Abstract

Amberlyst 15 (A-15) is one of the most common heterogeneous catalysts in organic synthesis. Since its development in 1962, A-15 has proved to be a highly efficient green catalyst in many organic reactions that require acid catalysis. In the last two decades, many reports had been issued that focused on the use of A-15 as a catalyst in heterocyclic synthesis. The use of A-15 implies many advantages as being inexpensive, non-toxic, easily handled, and easily separable from the reaction mixture. Other advantages include easy separation of the products and the recyclability. The latter is highly useful in sustainable chemistry. The present review summarizes the applications of Amberlyst 15 as a green catalyst in the synthesis of heterocycles during the last decade (from 2010 till 2019). The review is classified according to the ring size with a focus on the mechanism of reactions catalyzed by A-15.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1. Introduction

5. Conclusions

1. INTRODUCTION

In the last two decades, heterogeneous catalysts have been attracting great interest since they are easily recovered and recyclable. These two advantages are highly recommended in large-scale chemical production in industry [1–3]. The use of solid acid catalysts in organic reactions offered many advantages such as operational simplicity, low cost, environmental compatibility, and ease of product isolation [1]. Amberlyst 15® (A-15) is one of the most commonly used solid acid catalysts in various organic reactions and transformations [4].

Amberlyst 15® is a macroporous polystyrene-based cation exchange resin bearing strongly acidic sulfonic groups. It is prepared by sulfonation of macroporous poly(styrene-co-divinylbenzene) using fuming or concentrated sulfuric acid. It was developed for the first time by Bortnick in 1962 [5, 6]. The term “macroporous” reflected that the resin was prepared by the mill technique in which two-phase materials have porosity even in the dry state. These pores act as microreactors which offer a catalytic environment quite different from that of free solution [5, 7].

Amberlyst 15 has a surface area of 42.5 m2 per gram (compared to <0.1 m2 per gram for conventional resins). It has chemical stability toward oxidizing agents, as well as remarkable physical stability evident by alternate wetting and drying [6]. However, it is thermally unstable above 120°C, and a significant reduction in the catalytic activity of Amberlyst 15 was reported at high temperature, which was attributed to decomposition of the sulfonic acid groups at temperatures above 120°C [8].

Being an excellent source of strong Brønsted acidity, Amberlyst 15 has been used in various acid-catalyzed reactions such as esterification, etherification, cyclization, and electrophilic aromatic substitution [4]. It has high H+-exchange capacity (4.7 mequiv/g) and surface area (42 m2/g) [6, 9]. The high acidic strength and surface area in combination with structural stability make A-15 a highly efficient catalyst in many organic reactions, and it displayed a superior catalytic activity if compared with other commercial resins [1, 4]. Other advantages of A-15 include its low cost, non-toxicity, easy to be measured, safe to be used, easily handled, and recyclable.

Amberlyst 15 is insoluble in almost all organic solvents, which makes it easy to be isolated from the reaction medium by filtration. This also makes the reaction work-up easier, and the products are mainly obtained in a pure form without resorting to chromatographic purification. This is very useful in scaling up of chemical reactions and sustainable chemistry [1, 4].

Very few review articles dealing with reactions catalyzed by Amberlyst 15 have been reported [4]. During the last decade, many reports were published on the use of A-15 to catalyze synthesis of heterocycles. This review summarizes data reported since 2010 till 2019 on the synthesis of heterocyclic compounds using A-15 as a catalyst. The contents is classified according to the ring size and the type of heteroatom.

2. SYNTHESIS OF FIVE-MEMBERED HETEROCYCLES

2.1. Synthesis of furans. In 2010, Palmieri et al. [10] reported the synthesis of 2,5-disubstituted furan derivatives 4 through the reaction of nitroalkanes 1 with α-oxoaldehydes 2, promoted by the basic catalyst Amberlyst A-21, followed by acidic treatment of the adducts, nitroalkanols 3, using A-15 (Scheme 1). The products were obtained in a one-step reaction without separation of intermediates 3, which contributed to the eco-sustainability of the procedure. The furans were obtained in good overall yields (56–84%). The reaction tolerated a wide variety of alkyl or aryl groups (R) in 1 and 2.

Some furan derivatives such as tetrahydrofuran (THF), 5-hydroxymethylfurfural (HMF), and furfural exhibit several industrial applications and can be derived from biomass and other renewable resources. The importance of each derivative and the use of A-15 for their production is summarized below.

Tetrahydrofuran (THF) has many industrial applications. It is mainly used as an organic solvent in chemical reactions and chromatography. It is also used in the production of polytetramethylene glycol (PTMEG), succinic acid, and adipic acid. Industrially, tetrahydrofuran (THF) is manufactured by many methods such as dehydration of butane-1,4-diol and catalytic hydrogenation of furan [11].

The synthesis and production of tetrahydrofuran (6) from butane-1,4-diol (5) using A-15 was reported in 2015 by Shinde et al. [11]. The aim was to intensify the process; therefore, batch kinetic experiments were performed using A-15 as a catalyst. The effects of water, temperature, and catalyst loading were examined. The presence of water (formed by dehydration of butane-1,4-diol using A-15; Scheme 2) was found to strongly affect the performance of the catalyst, and hence its removal was necessary to improve the conversion. Therefore, reactive distillation was applied, and the reaction rate was increased through removal of water formed in the reaction itself. Reaction and distillation in a single vessel is considered a well-known technology that is highly useful in equilibrium-limited liquid phase chemical reactions. Moreover, the application of reactive distillation makes the industrial process continuous and increases the catalyst life [12–14].

5-Hydroxymethylfurfural (HMF) is one of the most promising and top value-added chemicals derived from biomass. 5-Hydroxymethylfurfural displays diverse industrial applications including production of the fuel additive 2,5-dimethylfuran (2,5-DMF), the polymer precursor furan-2,5-dicarboxylic acid (FDCA), and furan-2,5-dicarbaldehyde (DFF), levulinic acid, and other value-added chemicals (Scheme 3) [15–17]. 5-Hydroxymethylfurfural is prepared by acid-catalyzed dehydration of monosaccharides with the highest yield obtained from D-fructose. Both homogeneous and heterogeneous catalysts were studied in this reaction. The use of heterogeneous catalysts like A-15 provided the advantages of recyclability and reaction scale-up; however, the low yield obtained limited its industrial application.

The dehydration of fructose to HMF using A-15 in various solvents such as methanol/THF [18], N,N-dimethylformamide (DMF) [19, 20], 1,4-dioxane [21, 22], dimethyl sulfoxide (DMSO) [23, 24] and ionic liquids [15, 25] was reported. The effect of solvent on the recyclability of A-15 in the dehydration of fructose to HMF was studied by Sampath and Kannan [26] (Scheme 4). It was noticed that a stable catalytic activity of A-15 (even up to seven cycles) was achieved in DMSO. On the contrary, the use of DMF decreased the catalytic effect significantly upon recycling. This was accounted for by the possible neutralization of the amino group of DMF with the acidic sites in A-15 to form ammonium ions as evidenced by FTIR and elemental analyses. The problem was overcome by treatment of the dead catalyst with a dilute acid, thereby restoring the catalytic activity of A-15 in DMF [26].

