Abstract

The dependence of the temperatures of magnetic phase transformations in porous ferromagnetic materials on the geometric characteristics (volume and shape) of pores and their distribution in a particular material has been studied. The geometric features of nanopores have been characterized by their effective pore radius and form factor (deviation of the pore shape from spherical). Estimations indicate that it is possible to obtain macroscopic samples of porous materials with decreased Curie temperatures, which can be further reduced in the case of complicated shapes of pores. These results were obtained in the framework of a cohesive model in application to pure porous nickel and cobalt.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

In recent years, nanostructured ferromagnetic materials have drawn considerable attention from researchers [1]. This interest is related to both the wide spectrum of possible technological applications of ferromagnetic nanostructures [2] and the variety of phenomena having fundamental significance (see, e.g., [1, 3, 4]). An important parameter characterizing the stability of ferromagnetic material properties is the Curie temperature corresponding to breakage of the magnetic order of a ferromagnet and its transition to a paramagnetic state (second-order phase transition). It is well known that the Curie temperature (and some other parameters [4, 5]) of ferromagnetic nanoscale particles depend on their dimensions [5–8] and shape [7, 8]. This is related to the increasing fraction of low-coordinated atoms in the near-surface layer with magnetic characteristics (magnetic moments, exchange integrals, magnetic anisotropy constants [5]) that differ from the bulk values. This fraction varies with decreasing size and complicating shape of magnetic nanoparticles. These scaling relations can be taken into account in the framework of significantly different model approaches [1, 5–8].

It should be noted that the formation of nanopowders or nanocomposite materials comprising ferromagnetic nanoparticles distributed in a bulk matrix on a substrate surface [7] is not the only possible approach to obtaining materials with large fractions of near-surface atoms. High values of the specific surface (~500 m3/g [9] or even up to several thousand m3/g [10]) can also be achieved in materials with distributed ensembles of nanopores in macroscopic objects. These structures can be obtained, e.g., at the initial stage of processes based on spark plasma- or selective laser sintering of nanopowders [11].

Let us consider the model of a porous material with the given volume fraction α of pores. Let pores possess a rather complicated configuration [12, 13] that can be described by two parameters: (i) effective pore diameter deff numerically equal to the diameter of a sphere with the volume equal to that of the pore and (ii) form factor k equal to the ratio of surface area A of the pore to surface area A0 of a sphere with the same volume, k = A/A0. This approach, which has been described in more detail previously [12–15], is not the only one possible (see, e.g., [12, 15–17]). According to the adopted model, the number of pores per gram of material (Npor) can be determined as

where ρ is the material density and a coefficient of 1 g provides the matching of units. The specific surface (Asp) can then be expressed as

To determine the influence of the number and geometry of nanopores on Curie temperature Tc, we used a simple relationship between Tc and cohesive energy Ecoh [18] as formulated in [6–8],

and experimentally verified in [6]. A similar approach to the description of ferromagnet–paramagnet transition and some other phase transformations was used by Guisbiers et al. [19, 20] and also demonstrated agreement with experiment. Here, \(E_{{coh}}^{{{\text{por}}}}\) and \(E_{{coh}}^{{{\text{bulk}}}}\) are the cohesive energies of the porous and continuous (bulk) material, respectively, and \(T_{c}^{{{\text{por}}}}\) and \(T_{c}^{{{\text{bulk}}}}\) are the Curie temperatures of the materials with and without nanopores.

Total number N of atoms per gram of the porous material is N = \(6\omega \cdot 1\,{\text{g/}}(\pi d_{{at}}^{3}\rho )\), where dat is the diameter of atom in the material and ω is the density of atomic packing in the material crystal structure. Number Ns of atoms situated on the walls of pores is

where η is the atomic packing density on the crystal surface. Upon accomplishing transformations, we eventually obtain the following formula:

Estimations of the cohesive energy of a porous material can be obtained from the following relations proposed in [18]:

where β is the first coordination number and εb is the atomic bond energy. Using Eqs. (1) and (2) and taking into account the above considerations, we eventually arrive at the following formula:

This expression yields estimations of the Curie temperature as functions of the volume fraction and geometric parameters of pores.

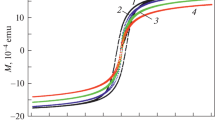

Figure 1 shows plots of Curie temperature \(T_{c}^{{{\text{por}}}}\) of nanoporous (a) cobalt and (b) nickel versus effective pore diameter deff and form factor k. These calculations have been restricted to materials with low specific surfaces (not exceeding 200 m3/g) as compared to the objects studied in [9, 10], with α = 0.70, ρ = 8900 g/cm3, and dat = 250 pm for Co and ρ = 8902 g/cm3 and dat = 248 pm for Ni. Cobalt has two stable polymorphic modifications: hexagonal α-Co and face-centered cubic (fcc) β-Co stable in the temperature range studied (with the α–β polymorph transition at ~427°C); in contrast, nickel has an fcc structure in the entire temperature range up to the melting point. The density of atomic packing in the volume structure of fcc crystals is ω ≈ 0.74, while the surface atomic packing density for fcc crystals was estimated at η ≈ 0.91 [21] (the same estimation was used in [19]).

