Abstract

The initial polycrystalline films of tungsten and titanium, whose surface has predominantly ultrananodispersed morphology and a thickness of 50 to 100 nm, are obtained by magnetron sputtering on conductive fluorinated tin oxide (FTO) films, which were deposited on glass substrates. At the next stage, the resulting films of tungsten and titanium are thermally oxidized in a programmable muffle furnace in an air atmosphere. The morphology, structural, and the optical properties of both the initial tungsten and titanium films and their oxides are studied. Some preliminary results are presented and the prospects for using the obtained tungsten oxide (WO3) and titanium dioxide (TiO2) films as electrochromic, photochromic and sensor materials are discussed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

INTRODUCTION

In microelectronic engineering, thin films of tungsten and titanium on various substrates, in addition to their direct application, can be used to form oxide layers for various functional purposes. Therefore, studying the formation processes of the accompanying and main phases in tungsten and titanium films during oxidation, as well as controlling the characteristics at the interphase boundaries in the entire system at various stages of oxidation, is both a scientific and practical task.

Tungsten oxide (WO3) is of interest to researchers from both the fundamental and applied points of view due to its unusual optical and other electrophysical properties [1–3]. WO3-based nanopowders and films can be successfully used to develop electrochromic and photochromic displays, as well as optical modulators and windows with adjustable light transmission [4–8]; to create resistive and semiconductor sensors of explosive (Н2, CxHy) and environmentally harmful gases (CO, NO2, etc.) [9–15]and to design various catalysts [16–18], etc.

Together with various methods of obtaining metal oxide semiconductor layers [19–21], when obtaining nanopowders and films of tungsten oxide (WO3 – x) [22–24], the controlled oxidation of condensed metal tungsten films with a granular structure and nanometer-sized thickness in an air atmosphere may be of considerable interest [24]. This method, which is distinguished by its simplicity and technological flexibility, provides ample opportunities for obtaining nanopowders and films of tungsten oxide (WO3 – x) and studies of metal-oxygen interaction processes.

Titanium dioxide (TiO2) and tungsten oxide are widely studied due to its strong photocatalytic activity, the creation of resistive and semiconductor sensors, in the development of electrochromic and photochromic devices, etc. [25–30]. For example, the development of photocatalysts based on it is currently a promising direction, since TiO2 is an inexpensive and chemically resistant material. Of particular interest is the synthesis of titanium dioxide in a thin-film state.

Thus, the problem of studying the oxidation processes of metal films of tungsten and titanium in an air atmosphere on a conductive SnO2 film doped with fluorine and deposited on a glass substrate is of not only fundamental but also applied significance.

EXPERIMENTAL

The substrate material for the deposition of layers of metallic tungsten and titanium consisted of samples of K-glass with a thickness of 3.8 mm manufactured by Pilkington (Britain) with a transparent conductive layer of SnO2 : F (fluorinated tin oxide (FTO)) and surface resistance of 20–25 Ohm/□, which was deposited on a glass substrate by the pyrolysis method [31]. The area of the substrates was 30 × 30 mm2. The W and Ti layers were deposited by magnetron sputtering using a Q150TS/E/ES setup at deposition rates of 10 to 30 nm/min, according to the procedure described in detail in [32]. The deposition current averaged 100 mA, and the deposition time, depending on the target material and the applied film thickness, varied in the range of 5 to 20 min.

Plates of pure W (99.99%) and Ti (99.99%) each 57 mm in diameter and 1 mm thick were used as the targets. The substrates were fixed on a holder rotating at a constant speed (15 rpm), and the distance between the target and the holder was 5 cm.

The effective thickness of the deposited layers was determined from the time of deposition of the material’s particles and controlled using a built-in meter according to the mass of the deposited metal.

In the course of the experiments, a series of samples of tungsten and titanium layers 50–100 nm thick were obtained. The samples obtained were subjected to thermal oxidation in an electric muffle furnace with programmed heating up to 600°C, by varying in each case the heating rate (from 3.5 to 20°C/min). The samples were kept at a constant oxidation temperature in the furnace for a certain time (30–120 min), and then the muffle furnace with the samples was naturally cooled for 20 h.