The deep eutectic solvents (DES) are mixtures of two compounds which have a melting point lower than that of each individual component [27]. These mixtures consist of a hydrogen bond-accepting (HBA) component and a hydrogen bond-donating (HBD) component which form a network of H-bonds. Some of DES may be liquid at room temperature with low volatility and flammability. Deep eutectic solvents are obtained from readily available and inexpensive components and are characterized by easy preparation (simply by mixing the two components). All these criteria make DES ideal as sustainable solvents in industry [27–35].

Recently, the dehydration of fructose and sucrose to HMF in DES promoted by A-15 as heterogeneous catalyst was investigated by Marullo et al. [36]. Eight DES that differ in their HBA and HBD were tested. By optimizing the reaction conditions (temperature, catalyst loading, and type of solvent components), 5-HMF was obtained in 78% yield at 60°C from fructose and in 69% yield at 80°C from sucrose. In general, a distinct beneficial effect was noticed upon coupling A-15 with dicarboxylic acid-based DES. Moreover, the catalyst was reused up to five cycles without loss of yield.

In 2012, Ru and coworkers [37] reported the use of A-15, ZnCl2, TsOH, FeCl3, and montmorillonite as dehydrating agents in the synthesis of 5-(α-D-glucosyloxymethyl)furfural (GMF) (Scheme 5). It was found that the use of A-15 afforded the product in 34% yield. Thus, GMF was prepared in good yield starting from highly concentrated isomaltulose–choline chloride melt (without a solvent) using different acid catalysts under mild reaction conditions. Among the catalysts used, ZnCl2 provided the highest yield (52%), while montmorillonite afforded the product in shorter reaction time in addition to the ease of handling and recyclability.

On the other hand, the conversion of xylose (a pentose derived from hemicellulose) into furfural using A-15 and hydrotalcite (HT) has been reported earlier [38–40]. The process involved isomerization of aldose into ketose catalyzed by hydrotalcite, followed by dehydration of ketose into furfural by Amberlyst 15. For example, Shirotori et al. [38] reported the dehydration of xylulose to furfural and the subsequent one-pot condensation reaction of furfural with malononitrile (Scheme 6). The catalysts used were metal/HT (Cr/hydrotalcite) to effect isomerization of xylose into xylulose, and Amberlyst 15 to effect dehydration of the latter into furfural. Hydrotalcite was used again to catalyze Knoevenagel condensation of furfural and malononitrile to afford furfurylidenemalononitrile in 44% yield.

The macroalgae-derived alginic acid was also used for the production of furfural in 18.5% yield under hydrothermal conditions using A-15 as a recyclable catalyst (Scheme 7). The use of A-15 improved the selectivity of the conversion of alginic acid into furfural rather than into formic acid and allowed easy separation of the product. Thus, the use of 600 mg A-15 on 2 wt % alginic acid increased the yield of furfural up to 14 %, while the yield of formic acid was reduced from 10.6 to <7%. Although the catalyst can be recycled up to 5 times, a reduction in the yield of furfural by 30% was noted. Deactivation of the catalyst may be attributed to the adsorption of alginic acid-derived by-products on the catalyst surface and blocking of the catalyst active sites [41].

2.2. Synthesis of thiophenes. In 2019, Chiurchiù et al. [42] reported the synthesis of thiophene-2-carboxylates 10 starting from β-nitroacrylates under continuous flow conditions using A-15 as a catalyst (Scheme 8). A similar procedure was reported earlier by the same team for the synthesis of 2,5-disubstituted furans [10]. The continuous flow synthetic protocol involved three steps: (1) Michael addition of thioacetic acid to β-nitroacrylates 7 to give adducts 8, (2) base-induced elimination of nitrous acid to give intermediates 9, and (3) acid-promoted domino cyclization–aromatization to give thiophenes 10. Amberlyst 15 was chosen as acid catalyst in the third step. The application of flow chemistry and the use of solid supported catalysts made it possible to obtain thiophenes without separation and purification of intermediates and thus provided an ecofriendly and sustainable method. Another advantage of this procedure was the high yield of thiophenes and versatility of substituents (R2) that can be introduced at the 5-position.

2.3. Synthesis of pyrroles. In 2014, Murthi and co-workers [43] reported the first synthesis of substituted pyrroles 11 via Amberlyst 15-mediated multicomponent reaction (MCR). The protocol consisted in reacting β-ketoesters, benzylamines, aromatic aldehydes, and nitromethane in the presence of A-15 under ultrasonic irradiation. The reaction is a metal-free MCR that was carried out at room temperature, and the catalyst was recycled three times. Nitromethane was used simultaneously as a reactant and solvent, so that no other solvent was needed (Scheme 9).

A probable mechanism involved in situ formation of β-enamino carbonyl compound 12 and nitroalkene 13 facilitated by A-15. Next followed nucleophilic attack of the enamino double bond on the electron-deficient nitroalkene double bond, intramolecular cyclization, and aromatization to afford 11. The reaction was accelerated by ultrasonication (Scheme 10).

2.4. Synthesis of oxazolidines. In 2017, Aldmairi et al. [44] reported a simple protocol for the synthesis of oxazolidines 17 by reacting aziridines 16 and allyl alcohols in the presence of a catalytic amount of A-15 as shown in Scheme 11.

2.5. Synthesis of dihydropyrazoles. In 2018, Kumar and coworkers reported the use of A-15 in the synthesis of thienylpyrazolecarboxamides 19 from chalcones 18 and semicarbazide hydrochloride (Scheme 12). The reaction was conducted at room temperature in 30–60 min, the products were obtained in good yields (65–77%), and the catalyst was recycled up to four times. Compounds 19 could also be obtained by conventional method via heating the same reactants in acetic acid for 1–2 h. Thus, the use of A-15 reduced the reaction time and afforded the products under milder conditions although no difference in the product yields was noticed [45].

The same authors carried out the reaction using thiosemicarbazide for the synthesis of dihydropyrazole-1-carbothioamides 21 [46]. The latter were also obtained at room temperature, in shorter reaction time, and in the same yields as in the conventional method (Scheme 13).

One year later, Prabhudeva et al. [47] reported the synthesis of 3-thienyldihydropyrazole-1-carboxamides 23 by reacting chalcones 22 and semicarbazide hydrochloride in the presence of A-15 in methanol at room temperature (Scheme 14).

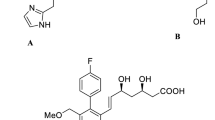

2.6. Synthesis of imidazoles. The synthesis of 2,4,5-trisubstituted imidazole derivatives 24 and 1,2,4,5-tetrasubstituted-1H-imidazole derivatives 25 was achieved via one-pot MCR of benzil, aldehydes, ammonium acetate, and primary amines (Scheme 15) [48]. The compounds were prepared under microwave irradiation (MW) using A-15 as a catalyst which provided short time (10–15 min), high yields (76–92%), and simple work-up procedure. Aldehydes carrying either electron-withdrawing or electron-donating groups at different positions can be used.

Nirwan and Pareek [49] applied similar reaction conditions for the synthesis of substituted imidazoles 26 in a short time (8–17 min) with excellent yields (89–97%). Amberlyst 15 was used as a mild, non-explosive, recyclable (up to seven times), green, and eco-friendly catalyst (Scheme 16).

2.7. Synthesis of triazoles. A highly efficient and eco-friendly method for the synthesis of 4-aryl-1,2,3-triazoles using A-15 as a recyclable acid catalyst was reported by Zhang et al. [50]. Thus, the reaction of nitro olefins 27 with sodium azide in the presence of A-15 afforded N-unsubstituted-1,2,3-triazoles 28 in high yields (80–96%). Nitro olefins 27 bearing either electron-donating or electron-withdrawing groups on the benzene ring can be used. Amberlyst 15 was recovered by filtration and reused up to 8 times without significant loss in catalytic activity (Scheme 17).

