 eV (O1s), second at 401.5 eV (N1s) and third at 286.3 eV (C1s). In Fig. 2b the fittings of (C1s) spectra are shown. With this analysis, it is possible to determine elemental percentage in the polymer structure. Analysis shows three typical peaks associated with C=C‒H (286.45) 56.57%, C‒N (287.3) 37.72%, C=O (289.6) 5.7%. This result corresponds to one expected from theory.

EDX technique utilizes X-radiation emitted from the sample during bombardment by electron beam to characterize elemental composition of the analyzed volume on micro- or nano-scale. Electron beam is scanned across the sample surface and generates X‑ray fluorescence from the atoms in its path. X-ray photons’ energy is characteristic of the element produced from. X-ray detector measures the number of emitted X-ray versus their energy. X-ray energy is characteristic of the chemical element from which the X-ray was emitted [22]. Table 1 shows results of EDX analysis for three areas of polymer surface. Taking into consideration the inaccuracy of the EDX analysis in determining the ratio of elements, polymer contains carbon 70.42%, nitrogen 13.48% and oxygen 15.02%. So, the ratio N/C was 19.1% (one nitrogen atom for five carbon atoms) and this result consists the polymer structure. High percentage of oxygen refers to the presence of water molecules trapped in the polymer structure.

Kinetic Study

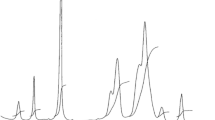

Reaction mixtures containing given amount of 2‑formyl pyrrole in alcohol 40% and 3 M of hydrochloric acid were left at room temperature for 24 h to complete the reaction and then UV–Vis spectra were recorded using blank of alcohol and acid (Fig. 3). As is seen, absorption spectra reveal a maximum absorption peak at 475 nm. Molecular absorption coefficient calculated from these data at 475 nm is equal to 443.3 L/(cm mol).

Kinetics of the polymerization reaction was studied at monomer concentration 0.1 M and acid concentration 5 M by measuring absorbance at 475 nm which corresponded to the current monomer concentration at time t. Figure 4 presents the consumption of the monomer concentration throughout reaction time and the dependence of the reaction rate from the time. One can observe that reaction rate increases at the beginning of the reaction, reaches a maximum value and then decreases.

To determine the reaction order with respect to the concentrations of the monomer and the acid, the kinetics of the reaction was studied at constant acid concentration and different monomer concentrations as well as at constant monomer concentration and various acid concentrations. The results are summarized in Fig. 5 as the logarithmic dependence of the initial reaction rate from the monomer and acid concentrations correspondingly. Thus, determined reaction orders with respect to monomer and acid concentrations were equal to 2 in both cases, while the apparent rate coefficient k was equal to 2.1 × 10–3 and 8.40 × 10–7 L/(mol s) for the experiments given on Figs. 5a, 5b respectively.

In order to study the second stage of the curve, we have chosen three points (at t = 135, 175, and 200 s) within the right part of the curve and determined the concentration of the reactants and the reaction rate (Fig. 6). The reaction order with respect to acid concentration and apparent rate constant were equal to 1 and 3.34 × 10–6 s–1.

(a) The dependence of the monomer concentration from reaction time at different concentrations of acidic catalyst: (1) y = (–6.77 × 10–6)x + 0.101, R2 = 0.963, (2) y = (–2.11 × 10–5)x + 0.1, R2 = 1.0, (3) y = (–1.14 × 10‒4)x + 0.0996, R2 = 0.982; (b) logarithmic dependence of the reaction rate from the acid concentration. y = 1.228x – 12.638, R2 = 0.931.

Basing on the kinetic data the following mechanism of the polymerization was proposed.

Aldehyde form in an acidic medium undergoes a transformation into an enol form [23, 24]. Resulted alcohol group becomes protonated by strong acid, then water molecule is emitted to give carbonium ion [23, 25]. This corresponds to the formation of active centers during the first stage of the reaction (second order reaction according to acid and monomer). On the second stage, polymer chains grow up by electrophilic addition of the carbonium ion to the aromatic ring (corresponding to the first order reaction according to acid and the monomer).

Thus, the kinetic scheme can be presented as follows:

Reaction rate, i.e., the rate of monomer consumption is described by the following equation:

From the equilibrium we can write:

From the above equations, it was found:

Equation (2) is referred to the polymerization reaction, which consists of two terms: the left term has the second order with respect to both monomer and acid concentrations and the right term has the first order with respect to acid concentration. At the beginning of the reaction, the concentration of all products is small enough to neglect the second term in Eq. (2) and the equation becomes as follows:

Considering that (\(k{\kern 1pt} ' = {{k}_{1}}{{E}_{1}}\)) the equation becomes as follows:

This is in accordance with the experimental data. The rate constant value k' was equal to 8.2 × 10‒5 L3/(mol3 s) in experiments with constant acid concentration and to 8.4 × 10–5 L3/(mol3 s) in experiments with constant monomer concentration presenting satisfied convergence of the results.