The surface morphology and size of the nanocrystals in the films were studied by scanning electron microscopy (SEM) using a Zeiss Merlin device (Zeiss, Germany).

The structure and phase composition of all the films being studied was analyzed at the Engineering Center of St. Petersburg State Technological Institute (Technical University) using a SmartLab 3 X-ray diffractometer (Rigaku Corporation). In diffraction measurements, we used an X-ray tube with either CuKα radiation or cobalt CoKα radiation. A D/Tex Ultra 250 detector was used. The dynamic range exceeds 2 × 108 imp./s. All the measurements were made in the angular range 2θ = 20°–60°.

The optical characteristics of the synthesized oxide nanolayers were studied by measuring their transmission spectra in the near UV and visible regions using an SF-56 spectrophotometer (LOMO, St. Petersburg).

The samples obtained were tested in designs of electrochromic devices (ECDs) as cathode tungsten oxide electrochromic layers in combination with an electrolyte (1 M solution of lithium perchlorate LiClO4 in propylene carbonate) and a transparent counter electrode in the form of a glass substrate coated with FTO. The electrochromic efficiency was determined by measuring the decrease in optical transparency under the action of a voltage of 3 V and a current density of 0.5–1.0 mA/cm2 with subsequent discoloration under the influence of voltage of the opposite polarity. For a fabricated electrochemical cell measuring 2 × 2 cm2, the transmission spectra were recorded in the wavelength range from 300 to 1100 nm in the initial, colored, and discolored states.

The observed electrochromic effect was characterized by the optical modulation contrast, calculated as

where Tdiscol and Tcol are transmittance coefficients (%) in the discolored and colored state, respectively.

The results obtained were compared with similar data for an electrochemical device based on the WO3 and TiO2 layers obtained by sol-gel synthesis and direct magnetron sputtering [29–31].

RESULTS AND DISCUSSION

We studied metal films of the initial tungsten and titanium, which were obtained by magnetron sputtering over SnO2 films deposited on glass substrates, and oxidized by heat treatment in an air atmosphere at 600°C, according to the method described above. The obtained W and Ti metal films were opaque in the visible region of the optical spectrum and had a uniform mirror surface 50–100 nm thick.

Scanning Electron Microscopy (SEM)

In Fig. 1 the morphologies of the surfaces of the initial conductive FTO film (a) and the same surface after heat treatment in air at 600°C for 2 h (b).

The surface of the original polycrystalline FTO film (see Fig. 1a) has a predominantly granular morphology, with a range of changes in the size of most individual crystals of 100 to 200 nm.

On the surface of some grains, twin seams can be observed, which are characteristic of cranked twins and are often observed not only in crystals of natural cassiterite (SnO2) but also on the surface morphology of polycrystalline films of cassiterite obtained by the laboratory method [33].

The surface of the oxidized polycrystalline SnO2 film doped with fluorine (see Fig. 1b) also has a predominantly granular morphology. Significant changes can also be observed, which are related to the appearance of a large number of elongated crystals with a tetragonal modification observed in the minerals of natural cassiterite (SnO2).

Although the number of elongated crystals did not exceed ∼10% of the total amount of all crystals on the surface in the original SnO2 film, their number increased markedly to more than 50% in oxidized SnO2. This is most likely due to recrystallization processes, which are typical for cases of prolonged thermal exposure to polycrystalline films.

Microfragments of the morphology of the initial tungsten (a) and titanium (b) films each 100 nm thick, which are deposited on top of a conductive SnO2 film doped with fluorine, are shown in Fig. 2. A common characteristic feature of the observed surfaces of the initial polycrystalline tungsten and titanium films is their nanodispersity, which is expressed in the fact that individual metal particles have sizes on the order of a few nm. It is difficult to detect the real size of such small particles using the SEM used, but the nature of the change in surface morphology after the deposition of layers of tungsten and titanium and the differences between them are obvious.

For the surface of films of metallic tungsten (see Fig. 2a), individual groups of particles are randomly combined into agglomerates, which in some cases reach a cross-sectional size across of 200 to 600 nm. The surface of titanium metal films (see Fig. 2b), consisting of individual metal particles with sizes on the order of several nm, apparently envelopes the surface of larger crystalline SnO2 particles with a dense layer; as a result of this, the clear faceting of the tin dioxide particles becomes less contrasting (blurred), particles of crystalline particles of SnO2 with smaller titanium particles adsorbed on the surface take rounded shapes, and the quasi-size of quasi-particles of SnO2 + Ti increases reaching values of 120 to 250 nm.

