Abstract

An efficient catalytic system has been developed on the basis of carbon-doped MoO3 (CPM-3) for the synthesis of 1,8-dioxodecahydroacridines by condensation of dimedone, aromatic aldehydes, and anilines in ethanol–water (3:1) under ultrasonication. The effects of addition of polyethylene glycol (PEG-400) and carbon (0, 1, 2, and 3 wt %) as substrates were investigated systematically to get the desired carbon-doped MoO3 material. The carbon source was prepared from the plant Acacia arabica, and the obtained samples were calcined at 500°C. The catalytic material was characterized by a number of sophisticated techniques such as XRD, SEM-EDS, FT-IR, TEM, NH3-TPD, and BET. The present protocol has several advantages, including the use of a non-corrosive, nontoxic, inexpensive, and recyclable catalytic material.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

INTRODUCTION

Heterocyclic compounds are important in the fields of medicinal chemistry, organic chemistry, biochemistry, and other areas of science [1]. Heterocyclic compounds exhibit antibacterial, antiviral, antifungal, anti-inflammatory, and antitumor activities [2–9]. Nitrogen-containing heterocycles constitute an important class for organic chemistry, and much research efforts aimed at synthesizing new heterocyclic compounds have contributed to the development of various synthetic protocols and found more applications in chemical sciences [10–14]. Nitrogen-containing heterocyclic compounds possess physiological and pharmacological properties and are constituents of many biologically important molecules, including vitamins, nucleic acids, pharmaceuticals, antibiotics, dyes, agrochemicals, etc. [15–20].

The use of ultrasonic irradiation in organic synthesis provides improved yields and is characterized by experimental simplicity, environmental friendliness, high efficiency [21–24], high crystallinity of the final products, and shortened reaction time [25–27].

1,8-Dioxodecahydroacridines and their derivatives can be regarded as polyfunctionalized 1,4-dihydropyridines. In recent years, 1,4-dihydropyridines and their derivatives have attracted strong interest for the treatment of cardiovascular diseases, such as angina pectoris [28] and hypertension [29]. Acridine derivatives have been used to synthesize labeled conjugates with medicines, peptides, proteins, and nucleic acids, which exhibit antitumor and DNA-binding properties [30–32]. They also exhibit antitumor, antitubercular, antimalarial, antibacterial, antihypertensive, fungicidal, anticancer, anti-inflammatory, and antidiabetic activities [33–41] and are used as dyes and photoinitiators [42–45], as well as semiconductors in materials science and luminescent agents in spectroscopy [46, 47].

Literature survey showed that there are various procedures for the synthesis of 1,8-dioxodecahydroacridines by condensation of dimedone, aldehydes, and aniline or ammonium acetate in the presence of several catalysts such as silica-bonded S-sulfonic acid (SBSSA) [48], Zn(OAC)2·H2O or L-proline [49], Amberlyst-15 [50–54], benzyl(triethyl)ammonium chloride (BTEAC) [55], proline [56], ZnO nanoparticles [57], CeCl3·7H2O [58], nano-Fe3O4 [59], silica-bonded N-propylsulfamic acid (SBNPSA) [60], microwave irradiation [61, 62], PMA-SiO2 [63], and p-dodecylbenzenesulfonic acid (DBSA) [64]. These methods suffer from one or more disadvantages such as long reaction time, low yield, the use of volatile solvents, and harsh reaction condition. Hence, we have developed a simple and efficient catalytic system for the synthesis of 1,8-dioxodecahydroacridine derivatives.

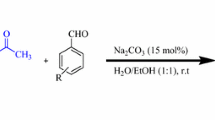

In last decade, rapid progress has been made in the field of transition metal oxides. In particular, molybdenum oxide (MoO3) exhibited high selectivity in the synthesis of heterocyclic compounds [65–71]. Our research focused on heterogeneous catalysis and synthesis of biologically active organic compounds [72, 73]. In continuation of these studies, now we were interested in finding a simple and efficient catalytic system using carbon-doped MoO3 (CPM-3). It was utilized for the synthesis of 1,8-dioxodecahydroacridine derivatives by condensation of dimedone, aldehydes, and aromatic amines in ethanol–water (3:1) under ultrasonication (Scheme 1).

RESULTS AND DISCUSSION

Initially, we studied the condensation of dimedone (2 mmol), benzaldehyde (1 mmol), and aniline (2 mmol) in the presence of CPM-3 as a model reaction. Various solvents such as benzene, chloroform, methanol, and acetonitrile were tried, but low to moderate yields were obtained. When ethanol and water were used, the results were satisfactory. A mixture of ethanol and water at a ratio of 1:1 provided moderate yields, whereas a good yield was achieved using ethanol–water at a ratio 3:1 without ultrasonication; however, the reaction time was longer. The best result (good to excellent yield) was observed in EtOH–H2O (3:1) under ultrasonic irradiation (Table 1).

After screening of solvents, we studied various catalysts. The reactions in the absence of a catalyst with and without ultrasonication gave poor yields, while the other catalysts like CM-0, CPM-1, and CPM-2 showed lower activity under the same conditions. As follows from the data in Table 2, CPM-3 showed the highest catalytic activity. This may be due to the small particle size and high porosity of the catalyst (see SEM, TEM, and BET surface analysis data below), which are related to the amount of carbon added.

