Abstract

The distributed beam-loss monitor based on the Cherenkov radiation in an optical fiber installed on the e–e+ Injection Complex at the Budker Institute of Nuclear Physics is considered. Monitor parameters are optimized based on a numerical model and experimental data. For a 45-m-long quartz fiber (with a core diameter of 550 μm) and a microchannel plate photomultiplier as a signal detector, a spatial resolution of less than 1 m is achieved. Software for processing photodetector signals, which allows the real-time monitoring of the distribution of beam loss along the entire beam line, is developed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

INTRODUCTION

Diagnostics of beam losses is important at all stages of charged particle accelerator operation, from its setup and start-up to the optimization of losses in real time during its normal operation. For the last two decades, a distributed beam-loss monitor based on the Vavilov–Cherenkov radiation in an optical fiber has been an alternative to local sensors. Along with many other accelerator centers [1, 2], this method of using optical fibers as a beam-loss diagnostics system was also developed at the Budker Institute of Nuclear Physics (BINP) SB RAS for the e–e+ Injection Complex [3]. This monitor can be used both in single-flight beam transfer channels and in a storage ring.

This report describes the requirements for the beam-loss monitor on the e–e+ Injection Complex at BINP. The results of the monitor operation with optimized parameters are presented. We also demonstrate software that allows configuring the beam passage in the accelerator in real time.

1 EXPERIMENTAL SETUP AND MONITOR REQUIREMENTS

The injection complex, which provides high-energy electron and positron beams for the two colliders at BINP SB RAS, consists of two consecutive linear accelerators with an energy of 300 and 500 MeV, a storage ring, and extraction channels, with the subsequent beam transportation to consumers. In the 2018/2019 season, the complex operated at 400 MeV with an injection frequency of 2 and 5 Hz for electrons and positrons, respectively. The frequency of extraction from the storage ring reached 1 Hz. In the storage ring with a perimeter of 27.4 m, the beam current is 20–40 mA, and the beam duration is less than 1 ns. The typical amount of beam losses during transport reaches 50%, so a standard system for monitoring beam losses is required.

The main requirements for a fiber-optic beam-loss monitor on the injection complex are (a) high spatial resolution of at least 1 m, which is determined based on the distance between the magnetic elements of the accelerator; (b) the resistance of the fiber to ionizing radiation, allowing the monitor to be operated at doses up to 103 Gy; and (c) optimal cost of components.

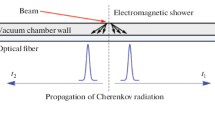

As a result of testing various types of optical fibers, photomultipliers (PMTs), and analog-to-digital converters (ADCs), a monitor with optimal parameters was selected. The fiber length was 45 m. Among optical fibers, the optimal choice in terms of the spatial resolution, resistance to ionizing radiation, and cost is a quartz fiber with stepped profile of refractive index (SPRI) and a core diameter of 550 μm. To achieve the best spatial resolution of the monitor, the light signal should be registered at the end of the fiber opposite to the direction of the electron beam. Owing to its fast response and high gain, the PMT based on the microchannel plate (MCP) is the optimal choice as a photodetector. Finally, the ADC should have a bandwidth of at least 200 MHz and a sampling rate of at least 500 M sample/s.

2 EXPERIMENTAL DATA

To monitor the distribution of electron beam losses, a fiber-optic loss monitor was installed in the extraction channel of the storage ring. The quartz multimode optical fiber with SPRI (FG550UEC, Thorlabs) selected for the monitor had the following parameters: the core/cladding diameter was 550/600 μm, NA = 0.22, and the maximum attenuation coefficient was 0.01 dB/m. The calculated dispersion value for this fiber is 0.19 ns/m. The MCP-PMT (JSC “Katod”, Novosibirsk) photodetector has a rise time of 0.5 ns and a duration (halfwidth) of the anode current pulse of at least 1.5 ns; the maximum of the sensitivity range of the photocathode corresponds to the maximum of the Cherenkov radiation spectrum (300–900 nm).

