Abstract

Based on the previously developed computer program for rigorous calculation of modes in optical fibers containing layers of various materials of arbitrary, including nanometer, thickness, the calculation and optimization of single-mode double adiabatic tapers covered with one, two and three-layer films: ITO, ITO/TiO2, TiO2/ITO/TiO2 of equal thickness is performed, with the aim of their application as the environment refractive index sensors. It is shown that in the range of wavelengths 1.00–1.6 µm, two, and in particular, three-layer coatings not only can increase the sensitivity, but also significantly reduce the width of the lossy mode resonance (LMR), which, in turn, leads to a significant increase in the figure of merit (FOM) of the sensor, defined as the sensitivity/width of the LMR.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

INTRODUCTION

Very promising and recently intensively studied sensors of the surrounding medium (mainly water) refractive index are fiber optic sensors (refractometers), whose sensitivity is based on the so-called lossy mode resonance (LMR). A necessary condition for the appearance of LMR is to cover the fiber section with a dielectric film with a sufficiently large real part and a noticeable imaginary part of the refractive index. In this case, the electromagnetic field of the wave propagating through the optical fiber and localized in the core and its surroundings, penetrates into a thin, nanometer layer of the dielectric with a high refractive index and excites a light wave in it. This leads to a noticeable, up to complete, attenuation of the electromagnetic wave propagating through the fiber in a certain region of wavelengths. In other words, the dependence of the transmission coefficient on the wavelength shows a minimum that can be easily detected experimentally. Since under LMR conditions the light field is concentrated in the coating film and contacts the environment, the position of the minimum transmittance on the wavelength axis depends significantly on the refractive index of the environment. All fiber-optic sensors operating in LMR mode are based on this effect.

Among the easiest to manufacture, and therefore the most reproducible, fiber sensors are distinguished, in which the sensitive layer is applied to a homogeneous area of the taper, previously thinned to the desired diameter by chemical etching [1–6]. Indium tin oxide (ITO) is widely used as coatings for generating LMR [7–9]. In ref. [10], it was proposed to use double layers of ITO∕TiO2 of nanometer thickness as a coating generating LMR. The theoretical calculation carried out in this work showed that the use of a two-layer ITO∕TiO2 coating can double the sensitivity of the sensor compared to a single-layer ITO coating. However, the results [10] refer to multimode fiber sensors that do not allow obtaining a sufficiently narrow LMR with a small FWHM value [11] and, as a result, with a high quality factor FOM, defined as a ratio sensitivity/FWHM. In current paper, on the basis of a rigorous modes calculation [12], we theoretically show, that the use of a two-layer coating ITO∕TiO2 and, in particular, a three-layer coating TiO2/ITO/TiO2, allows not only to increase the sensitivity of the sensor manufactured on the basis of a single-mode adiabatic fiber-optic taper, but also to obtain record values of the figure of merit (FOM).

RESULTS

We calculated and optimized three types of sensors: single-layer ITO, two-layer ITO/TiO2, and three-layer TiO2/ITO/TiO2 coatings with nanometer thickness. The standard single-mode optical fiber SMF28 was chosen as the basis for calculations, as well as in [13, 14]. The refractive index of the silica reflecting cladding of this fiber was calculated using the Sellmeier formula [15] and is greater by 0.16% in the core glass of the fiber in accordance with the Corning ® specification. The results of ellipsometric measurements of the refractive index of ITO films of nanometer thickness presented in [14] show an almost linear refractive index dependence on the wavelength: ranging from 1.93 + 0.007i to 1.90 + 0.02i in the 1150–1700 nm wavelength band. The real part of the TiO2 refraction index is about 2.3, while the imaginary part is almost zero [16]. This data was used in the calculations.

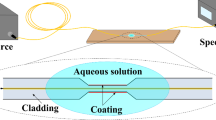

The sensing element of the sensor under consideration is a homogeneous section of a double adiabatic fiber taper etched out to a certain diameter and covered with a film of nanometer thickness, which under the conditions of the so-called LMR provides penetration of a noticeable portion of the lightwave field into the surrounding (water) environment. As shown by the preliminary calculation, the maximum value of the figure of merit (FOM) of such a fiber taper sensor is achieved when the diameter of a homogeneous section is approximately 28 μm. This fixed value was used in further calculations. The thicknesses of ITO and TiO2 films in two and three-layer structures were assumed to be equal. The calculation results are shown in Figs. 1 and 2. When calculating FWHM, we used the developed effective method for approximation of asymmetric resonant curves, based on the results of [17].

Note that the maximum FOM, about 800 nm/RIU, obtained for a three-layer TiO2/ITO/TiO2 coating with a layer thickness of about 33 nm, is appeared to be a record for optical fiber sensors of the refractive index of an aqueous medium. In particular, it significantly exceeds the FOM values reported in [14].

Calculations have shown that a further increase in the number of layers of ITO/TiO2 does not improve the sensor characteristics and, thus, three-layer TiO2/ITO/TiO2 films with layers of equal thickness are optimal. It should be noted that in this paper we have limited ourselves, for simplicity, to considering only equal thickness layers of ITO and TiO2. The use of unequal layers can give some improvement in sensory characteristics, but requires much more extensive calculations.