This form of morphology of metal films can be related to both their heterogeneous interaction with the surface of the SnO2 film and technological modes of magnetron sputtering.

Micrographs of the morphology of the initial W and Ti films oxidized by heat treatment in an air atmosphere are presented in Fig. 3.

A common characteristic feature in these images is the presence on the surface of the films of individual particles with a noticeable crystal faceting.

The surface morphology of tungsten films (see Fig. 3a) oxidized by heat treatment in air is characterized by the presence of fairly well-faceted crystals. The crystals are randomly oriented, and the size varies in the range of 100 to 400 nm.

The surface morphology of titanium films (see Fig. 3b) oxidized by heat treatment in air is also characterized by the presence of faceted crystals. The crystals are randomly oriented, but the size varies within narrower limits of 100 to 150 nm. Individual crystal groups of 3 to 5 crystals are lined up, but randomly oriented. Their number does not exceed 10–15% in relation to the number of other crystals on the surface.

X-Ray Phase Analysis (XRD)

The X-ray spectrum of the survey diffractogram (θ–2θ scan, CuKα radiation) of the original SnO2 film doped with fluorine (FTO), which was deposited on a glass substrate, is shown in Fig. 4 (top).

Comparison of the X-ray diffraction pattern of the FTO film with the corresponding X-ray pattern of cassiterite (SnO2) from the PDF database [34].

The corresponding X-ray diffraction pattern of cassiterite (000-05-0467) from the PDF database [34], which shows the main reflections in the form of line intensities and the corresponding angles 2θ, related to the crystalline phase of cassiterite, is shown in Fig. 4 (bottom).

On the X-ray diffraction pattern of the FTO film (upper spectrum), the designation of the direction of the plane, which in the compared spectrum (lower spectrum) corresponds to a certain angle 2θ, is shown next to each reflection.

The diffractogram of the FTO film shows only the set of main reflections related to the crystalline phase of cassiterite, which was identified using the database.

The corresponding X-ray phase analysis was carried out in order to study the structural and phase composition of the initial films of tungsten and titanium, which are deposited on top of a conductive SnO2 film doped with fluorine.

The X-ray spectrum of the survey diffractogram (θ–2θ scan, CuKα radiation) of the original FTO film, on top of which a tungsten metal film with a thickness of 100 nm was deposited, is shown in Fig. 5.

An analysis of the X-ray diffraction pattern indicates that the observed set of reflections belongs to the crystalline phase of cassiterite, which was previously identified using the database, and the absence of crystalline tungsten reflections on the mirror surface of the tungsten film indicates that it is X-ray amorphous. The screening effect of the tungsten film is illustrated by the fact that some weaker reflections of SnO2 that were previously seen on the previous original FTO film are missing.

The X-ray spectrum of the survey diffractogram (θ–2θ scan, CoKα radiation) of the original SnO2 film doped with fluorine (FTO), on top of which a titanium metal film 100 nm thick was deposited, is shown in Fig. 6.

It can be seen that the general character of those reflections observed in Fig. 6 for a two-layer SnO2\(\left\langle {\text{F}} \right\rangle \) + Ti film, their number and the crystal directions of the planes assigned to them are similar to the X-ray spectrum shown in Fig. 5 for the double layer SnO2\(\left\langle {\text{F}} \right\rangle \) + W film. The fundamental difference consists only in the mismatch of the 2θ angles in both spectra in which reflections are observed and which is explained by the use of two different X-ray tubes with different radiation (CuKα and CoKα).

Further, the XRD analysis of tungsten and titanium films, which are deposited on top of a conductive SnO2 film and oxidized by heat treatment in air at 600°C, is carried out in order to study their composition and structure.

The X-ray spectrum of the survey diffractogram (θ–2θ scan, CuKαradiation) of the original SnO2 film doped with fluorine (FTO), on top of which a tungsten metal film (100 nm thick) was deposited, and then oxidized in air at 600°C, is shown in Fig. 7 (top).