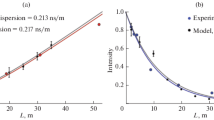

Figure 1 shows the distribution of electron-beam losses in the output channel from the storage ring obtained at the two ends of the optical fiber. Registering a signal propagating in the direction opposite to the direction of the beam provides information about places of three significant beam losses. The signal from the opposite end gives information about a single loss, peak D, which is a combination of overlapping losses B and C. Peak A characterizes the typical loss in the region of the beam injection near the septum magnet SM. The half-width of peak D is 3.8 m at a length of the fiber segment of 31 m. For comparison, the half-width of peak B is 0.9 m at a length of 19 m. Thus, compared to the signal co-propagating to the beam, the counterpropagating signal provides four times better spatial resolution of the beam-loss monitor. Considering the difference in gain coefficient of PMTs, the signal intensity is an order of magnitude lower in this case. Both of these conclusions are in good agreement with the results of analytical calculations and numerical modeling.

3 SOFTWARE

Software developed for processing the monitor signals allows adjusting the accelerator operation in the real-time mode by tracking the distribution of beam losses along the accelerator structure. To determine the location of the beam loss, the program recalculates the arrival time of the ADC signal in the longitudinal coordinate. Since it was decided to use the counterpropagating light signal, the time-to-coordinate conversion coefficient is approximately c/(n + 1), where n is the refractive index of the fiber core. To obtain a more accurate distribution of losses, the noise recorded in the absence of the beam is subtracted from the signal and square spline interpolation is applied. For the visual tracking of losses, the signal recorded with the previous set of parameters of the magnetic system can be saved and superimposed on the results of current measurements.

Figure 2 shows a program window, which allows overlaying the measurement result with the accelerator structure and with the result of previous measurement, as well as controlling the voltage applied to the PMT. The data in Fig. 2 illustrate the typical distribution of beam losses in the process of adjusting the electron beam injection. In all cases there are beam losses at the point (after the septum magnet SM) of its injection from the storage ring. All data were obtained at the same voltage applied to the PMT. The distribution shown in gray corresponds to the “torsion” of the magnetic correction of the 3M5 and 5M4 dipoles. The loss distribution corresponding to the optimized beam transport is shown in blue.

CONCLUSIONS

The results of the parameter optimization of the fiber-optic beam loss monitor installed on the e–e+ Injection Complex at BINP SB RAS are presented. For a 45-m-long quartz fiber (with a core diameter of 550 μm) and an MCP-PMT device as a photodetector, a spatial resolution of the monitor of less than 1 m was achieved. Software for processing photodetector signals has been developed which allows adjusting the accelerator operation in real-time.

REFERENCES

E. Nebot del Busto et al., in Proceedings of the IBIC 2014, 4th International Beam Instrumentation Conference, Melbourne, Australia, September 13–17,2015, p. 580.

X.-M. Marechal, Y. Asano, and T. Itoga, Nucl. Instrum. Methods Phys. Res., Sect. A 673, 32–45 (2012).

Yu. Maltseva et al., in Proceedings of the 26th Russian Particle Accelerator Conference RuPAC2018, Protvino, Russia, October 1–5,2018, p. 39.

Yu. I. Maltseva et al., Phys. Usp. 58, 516–519 (2015).

Yu. Maltseva and V. G. Prisekin, in Proceedings of the 26th Russian Particle Accelerator Conference RuPAC2018, Protvino, Russia, October 1–5,2018, p. 486.

G. Battistoni et al., Ann. Nucl. Energy, 10–18 (2015).

J. M. Senior, Optical Fiber Communications Principles and Practice, 3rd ed. (Pearson Education, 2009).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by V. Alekseev

Rights and permissions

About this article

Cite this article

Maltseva, Y.I., Astrelina, K.V. Optimizing Parameters of the Fiber-Optic Beam-Loss Monitor for the VEPP-5 Injection Complex. Phys. Part. Nuclei Lett. 17, 594–596 (2020). https://doi.org/10.1134/S1547477120040329

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1547477120040329