Gunduz et al. [51] recently reported a new method for the synthesis of 4- and 5-(2,4-dihydroxybenzoyl)triazoles 30 via a metal-free one-step protocol in which A-15 was used as a catalyst. The reaction involved azide–alkyne cycloaddition of o-alkynoyl resorcinols 29 and benzyl azide in metal-free acid medium to give two regioisomers 30a and 30b, the former being the major product. Due to metal-free conditions, there was no need to protect metal-sensitive groups like OH (Scheme 18).

2.8. Synthesis of tetrazoles. In 2013, Shelkar and co-workers [9] used the solid acid resin Amberlyst 15 as an effective heterogeneous catalyst for the synthesis of 5-substituted 1H-tetrazole derivatives 32 by reacting aromatic or aliphatic nitriles 31 with sodium azide (Scheme 19). In this study, different solid acid catalysts were examined such as Amberlyst 15, Amberlite 120, montmorilonite, aluminum oxide, sulfated zirconia, and phosphated zirconia. Among them, A-15 displayed the highest catalytic activity. This superior catalytic activity was explained by the authors in the light of the higher H+-exchange capacity and surface area of A-15 together with its lower moisture content (1.5–1.6%) compared to the other catalysts tested. Moreover, the catalyst was recycled up to three times without noticeable decrease in the catalytic activity.

Regarding the aromatic nitriles used, the presence of electron-donating substituents at the para position gave excellent yields (87–94%), and at the ortho position, lower yield (82%). Whilst, the presence of electron-withdrawing groups at the meta position greatly reduced the overall yield (75%). Poor yields were obtained with aliphatic nitriles (36% from acetonitrile and 54% from acrylonitrile).

3. SYNTHESIS OF SIX-MEMBERED HETEROCYCLES

3.1. Synthesis of pyrans. In 2015, Vyskocilova et al. [52] reported the synthesis of Florosa or Florol [2-isobutyl-4-methyltetrahydro-2H-pyran-4-ol (35)] via reacting isovaleraldehyde (33) and isoprenol (34) (Scheme 20). Four catalysts were tested (sulfuric acid, Amberlyst 15, p-toluenesulfonic acid, and p-dodecylbenzenesulfonic acid), and the best results were obtained with sulfuric acid and Amberlyst 15. This reaction is a variant of the Prins reaction [53, 54] in which an aldehyde adds to an alkene in acid medium as illustrated in Scheme 20.

The synthesis of 6α-hydroxy-6-methyl-2H-pyran-3(6H)-one (37) through transformation of 2,5-bis-hydroxymethylfuran (BHMF) (36) using A-15 as an acid catalyst and utilizing a green chemistry protocol was reported in 2016 by Gelmini and coworkers [55]. The reaction was carried out in one pot in water and in the absence of oxidizing agent (Scheme 21).

The mechanism proposed by the authors involved hydration of one C=C bond of the furan ring in 36, followed by dehydration of the hydroxymethyl group on the other side of the ring. Ring opening of the intermediate furan afforded a keto–enol intermediate. Nucleophilic attack of the hydroxy group on the terminal C=O bond of the keto form led to the formation of pyran derivative 37 as the major product. Whilst, hydration of the keto form afforded by-products 38 and 39 (Scheme 22) [55].

3.2. Synthesis of pyrimidines. In 2012, Jetti et al. [56, 57] reported the use of A-15 as a green catalyst for Biginelli-like reactions. Thus, 3,4-dihydropyrimidin-2(1H)-ones(thiones) 40 and 41 were prepared by one-pot reaction of urea or thiourea, aromatic or heterocyclic aldehydes, and β-diketones. In this study, five solid acid ion-exchange resins were tested, including Amberlyst 70, Amberlyst 15 DRY, Indion-130, Indion-190, and Nafion-H. Amberlyst 15 turned out to be the most efficient catalyst. The protocol is simple, efficient, environmentally benign, and eco-friendly. The products were easily isolated in high yields (80–95%), and the catalyst was easily separated by filtration and reused without any appreciable loss in activity. The aldehydes used included various aromatic derivatives carrying electron-donating or electron-withdrawing groups, as well as heterocyclic aldehydes (Scheme 23).

In 2016, Shen et al. [58] reported the reaction of Amberlyst 15 with chlorine, bromine, and iodine to afford a series of halogenated macroporous sulfonic resins. The halogenation was performed in aqueous medium, except for the iodination which needed an acid oxidant such as nitric acid (Scheme 24). These resins were used as catalysts for the Biginelli reaction to evaluate their catalytic performance. The catalytic activity of the halogenated resins was better than that of Amberlyst 15 and followed the order: A-15-Br > A-15-Cl ≈ A-15-I > A-15. Thus, the halogenation improved the thermal stability and catalytic activity of the resin probably due to the positive inductive effect and hydrophobicity of halogens. The best catalytic activity was exhibited by A-15-Br containing 31.27% of bromine (Scheme 25).

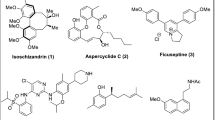

4. SYNTHESIS OF FUSED HETEROCYCLIC SYSTEMS

4.1. Synthesis of benzazoles. In 2013, Rambabu et al. [59] reported a general method for the synthesis of benzazoles (benzothiazoles, benzoxazoles, and benzimidazoles) 43 and 44 in water using A-15 as a recyclable catalyst under ultrasonic irradiation (Scheme 26). The method consisted of reacting 2-aminophenol, 2-aminobenzenethiol, or benzene-1,2-diamine and carboxylic acids in water under ultrasound. Alternatively, N-acyl derivatives of the same amines reacted under similar conditions to afford 2-alkyl/aryl-1,3-benzazoles 44. The use of water as a green solvent afforded the target compounds in good to excellent yields (80–92%), and the catalyst was recycled up to three times. The reaction tolerated aromatic acids with various electron-donating and electron-withdrawing substituents, as well as heterocyclic acids (isonicotinic acid); however, the use of aliphatic acids was less effective.

4.2. Synthesis of chromenes. In 2015, Guha et al. [60] reported an easy and efficient synthesis of 2-aryl-4-(indol-3-yl)-4H-chromenes 47 starting from 2-hydroxychalcones 45 and indoles 46 using A-15 as an efficient recyclable heterogeneous catalyst. The presence of an electron-withdrawing group on either of the phenyl rings of 2-hydroxychalcone improved the yield, while the presence of an electron-releasing group decreased the yield. 2-Methylindole gave better yields (70–78%) than indole (53–74%), and the latter gave better yields than 5-methoxy- or 5-bromoindole (55–65%) (Scheme 27). The reaction involved three steps, namely Michael addition, cyclization, and dehydration, and all these steps were catalyzed by A-15 as indicated in Scheme 28.

The same team reported the use of a cyclic diketone, indan-1,3-dione, to obtain 2-(2-phenyl-4H-chromen-4-ylidene)-2H-indene-1,3-diones 49 (Scheme 29). The proposed mechanism involved the above-mentioned three steps along with an extra step (aerial oxidation) 49 [61].

