Abstract

A theoretical model is proposed that describes the mechanism of dissolution of pores at grain boundaries in ultra-fine-grained materials during long-term annealing. Within the framework of the model, the dissolution of a pore occurs due to the emission of vacancies and the climb of grain-boundary dislocations along the grain boundary to the pore. It is shown that in this case a significant decrease in the total energy of the system occurs. The results of the model are in good agreement with the available experimental observations of pore dissolution during annealing of an ultra-fine-grained Al–Zr alloy.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

INTRODUCTION

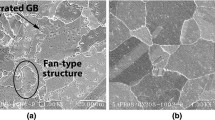

Materials with an ultra-fine-grained (UFG) structure often have high strength combined with sufficient plasticity [1]. It is also known that the separation of the second phase in such materials can improve their mechanical characteristics [2]. In experiments [3–5], an accelerated separation of the second phase was noted in UFG materials obtained by methods of severe plastic deformation. For example, in the Al–Zr UFG aluminum alloy, obtained by the method of severe plastic deformation and then annealed at a temperature of 230°C, a significant amount of nanoscale precipitates of the Al3Zr phase was observed [5]. However, the reasons for the accelerated kinetics of the formation of precipitates of the second phase in UFG structures remain poorly understood. In the course of studying the process of annealing this alloy in situ in a scanning transmission electron microscope, Lefebvre et al. [6] found at the initial stage of annealing, during the first 10 min, multiple formation of pores along grain boundaries (GBs) and their triple junctions, which the authors explained by rearrangement of nonequilibrium GBs with the release and coagulation of a significant amount of free volume. At the second (long-term, for 3 h) stage of annealing, gradual dissolution of pores was observed up to the complete disappearance of some of them [6]. Such dissolution of pores, accompanied by the emission of vacancies, can promote accelerated precipitation in UFG structures. To explain this observation, the authors of [6] proposed a theoretical model describing the dissolution of a pore in a GB triple junction upon prolonged annealing of the material. Within the framework of this model, the overgrowth of a pore, which was supposed to originate at junction partial wedge disclination in a GB triple junction, was carried out due to the climb of grain-boundary dislocations (GBDs) to the pore. Note, however, that many of the pores observed in [6] were located not in GB triple junctions, but in their rectilinear sections, so that the model proposed by the authors cannot, strictly speaking, be used directly to explain the disappearance of these pores. For this purpose, the model proposed in [6] can be adapted accordingly.

The purpose of this work is to theoretically describe the dissolution of a pore formed on a partial wedge grain-boundary disclination during prolonged annealing. The ideological basis for this description is the model from [6], substantially altered and refined for the case of a separate GB.

It is known that, upon annealing, nonequilibrium GBs (GBs containing extrinsic GBDs) pass into an equilibrium state due to a decrease in the number of these GBDs. The decrease in the density of extrinsic GBDs is usually associated with their annihilation, emission from GBs, and/or drift to grain-boundary sinks. The pores formed on the GB can act as such sinks. Within the framework of the present model, as before [6], it is assumed that the driving force contributing to the overgrowth of pores during annealing is a decrease in the density of extrinsic GBDs as a result of their climb over the GB towards the pores. Climb of the GBDs to the pore leads to its gradual overgrowth due to the emission of vacancies, which diffuse predominantly along the same GB, facilitating the climb of the GBDs to the pore. As a result, a positive feedback is formed: the greater number of the GBDs approaching the pores, the stronger decrease in the strain energy of the grain-boundary disclinations on which pores originated, and the more favorable it becomes for vacancies to be emitted and ensure the subsequent climb of the GBDs to these pores.

Figure 1 shows a two-dimensional model of pore overgrowth as a result of the climb of extrinsic GBDs along the GB with a pore during long-term annealing. In the initial state, there is a pore with radius r0, which formed on a positive partial grain-boundary disclination with a strength +ω (+ω-disclination) (Fig. 1a). The extrinsic GBDs are shown as two identical walls of edge dislocations of opposite signs with an average distance s between dislocations. As the GBDs climb to the pore, they are absorbed by the pore, and annihilated inside it, the number of GBDs decreases and the pore radius decreases, r < r0 (Fig. 1b). The walls of the extrinsic GBDs adjacent to the pore are modeled by two identical but oppositely oriented biaxial dipoles of partial wedge disclinations [7] of strength ±ω/2 (±ω/2-disclinations) (Fig. 1c), so that the modulus of the total strength of negative –ω/2-disclinations is equal to the strength of the +ω-disclination located inside the pore. Thus, negative \( - \omega {\text{/}}2\)-disclinations, together with a junction intersection +ω-disclination, form two disclination dipoles with arms L0 and strength ±ω/2 (±ω/2-dipoles) (Fig. 1c), a linear disclination quadrupole (DQ) [7]. In this case, the climb of the extrinsic GBDs to the overgrowning pore is equivalent to a decrease in the arm L < L0 of these disclination dipoles and the total size of DQs 2L < 2L0 (Fig. 1d).