Under the developed conditions, good to excellent yields (74–93%) were obtained with aldehydes containing both electron-withdrawing and electron-donating groups in the aromatic ring. Also, both aniline and p-toluidine equally underwent the excellent conversion. The structure of all products was confirmed by FT-IR, 1H NMR, and mass spectra (Table 3).

The reusability of the catalyst was tested using the same model reaction under the optimized conditions. After completion of the reaction, the catalyst was easily separated from the reaction mixture by simple filtration, washed with n-hexane, and dried at 80°C. The isolated catalyst was then used for the next run. It was found that CPM-3 could be reused at least 4 times without significant loss in catalytic activity (Fig. 1) [72, 74].

Catalyst characterization. Catalyst characterization is one of the crucial aspects of catalyst design since it gives information about crystallinity, surface structure, nature of active sites, particle size and morphology, acidity, basicity, and other characteristic features. The prepared samples were characterized by various sophisticated techniques.

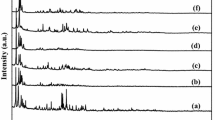

Figure 2 shows the XRD patterns of carbon-doped MoO3 with addition of PEG-400, namely CPM-0, CPM-1, CPM-2, and CPM-3 samples. Highly intense and sharp peaks at 2θ = 23.36, 25.75, 27.30, 33.61, and 38.96 were observed due to the planes (110), (040), (021), (111), and (060) corresponding to the orthorhombic crystal symmetry. All XRD peaks exactly matched literature values for MoO3 peaks from the JCPDS card 76-1003 [75] with the crystal lattice parameters a = 3.9628, b = 13.8550, and c = 3.6964 Å. The strong and sharp peaks suggest that the examined samples are crystalline. The peak observed in Fig. 2d at 2θ = 30.0° for the plane (421) corresponds to the cubic crystal symmetry of carbon [76]. The average particle size of the powder were calculated using the Debye–Scherrer formula; it was estimated around 9–10 nm [77, 78].

The surface morphology and elemental composition of the catalyst were studied by scanning electron microscopy (SEM) in combination with energy-dispersive X-ray spectroscopy (EDS). Figure 3 shows the morphology of CPM-3. It is clearly seen that the sample is characterized by porous surface with small particle size. The elemental composition of CPM-3 was determined by EDS (Fig. 3d). The observed Mo/C/O atomic ratio is fairly close to the expected bulk ratio, indicating a good distribution of the metal species over the sample. Furthermore, it is seen that the minimum stoichiometric ratio of required elements in CPM-3 is maintained.

Figure 4 shows the FT-IR spectra of CPM-0 and CPM-3, respectively. A sharp band in the range 540–595 cm–1 was assigned to the Mo–Mo bond, and the Mo=O terminal double bond gave rise to a band around 793–853 cm–1. Absorption bands at 1410– 1600 cm–1 were attributed to C–C and C=C vibrations, and the band around 2926 cm–1 may appear due to CH2 and or C(OH) stretching modes [79]. The broad band around 3417–3450 cm–1 was assigned to O–H stretching modes of the adsorbed water [80, 81].

The TEM image of CPM-3 shown in Fig. 5 clearly indicates the presence of highly crystalline nanorods of MoO3 with a particle size of 10.42 to 18.57 nm. It follows from the selected area electron diffraction (SAED) pattern that the obtained d and hkl values correspond to the orthorhombic crystal structure of MoO3. These values are also consistent with those observed in the XRD pattern [82, 83].

The ammonia temperature programmed desorption (NH3-TPD) provides information about the total concentration and strength of acidic sites present in a material. The results of NH3-TPD analysis of CPM-3 are shown in Fig. 6. A broad ammonia desorption profile in the range 400–550°C suggests the presence of a large number of acid sites with moderate strength. In addition to this broad peak, one low-temperature desorption peak is also observed in the range 200–350°C. Clearly, ammonia desorption in two regions indicates that the material has both Lewis and Brønsted acidic sites.

The first low-temperature desorption peak observed at 262°C is mainly due to Lewis sites present in the CPM-3 sample. Likewise, the broad desorption peak observed around 519°C corresponds to Brønsted acidic sites [84–86]. It is frequently postulated that ammonia may reduce the surface of oxides; therefore, the high-temperature peak found for the MoO3 sample could be indicative of strong acid sites created by reduction during the TPD process [87].

The surface area of CPM-3 was determined by the Brunauer–Emmett–Teller method (Fig. 7) based on the nitrogen adsorption/desorption isotherm. The single-point surface area was estimated at 2.5042 m2/g (p/p0), and the BET surface area, at 2.7629 m2/g [88]. It means that prepared material has a large surface area and hence it could be expected to show high catalytic activity.

The average pore diameter of CPM-3 is 14.10 nm, which indicates increased pore size and surface area. Similar results were obtained from the XRD (12.02 nm) and TEM data (10.42 to 18.57 nm).

Similarly, the BJH (Barrett, Joyner, and Halenda) pore volume of CPM-3 is 3.56×10−3 cm3/g (Fig. 8). The decrease in the average pore diameter is due to the formation of porous surface which is also observed in SEM images [89].