One year later, the same research group [62] reported the use of 1,3-dimethylbarbituric acid instead of indole under similar reaction conditions. The products were 1,3-dimethyl-5-(2-phenyl-4H-chromen-4-ylidene)pyrimidine-2,4,6(1H,3H,5H)-triones 51 (Scheme 30). In this work, Amberlyst 15, fused ZnCl2, and anhydrous FeCl3 were examined as catalysts; among them, Amberlyst 15 showed superior catalytic activity. Here also, the reaction involved a domino sequence of Michael addition, cyclization, dehydration, and aerial oxidation. 2-Hydroxychalcones 50 can bear both electron-donating and electron-withdrawing groups at their phenyl rings; the highest yields (80–85%) obtained when methoxy group was present at different positions of the phenyl rings.

The same reaction using 2-hydroxychalcones 52 and either of dimedone, 4-hydroxycoumarin, 2-hydroxynaphthoquinone, 2-naphthol, or 1-naphthol afforded several types of 2,8-dioxabicyclo[3.3.1]nonanes 53. It was observed that the catalyst could be reused up to four times without significant decrease in catalytic activity (Scheme 31) [63].

4.3. Synthesis of coumarins. In 2017, Bouasla et al. [64] reported the synthesis of coumarin derivatives 54 under microwave irradiation and solvent-free conditions using A-15 as a heterogeneous acid catalyst. The synthesis is an application of Pechmann reaction [53, 65] which involves Lewis or Brønsted acid-mediated condensation of phenol with β-keto ester to give coumarin ring. Thus, phenol or resorcinol and ethyl acetoacetate were allowed to react in the presence of different catalysts such as Amberlyst 15, zeolite β, and sulfonic acid-functionalized hybrid silica under solvent-free conditions and microwave irradiation. The most active catalyst was A-15 which gave 7-hydroxy-4-methylcoumarin and 4-methylcoumarin in 97 and 43% yields, respectively. The role of the acid catalyst is to protonate the carbonyl group of ethyl acetoacetate to facilitate nucleophilic attack on it by phenol or resorcinol. Due to large number of catalytic sites, A-15 displayed higher catalytic activity and enabled the formation of coumarins in 20 min (Scheme 32).

One year later, Merza [66] applied Pechmann condensation for the preparation of 5,7-dihydroxy-4-methylcoumarin (55) and 6-hydroxy-1-methyl-3H-benzo[f]chromen-3-one (56) using A-15 as a green catalyst. Both compounds have pleasant odor and can be used in perfumes. The compounds were synthesized via reacting phloroglucinol or 1,3-dihydroxynaphthalene with ethyl acetoacetate under solvent-free conditions. The use of A-15 as a heterogeneous catalyst in an amount of 10 mol % provided high yields of 55 (95%) and 56 (88%). The products were easily isolated, and the catalyst was recycled up to 5 times (Scheme 33). The mechanism of the Pechmann reaction involves transesterification of the phenolic compound and intramolecular hydroxyalkylation, followed by dehydration to give coumarin ring as shown in Scheme 34. All these steps require an acid catalyst [53, 67, 68].

4.4. Synthesis of quinoxalines. In 2010, Liu and coworkers [69, 70] reported a green and efficient protocol for the synthesis of quinoxaline derivatives 59 by condensation of 1,2-diamines 57 and 1,2-dicarbonyl compounds 58 in water catalyzed by A-15 (Scheme 35). In this reaction, the nature of substituents on the diamine component affected the conversion. Aromatic diamines bearing electron-donating groups reacted faster than o-phenylenediamine. In contrast, the presence of an electron-withdrawing substituent deactivated the aromatic diamine. On the other hand, the nature of substituents on 1,2-diketones had no significant effect on the yield. The catalyst was recycled for five times with no noticeable change in catalytic activity. The procedure can be regarded as simple, applicable to a large number of substrates, and scalable.

One year later, Chari [71] reported the synthesis of 3,4-dihydroquinoxalin-2-amine derivatives 61 at room temperature via multi-component reaction of o-phenylenediamines 60, ketones, and various isocyanides in ethanol in the presence of A-15. The products were obtained in excellent yields (85–99%), and the catalyst can be recycled up to three times. The ketones used can be aliphatic, substituted aromatic, and cyclic, and the best results were obtained with ketones carrying a methyl group. The diamine or its chloro derivative, as well as cyclohexyl or benzyl isocyanide, were also all tolerated in the reaction (Scheme 36).

The proposed mechanism (Scheme 37) involved Amberlyst 15-catalyzed formation of Schiff bases 62 from ketones and diamines. Nucleophilic attack of isocyanide on the imine bond was followed by intramolecular cyclization, and imine–enamine tautomerization gave more stable quinoxalines 61 due to conjugation with the aromatic ring [72].

4.5. Synthesis of quinazolines. In 2012, Murthy et al. [73] reported the use of A-15 as a catalyst for the reaction of 2-aminobenzamides 64 and aromatic aldehydes to synthesize 2-substituted 2,3-dihydroquinazolin-4(1H)-ones 65 (Scheme 38). The reaction tolerated aldehydes bearing both electron-donating and electron-withdrawing groups, and the products were obtained in excellent yields (96–98%) and short reaction times (10–30 min).

A year later, the same research team [74] reported the synthesis of spiro-2,3-dihydroquinazolin-4(1H)-ones 67 using A-15 as a green and reusable catalyst. The reaction was conducted in an open flask under ultrasonication at room temperature. Thus, reacting a mixture of 2-aminobenzamide 66 and cyclic ketone under the above-mentioned conditions afforded target quinazolines 67 within few minutes, and the products did not require further chromatographic purification (Scheme 39). The carbonyl compounds used included cyclic aliphatic ketones (piperidin-4-one, cyclopentanone, cyclohexanone, and cycloheptanone) and cyclic aromatic ketones (indanone and isatins). The catalyst was recovered and recycled up to three times. The reaction mechanism involved the formation of imine intermediate, followed by intramolecular cyclization. It was presumed that A-15 catalyzed both steps.

4.6. Synthesis of benzothiadiazines. In 2013, Kumar and co-workers [75] reported the green synthesis of 1,2,4-benzothiadiazine 1,1-dioxides 69 by reacting 2-aminobenzenesulfonamides 68 with carbonyl compounds. The reaction was conducted at room temperature in water under ultrasonic irradiation in the presence of Amberlyst 15 as a catalyst (Scheme 40). The carbonyl compounds used included cyclic aliphatic ketones (piperidinone, cyclopentanone, cyclohexanone, and cycloheptanone), cyclic aromatic ketones (isatins), and aromatic aldehydes bearing electron-donating and electron withdrawing groups. The reaction was insensitive to air or moisture, and thus it can be carried out in an open flask. The products were isolated in pure form without chromatographic purification. The use of ultrasounic irradiation shortened the reaction time, presumably due to activation of the catalyst and better dispersion of the reactants in water. The reaction mechanism involved the formation of imines. Thereafter, intramolecular cyclization of the sulfonamide group on the imine C=N bond occurred to give spiro products, and both steps were catalyzed by A-15.

4.7. Synthesis of naphthyridines. The reaction of 5,5-dimethyl-2-arylidinecyclohexane-1,3-diones 70 and 2-aminopyridine in anhydrous ethanol using A-15 as a catalyst gave 8,8-dimethyl-5-(aryl/heteroaryl)-7,8,9,10-tetrahydro[b][1,8]naphthyridine-6(5H)-ones 71 [76]. The procedure is eco-friendly, and it afforded the target compounds in high yields (90–98%) with high diversity in the aryl groups. The catalyst was separated and reused up to four times with only slight reduction in its catalytic activity. The role of A-15 as acid catalyst is to protonate the carbonyl group in order to facilitate nucleophilic attack of the amino group on the carbonyl carbon atom (Scheme 41).