Model of the dissolution of pore at the grain boundary during long-term annealing as a result of the climb of extrinsic GBDs to it. (a) The initial configuration of the GBD walls near the pore. (b) Shrinkage of the pore due to the GBD climbing towards it. (c) Representation of the walls of the extrinsic GBDs as a linear disclination quadrupole consisting of two biaxial dipoles of partial wedge disclinations with strengths ±ω/2 (±ω/2-disclinations) and arms L0. (d) Overgrowing of the pore as a result of a decrease in the size of the disclination quadrupole 2L.

Let us consider the energy characteristics of the initial stage of pore dissolution as a result of a decrease in the DQ size of 2L by a distance \(2p\). In this case, under the assumption that \(L \gg r\), the influence of the free surface of the pore can be ignored when calculating the DQ energy. Let us assume (1) that all vacancies emitted by the pore are absorbed by the GBDs and (2) that all the GBDs climb synchronously, keeping the period in their walls constant (Figs. 1a, 1c). As the pore radius decreases from the initial r0 to the current value r, the pore emits vacancies in the amount of \(n \approx V{\text{/}}{{a}^{3}} \approx \pi {\kern 1pt} (r_{0}^{2} - {{r}^{2}}){\text{/}}{{a}^{2}}\), where V is the change in the pore volume per one transverse atomic plane of thickness a. The distribution of these vacancies uniformly over \(2N = 2({{L}_{0}} - {{r}_{0}}){\text{/}}s\) GBDs in two walls leads to their synchronous climb over a distance of \(p \approx an{\text{/}}(2N) \approx s(r_{0}^{2} - {{r}^{2}}){\text{/}}q\), where q = 2a(L0 – r0)/π is the effective cross-sectional area of the wall. From this, we find that \(r \approx {{r}_{0}}{{[1 - pq{\text{/}}(sr_{0}^{2})]}^{{1/2}}}\) . In the experiments of [6], grain-boundary pores of radius \({{r}_{0}} \approx 30{-}40\) nm were observed. In this case, the characteristic dimensions of GBs containing these pores were \({{L}_{0}} \approx 200{-}300\) nm. For \(a \approx 0.3\) nm, we obtain that dimensionless parameter \(\beta = q{\text{/}}r_{0}^{2}\) was approximately equal to 0.02–0.06. For the case in which the GBDs climb over a relatively large distance (at \(p > s\)), we introduce the notation \(m = p{\text{/}}s\). Its integer part [m] shows the number of GBDs that reached the pore boundary, were absorbed by the pore, and annihilated inside it. As a result, we have \(r \approx {{r}_{0}}\,{{(1 - 0.04{\kern 1pt} m)}^{{1/2}}}\), where the average value \(\langle \beta \rangle \approx 0.04\) is taken.

Let us now write energy difference \(\Delta W\) between the current state of the defect system in the form of a pore with radius r and a DQ with a size of \(2L = 2({{L}_{0}} - p)\) of total energy \(W\) and the initial state of this system with the corresponding parameters r0 and \({{L}_{0}}\) and total energy \({{W}_{0}}\). The transition between these states is energetically favorable when the condition \(\Delta W = W - {{W}_{0}} < 0\) is met. Energy difference \(\Delta W\) can be written as

where \({{E}_{{s0}}} = D{{\omega }^{2}}L_{0}^{2}{\text{ln}}2{\text{/}}2\) and \({{E}_{s}} = D{{\omega }^{2}}{{L}^{2}}{\text{ln}}2{\text{/}}2\) are the strain energies of the DQ [7] before and after the decrease in its size, \({{E}_{{\gamma 0}}} = 2\pi \,{{r}_{0}}{{\gamma }_{s}}\) and \({{E}_{\gamma }} = 2\pi r{{\gamma }_{s}}\) are the energy of the pore surface before and after the beginning of its overgrowth as the size of the DQ decreases, and \({{E}_{{gb}}} = 2p{{\gamma }_{{gb}}}\) is the energy of new sections of the GB that appeared as a result of the overgrowth of the pore. Here, \(D = G{\text{/}}[2\pi (1 - \nu )]\), \(G\) is the shear modulus, \(\nu \) is the Poisson ratio, \({{\gamma }_{s}}\) is the specific energy of the pore surface, and \({{\gamma }_{{gb}}}\) is the specific energy of the GB. Then, taking into account the dependence obtained above, \(r(m)\), expression (1) is transformed to the form