EXPERIMENTAL

Reagent-grade chemicals, namely ammonium heptamolybdate, oxalic acid, and ammonia (Ranbaxy Fine Chemicals), as well as poly(ethylene glycol)-400 (PEG-400) (Qualigens Fine Chemicals), were used without further purification. X-Ray diffraction analysis (XRD) of calcined samples was carried out with a Philips X-ray diffractometer (Cu Kα radiation, λ 1.54 Å; 2θ range 20–80°). Surface morphology study and elemental analysis were carried out using scanning electron microscopy with energy dispersive X-ray spectroscopy (SEM/EDS) using a JEOL JED 2300 (LA) instrument. The IR spectra were recorded on a Shimadzu FTIR/4100 (Japan) spectrometer in the range 4000–500 cm−1. The 1H and 13C NMR spectra were recorded on a Varian Mercury 300 spectrometer at 300 and 75 MHz, respectively, using TMS as internal standard. The microscopic nanostructure and particle size were determined using a Philips CM-200 transmission electron microscope at 200 kV (L = 600, l = 0.0025 nm), and the selected area electron diffraction (SAED) patterns of the prepared samples were produced to get general information about the obtained crystals. Temperature-programmed desorption (NH3-TPD) measurements were carried out on a Micromeritics ChemiSorb 2750 instrument (Chemisoft TPx V1.02 software). A 100-mg sample was pretreated at 150°C in a helium flow of 25 cm3/min for 1 h. Gaseous ammonia was then added to the helium environment, and the sample was saturated for 30 min at 150°C. The helium gas was flushed for stable baseline, the sample was cooled to room temperature, and TPD measurements were performed from 50 to 500°C at a rate of 10 deg/min. The surface area of samples was characterized by the BET method by measuring the adsorption of nitrogen at 77 K with a Micromeritics ASAP 2010 instrument.

Preparation of carbon-doped MoO3 with PEG-400. A series of modified samples, viz. CPM-0, CPM-1, CPM-2, and CPM-3, were prepared by addition of carbon powder to a solution containing PEG-400 on MoO3 by simple impregnation method. Solutions of ammonium heptamolybdate (0.2 M), oxalic acid (0.2 M), and PEG-400 (0.5 M) were mixed together, and finely powdered carbon (0, 1, 2, 3 wt %) was added to the mixture. Excess water was evaporated with continuous stirring, and the residue was dried at 110°C for 12 h and then calcined at 500°C for 2 h in air atmosphere. The carbon used for doping was prepared from the natural plant source Acacia arabica according to the procedure reported previously [74, 90].

General procedure for the synthesis of 1,8-dioxodecahydroacridine derivatives 4a–4k. A mixture of dimedone (2 mmol), benzaldehyde (1 mmol), aniline (1 mmol), and catalyst (0.1 g) in ethanol–water (3:1, 20 mL) was placed in a single-neck round-bottom, which was immersed in a water bath of an ultrasonic cleaner and exposed to high-intensity ultrasonic irradiation (600 W, 20 kHz) for a required time. The progress of the reaction was monitored by TLC using petroleum ether–ethyl acetate as eluent. After completion of the reaction, the mixture was heated to dissolve the product, and the catalyst was separated from the reaction mixture by simple filtration. The filtrate was evaporated, and the crude product was recrystallized from ethanol.

3,3,6,6-Tetramethyl-9,10-diphenyl-3,4,6,7,9,10-tetrahydroacridine-1,8(2H,5H)-dione (4a). White solid, mp 254–255°C. IR spectrum (KBr), ν, cm–1: 2953, 2870, 1662, 1488, 1366, 1201, 1151, 955, 833, 740, 698. 1H NMR spectrum (300 MHz, CDCl3), δ, ppm: 7.54–7.42 m (5H), 7.32–7.09 m (5H), 4.74 s (1H), 2.45 d (4H), 2.18 d (4H), 1.09 s (6H), 0.98 s (6H). 13C NMR spectrum (75 MHz, CDCl3), δC, ppm: 27.1, 33.9, 40.2, 51.4, 109.0, 117.1, 120.3, 131.0, 140.8, 152.4, 196.0. Mass spectrum: m/z 426.24 [M – H]+. C29H31NO2.

3,3,6,6-Tetramethyl-9-(3-nitrophenyl)-10-phenyl-3,4,6,7,9,10-tetrahydroacridine-1,8(2H,5H)-dione (4b). Yellow solid, mp 285–287°C. IR spectrum (KBr), ν, cm–1: 3292, 2953, 1589, 1367, 1261, 1201, 1145, 987, 817, 691, 574. 1H NMR spectrum (300 MHz, CDCl3), δ, ppm: 8.38 s (1H), 7.48 s (1H), 7.33 s (2H), 6.72–6.59 m (5H), 4.72 s (1H), 2.44 d (4H), 2.20 d (4H), 1.08 s (6H), 0.99 s (6H).

9-(4-Chlorophenyl)-3,3,6,6-tetramethyl-10-phenyl-3,4,6,7,9,10-tetrahydroacridine-1,8(2H,5H)-dione (4c). Yellow solid, mp 271–272°C. IR spectrum (KBr), ν, cm–1: 3202, 2953, 1653, 1472, 1356, 1198, 1102, 997, 859, 711, 658, 699, 574. 1H NMR spectrum (300 MHz, CDCl3), δ, ppm: 8.15 s (2H), 7.85 s (2H), 7.26–7.16 m (5H), 4.71 s (1H), 2.46 d (4H), 2.21 d (4H), 1.10 s (6H), 0.98 s (6H).