Muthukrishnan and co-workers [77] recently reported the synthesis of complex hybrid heterocycles containing [1,6]naphthyridine and coumarin/pyrazole moieties using A-15 in polyethylene glycol (PEG 200). In this work, 2-aminobenzaldehydes 72 bearing a tethered alkyne moiety were allowed to react with 3-aminocoumarins 73 or 3-methyl-1-aryl-1H-pyrazol-5-amines 75 using A-15 in PEG-200. The products were 12,13-dihydro-6H-benzo[h]chromeno[3,4-b][1,6]naphthyridin-6-ones 74 and 6,10-dihydro-5H-benzo[h]pyrazolo[3,4-b][1,6]naphthyridines 76, respectively (Scheme 42).

The synthesis of compounds 74 and 76 is characterized by a very high atom economy (over 96% in all cases) as the only by-product is a water molecule. Also, the carbon efficiency of the reaction is 100% (calculated as the percent weight ratio of carbon in the product and in the reactants). The advantages of this protocol included the use of green solvent, very high atom economy, recyclability of the catalyst, and the formation of water as the only side product [77].

This metal-free green protocol involved an intramolecular hetero-Diels–Alder reaction as the key step. The reaction mechanism involved initial reaction between aldehyde 72 and heterocyclic amine to form Schiff base intermediate 77 which underwent A-15-catalyzed [4+2]-cycloaddition (hetero-Diels–Alder) followed by air oxidation to afford product 74 or 76 (Scheme 43) [77].

4.8. Synthesis of perimidines. In 2014, Patil and Shankarling [78] reported the use of A-15 for the synthesis of 2,3-dihydro-1H-perimidine derivatives 79. The latter were prepared via reacting naphthalene-1,8-diamine 78 with various ketones using A-15 as an acid catalyst (Scheme 44). The use of A-15 provided high yields of 79 (85–97%) in addition to easy recovery and reusability of the catalyst. Furthermore, the reaction was scaled up to a gram level. The reaction was selective for dialkyl and aryl alkyl ketones. Furthermore, alkyl aryl ketones bearing electron-withdrawing groups on the aryl ring reacted faster than those bearing an electron-donating group. Compared to other synthetic routed to perimidines, this procedure is characterized as metal-free, non-toxic, and cost effective.

4.9. Synthesis of pyrazolo[1,5-c]pyrimidines and pyrido[1,2-a]pyrimidines. Maurya and Gupta [79] reported the synthesis of 2-aryl-7-phenylpyrazolo[1,5-c]pyrimidines 81 and pyrido[1,2-a]pyrimidin-2-ones 82 through the reaction of enamines 80 and benzamide or 2-aminopyridine in TFA using A-15 as a catalyst (Scheme 45).

4.10. Synthesis of xanthenes. The synthesis of (E)-9-aryl-5-(arylmethylidene)-1-oxo-1,2,3,4,5,6,7,8-octahydroxanthenes and their lower analogues 85 was reported in 2013 by Samanta et al. [80], who described the A-15-catalyzed cyclocondensation of dibenzylidenecyclohexanones and cyclopentanones 83 with cyclohexane-1,3-diones 84 as shown in Scheme 46.

4.11. Synthesis of dipyrimido[1,2-a]pyrimidines. New 2-phenyl-3H-dipyrimido[1,2-a]pyrimidin-4(5H)-one derivatives 87 were synthesized by Hese and co-workers [81 by reacting pyrido[1,2-a]pyrimidine-3-carbonitriles 86 and benzoic acid in the presence of a catalytic amount of A-15 in PEG-400 (Scheme 47).

4.12. Synthesis of spiro indole derivatives. In 2015, Pasha et al. [82] reported for the first time that Amberlyst 15 can catalyze Povarov reaction of N-arylmethylidene-1H-indazol-6-amines and indoles (Scheme 48). The reaction was carried out at room temperature between imines (formed in situ from aromatic/heteroarpmatic aldehydes and indazol-6-amines 88) and indole or 5-bromoindole 89. The products were exo-1,6,7,7a,12,12a-hexahydroindolo[3,2-c]pyrazolo[3,4-f]quinolinones 90 which were obtained with excellent regio- and stereoselectivity (only one diastereoisomer was formed). The Povarov reaction is an inverse electron-demand aza-Diels–Alder reaction, i.e., a [4+2]-cycloaddition reaction between an N-arylimine (diene) and an electron-rich olefin (dienophile). The products are quinoline or tetrahydroquinoline derivatives [53, 83–85].

In 2019, Niu et al. [86] reported the preparation of spiro compounds 94 and 96 via two different pathways starting from isatins 91, isoxazol-5-one 93, and pyrazol-5-amines 92 or 6-aminopyrimidine-2,4-diones 95. In both reactions, A-15 was used as a recyclable catalyst. The products were spiro[indole-3,4′-isoxazolo[5,4-b]pyrazolo[4,3-e]pyridin]-2-ones 94 and spiro[isoxazolo[5,4-b]quinoline-4,5′-pyrrolo[2,3-d]pyrimidine]-2′,4′,6′(1′H,3′H,7′H)-triones 96. Many electron-donating and electron-withdrawing groups at different positions of the isatin ring were tolerated (Scheme 49).

Probable mechanisms for the formation of compounds 94 and 96 are presented in Schemes 50 and 51. The first step was Amberlyst 15-catalyzed condensation of isatin 91 and aminopyrazole 92 to give intermediate 97. The latter reacted with isoxazole 93 to give adduct 98. Tautomerization of 98 followed by intramolecular cyclization and dehydration afforded the target compound (Scheme 50).

The first step in the synthesis of 96 was also A-15-catalyzed condensation of isatin 91 and 6-aminopyrimidine 95. However, intermediate 100 underwent tautomerism followed by intramolecular cyclization, where the amino group of pyrimidine attacked the carbonyl group of isatin to give intermediate 101. Ring opening of the five-membered of isatin ring and further attack of the liberated amino group on the carbonyl group of isoxazole afforded spiro intermediate 103, and dehydration of the latter gave compound 96 (Scheme 51).

4.13. Synthesis of benzothiazolo[2,3-b]quinazolines. Kidwi et al. [87] reported a simple MCR for the synthesis of benzothiazolo[2,3-b]quinazolin-1-ones 104 that involved the condensation of 2-aminobenzothiazole, different aldehydes, and cyclic β-diketone using A-15 in PEG 400 as an environmentally benign and reusable (up to 4 times) catalytic system. Aldehydes containing both electron-donating and electron-withdrawing groups were well tolerated in this reaction (Scheme 52).

In 2014, Wu and coworkers [88] reported similar reaction using 2-hydroxy-1,4-naphthoquinone as a ketone component (Scheme 53). The products were 13-aryl-13H-benzo[g]benzothiazolo[2,3-b]quinazoline-5,14-dione derivatives 105. The procedure is a multicomponent reaction involving 2-aminobenzothiazole, aromatic aldehydes, and 2-hydroxy-1,4-naphthoquinone in the presence of A-15 under solvent-free conditions.

