Abstract

The electrical properties of barium–strontium titanate films and tunable capacitors based on them are studied in a wide frequency range. The dielectric losses in ferroelectric films at frequencies up to 30 GHz are estimated based on the parameters of capacitors measured using various resonance techniques. Direct measurements of the properties of the films were carried out at a frequency of 60 GHz using the open-resonator technique. Based on the comparison with semiconductor analogues, the prospects of using thin-film ferroelectric elements in the millimeter-wavelength range are shown.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Currently, one promising way to achieve a high capacity of telecommunication networks is to switch to the millimeter wavelength range, which is resulting in the development of the corresponding element base, in particular, electrically controlled elements. Traditionally, tunable microwave devices employ semiconductor varactors [1–3]. However, a significant decrease in the Q-factor of these elements with increasing frequency makes it difficult to use them in the millimeter-wavelength range and stimulates the search for alternative materials. One possible such alternative is the use of controlled elements based on ferroelectric (FE) films [4]. The promise of using these materials in microwave applications is due to their high nonlinearity, absence of dispersion, and relatively low dielectric loss at frequencies up to 100 GHz. FE elements can be implemented in a planar version on a dielectric substrate [5] and in the form of a plane-parallel metal–insulator–metal (MIM) structure [6], which makes it possible to use them in both high-power and small-signal devices [7]. Traditionally, it is believed that the factor limiting the use of ferroelectrics is the strong dependence of the material properties on temperature as compared with that of semiconductors. However, today it has been shown that multilayer capacitive structures based on BaxSr1 –xTiO3 (BSTO) barium–strontium titanate films with different Ba contents in the layers exhibit a temperature coefficient on the order of 10–4 K–1 in a wide temperature range, which is comparable with the data for semiconductor varactors [8].

The characterization of microwave-controlled elements is a complex problem, since there is no universal technique making it possible to estimate the Q-factor in a wide frequency range with sufficient accuracy. Many authors refer to data on the Q-factor of capacitive FE structures only in the frequency range of 1 kHz–1 MHz, which does not allow one to conclude that such films are applicable at higher frequencies because of a nonlinear dependence of the losses on frequency. The authors of a few works in which the properties of FE microwave elements using probe stations present adequate data on the Q-factor at frequencies up to 20 GHz; at higher frequencies, the measurement error is comparable with the values of the measured quantity [4, 9–11].

The promises of using ferroelectrics in the microwave range necessitate the direct characterization of the parameters of the FE elements of planar and MIM structures at frequencies above 1 GHz. To solve this problem, in this work, we used resonance measurement techniques, which made it possible to ensure high accuracy of determining the parameters of microwave elements and FE films in a wide frequency range. A comparison of the obtained data with the characteristics of industrially produced semiconductor varactors is carried out.

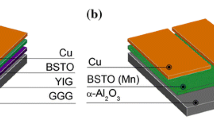

The structures under study were formed on 0.5‑mm-thick single-crystal sapphire substrates (Al2O3, r-cut). For MIM capacitors, a 100-nm-thick platinum layer of the lower electrode was deposited on the substrate by magnetron sputtering of a platinum target in an argon atmosphere at a temperature of 450°C. The topology of the Pt electrode was formed using photolithography and ion etching. Ferroelectric films were deposited on the formed lower electrode by high-frequency magnetron sputtering of BSTO ceramic targets (x = 0.3, 0.5, and 0.9) in an oxygen atmosphere at a pressure of 2 Pa. The substrate temperature in the process of film deposition was 800°C [12]. In planar and single-layer MIM structures, a BSTO film of a composition with x = 0.3 was used, which exhibits the best ratio between the controllability and microwave losses [13]. When forming multilayer MIM elements, layers of the compositions with x = 0.5 and 0.9 were used to achieve the thermal stabilization of the structure parameters in the temperature range of 250–400 K [8]. The thickness of BSTO film for planar capacitors was 700 nm, while, for MIM structures, it was 300 nm (multilayer structures were formed from 200- and 150-nm-thick layers of compositions with x = 0.5 and 0.9, respectively). After depositing an FE film during the formation of MIM capacitors, the film was lithographed by chemical etching in a HF–HNO3 acid mixture. The upper electrodes were produced by thermally applying 1-μm-thick Cu film with an adhesion chromium underlayer. The dimensions of the working area of the MIM capacitors were 4 × 10 μm; for planar capacitors, the gap length was 0.4 mm and the gap width was 3 μm.