3,3,6,6-Tetramethyl-9-(4-methylphenyl)-10-phenyl-3,4,6,7,9,10-tetrahydroacridine-1,8(2H,5H)-dione (4d). Green solid, mp 290–292°C. IR spectrum (KBr), ν, cm–1: 3321, 2963, 1716, 1610, 1472, 1378, 1240, 1134, 1071, 987, 859, 754, 648, 699, 574. 1H NMR spectrum (300 MHz, CDCl3), δ, ppm: 8.52 m (1H), 7.85 m (1H), 7.79 m (2H), 7.26–7.00 m (5H), 4.71 s (1H), 2.45 d (4H), 2.24 d (4H), 2.41 s (3H), 1.09 s (6H), 0.99 s (6H).

9-(2-Chlorophenyl)-3,3,6,6-tetramethyl-10-phenyl-3,4,6,7,9,10-tetrahydroacridine-1,8(2H,5H)-dione (4e). Yellow solid, mp 188–190°C. IR spectrum (KBr), ν, cm–1: 3397, 2953, 1726, 1610, 1472, 1378, 1230, 1198, 1134, 1071, 987, 849, 743, 658, 699, 574. 1H NMR spectrum (300 MHz, CDCl3), δ, ppm: 7.47 m (1H), 7.37–7.25 m (3H), 7.13–7.08 m (5H), 4.87 s (1H), 2.45 d (4H), 2.33 d (4H), 1.11 s (6H), 0.94 s (6H).

9-(3-Hydroxyphenyl)-3,3,6,6-tetramethyl-10-(4-methylphenyl)-3,4,6,7,9,10-tetrahydroacridine-1,8(2H,5H)-dione (4f). White solid, mp 281–182°C. IR spectrum (KBr), ν, cm–1: 3312, 2963, 1663, 1526, 1463, 1356, 1198, 1134, 997, 817, 732, 691, 699, 574. 1H NMR spectrum (300 MHz, CDCl3), δ, ppm: 7.42–7.29 m (4H), 5.37 s (1H), 4.83 s (1H), 2.50 d (4H), 2.18 d (4H), 2.37 s (3H), 1.11 s (6H), 0.99 s (6H).

9-(4-Methoxyphenyl)-3,3,6,6-tetramethyl-10-phenyl-3,4,6,7,9,10-tetrahydroacridine-1,8(2H,5H)-dione (4g). Light yellow solid, mp 222–224°C. IR spectrum (KBr), ν, cm–1: 3309, 2956, 1662, 1595, 1452, 1361, 1199, 1141, 1003, 840, 742, 698, 572, 524. 1H NMR spectrum (300 MHz, CDCl3), δ, ppm: 7.30 m (2H), 7.18–7.23 m (2H), 7.16–7.07 m (5H), 4.75 s (1H), 2.46 d (4H), 2.21 d (4H), 3.29 s (3H), 1.10 s (6H), 0.99 s (6H).

3,3,6,6-Tetramethyl-10-(4-methylphenyl)-9(3-nitrophenyl)-3,4,6,7,9,10-tetrahydroacridine-1,8(2H,5H)-dione (4h). White solid, mp 150–151°C. IR spectrum (KBr), ν, cm–1: 3312, 2963, 1663, 1515, 1356, 1198, 1145, 997, 807, 699, 574. 1H NMR spectrum (300 MHz, CDCl3), δ, ppm: 7.40–7.25 m (8H), 4.83 s (1H), 2.50 d (4H), 2.22 d (4H), 2.50 s (3H), 1.11 s (6H), 0.99 s (6H).

9-(4-Chlorophenyl)-3,3,6,6-tetramethyl-10-(4-methylphenyl)-3,4,6,7,9,10-tetrahydroacridine-1,8(2H,5H)-dione (4i). Yellow–green solid, mp 220–221°C. IR spectrum (KBr), ν, cm–1: 3312, 2953, 1663, 1472, 1356, 1198, 1092, 997, 849, 711, 606, 699, 521. 1H NMR spectrum (300 MHz, CDCl3), δ, ppm: 7.85 s (2H), 7.45 s (2H), 7.26–7.15 m (4H), 4.71 s (1H), 2.46 d (4H), 2.21 d (4H), 2.51 s (3H), 1.10 s (6H), 0.99 s (6H).

3,3,6,6-Tetramethyl-9,10-bis(4-methylphenyl)-3,4,6,7,9,10-tetrahydroacridine-1,8(2H,5H)-dione (4j). Yellow–green solid, mp 194–196°C. IR spectrum (KBr), ν, cm–1: 3202, 2963, 1663, 1463, 1356, 1198, 1102, 997, 882, 700, 658, 699, 574. 1H NMR spectrum (300 MHz, CDCl3), δ, ppm: 7.98–7.00 m (8H), 4.71 s (1H), 2.45 d (4H), 2.24 d (4H), 2.49 s (6H), 1.09 s (6H), 0.99 s (6H).