At later stages, the intermediate products accumulate in the system. In this case, the second term in Eq. (2) predominates and the first term is neglected:

where C= \(({{k}_{2}}{{E}_{2}}[{{m}_{2}}] + {{k}_{3}}{{E}_{3}}[{{m}_{3}}] + \ldots + {{k}_{n}}{{E}_{n}}[H{{m}_{{n - 1}}}])\).

This corresponds to experimental kinetic data during the second stage. Value of the reaction rate constant determined from kinetic data is equal to 3.7 × 10–5 L/(mol s) in experiments with constant acid concentration and to 3.4 × 10–5 L/(mol s) in experiments with constant monomer concentration. Thus, the suggested scheme describes satisfactorily the polymerization kinetics.

CONCLUSIONS

Polymer was synthesized by simple and easy method, with catalysis of hydrochloric acid in alcoholic solution of 2-formyl pyrrole and characterization techniques confirmed its structure. Polymerization kinetics was studied, reaction consists of two phases. The first was second order reaction for both the monomer and the acid, the second was first order reaction for both the monomer and the acid. Reaction mechanism was suggested based on empirical data.

REFERENCES

B. X. Valderrama-García, E. Rodríguez-Alba, E. G. Morales-Espinoza, K. M. Chane-Ching, and E. Rivera, Molecules 21, 172 (2016).

A. Mirsakiyeva, PhD Thesis (KTH R. Inst. Technol., Stockholm, Sweden, 2017).

T. Kasa and F. Gebrewold, Adv. Phys. Theor. Appl. 62, 28 (2017).

J. C. Zhang, X. Zheng, M. Chen, X. Y. Yang, and W. L. Cao, eXPRESS Polym. Lett. 5, 401 (2011).

L. Duan, J. Lu, W. Liu, P. Huang, W. Wang, and Z. Liu, Colloids Surf., A 414, 98 (2012).

S. C. Hernandez D. Chaudhari, W. Chen, N. Myung, and A. Mulchandani, InterScience 19, 2125 (2007).

G. Bayramoğlu, M. Karakışla, B. Altıntaş, A. U. Metin, M. Saçak, and M. Y. Arıca, Process Biochem. 44, 880 (2009).

H. Gherras, A. Yahiaoui, A. Hachemaoui, A. Belfeda, A. Dehbi, and A. I. Mourad, J. Semicond. 39, 102001 (2018).

X. Ding, F. Tan, H. Zhao, M. Hua, M. Wang, Q. Xin, and Y. Zhang, J. Membr. Sci. 570‒571, 53 (2019).

G. H. Shim and S. H. Foulger, Photonics Nanostruct.: Fundam. Appl. 10, 440 (2012).

P. M. Carrasco, H. J. Grande, M. Cortazar, J. M. Alberd, J. Areizaga, and J. A. Pomposa, Synth. Met. 156, 420 (2006).

Z. A. Boeva and V.G. Sergeyev, Polym. Sci., Ser. C 56, 144 (2014).

P. Zarrintaj, H. Vahabi, M. R. Saeb, and M. Mozafari, “Application of Polyaniline and Its Derivatives,” in Fundamentals and Emerging Applications of Polyaniline, Ed. M. Mozafari and N. P. S. Chauhan (Elsevier, Amsterdam, 2019), pp. 259–272.

R. Reza Ansari, E.-J. Chem. 3, 186 (2006).

W.-L. Yuan, X. Yang, L. He, Y. Xue, S. Qin, and G.‑H. Tao, Front. Chem. 6, 59 (2018).

T.-H. Le, Y. Kim, and H. Yoon, Polymers 9, 150 (2017).

Y. Hoshina and T. Kobayashi, Engineering 4, 139 (2012).

H. Braunling and R. Becker, US Patent No. 5004560A (1991).

A. K. Mishra, J. At., Mol., Condens. Nano Phys. 5, 159 (2018).

C. Jubsilp, T. Takeichi, and S. Rimdusit, “Polymerization Kinetics,” in Handbook of Benzoxazine Resins, Ed. by H. Ishida and T. Agag (Elsevier, Amsterdam, 2011), pp. 157–174.

L. Yahia and L. K. Mireles, “X-ray Photoelectron Spectroscopy (XPS) and Time-of-flight Secondary Ion Mass Spectrometry (ToF SIMS),” in Characterization of Polymeric Biomaterials, Ed. by M. C. Tanzi and S. Farè (Woodhead Publ., Cambridge, 2017), pp. 83–97.

J. Bergström, Mechanics of Solid Polymers (Elsevier, Amsterdam, 2015).

M. B. Zaman and D. F. Perepichka, Chem. Commun. 33, 4187 (2005).

A. Douhal, F. Lahmani, and A. H. Zewail, Chem. Phys. 207, 477 (1996).

R. J. Ouellette and J. D. Rawn, “Alcohols and Phenols,” in Principles of Organic Chemistry (Elsevier, Boston, 2015), pp. 209–238.

Funding

This work was supported by Damascus University and Al-Furat University.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Al-Hamdan, A., Al-Falah, A., Al-Deri, F. et al. Synthesis, Characterization, and Kinetic Study of Poly(2-formyl pyrrole). Polym. Sci. Ser. B 63, 191–198 (2021). https://doi.org/10.1134/S1560090421030015

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1560090421030015