The corresponding X-ray diffraction patterns of cassiterite (SnO2) (000-05-0467) and tungsten oxide (WO3) 000-20-1323 from the PDF database [34, 35], which show the main reflections in the form of line intensities and the corresponding 2θ angles, related to the crystalline phases of cassiterite and tungsten oxide, are shown in Fig. 7 (bottom).

The X-ray diffraction pattern of the SnO2\(\left\langle {\text{F}} \right\rangle \) + WO3 (upper spectrum), next to three reflections, is the designation of the direction of the plane, which in the compared spectrum (lower spectrum) corresponds to a certain angle 2θ: they are all related to the main cassiterite reflections and agree with the selected X-ray pattern for cassiterite from the database (000-05-0467).

The fact that other less intense reflections of cassiterite are not visible is explained by the screening effect of the thick oxidized tungsten film. The X-ray diffraction pattern under consideration shows a number of reflections, of which the most intense is observed at 24.3661° and is consistent with the X-ray pattern of tungsten oxide (WO3) 000-20-1323 from the PDF database [35].

It should be noted that \(\left\langle {\text{F}} \right\rangle \) a set of two groups of reflections, of which one group can be attributed to the crystalline phase of cassiterite and the other group to the phase of tungsten oxide, can be observed on the X-ray diffraction pattern of a two-layer SnO2\(\left\langle {\text{F}} \right\rangle \) + WO3 film.

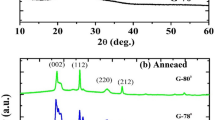

The X-ray spectrum of the survey diffractogram (θ–2θ scan, CoKαradiation) of the original SnO2 film doped with fluorine (FTO), on top of which a titanium metal film (100 nm thick) was deposited, and then oxidized in air at 600°C, is shown in Fig. 8 (top).

As a comparison, the corresponding X-ray diffraction patterns of cassiterite (SnO2) (000-05-0467) and titanium oxide (TiO2) 000-21-1272 from the PDF database [34, 36], which show the main reflections in the form of line intensities and corresponding 2θ angles, related to the crystalline phases of cassiterite and titanium oxide, are shown in Fig. 8 (top).

The X-ray diffraction pattern of the SnO2\(\left\langle {\text{F}} \right\rangle \) + TiO2 film (upper spectrum), above the three reflections, is the designation of the direction of the plane, which in the compared spectrum (lower spectrum) corresponds to a certain 2θ angle: they are all related to the main reflections of cassiterite and agree with the selected radiograph for cassiterite from the database (000-05-0467).

Also, in the X-ray diffraction pattern under consideration, we can notice a number of reflections, of which the most intense one is observed at 29.4423°, and the others at 43.1684°, 44.1908°, 45.1100°, and 56.4288°, respectively, and which are in satisfactory agreement with the X-ray pattern of titanium oxide (TiO2) 000-21-1272 from the PDF database [36]. It should be noted that the difficulty in identifying three closely spaced peaks with values of 43.1684°, 44.1908°, and 45.1100° and that are related to titanium oxide can be explained by the effect on them of a more intense peak of tin dioxide, which has a value of 44.3676°.

Optical Characteristics

The optical transmission spectra of SnO2:F, SnO2:F + WO3, and SnO2:F + TiO2 are shown in Fig. 9. The last two films were obtained by oxidizing in an air atmosphere at 600°C metal films of the corresponding metals 100 nm thick, deposited on top of the initial SnO2:F film.

The obtained samples showed a fairly high transparency and their average degree of light transmission in the visible wavelength range from 380 to 780 nm (GOST (State Standard) EH 410-2014) in the initial state was 80% for SnO2:F, 70% for SnO2:F + TiO2, and 60% for SnO2:F + WO3.

Such transmission parameters predetermine good prospects for the use of these films as electrodes for electrochromic devices.

Tin oxide, SnO2, is a typical transparent n-type semiconductor with a wide forbidden gap, which, depending on the technological conditions for obtaining the material, varies in the range 3.6–4.0 eV [37]. In [38], the band gap for SnO2 nanoparticles with a diameter of 30 to 40 nm has a range of 3.76 to 4.24 eV and was calculated based on the optical absorption spectra.