9-(2-Chlorophenyl)-3,3,6,6-tetramethyl-10-(4-methylphenyl)-3,4,6,7,9,10-tetrahydroacridine-1,8(2H,5H)-dione (4k). Yellow solid, mp 188–190°C. IR spectrum (KBr), ν, cm–1: 3397, 2963, 1663, 1472, 1356, 1198, 1134, 1007, 839, 732, 617, 699, 574. 1H NMR spectrum (300 MHz, CDCl3), δ, ppm: 7.37 m (1H), 7.34–7.25 m (3H), 7.16–7.06 m (4H), 4.87 s (1H), 2.45 d (4H), 2.30 d (4H), 2.51 s (3H), 1.11 s (6H), 0.94 s (6H).

CONCLUSIONS

A new methodology has been proposed for the preparation of 1,8 dioxodecahydroacridine derivatives from dimedone, benzaldehydes, and anilines in the presence of carbon-doped MoO3 in EtOH/H2O (3:1) solvent system under ultrasonication. The effect of the concentration of carbon substrate in PEG-400/MoO3 was successfully evaluated. The catalyst was recovered and reused at least four times without any noticeable loss of reactivity. The advantages of the proposed method include mild reaction conditions, experimental simplicity, short reaction time, and high yield.

REFERENCES

Santana, L., Uriarte, E., Roleira, F., Milhazes, N., and Borges, F., Curr. Med. Chem., 2004, vol. 11, p. 3239. https://doi.org/10.2174/0929867043363721

El-salam, N., Mostafa, M., Ahmed, G., and Alothman, O., J. Chem., 2013, vol. 2013, article ID 890617. https://doi.org/10.1155/2013/890617

Azab, M., Youssef, M., and El-Bordany, E., Molecules, 2013, vol. 18, p. 832. https://doi.org/10.3390/molecules18010832

Salem, M., Sakr, S., El-Senousy, W., Madkour, H., Arch. Pharm. (Weinheim), 2013, vol. 346, p. 766. https://doi.org/10.1002/ardp.201300183

Cao, X., Sun, Z., Cao, Y., Wang, R., Cai, T., Chu, W., Hu, W., and Yang, Y., J. Med. Chem., 2014, vol. 57, p. 3687. https://doi.org/10.1021/jm4016284

El-Sawy, E., Ebaid, M., Abo-Salem, H., Al-Sehemi, A., and Mandour, A., Arab. J. Chem., 2013, vol. 7, p. 914. https://doi.org/10.1016/j.arabjc.2012.12.041

Chen, Y., Yu, K., Tan, N., Qiu, R., Liu, W., Luo, N., Tong, L., Au, C., Luo, Z., and Yin, S., Eur. J. Med. Chem., 2014, vol. 79, p. 391. https://doi.org/10.1016/j.ejmech.2014.04.026

El-Sawy, E., Mandour, A., El-Hallouty, S., Shaker, K., and Abo-Salem, H., Arab. J. Chem., 2013, vol. 6, p. 67. https://doi.org/10.1016/j.arabjc.2012.04.003

Mabkhot, Y., Barakat, A., Al-Majid, A., Alshahrani, S., Yousuf, S., and Choudhary, M., Chem. Cent. J., 2013, vol. 7, p. 112. https://doi.org/10.1186/1752-153X-7-112

Li, X., He, L., Chen, H., Wu, W., and Jiang, H., J. Org. Chem., 2013, vol. 78, p. 3636. https://doi.org/10.1021/jo400162d

Santos, C., Freitas, M., and Fernandes, E., Eur. J. Med. Chem., 2018, vol. 157, p. 1460. https://doi.org/10.1016/j.ejmech.2018.07.073

Kalaria, P., Karad, S., and Raval, D., Eur. J. Med. Chem., 2018, vol. 158, p. 917. https://doi.org/10.1016/j.ejmech.2018.08.040

Kerru, N., Bhaskaruni, S., Gummidi, L., Maddila, S., Maddila, S., and Jonnalagadda, S., Synth. Commun., 2019, vol. 49, p. 2437. https://doi.org/10.1080/00397911.2019.1639755

Kerru, N., Singh, P., Koorbanally, N., Raj, R., and Kumar, V., Eur. J. Med. Chem., 2017, vol. 142, p. 179. https://doi.org/10.1016/j.ejmech.2017.07.033

Eftekhari-Sis, B., Zirak, B., and Akbari, M.A., Chem. Rev., 2013, vol. 113, p. 2958. https://doi.org/10.1021/cr300176g

Kerru, N., Maddila, S., and Jonnalagadda, S.B., Curr. Org. Chem., 2019, vol. 23, p. 3154. https://doi.org/10.2174/1385272823666191202105820

Ju, Y. and Varma, R.S., J. Org. Chem., 2006, vol. 71, p. 135. https://doi.org/10.1021/jo051878h

Zarate, D.Z., Aguilar, R., Hernandez-Benitez, R.I., Labarrios, E.M., Delgado, F., and Tamariz, J., Tetrahedron, 2015, vol. 71, p. 6961. https://doi.org/10.1016/j.tet.2015.07.010

Leeson, P.D. and Springthorpe, B., Nat. Rev. Drug Discovery, 2007, vol. 6, p. 881. https://doi.org/10.1038/nrd2445