4.14. Synthesis of thiazolo[3,4-a]benzimidazoles. Chaskar et al. [89] reported the MCR of o-phenylenediamine, 2-mercaptoacetic acid, and benzaldehyde to afford 1-phenyl-1H,3H-thiazolo[3,4-a]benzimidazole 106 (Scheme 54). Different heterogeneous catalysts were examined; among them, A-15 afforded the target compound in 79% yield. The best catalyst used in this study was silica-supported sodium hydrogen sulfate (NaHSO4-SiO2).

4.15. Other multicomponent reactions. Recently, A-15 was examined as a catalyst for many multicomponent reactions; however, the yields of the products were low, which precluded the use of A-15 as a first choice catalyst for these reactions. Examples included the syntheses of pyrano[2,3-d]pyrimidine [90], pyrano[3,2-c]pyridine [91], indenopyrrolo[3,2-c]pyridinone [92], 1H-pyrazolo[4′,3′:5,6]pyrido[2,3-d]pyrimidine-5,7(4H,6H)-dione [93], and 1′,9′-dihydro-5′H-spiro[indole-3,4′-pyrano[4,3-b]pyrazolo[4,3-e]pyridine]-2,5′-dione derivatives [94] (Schemes 55–59).

5. CONCLUSIONS

Amberlyst 15 emerged as a highly useful green catalyst in the synthesis of mono, di-, and polycyclic heterocyclic compounds. Its use offered many advantages over homogenous catalyst, as well as other heterogeneous catalysts. Recyclability and environmental friendliness are the most fascinating properties of A-15 that make it highly recommended catalyst in sustainable chemistry. Other advantages include its low cost, ease of handling, and ease of separation from the reaction mixture. Moreover, the products can be easily separated in the pure form. Compared with other commercial resins, A-15 displays superior catalytic activity owing to its high acidity, surface area, and structural stability. This review will be useful for organic chemists working in the fields of heterocyclic synthesis and green catalysis.

REFERENCES

Kitanosono, T., Masuda, K., Xu, P., and Kobayashi, S., Chem. Rev., 2018, vol. 118, p. 679. https://doi.org/10.1021/acs.chemrev.7b00417

Wacławek, S., Padil, V.V.T., and Černík, M., Ecol. Chem. Eng. S, 2018, vol. 25, no. 1, p. 9. https://doi.org/10.1515/eces-2018-0001

Kokel, A., Schäfer, C., and Török, B., Curr. Org. Synth., 2019, vol. 16, no. 4, p. 615. https://doi.org/10.2174/1570179416666190206141028

Pal, R., Sarkar, T., and Khasnobis, S., Arkivoc. 2012, vol. 2012, part (i), p. 570. https://doi.org/10.3998/ark.5550190.0013.114

Abrams, I.M. and Milk, J.R., React. Funct. Polym., 1997, vol. 35, p. 7. https://doi.org/10.1016/S1381-5148(97)00058-8

Kunin, R., Meitzner, E., Oline, J., Fischer, S., and Frisch, N., Ind. Eng. Chem. Prod. Res. Dev., 1962, vol. 1, no. 2, p. 140. https://doi.org/10.1021/i360002a016

Corain, B., Zecca, M., and Jeřábek, K., J. Mol. Catal. A: Chem., 2001, vol. 177, no. 1, p. 3. https://doi.org/10.1016/S1381-1169(01)00305-3

Miyazawa, T., Kusunoki, Y., Kunimori, K., and Tomishige, K., J. Catal., 2006, vol. 240, no. 2, p. 213. https://doi.org/10.1016/j.jcat.2006.03.023

Shelkar, R., Singh, A., and Nagarkar, J., Tetrahedron Lett., 2013, vol. 54, no. 1, p. 106. https://doi.org/10.1016/j.tetlet.2012.10.116

Palmieri, A., Gabrielli, S., and Ballini, R., Chem. Commun., 2010, vol. 46, no. 33, p. 6165. https://doi.org/10.1039/c0cc01097a

Shinde, V.M., Patil, G.N., Katariya, A., and Mahajan, Y.S., Chem. Eng. Process., 2015, vol. 95, p. 241. https://doi.org/10.1016/j.cep.2015.06.016

Taylor, R. and Krishna, R., Chem. Eng. Sci., 2000, vol. 55, no. 22, p. 5183. https://doi.org/10.1016/S0009-2509(00)00120-2

Segovia-Hernández, J.G., Hernández, S., and Bonilla Petriciolet, A., Chem. Eng. Process., 2015, vol. 97, p. 134. https://doi.org/10.1016/j.cep.2015.09.004

Gupta, R., Shah, S., and Dubey, S., Imp. J. Interdiscip. Res., 2016, vol. 2, no. 12, p. 314. https://www.onlinejournal.in/IJIRV2I12/051.pdf

Rosatella, A.A., Simeonov, S.P., Frade, R.F.M., and Afonso, C.A.M., Green Chem., 2011, vol. 13, no. 4, p. 754. https://doi.org/10.1039/c0gc00401d

Gallezot, P., Chem. Soc. Rev., 2012, vol. 41, no. 4, p. 1538. https://doi.org/10.1039/c1cs15147a

Fan, W., Verrier, C., Queneau, Y., and Popowycz, F., Curr. Org. Synth., 2019, vol. 16, p. 583. https://doi.org/10.2174/1570179416666190412164738

Zhu, H., Cao, Q., Li, C., and Mua, X., Carbohydr. Res., 2011, vol. 346, no. 13, p. 2016. https://doi.org/10.1016/j.carres.2011.05.026

Takagaki, A., Ohara, M., Nishimura, S., and Ebitani, K., Chem. Commun., 2009, p. 6276. https://doi.org/10.1039/b914087e

Tuteja, J., Nishimura, S., and Ebitani, K., Bull. Chem. Soc. Jpn., 2012, vol. 85, no. 3, p. 275. https://doi.org/10.1246/bcsj.20110287

Jeong, J., Antonyraj, C.A., Shin, S., Kim, S., Kim, B., Lee, K.Y., and Cho, J.K., J. Ind. Eng. Chem., 2013, vol. 19, no. 4, p. 1106. https://doi.org/10.1016/j.jiec.2012.12.004

Aellig, C. and Hermans, I., ChemSusChem, 2012, vol. 5, no. 9, p. 1737. https://doi.org/10.1002/cssc.201200279

Shimizu, K.-i., Uozumi, R., and Satsuma, A., Catal. Commun., 2009, vol. 10, no. 14, p. 1849. https://doi.org/10.1016/j.catcom.2009.06.012

Wang, J., Xu, W., Ren, J., Liu, X., Lu, G., and Wang, Y., Green Chem., 2011, vol. 13, no. 10, p. 2678. https://doi.org/10.1039/c1gc15306d

Lansalot-Matras, C. and Moreau, C., Catal. Commun., 2003, vol. 4, no. 10, p. 517. https://doi.org/10.1016/S1566-7367(03)00133-X

Sampath, G. and Kannan, S., Catal. Commun., 2013, vol. 37, p. 41. https://doi.org/10.1016/j.catcom.2013.03.021

Alonso, D.A., Baeza, A., Chinchilla, R., Guillena, G., Pastor, I.M., and Ramón, D.J., Eur. J. Org. Chem., 2016, vol. 2016, p. 612. https://doi.org/10.1002/ejoc.201501197

Paiva, A., Craveiro, R., Aroso, I., Martins, M., Reis, R.L., and Duarte, A.R.C., ACS Sustainable Chem. Eng., 2014, vol. 2, no. 5, p. 1063. https://doi.org/10.1021/sc500096j