To carry out experimental studies of the microwave parameters of ferroelectric films and elements based on them, resonance techniques were used to ensure high accuracy of measurements through the use of special measurement models in different frequency ranges. At frequencies of the order of 1 GHz, measurements were performed using a symmetric strip microwave resonator short-circuited at the ends [14]; at 10 GHz, using a strip resonator on a suspended substrate [15]; and, at a frequency of 30 GHz, using the capacitor self-resonance method [16]. At a frequency of 60 GHz, direct measurements of the properties of a BSTO film using the open resonator technique were performed [16]. Capacitance C of the capacitors was measured at frequencies of the order of 1 and 10 GHz and then used in measurements at a frequency of 30 GHz, due to the absence of dispersion. The controllability of the capacitors was calculated as the ratio of the capacitances at zero and maximum applied control voltage,

Figure 1 shows the dependences of the capacitance of the capacitors under study, normalized to initial capacitance C0, as a function of the control voltage, measured at a frequency of 1.8 GHz. It can be seen that the value of the controllability is n = 2 or more for both planar and MIM elements, which indicates high quality of the FE layers. The field strengths of 200 V/μm in the gap correspond to control voltages of 60 and 140 V for MIM and planar elements, respectively. Figure 2 presents a histogram of the Q-factors (Q = 1/tanδ) of ferroelectric capacitors of various designs in the frequency range of 1–30 GHz compared to the Q-factors of semiconductor varactors manufactured by SkyWorks [17]. Note that, already at a frequency of 8 GHz, planar FE elements outperform their semiconductor counterparts in the Q-factor by more than two times; at 30 GHz, the advantage of planar elements over varactors increases up to five times and that of MIM elements up to three times. It is evident that the use of ferroelectric elements at frequencies of 10 GHz and higher is promising due to a higher Q-factor.

In the general case, the Q-factor of an FE capacitor is the sum of the losses in the metal electrodes, the ferroelectric film, and the substrate. To develop ferroelectric microwave elements, it is necessary to understand the contribution of metal electrodes [6] and the FE film to the total loss of a capacitor.

The calculation of microwave losses directly in an FE film in the frequency range of 1–30 GHz was performed on the basis of the measured parameters of planar FE capacitors. From the viewpoint of the equivalent circuit of a microwave capacitor, the resistance of metal electrodes can be represented by the series connection of a resistor. On the basis of the resistivity of a copper film of 3 × 10–8 Ω m, its thickness of 1 μm, and the dimensions of the electrodes of a planar capacitor of 0.5 × 0.4 mm, the resistance of metal electrodes can be estimated as 7.5 × 10–2 Ω. Such a resistance when using a serial equivalent circuit for a measured capacitance of C = 0.38 pF of a capacitor corresponds to microwave loss tangent tanδM = RωC = 2 × 10–4 (Q-factor QM = 5000) at 1 GHz and tanδM = 6 × 10–3 at 30 GHz (QM = 160). In comparison with the measured values of the total Q-factors of the elements, QΣ, the losses in the metal electrodes can be neglected. The ferroelectric film and the dielectric substrate in a planar capacitor, according to the partial capacitance method [5], are equivalently connected in parallel as capacitors with capacitances CFE and CS, respectively, while the energy of the electric field is distributed between the film and the substrate. The dielectric losses in the sapphire substrate are relatively small and are on the order of tanδS = 10–4; therefore, they can also be ignored when considering the total Q‑factor of the capacitor. Thus, the Q-factor of a capacitor is due exclusively to the losses in the ferroelectric layer, which can be determined as

Here, CΣ = CFE + CS is the total capacitance of the capacitor and the capacitance of the ferroelectric layer is CFE = CΣ – CS, where CS is calculated using the partial capacitance technique [7]. For the given topological sizes of a planar capacitor, CS = 0.08 pF. Thus, for the measured capacitance of the capacitor of CΣ = 0.38 pF, the dielectric loss of the film is determined as tanδFE = 1.27 (1/QΣ). Figure 3 shows the frequency dependence of the losses in a ferroelectric film (x = 0.3) in the range of 1 to 60 GHz, where the dielectric losses at a frequency of 60 GHz were determined by the open resonator technique.