Kerru, N., Gummidi, L., Maddila, S., Gangu, K.K., and Jonnalagadda, S.B., Molecules, 2020, vol. 25, article no. 1909. https://doi.org/10.3390/molecules25081909

Pétrier, C. and Luche, J.L., Synthetic Organic Sonochemistry, Luche, J.-L., Ed., New York: Plenum Press, 1998, p. 51. https://doi.org/10.1007/978-1-4899-1910-6_2

Li, J.-T., Yang, W.-Z., Wang, S.-X., Li, S.-H., and Li, T.-S., Ultrason. Sonochem., 2002, vol. 9, p. 237. https://doi.org/10.1016/S1350-4177(02)00079-2

Fillion, H. and Luche, J.L., Synthetic Organic Sonochemistry, Luche, J.-L., Ed., New York: Plenum Press, 1998, p. 91. https://doi.org/10.1007/978-1-4899-1910-6_3

Cintas, P. and Luche, J.-L., Green Chem., 1999, vol. 1, p. 115. https://doi.org/10.1039/A900593E

Ohayon, E. and Gedanken, A., Ultrason. Sonochem., 2010, vol. 17, p. 173. https://doi.org/10.1016/j.ultsonch.2009.05.015

Askarinejad, A. and Morsali, A., Ultrason. Sonochem., 2009, vol. 16, p. 124. https://doi.org/10.1016/j.ultsonch.2008.05.015

Landau, M.V., Vradman, L., Herskowitz, M., and Koltypin, Y., J. Catal., 2001, vol. 201, p. 22. https://doi.org/10.1006/jcat.2001.3227

Antman, E., Muller, J., Goldberg, S., Macalpin, R., Rubenfire, M., Tabatznik, B., Liang, C., Heupler, F., Achuff, S., Reichek, N., Geltman, E., Kerin, N.Z., Neff, R.K., and Raunwald, E., Engl. J. Med., 1980, vol. 302, p. 1269. https://doi.org/10.1056/NEJM198006053022301

Hornung, R.S., Gould, B.A., Jones, R.I., Sonecha, T.N., and Raferty, E.B., Am. J. Cardiol., 1983, vol. 51, p. 1323. https://doi.org/10.1016/0002-9149(83)90306-5

Delfourne, E., Roubin, C., and Bastide, J., J. Org. Chem., 2000, vol. 65, p. 5476. https://doi.org/10.1021/jo000011a

Antonini, J., Polucci, P., Magnano, A., and Martelli, S., J. Med. Chem., 2001, vol. 44, p. 3329. https://doi.org/10.1021/jm010917o

Ferlin, M.G., Marzano, C., Chiarelotto, G., Baccichetti, F., and Bordin, F., Eur. J. Med. Chem., 2000, vol. 35, p. 827. https://doi.org/10.1016/S0223-5234(00)00170-7

Mikata, Y., Yokoyama, M., Mogami, K., Kato, M., Okura, I., Chikira, M., and Yano, S., Inorg. Chim. Acta, 1998, vol. 279, p. 51. https://doi.org/10.1016/S0020-1693(98)00035-8

Sirisha, K., Bikshapathi, D., Achaiah, G., and Reddy, V.M., Eur. J. Med. Chem., 2011, vol. 46, p. 1564. https://doi.org/10.1016/j.ejmech.2011.02.003

Spalding, D.P., Chapin, E.C., and Mosher, H.S., J. Org. Chem., 1954, vol. 19, p. 357. https://doi.org/10.1021/jo01368a011

Solanki, M.J., Vachharajani, P.R., Dubal, G.G., and Shah, V.H., Int. J. ChemTech. Res., 2011, vol. 3, p. 1139. https://www.sphinxsai.com/Vol.3No.3/Chem/pdf/CT=22(1139-1144)JS11.pdf

Ogawa, T., Nakato, A., Tsuchida, K., and Hatayama, K., Chem. Pharm. Bull., 1993, vol. 41, p. 108. https://doi.org/10.1248/cpb.41.108

Wainwright, M.J., Antimicrob. Chemother., 2001, vol. 47, p. 1. https://doi.org/10.1093/jac/47.1.1

Sirisha, K., Achaiah, G., and Reddy, V.M., Arch Pharm., 2010, vol. 343, p. 342. https://doi.org/10.1002/ardp.200900243

Davoodnia, A., Zare-Bidaki, A., and Behmadi, H., Chin. J. Catal., 2012, vol. 33, p. 1797. https://doi.org/10.1016/S1872-2067(11)60449-X

Godfraid, T., Miller, R., and Wibo, M., Pharmacol Rev., 1986, vol. 38, p. 321. https://pharmrev.aspetjournals.org/content/38/4/321

Shanmugasundaram, P., Murugan, P., and Ramakrishnan, V.T., Heteroat. Chem., 1996, vol. 7, p. 17. https://doi.org/10.1002/(SICI)1098-1071(199601)7:1<17::AID-HC3>3.0.CO;2-%23

Murugan, P., Shanmugasundaram, P., Ramakrishnan, V.T., Venkatachalapathy, B., Srividya, N., Ramamurthy, P., Gunasekaran, K., and Velmurugan, D., J. Chem. Soc., Perkin Trans. 2, 1998, vol. 2, p. 999. https://doi.org/10.1039/A701401E