The Tauz method was used to directly estimate the band gap of SnO2:F, SnO2:F + WO3, and SnO2:F + TiO2 [39]. The corresponding dependences in the (logT/λ)2–E coordinates are shown in Fig. 10, where T is the transmittance coefficient of the sample, and E = hc/λ is the energy of photons (eV). The optical band gap was determined by extrapolating the linear regions of the Tauz plots to the abscissa axis.

Within the experimental accuracy, the calculated values of the band gap of the synthesized SnO2:F, SnO2:F + WO3, and SnO2:F + TiO2 layers are about 3.9, 3.6, and 3.4 eV, respectively.

These values are slightly different from the corresponding reference data for SnO2 (~3.6 eV), TiO2 (3.0–3.3 eV), and WO3 (2.8–3.0 eV), which is apparently due to the presence of fluorine in FTO, nanoscale effects, and the formation of additional phases or compounds at the interphase boundaries.

Electrochromic Properties

Testing the obtained tungsten oxide layers in the design of electrochromic cells with a glass substrate-FTO-WO3-electrolyte-FTO-glass substrate structure showed a decrease in integral light transmission in the wavelength range 380–780 nm from 67% to Tcol = 39%, which was accompanied by intense blue coloration, followed by an increase in transparency to about Tdiscol = 49% when discolored by voltage of the opposite polarity.

The considered data show the possibility of a controlled change in light transmission and coloration using ECDs, providing an optical modulation contrast of up to about 20.5%. This value is comparable to or exceeds the previously achieved values for WO3 layers and TiO2 obtained by the sol–gel synthesis (up to 18% [29, 30]) and direct magnetron sputtering (up to 27% [31]).

Thus, tungsten oxide layers obtained by the thermal oxidation of W and Ti, in principle, have an electrochromic effect and, with further optimization of the conditions for their preparation, can be used as one of the functional layers of electrochromic devices.

CONCLUSIONS

The results of the X-ray diffraction analysis of tungsten and titanium metal films deposited on conductive FTO films confirm their strong amorphism in comparison with the crystalline cassiterite layer on which they are deposited.

The X-ray diffraction patterns of the oxidized layers (WO3 and TiO2) confirm the complete transformation of the metal layers into oxide ones.

The optical transmission spectra of all the investigated metal oxide layers showed a fairly high degree of light transmission in the visible wavelength range.

The tungsten oxide layers obtained by the thermal oxidation of W have a pronounced electrochromic effect.

REFERENCES

Johansson, M., Zietz, B., Niklasson, G., and Österlund, L., Optical properties of nanocrystalline WO3 and WO3 – x thin films prepared by DC magnetron sputtering, J. Appl. Phys., 2014, vol. 115, no. 21, pp. 1–16.

Ataallaa, M., Afify, A.S., Hassanc, M., Abdallah, M., Milanova, M., Aboul-Eneinf, H.Y., and Amr, M., Tungsten-based glasses for photochromic, electrochromic, gas sensors, and related applications: A review, J. Non-Cryst. Solids, 2018, vol. 491, no. 1, pp. 43–54.

Madhavi, V., Kondaiah, P., Hussain, O.M., and Uthanna, S., Structural, optical, and luminescence properties of reactive magnetron sputtered tungsten oxide thin films, Int. Scholarly. Res. Not., 2012, vol. 2012, 801468.

Belousov, A.L. and Patrusheva, T.N., Electrochromic oxide materials, J. Sib. Fed. Univ. Eng. Technol., 2014, vol. 6, no. 7, pp. 698–710.

Krysa, J., Zlamal, M., Kment, S., and Hubicka, Z., Photo-electrochemical properties of WO3 and α-Fe2O3 thin films, Chem. Eng. Trans., 2014, vol. 41, pp. 379–384.

Hammad, A.S., El-Bery, H.M., El-Shazly, A.H., and Elkady, M.F., Effect of WO3 morphological structure on its photoelectrochemical properties, Int. J. Electrochem. Sci., 2018, vol. 13, pp. 362–372.

Maiorov, V.A., Window glasses: State and prospects, Opt. Spectrosc., 2018, vol. 124, no. 4, pp. 594–608.

Maiorov, V.A., Electrochromic glasses with separate regulation of transmission of visible light and near-infrared radiation (review), Opt. Spectrosc., 2019, vol. 126, no. 4, pp. 412–430.