Using expression (2), we numerically construct the dependences of the change in energy \(\Delta W\) on the number of GBDs, [m], by which the number of GBDs in the walls decreased as a result of their absorption by the pore and subsequent annihilation. The calculation will be carried out using the example of UFG Al–Zr alloy, using the following values of the material parameters: G = 27 GPa, \(\nu = 0.31\), \(b = 0.1\) nm, \({{\gamma }_{s}} = 1.5\) J m–2, and \({{\gamma }_{{gb}}} = 0.5\) J m–2. The remaining parameters of the defect system are set equal: \({{r}_{0}} = 40\) nm; \({{L}_{0}} = 200\), 250, and 300 nm; \(\omega \approx b{\text{/}}s\); \(s = 0.5\) and 1 nm. The calculated dependences \(\Delta W(m)\) obtained at these values are shown in Fig. 2. It can be seen from them that a decrease in the DQ size and a corresponding decrease in the pore size are accompanied by a significant decrease in the total energy of the system.

Thus, a theoretical model has been developed that describes the mechanism of pore dissolution observed in [6] in rectilinear sections of grain boundaries in UFG materials during long-term annealing. According to this model, the overgrowth of a pore that originated on a grain-boundary disclination is carried out by emitting vacancies that migrate along the GB and are absorbed by the GBDs, which climb towards the pore due to the absorption of vacancies. Using the UFG Al–Zr alloy as an example, the energy efficiency of the considered process of pore dissolution is shown. The proposed mechanism of pore dissolution in UFG materials is in good agreement with the available experimental data [4–6].

REFERENCES

X. Sauvage, G. Wilde, S. V. Divinski, Z. Horita, and R. Z. Valiev, Mater. Sci. Eng. A 540, 1 (2012). https://doi.org/10.1016/j.msea.2012.01.080

A. Deschamps, G. Fribourg, Y. Bréchet, J. L. Chemin, and C. R. Hutchinson, Acta Mater. 60, 1905 (2012). https://doi.org/10.1016/j.actamat.2012.01.002

X. Sauvage, A. Duchaussoy, and G. Zaher, Mater. Trans. 60, 1151 (2019). https://doi.org/10.2320/matertrans.MF201919

Y. Nasedkina, X. Sauvage, E. V. Bobruk, M. Yu. Murashkin, R. Z. Valiev, and N. A. Enikeev, J. Alloys Compd. 710, 736 (2017). https://doi.org/10.1016/j.jallcom.2017.03.312

T. A. Latynina, A. M. Mavlyutov, M. Y. Murashkin, R. Z. Valiev, and T. S. Orlova, Philos. Mag. 99, 2424 (2019). https://doi.org/10.1080/14786435.2019.1631501

W. Lefebvre, N. V. Skiba, F. Chabanais, M. Yu. Gutkin, T. S. Orlova, T. A. Latynina, L. Rigutti, and M. Yu. Murashkin, J. Alloys Compd. 862, 158455 (2021). https://doi.org/10.1016/j.jallcom.2020.158455

V. I. Vladimirov and A. E. Romanov, Disclinations in Crystals (Nauka, Leningrad, 1986) [in Russian].

Funding

This work was supported in part by the Russian Foundation for Basic Research (grant no. 19-08-00474) and (for N.V. Skiba) by the Ministry of Science and Higher Education of the Russian Federation (assignment no. 0784-2020-0027).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Additional information

Translated by M. Drozdova

Rights and permissions

About this article

Cite this article

Gutkin, M.Y., Orlova, T.S. & Skiba, N.V. A Model of Pore Dissolution at Grain Boundaries during Annealing of an Ultra-Fine-Grained Aluminum Alloy. Tech. Phys. Lett. 48, 8–11 (2022). https://doi.org/10.1134/S1063785022010047

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1063785022010047