Thus, as shown by the experimental studies, tunable capacitors based on ferroelectric BSTO films have a high Q-factor with sufficient controllability in the microwave range. The FE elements compete with their semiconductor counterparts in the Q-factor at frequencies above 10 GHz, and multi-layer thermostable structures, at frequencies above 30 GHz. A slight increase in dielectric loss in a ferroelectric film with increasing frequency up to 60 GHz suggests a high potential for using ferroelectric elements in tunable devices in the millimeter-wave band.

FUNDING

This work was supported by the Russian Science Foundation, project no. 18-79-10156.

CONFLICT OF INTEREST

The authors declare that they have no conflict of interest.

REFERENCES

F. Venneri, S. Costanzo, and G. di Massa, IEEE Trans. Antennas Propag. 61, 635 (2013).

Q. Ma, D. Leenaerts, and R. Mahmoudi, in Proceedings of the 2013 IEEE Radio Frequency Integrated Circuits Symposium RFIC (IEEE, 2013), p. 61.

H. Kamoda, T. Iwasaki, J. Tsumochi, and T. Kuki, in Proceedings of the 2009 IEEE MTT-S International Microwave Symposium (IEEE, 2009), p. 1177.

A. Vorobiev, P. Rundqvist, K. Khamchane, and S. Gevorgian, Appl. Phys. Lett. 83, 3144 (2003).

O. G. Vendik, S. P. Zubko, and M. A. Nikol’skii, Tech. Phys. 44, 349 (1999).

M. M. Gaidukov, A. G. Gagarin, A. B. Kozyrev, S. V. Razumov, A. V. Tumarkin, and A. G. Altynnikov, Tech. Phys. Lett. 34, 565 (2008).

O. G. Vendik, Phys. Solid State 51, 1529 (2009).

M. M. Gaidukov, A. V. Tumarkin, A. G. Gagarin, and A. B. Kozyrev, Tech. Phys. Lett. 40, 337 (2014).

G. Houzet, L. Burgnies, G. Velu, J. C. Carru, and D. Lippens, Appl. Phys. Lett. 93, 053507 (2008).

A. Ghalem, F. Ponchel, D. Remiens, J. F. Legier, and T. Lasri, IEEE Trans. Ultrason. Ferroelectr. Freq. Control 60, 880 (2013).

R. de Paolis, F. Coccetti, S. Payan, S. Maglione, and G. Guégan, in Proceedings of the 2014 44th European Microwave Conference (IEEE, 2014), p. 492.

A. V. Tumarkin, V. I. Al’myashev, S. V. Razumov, M. M. Gaidukov, A. G. Gagarin, A. G. Altynnikov, and A. B. Kozyrev, Phys. Solid State 57, 553 (2015).

S. V. Razumov, A. V. Tumarkin, M. M. Gaidukov, A. G. Gagarin, A. B. Kozyrev, O. G. Vendik, A. V. Ivanov, O. U. Buslov, V. N. Keys, L. C. Sengupta, and X. Zhang, Appl. Phys. Lett. 81, 1675 (2002).

M. M. Gaidukov, A. B. Kozyrev, and A. S. Ruban, Radiotekh. Elektron. (Moscow) 20, 2588 (1975).

A. B. Kozyrev, V. N. Keis, G. Koepf, R. Yandrofski, O. I. Soldatenkov, K. A. Dudin, and D. P. Dovgan, Microelectron. Eng. 29, 257 (1995).

A. Kozyrev, O. Buslov, V. Keis, D. Dovgan, I. Kotelnikov, P. Kulik, L. Sengupta, L. Chiu, B. Treadway, T. Kaydanova, J. D. Perkins, J. Alleman, and D. S. Ginley, Integr. Ferroelectr. 55, 895 (2003).

http://www.skyworksinc.com/Products_Diodes.aspx.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by E. Chernokozhin

Rights and permissions

About this article

Cite this article

Altynnikov, A.G., Gagarin, A.G., Tumarkin, A.V. et al. Characterization of the Properties of Barium–Strontium Titanate Films and Controlled Elements Based on Them in the Frequency Range of 1–60 GHz. Tech. Phys. Lett. 45, 540–543 (2019). https://doi.org/10.1134/S1063785019060026

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1063785019060026