Kanan, S.M., El-Kadri, O.M., Abu-Yousef, I.A., and Kanan, M.C., Semiconducting metal oxide based sensors for selective gas pollutant detection, J. Sens., 2009, vol. 9, pp. 8158–8196.

Zhang, H., Wang, Y., Zhu, X., Li, Y., and Cai, W., Bilayer Au nanoparticle-decorated WO3 porous thin films: On-chip fabrication and enhanced NO2 gas sensing performances with high selectivity, Sens. Actuators, B, 2019, vol. 280, pp. 192–200.

Mirzaei, A., Kim, J.-H., Kim, H.W., and Kim, S.S., Gasochromic WO3 nanostructures for the detection of hydrogen gas: An overview, Appl. Sci., 2019, vol. 9, pp. 1–21.

Staerz, A., Somacescu, S., Epifani, M., Russ, T., Weimar, U., and Barsan, N., WO3 based gas sensors, in Proceedings of the Eurosensors 2018, Graz, 2018, vol. 2, pp. 1–4.

Urbańczyk, M., Maciak, E., Gut, K., Pustelny, T., and Jakubik, W., Layered thin film nanostructures of Pd/WO3 – x as resistance gas sensors, Bull. Pol. Acad. Sci.: Tech. Sci., 2011, vol. 59, no. 4, pp. 401–407.

Hua, D., Zhou, Z., Hua, Q., Li, J., Lu, X., Xie, Y., Xiao, H., Li, M., and Yang, J., Transformation of 2-butene into propene on WO3/MCM-48: Metathesis and isomerization of n-butene, Catalysts, 2018, vol. 8, no. 12, pp. 1–11.

Rumyantseva, M.N., Bulova, M.N., Chareev, D.A., Ryabova, L.I., Akimov, B.A., Arkhangel’skii, I.V., and Gas’kov, A.M., Synthesis and study of nanocomposites based on semiconductor oxides SnO2 and WO3, Vestn. Mosk. Univ., Ser. 2: Khim., 2001, vol. 42, no. 5, pp. 348–355.

Yang, X., Wu, N., Miao, Y., and Li, H., Modification effects of B2O3 on the structure and catalytic activity of WO3-UiO-66, Nanomaterials, 2018, vol. 8, pp. 1–17.

Pašti, I.A., Gavrilov, N.M., and Mentus, S.V., Electrocatalytic behavior of Pt/WO3 composite layers formed potentiodynamically on tungsten surfaces, Int. J. Electrochem. Sci., 2017, vol. 12, pp. 5772–5791.

Yang, X.-L., Dai, W.-L., Guo, C., Chen, H., Cao, Y., Li, H., He, H., and Fan, K., Synthesis of novel core-shell structured WO3/TiO2 spheroids and its application in the catalytic oxidation of cyclopentene to glutaraldehyde by aqueous H2O2, J. Catal., 2005, vol. 234, pp. 438–450.

Bochenkov, V.E. and Sergeev, G.B., Sensitivity, selectivity, and stability of gas-sensitive metal-oxide nanostructures, in Metal Oxide Nanoparticles and Their Applications, Umar, A. and Hahn, Y.B, Eds., Am. Sci., 2010, pp. 31–52.

Rorigues, J.A. and Fernandez-Garcia, M., Synthesis, Properties, and Applications of Oxide Nanomaterials, Hoboken: Wiley, 2007.

Dey, A., Semiconductor metal oxide gas sensors: A review, Mater. Sci. Eng., A, 2018, vol. 229, pp. 206–217.

Gromov, A.A., Kvon, Ya.S., Il’in, A.P., and Vereshchagin, V.I., Specific features of the oxidation of a tungsten nanopowder, Russ. J. Phys. Chem. A, 2004, vol. 78, no. 9, pp. 1484–1487.

Kolobkova, E.V., Sokhovich, E.V., and Zemko, V.S., The influence of synthesis conditions on structure and thermal properties of electrochromic WO3 films, Izv. St. Petersburg. Tekhnol. Inst., 2016, vol. 45, no. 19, pp. 3–7.