Vanda, H., Dai, Y., Wilson, E.G., Verpoorte, R., and Choi, Y.H., C. R. Chim., 2018, vol. 21, no. 6, p. 628. https://doi.org/10.1016/j.crci.2018.04.002

Liu, Y., Friesen, J.B., McAlpine, J.B., Lankin, D.C., Chen, S.-N., and Paul, G.F., J. Nat. Prod., 2018, vol. 81, no. 3, p. 679. https://doi.org/10.1016/j.physbeh.2017.03.040

Hayyan, M., Hashim, M.A., Hayyan, A., Al-Saadi, M.A., AlNashef, I.M., Mirghani, M.E.S., and Saheed, O.K., Chemosphere, 2013, vol. 90, no. 7, p. 2193. https://doi.org/10.1016/j.chemosphere.2012.11.004

Smith, E.L., Abbott, A.P., and Ryder, K.S., Chem. Rev., 2014, vol. 114, no. 21, p. 11060. https://doi.org/10.1021/cr300162p

Suriyanarayanan, S., Olsson, G.D., Kathiravan, S., Ndizeye, N., and Nicholls, I.A., Int. J. Mol. Sci., 2019, vol. 20, no. 12, p. 2857. https://doi.org/10.3390/ijms20122857

Qin, H., Hu, X., Wang, J., Cheng, H., Chen, L., and Qi, Z., Green Energy Environ., 2020, vol. 5, no. 1, p. 8. https://doi.org/10.1016/j.gee.2019.03.002

Ünlü, A.E., Arlkaya, A., and Takaç, S., Green Process. Synth., 2019, vol. 8, no. 1, p. 355. https://doi.org/10.1515/gps-2019-0003

Marullo, S., Rizzo, C., and D’anna, F., ACS Sustainable Chem. Eng., 2019, vol. 7, no. 15, p. 13359. https://doi.org/10.1021/acssuschemeng.9b02605

Ru, C., Luff, C., Begli, A.H., and Koenig, B., Synth. Commun., 2012, vol. 42, no. 21, p. 3112. https://doi.org/10.1080/00397911.2011.576375

Shirotori, M., Nishimura, S., and Ebitani, K., Catal. Sci. Technol., 2014, vol. 4, no. 4, p. 971. https://doi.org/10.1039/c3cy00980g

Dias, A.S., Pillinger, M., and Valente, A.A., J. Catal., 2005, vol. 229, no. 2, p. 414. https://doi.org/10.1016/j.jcat.2004.11.016

Lanzafame, P., Temi, D.M., Perathoner, S., Spadaro, A.N., and Centi, G., Catal. Today, 2012, vol. 179, no. 1, p. 178. https://doi.org/10.1016/j.cattod.2011.07.018

Jeon, W., Ban, C., Kim, J.E., Woo, H.C., and Kim, D.H., J. Mol. Catal. A: Chem., 2016, vol. 423, p. 264. https://doi.org/10.1016/j.molcata.2016.07.020

Chiurchiù, E., Patehebieke, Y., Gabrielli, S., Ballini, R., and Palmieri, A., Adv. Synth. Catal., 2019, vol. 361, no. 9, p. 2042. https://doi.org/10.1002/adsc.201801660

Murthi, P.R.K., Rambabu, D., Rao, M.V.B., and Pal, M., Tetrahedron Lett., 2014, vol. 55, no. 2, p. 507. https://doi.org/10.1016/j.tetlet.2013.11.073

Aldmairi, A.H., Knight, D.W., and Wirth, T., Synlett, 2017, vol. 28, no. 20, p. 2976. https://doi.org/10.1055/s-0036-1591513

Kumar, A.D., Prabhudeva, M.G., Bharath, S., Kumara, K., Lokanath, N.K., and Kumar, K.A., Bioorg. Chem., 2018, vol. 80, p. 444. https://doi.org/10.1016/j.bioorg.2018.06.023

Prabhudeva, M.G., Kumara, K., Dileep Kumar, A., Ningappa, M.B., Lokanath, N.K., and Ajay Kumar, K., Res. Chem. Intermed., 2018, vol. 44, no. 11, p. 6453. https://doi.org/10.1007/s11164-018-3501-2

Prabhudeva, M.G., Vivek, H.K., and Kumar, K.A., Chem. Data Collect., 2019, vol. 20, article ID 100193. https://doi.org/10.1016/j.cdc.2019.100193

Pandit, S.S., Bhalerao, S.K., Aher, U.S., Adhav, G.L., and Pandit, V.U., J. Chem. Sci., 2011, vol. 123, no. 4, p. 421. https://doi.org/10.1007/s12039-011-0097-0

Nirwan, N. and Pareek, C., Int. J. Sci. Res. Sci. Technol., 2017, vol. 3, no. 8, p. 76. https://doi.org/10.32628/IJSRST173824

Zhang, H., Dong, D.-Q., and Wang, Z.-L., Synthesis, 2016, vol. 48, no. 1, p. 131. https://doi.org/10.1055/s-0035-1560488

Gunduz, H., Kumbaraci, V., Özkılıç, Y., Tüzün, N., and Talinli, N., ChemistrySelect, 2019, vol. 4, no. 24, p. 7278. https://doi.org/10.1002/slct.201901403

Vyskočilová, E., Rezková, L., Vrbková, E., Paterová, I., and Červený, L., Res. Chem. Intermed., 2016, vol. 42, no. 2, p. 725. https://doi.org/10.1007/s11164-015-2052-z

Li, J.J., Name Reactions. A Collection of Detailed Mechanisms and Synthetic Applications, Cham: Springer, 2014, 5th ed. https://doi.org/10.1007/978-3-319-03979-4

Prins, H.J., Chem. Weekbl., 1919, vol. 16, p. 1072.

Gelmini, A., Albonetti, S., Cavani, F., Cesari, C., Lolli, A., Zanotti, V., and Mazzoni, R., Appl. Catal., B, 2016, vol. 180, p. 38. https://doi.org/10.1016/j.apcatb.2015.06.003

Jetti, S.R., Verma, D., and Jain, S., Int. Scholarly Res. Not., 2012, vol. 2012, article ID 480989. https://doi.org/10.5402/2012/480989

Jetti, S.R., Neelaiah Babu, G., Paliwal, P., Bhatewra, A., Kadre, T., and Jain, S., Pharma Chem., 2012, vol. 4, no. 1, p. 417.

Shen, P., Xu, M., Yin, D., Xie, S., Zhou, C., and Li, F., Catal. Commun., 2016, vol. 77, p. 18. https://doi.org/10.1016/j.catcom.2016.01.010

Rambabu, D., Murthi, P.R.K., Dulla, B., Rao, M.V.B., and Pal, M., Synth. Commun., 2013, vol. 43, no. 22, p. 3083. https://doi.org/10.1080/00397911.2013.769605

Guha, C., Sepay, N., and Mallik, A.K., Monatsh. Chem., 2015, vol. 146, no. 8, p. 1349. https://doi.org/10.1007/s00706-014-1401-8

Guha, C., Samanta, S., Sepay, N., and Mallik, A.K., Tetrahedron Lett., 2015, vol. 56, no. 34, p. 4954. https://doi.org/10.1016/j.tetlet.2015.07.005

Sepay, N., Mallik, S., Guha, C., and Mallik, A.K., RSC Adv., 2016, vol. 6, no. 98, p. 96016. https://doi.org/10.1039/c6ra13584f

Samanta, S., Sepay, N., Mallik, S., Mondal, R., Rahaman Molla, M., and Mallik, A.K., Synth. Commun., 2017, vol. 47, no. 23, p. 2195. https://doi.org/10.1080/00397911.2017.1365906

Bouasla, S., Amaro-Gahete, J., Esquivel, D., López, M.I., Jiménez-Sanchidrián, C., Teguiche, M., and Romero-Salguero, F.J., Molecules, 2017, vol. 22, no. 12, p. 2072. https://doi.org/10.3390/molecules22122072

Von Pechmann, H. and Duisberg, C., Ber., 1883, vol. 16, p. 2119. https://doi.org/10.1002/cber.188301602117

Merza, J., Chem. Mater. Res., 2018, vol. 10, no. 3, p. 16.