Islam, A., Murugan, P., Hwang, K.C., and Cheng, C.H., Synth. Met., 2003, vol. 139, p. 347. https://doi.org/10.1016/S0379-6779(03)00112-7

Tu, S.J., Miao, C., Gao, Y., Fang, F., Zhuang, Q., Feng, Y., and Shi, D., Synlett, 2004, vol. 2004, no. 2, p. 255. https://doi.org/10.1055/s-2003-44981

Papagni, A., Campiglio, P., and Campione, M., J. Fluorine Chem., 2008, vol. 129, p. 294. https://doi.org/10.1016/j.jfluchem.2008.01.005

Reddy, B.V.S., Antony, A., and Yadav, J.S., Tetrahedron Lett., 2010, vol. 51, p. 3071. https://doi.org/10.1016/j.tetlet.2010.04.018

Niknam, K., Panahi, F., Saberi, D., and Mohagheghnejad, M., J. Heterocycl. Chem., 2010, vol. 47, p. 292. https://doi.org/10.1002/jhet.303

Balalaie, S., Chadegani, F., Darviche, F., and Bijanzadeh, H.R., Chin. J. Chem., 2009, vol. 27, p. 1953. https://doi.org/10.1002/cjoc.200990328

Das, B., Thirupathi, P., Mahender, I., Reddy, V.S., and Rao, Y.K., J. Mol. Catal. A: Chem., 2006, vol. 247, p. 233. https://doi.org/10.1016/j.molcata.2005.11.048

Dhruva, K. and Jagir, S., Synth. Commun., 2010, vol. 40, p. 510. https://doi.org/10.1080/00397910902987792

Shen, W. and Wang, W., Arkivoc, 2008, vol. 2008, part (xvi), p. 1. https://doi.org/10.3998/ark.5550190.0009.g01

Shen, W., Wang, L., Tian, H., Tang, J., and Yu, J., J. Fluorine Chem., 2009, vol. 130, p. 522. https://doi.org/10.1016/j.jfluchem.2009.02.014

Alinezhada, H., Tajbakhsha, M., Norouzia, M., Bagheryc, S., and Rakhtshah, J., J. Chem. Sci., 2013, vol. 125, p. 1517. https://doi.org/10.1007/s12039-013-0517-4

Wang, X.S., Zhang, M-M., Zeng, Z-S., Shi, D-Q, Tu, S-J., Wei, X-Y., and Zong, Z-M., Arkivoc, 2006, vol. 2006, no. 2, p. 117. https://doi.org/10.3998/ark.5550190.0007.213

Venkatesan, K., Pujari, S.S., and Srinivasan, K.V., Synth. Commun., 2009, vol. 39, p. 228. https://doi.org/10.1080/00397910802044306

Safaei-Ghomi, J., Ghasemzadeh, M.A., and Zahedi, S., J. Mex. Chem. Soc., 2013, vol. 57, p. 1. https://doi.org/10.29356/jmcs.v57i1.228

Fan, X., Li, Y., Zhang, X., Qu, G., and Wang, J., Heteroat. Chem., 2007, vol. 18, p. 786. https://doi.org/10.1002/hc.20410

Ghasemzadeh, M.A., Safaei-Ghomi, J., and Molaei, H., C. R. Chim., 2012, vol. 15, p. 969. https://doi.org/10.1016/j.crci.2012.08.010

Rashedian, F., Saberib, D., and Niknam, K., J. Chin. Chem. Soc., 2010, vol. 57, p. 998. https://doi.org/10.1002/jccs.201000139

Miao, C.B., Tu, S.J., Gao, Y., Feng, Y.J., and Feng, J.C., Chin. J. Chem., 2002, vol. 20, p. 703. https://doi.org/10.1002/cjoc.20020200716

Wang, X.S., Shi, D.Q., Wang, S.H., and Tu, S.J., Chin. J. Org. Chem., 2003, vol. 23, p. 1291. http://sioc-journal.cn/Jwk_yjhx/EN/abstract/article_327622.shtml

Subramanyam, M., Varala, R., Sreenivasulu, R., Rao, M.V.B., and Rao, K.P.A., Lett. Org. Chem., 2018, vol. 15, p. 915. https://doi.org/10.2174/1570178615666180212153735

Jin, T.S., Zhang, J.S., Guo, T.T., Wang, A.Q., and Li, T.S., Synthesis, 2004, vol. 2004, no. 12, p. 2001. https://doi.org/10.1055/s-2004-829151

Zhang, J., Li, C., Guan, W., Chen, X., Tsang, C-W., and Liang, C., Ind. Eng. Chem. Res., 2020, vol. 59, p. 4313. https://doi.org/10.1021/acs.iecr.9b06442

Lee, W.-S., Wang, Z., Wu, R.J., and Bhan, A., J. Catal., 2014, vol. 319, p. 44. https://doi.org/10.1016/j.jcat.2014.07.025

Boullosa-Eiras, S., Lødeng, R., Bergem, H., Stöcker, M., Hannevold, L., and Blekkan, E.A., Catal. Today, 2014, vol. 223, p. 44. https://doi.org/10.1016/j.cattod.2013.09.044