CONCLUSIONS

Based on the previously developed computer program for rigorous calculation of modes in optical fibers containing layers of various materials of arbitrary, including nanometer thickness, calculation and optimization of single-mode double adiabatic fiber tapers covered with one, two and three-layer films of equal thickness: ITO, ITO/TiO2, TiO2/ITO/TiO2 has been performed in order to apply them as the environment refractive index sensors.It is shown that in the range of wavelengths 1.00–1.6 µm, two, and especially three-layer coatings allow not only to increase the sensitivity, but also significantly reduce the width of the LMR, which, in turn, leads to a significant increase in the quality factor of the sensor FOM, defined as sensitivity/FWHM, up to record values for fiber-optic sensors of the order of 800 nm/RIU. Further increase in the number of ITO /TiO2 layers does not improve the sensor performance, and thus three-layer TiO2/ITO/TiO2 films with layers of equal thickness are optimal.

REFERENCES

J. M. Corres, I. R. Matias, J. Bravo, and F. J. Arregui, “Tapered optical fiber biosensor for the detection of anti-gliadin antibodies,” Sens. and Act. B: Chem. 135, 166–171 (2008).

A. B. Socorro, J. M. Corres, I. Del Villar, F. J. Arregui, and I. R. Matias, “Fiber-optic biosensor based on lossy mode resonances,” Sens. and Act. 174, 263–269 (2012).

J. Villatoro, D. Monzon-Hernández, and E Mejía, “Fabrication and modeling of uniform-waist single-mode tapered optical fiber sensors,” Appl. Opt. 42 (13), 2278–2283 (2003).

S. Zhu, F. Pang, S. Huang, F. Zou, Y. Dong, and T. Wang, “High sensitivity refractive index sensor based on adiabatic tapered optical fiber deposited with nanofilm by ALD,” Opt. Express 23, 13880–13888 (2015).

S. Zhu, F. Pang, S. Huang, F. Zou, Q. Guo, J. Wen, and T. Wang, “High sensitivity refractometer based on TiO2-coated adiabatic tapered optical fiber via ALD technology,” Sensors 16, 1295, (2016).

Qi Wang and W.-M. Zhao, “A comprehensive review of lossy mode resonance-based fiber optic sensors,” Optics and Lasers in Eng. 100, 47–60, (2018).

I. Del Villar, C. R. Zamarreno, M. Hernaez, F. J. Arregui, and I. R. Matias, “Lossy mode resonance generation with indium tin- oxide-coated optical fibers for sensing applications,” J. Lightwave Technol. 28, 111–117 (2010).

I. Del Villar, M. Hernaez, C. R. Zamarreno, P. Sanchez, C. Fernandez-Valdivielso, F. J. Arregui, and I. R. Matias, “Design rules for lossy mode resonance based sensors,” Appl. Opt. 51, 4298–4307 (2012).

M. Hernaez, I. Del Villar, C. R. Zamarreno, F. J. Arregui, and I. R. Matias, “Optical fiber refractometers based on lossy mode resonances supported by TiO2 coatings,” Appl. Opt. 49, 3980–3985 (2010).

N. Paliwal and J. John, “Theoretical modeling of lossy mode resonance based refractive index sensors with ITO/TiO2 bilayers,” Appl. Opt. 53 (15), 3241–3246 (2014).

A. B. Socorro, I. Del Villar, J. M. Corres, F. J. Arregui, and I. R. Matias, “Spectral width reduction in lossy mode resonance-based sensors by means of tapered optical fibre structures,” Sens. Act. B: Chem. 200, 53–60 (2014).

E. I. Golant and K. M. Golant, “Fields and modes in thin film coated optical waveguides,” in Proc. 2019 Photonics & Electromagnetics Research Symp.—Spring (PIERS—SPRING), Rome, Italy, June 17–20, 2019 (PIERS—SPRING, 2019), pp. 725–732.

F. J. Arregui, I. Del Villar, C. R. Zamarreno, P. Zubiate, and I. R. Matias, “Giant sensitivity of optical fiber sensors by means of lossy mode resonance,” Sens. Act. B: Chem. 232, 660–665 (2016).

I. Del Villar, P. Zubiate, C. R. Zamarreno, F. J. Arregui, and I. R. Matias, “Optimization in nanocoated D‑shaped optical fiber sensors,” Opt. Express 25, 10743 (2017).

I. H. Malitson, “Comparison of the refractive index of fused silica,” J. Opt. Soc. Am. 55, 1205–1209 (1965).

M. Magnozzi, S. Terreni, L. Anghinolfi, S. Uttiya, M. M. Carnasciali, G. Gemme, M. Neri, M. Principe, I. Pinto, L.-C. Kuo, S. Chao, and M. Canepa, “Optical properties of amorphous SiO2–TiO2 multi-nanolayered coatings for 1064-nm mirror technology,” Opt. Mater. 75, 94–101 (2018).

A. L. Stancik and E. B. Brauns, “A simple asymmetric lineshape for fitting infrared absorption spectra,” Vibrational Spectroscopy 47, 66–69 (2008).

Funding

This research was supported by Russian Foundation of Basic Research (Project 20-07-00063).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Golant, E.I., Pashkovskii, A.B. & Golant, K.M. Lossy Mode Resonance Sensors Based on Double ITO/TiO2 and Triple TiO2/ITO/TiO2 Thin Film Coated Single Mode Fiber Taper. J. Commun. Technol. Electron. 65, 1457–1459 (2020). https://doi.org/10.1134/S1064226920120086

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1064226920120086