Hoefnagel, A.J., Gunnewegh, E.A., Downing, R.S., and Van Bekkum, H., J. Chem. Soc., Chem. Commun., 1995, no. 2, p. 225. https://doi.org/10.1039/C39950000225

Khandekar, A.C. and Khadilkar, B.M., Synlett, 2002, vol. 2002, p. 152. https://doi.org/10.1055/s-2002-19332

Nageswar, Y.V.D., Reddy, K.H.V., Ramesh, K., and Murthy, S.N., Org. Prep. Proced. Int., 2013, vol. 45, no. 1, p. 1. https://doi.org/10.1080/00304948.2013.743419

Liu, J.-Y., Liu, J., Wang, J.-D., Jiao, D.-Q., and Liu, H.-W., Synth. Commun., 2010, vol. 40, no. 14, p. 2047. https://doi.org/10.1080/00397910903219401

Chari, M.A., Tetrahedron Lett., 2011, vol. 52, no. 46, p. 6108. https://doi.org/10.1016/j.tetlet.2011.09.015

Shaabani, A., Maleki, A., Mofakham, H., and Khavasi, H.R., J. Comb. Chem., 2008, vol. 10, no. 2, p. 323. https://doi.org/10.1021/cc7001777

Murthy, P.V., Rambabu, D., Krishna, G.R., Reddy, C.M., Prasad, K.R.S., Rao, M.V.B., and Pal, M., Tetrahedron Lett., 2012, vol. 53, no. 7, p. 863. https://doi.org/10.1016/j.tetlet.2011.12.023

Rambabu, D., Kumar, S.K., Sreenivas, B.Y., Sandra, S., Kandale, A., Misra, P., Rao, M.V.B., and Pal, M., Tetrahedron Lett., 2013, vol. 54, no. 6, p. 495. https://doi.org/10.1016/j.tetlet.2012.11.057

Kumar, S.K., Rambabu, D., Kumar, C.H.V., Sreenivas, B.Y., Prasad, K.R.S., Rao, M.V.B., and Pal, M., RSC Adv., 2013, vol. 3, no. 47, p. 24863. https://doi.org/10.1039/c3ra44703k

Jetti, S.R., Bhatewara, A., Kadre, T., and Jain, S., Pharma Chem., 2016, vol. 8, no. 5, p. 98.

Muthukrishnan, I., Vachan, B.S., Karuppasamy, M., Eniyaval, A., Uma Maheswari, C., Nagarajan, S., Menéndez, J.C., and Sridharan, V., Org. Biomol. Chem., 2019, vol. 17, no. 28, p. 6872. https://doi.org/10.1039/c9ob01256g

Patil, V.V. and Shankarling, G.S., Catal. Commun., 2014, vol. 57, p. 138. https://doi.org/10.1016/j.catcom.2014.08.024

Maurya, H.K. and Gupta, A., Tetrahedron Lett., 2014, vol. 55, no. 10, p. 1715. https://doi.org/10.1016/j.tetlet.2014.01.095

Samanta, S., Das Gupta, A., Mondal, R., and Mallik, A.K., J. Chem. Sci., 2013, vol. 125, no. 4, p. 737. https://doi.org/10.1007/s12039-013-0442-6

Hese, S.V., Kamble, R.D., Mogle, P.P., Kamble, S.S., Hebade, M.J., Ambhore, A.N., Kadam, S.N., Gacche, R.N., and Dawane, B.S., J. Chem. Pharm. Res., 2015, vol. 7, no. 7, p. 784.

Pasha, J., Kandagatla, B., Sen, S., Seerapu, G.P.K., Bujji, S., Haldar, D., Nanduri, S., and Oruganti, S., Tetrahedron Lett., 2015, vol. 56, no. 18, p. 2289. https://doi.org/10.1016/j.tetlet.2015.03.078

Povarov, L.S. and Mikhailov, B.M., Bull. Acad. Sci. USSR, Div. Chem. Sci., 1963, vol. 12, p. 871. https://doi.org/10.1007/BF01134751

Kouznetsov, V.V., Tetrahedron, 2009, vol. 65, no. 14, p. 2721. https://doi.org/10.1016/j.tet.2008.12.059

Makioka, Y., Shindo, T., Taniguchi, Y., Takaki, K., and Fujiwara, Y., Synthesis, 1995, vol. 1995, p. 801. https://doi.org/10.1055/s-1995-4002

Niu, Q., Xi, J., Li, L., Li, L., Pan, C., Lan, M., and Rong, L., Tetrahedron Lett., 2019, vol. 60, no. 43, p. 4. https://doi.org/10.1016/j.tetlet.2019.151181

Mazaahir, K., Ritika, C., and Divya, B., Sci. China Chem., 2012, vol. 55, no. 10, p. 2154. https://doi.org/10.1007/s11426-012-4665-z

Wu, L., Zhang, C., and Li, W., Bioorg. Med. Chem. Lett., 2014, vol. 24, no. 6, p. 1462. https://doi.org/10.1016/j.bmcl.2014.02.018

Chaskar, A., Padalkar, V., Phatangare, K., Takale, S., and Murugan, K., Green Chem. Lett. Rev., 2013, vol. 6, no. 3, p. 217. https://doi.org/10.1080/17518253.2012.739209

Xia, Q., Li, C., Zhang, Y., Qi, C., and Zhang, F., ChemistrySelect, 2018, vol. 3, no. 32, p. 9232. https://doi.org/10.1002/slct.201801411

Xu, Z., Du, Y., Wang, S., Wu, Z., Lou, Y., and Zhang, F., J. Heterocycl. Chem., 2019, vol. 56, no. 9, p. 2517. https://doi.org/10.1002/jhet.3646

Li, C., Zhang, F., and Qi, C., Synlett, 2018, vol. 29, no. 20, p. 2707. https://doi.org/10.1055/s-0037-1609655

Satasia, S.P., Kalaria, P.N., and Raval, D.K., Org. Biomol. Chem., 2014, vol. 12, p. 1751. https://doi.org/10.1039/b000000x

Li, C. and Zhang, F., ChemistrySelect, 2018, vol. 3, no. 6, p. 1815. https://doi.org/10.1002/slct.201702942

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The author declares no conflict of interest.

Rights and permissions

About this article

Cite this article

El-Nassan, H.B. Amberlyst 15®: An Efficient Green Catalyst for the Synthesis of Heterocyclic Compounds. Russ J Org Chem 57, 1109–1134 (2021). https://doi.org/10.1134/S1070428021070125

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1070428021070125