As can be seen from the data in Fig. 1, the presence of pores, an increase in preform factor k, and a decrease in effective pore diameter deff (i.e., growth in the specific surface) lead to a significant reduction in the Curie temperature of the porous material. Note that the presence of, e.g., a liquid filling the pores can lead to some correction of these estimations (the filling of pores can be taken into account in the framework of an approach proposed in [7]). The proposed relation (3) describing the decrease in the Curie temperature of porous materials corresponds to the approximation of identical isolated pores (with the same dimensions and shapes) distributed in the matrix material. Additional refinement of the obtained estimations can be achieved by calculating specific surface Asp using the pore size and shape distributions (analogous to those experimentally determined in [22]) and taking into account the possible merging of pores with the formation of “wormlike” structures (and some decrease in the specific surface as a result of eliminated spacers). These refinements can lead to a slight correction of calculated Curie temperature \(T_{c}^{{{\text{por}}}}\) due to Asp variation, but do not change the established laws of Curie temperature variation.

It should also be noted that the broad spectrum of technological applications of porous materials includes, e.g., matrices of nanoreactors with pores filled by reaction mixtures (see [12] and references therein). Many applications involve magnetocaloric phenomena in ferromagnetic structures—in particular, the widely used heating of ferromagnetic nanoparticles as invasive agents in alternating magnetic fields (as a result of hysteresis losses, magnetization vector reversal, etc.) for malignant tumor treatment [5], where the temperature of nanoparticles is controlled by their morphology-dependent Curie point. In these porous ferromagnetic materials, the possibility of controlling the Curie temperature by using nanoparticles with variable volume fraction and morphology of pores allows obtaining matrices with self-limited growth of the magnetic-field-induced heating temperature. The aforementioned nanoporous ferromagnetic materials are also characterized by high catalytic activity in some widely used reactions [20]. Materials with a high specific surface of pores [9, 10] would probably provide an even more significant reduction in the Curie temperature, up to the level reported in [5].

REFERENCES

R. Ferrando, Front. Nanosci. 10, 245 (2016).

Nanomagnetism: Fundamentals and Applications, Ed. by C. Binns (Elsevier, Amsterdam, 2014), Vol. 6.

A. V. Zdoroveyshchev, O. V. Vikhrova, P. B. Demina, M. V. Dorokhin, A. V. Kudrin, A. G. Temiryazev, and M. P. Temiryazeva, Phys. Solid State 61, 1577 (2019).

S. V. Stolyar, S. V. Komogortsev, L. A. Chekanova, R. N. Yaroslavtsev, O. A. Bayukov, D. A. Velikanov, M. N. Volochaev, E. V. Cheremiskina, M. Sh. Bairmani, P. E. Eroshenko, and R. S. Iskhakov, Tech. Phys. Lett. 45, 878 (2019).

V. N. Nikiforov, A. N. Ignatenko, and V. Yu. Irkhin, J. Exp. Theor. Phys. 124, 304 (2017).

X. He, W. Zhong, C.-T. Au, and Y. Du, Nanoscale Res. Lett. 8, 446 (2013).

L.-F. Cao, D. Xie, M.-X. Guo, H. S. Park, and T. Fijita, Trans. Nonferr. Met. Soc. China 17, 1451 (2007).

H. Delavari, H. M. Hosseini, and A. Simchi, Chem. Phys. 383, 1 (2011).

D. S. Gaev and S. Sh. Rekhviashvili, Semiconductors 46, 137 (2012).

H. K. Chae, D. Y. Siberio-Pŕez, J. Kim, Y. Go, M. Eddaoudi, A. J. Matzger, M. O’Keeffe, and O. M. Yaghi, Nature (London, U.K.) 427, 523 (2004).

I. V. Erofeeva, M. V. Dorokhin, A. V. Zdoroveishchev, Yu. M. Kuznetsov, A. A. Popov, E. A. Lantsev, A. V. Boryakov, and V. E. Kotomina, Semiconductors 52, 1559 (2018).

A. V. Shishulin and V. B. Fedoseev, J. Mol. Liq. 278, 363 (2019).

A. V. Shishulin and V. B. Fedoseev, Tech. Phys. Lett. 45, 697 (2019).

V. B. Fedoseev and A. V. Shishulin, Phys. Solid State 60, 1398 (2018).

A. V. Shishulin, V. B. Fedoseev, and A. V. Shishulina, Tech. Phys. 64, 512 (2019).

A. V. Shishulin, V. B. Fedoseev, and A. V. Shishulina, Tech. Phys. 64, 1343 (2019).

M. N. Magomedov, Tech. Phys. Lett. 42, 761 (2016).

F. Aqra and A. Ayyad, Appl. Surf. Sci. 324, 308 (2014).

G. Guisbiers, Nanoscale Res. Lett. 5, 1132 (2010).

G. Guisbiers and G. Abudukelimu, J. Nanopart. Res. 15, 1431 (2013).

M. Attarian Shandiz, J. Phys.: Condens. Matter 20, 325237 (2008).

V. N. Chuvil’deev, A. V. Nokhrin, V. I. Kopylov, M. S. Boldin, M. M. Vostokov, M. Y. Gryaznov, N. Y. Tabachkova, and P. Tryaev, J. Mater. Sci. 54, 14926 (2019).

Funding

This work was performed in the framework of a state order to the Institute of Organometallic Chemistry (Nizhny Novgorod) and supported by the Russian Foundation for Basic Research, project no. 18-08-01356A.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflict of interest.

Additional information

Translated by P. Pozdeev

Rights and permissions

About this article

Cite this article

Shishulin, A.V., Fedoseev, V.B. & Shishulina, A.V. Variation of the Curie Temperature in Porous Materials. Tech. Phys. Lett. 46, 680–682 (2020). https://doi.org/10.1134/S106378502007024X

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S106378502007024X