Tutov, E.A., Logacheva, V.A., Khoviv, A.M., Tutov, E.E., and Pribytkov, D.M., Study of oxidation of thin tungsten films on silicon, Kondens. Sredy Mezhfaz. Granitsy, 1995, vol. 9, no. 3, pp. 266–271.

Chenari, H.M., Seibel, C., Hauschild, D., Reinert, F., and Abdollahian, H., Titanium dioxide nanoparticles: Synthesis, X-ray line analysis and chemical composition study, Mater. Res., 2016, vol. 19, no. 6, pp 1319–1323.

Li, Z., Yao, Z.J., Haidry, A.A., Plecenik, T., Xie, L.J., Sun, L.C., and Fatima, Q., Resistive-type hydrogen gas sensor based on TiO2: A review, Int. J. Hydrogen Energy, 2018, vol. 43, no. 45, pp. 1–19.

Zakrzewska, K. and Radecka, M., TiO2-based nanomaterials for gas sensing-influence of anatase and rutile contributions, Nanoscale Res. Lett., 2017, vol. 89, no. 12, pp. 1–8.

Sorar, I., Pehlivan, E., Niklasson, G., and Granqvist, C., Electrochromism of DC magnetron sputtered TiO2 thin films: Role of deposition parameters, Sol. Energy Mater. Sol. Cells, 2013, vol. 115, pp. 172–180.

Gillaspie, D.T., Tenent, R.C., and Dillon, A.C., Metal-oxide films for electrochromic applications: Present technology and future directions, J. Mater. Chem., 2010, vol. 20, pp. 9585–9592.

Raza, M.A., Habib, A., Kanwal, Z., Hussain, S.S., Iqbal, M.J., Saleem, M., Riaz, S., and Naseem, S., Optical CO2 gas sensing based on TiO2 thin films of diverse thickness decorated with silver nanoparticles, Adv. Mater. Sci. Eng., 2018, vol. 2018, 2780203.

Serenko, S.A., Uvarov, N.F., and Gavrilenko, V.A., Synthesis and properties of transparent conducting films of tin dioxide doped with fluorine, Khim. Interesakh. Ustoich. Razvit., 2015, vol. 23, pp. 103–106.

Baryshev, M.G, Bolotin, S.N., Petriev, I.S., Frolov, V.Yu., and Dzhimak, S.S., Application of methods of electrothermal and magnetron sputtering to create hydrogen-permeable metal catalysts, Ekol. Vestn. Nauch. Tsentr. ChES, 2014, no. 2, pp. 20–24.

Tomaev, V.V. and Glazov, A.I., Morphology of polycrystalline cassiterite films, Crystallogr. Rep., 2014, vol. 59, no. 5, pp. 749–752.

Swanson, H.E. and Tatge, E., Standard X-ray diffraction powder patterns, Natl. Bur. Stand. Circ. (U. S.), 1953, vol. 539, no. 1, pp. 54–55.

Roth, R.S. and Waring, J.L., Phase equilibria as related to crystal structure in the system niobium pentoxide–tungsten trioxide, J. Res. Natl. Bur. Stand., Sect. A, 1966, vol. 70A, pp. 281–303.

Huberty, J. and Xu, H., Kinetics study on phase transformation from titania polymorph brookite to rutile, J. Solid State Chem., 2008, vol. 181, pp. 508–514.

Batzill, M. and Diebold, U., The surface and materials science of tin oxide, Prog. Surf. Sci., 2005, vol. 79, nos. 2–4, pp. 47–154.

Leng, D., Wu, L., Jiang, H., Zhao, Y., Zhang, J., Li, W., and Feng, L., Preparation and properties of SnO2 film deposited by magnetron sputtering, Int. J. Photoenergy, 2012, vol. 2012, 235971.

Tauc, J., Grigorovici, R., and Vancu, A., Optical properties and electronic structure of amorphous germanium, Phys. Status Solidi B, 1966, vol. 15, p. 627.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Rights and permissions

About this article

Cite this article

Tomaev, V.V., Sokhovich, E.V., Myakin, S.V. et al. Obtaining and Studying Films of Tungsten, Titanium and Their Oxides. Glass Phys Chem 48, 61–68 (2022). https://doi.org/10.1134/S1087659622010151

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1087659622010151