Xiao, L.-P., Wang, S., Li, H., Li, Z., Shi, Z.-J., Xiao, L., Sun, R.C., Fang, Y., and Song, G., ACS Catal., 2017, vol. 7, p. 7535. https://doi.org/10.1021/acscatal.7b02563

Mortensen, P.M., de Carvalho, H.W.P., Grunwaldt, J.-D., Jensen, P.A., and Jensen, A.D., J. Catal., 2015, vol. 328, p. 208. https://doi.org/10.1016/j.jcat.2015.02.002

Nolte, M.W., Zhang, J., and Shanks, B.H., Green Chem., 2016, vol. 18, p. 134. https://doi.org/10.1039/C5GC01614B

Sedri, A., Naeimi, A., and Mohammadi, S.Z., Carbohydr. Polym., 2018, vol. 199, p. 236. https://doi.org/10.1016/j.carbpol.2018.06.104

Lande, M.K., Navgire, M.E., Rathod, S.B., Katkar, S.S., Yelwande, A.A., and Arbad, B.R., J. Ind. Eng. Chem., 2012, vol. 18, p. 277. https://doi.org/10.1016/j.jiec.2011.11.048

Yelwande, A.A. and Lande, M.K., Res. Chem. Intermed., 2020, vol. 46, p. 5479. https://doi.org/10.1007/s11164-020-04273-x

Navgire, M.E., Yelwande, A.A., Arbad, B.R., and Lande, M.K., Chin. J. Chem., 2011, vol. 29, p. 2049. https://doi.org/10.1002/cjoc.201180355

Kihlborg, L., Ark. Kemi, 1963, vol. 21, p. 471.

Klug, H.P. and Alexander, L.E., X-Ray Diffraction Procedures for Polycrystalline and Amorphous Materials, New York, Wiley, 1974, 2nd ed.

Taylor, A., X-Ray Metallography, John Wiley, New York, 1961, p. 678.

Cullity, B.D., Elements of X-Ray Diffraction, Reading MA: Addison-Wesley, 1978, p. 284, 2nd ed.

Oyama, S.T., Radhakrishnan, S., Seman, M., Kondo, J.N., Domen, K., and Asakura, K., J. Phys. Chem. B, 2003, vol. 107, p. 1845. https://doi.org/10.1021/jp0220276

Ganguly, A. and George, R., Bull. Mater. Sci., 2007, vol. 30, p. 183. https://doi.org/10.1007/s12034-007-0033-6

Cheng, T., Fang, Z., Zou, G., Hu, Q., Hu, B., Yang, B., and Zhang, Y., Bull. Mater. Sci., 2006, vol. 29, p. 701. https://www.ias.ac.in/article/fulltext/boms/029/07/0701-0704

Gorska, P., Zaleska, A., and Kowalska, E., Appl. Catal., B., 2008, vol. 84, p. 440. https://doi.org/10.1016/j.apcatb.2008.04.028

Andrews, K.W., Dyson, D.J., and Keown, S.R., Interpretation of Electron Diffraction Patterns, New York: Plenum Press, 1971, 2nd ed.

Bian, G.-Z., Fan, L., Fu, Y.-L., and Fujimoto, K., Ind. Eng. Chem. Res., 1998, vol. 37, p. 1736. https://doi.org/10.1021/ie970792e

Schuh, K., Kleist, W., Høj, M., Jensen, A.D., Beato, P., Patzke, G.R., and Grunwaldt, J.-D., J. Solid State Chem., 2015, vol. 228, p. 42. https://doi.org/10.1016/j.jssc.2015.04.011

Oyama, S., Bull. Chem. Soc. Jpn., 1988, vol. 61, p. 2585. https://doi.org/10.1246/bcsj.61.2585

Abon, M., Mingot, B., Massardier, J., and Volta, J., Stud. Surf. Sci. Catal., 1990, vol. 55, p. 747. https://doi.org/10.1016/S0167-2991(08)60209-8

Tsutsumi, K., Characterization of Heterogeneous Catalysts, Tokyo: Kodansha, 1985.

Zhang, J., Li, C., Guan, W., Chen, X., Chen, X., and Tsang, C., Ind. Eng. Chem. Res., 2020, vol. 59, p. 4313. https://doi.org/10.1021/acs.iecr.9b06442

Navgire, M.E., Lande, M.K., Gambhire, A.B., Rathod, S.B., Aware, D.V., and Bhitre, S.R., Bull. Mater. Sci., 2011, vol. 34, p. 535. https://doi.org/10.1007/s12034-011-0108-2

ACKNOWLEDGMENTS

The authors are grateful to the Head, Department of Chemistry, Dr. Babasaheb Ambedkar Marathwada University, Aurangabad, India, and Principal, Jijamata College of Science and Arts, Bhende, Newasa, Ahmednagar, for providing all required facilities to carry out this study.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare the absence of conflict of interest.

Rights and permissions

About this article

Cite this article

Navgire, M.E., Bhitre, S.R., Yelwande, A.A. et al. One-Pot Synthesis of 1,8-Dioxodecahydroacridines Catalyzed by Carbon-Doped MoO3. Russ J Org Chem 58, 394–404 (2022). https://doi.org/10.1134/S1070428022030198

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1070428022030198