Abstract

Variation in the shape of microdrops of a highly concentrated magnetic colloid resulting from phase separation in a magnetic fluid has been studied. It has been found that even weak magnetic fields (such as those comparable to the geomagnetic field) substantially influence the geometry and behavior of microdrops. Different configurations of microdrops in a rotating magnetic field have been considered. The occurrence of a rotation moment that acts on a macrodrop of a magnetic fluid in a rotating magnetic field has been shown. The rotation moment is due to the rotation of concentrated phase microdrops inside the macrodrop. The macroscopic rotation frequency of a drop’s surface as a function of the applied magnetic field frequency and strength has been measured.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

INTRODUCTION

Rotation of liquid masses in limited volumes has been a popular object of investigation and remains an urgent challenge today. The use of magnetic fluids, whose properties can be controlled by applying external magnetic fields, has opened new opportunities for such investigations. A magnetic fluid is an ultradisperse colloid of ferro- or ferrimagnetic nanoparticles in a carrier liquid. The dynamics of magnetic fluid drops in external stationary and rotating magnetic fields was investigated [1–5]. New trends in this area, such as the use of magnetic fluids in microfluidic technologies [6], initiated studies on the behavior of magnetic fluid drops subjected to a rotating magnetic field under different ambient conditions. For example, variation in the shape of microdrops of a magnetic fluid that were dispersed in a nonmagnetic medium with a low interfacial tension, as well as microdrops of a nonmagnetic fluid placed in a magnetic one, was studied in [7–9]. In both cases, the fluids were subjected to rotating and stationary magnetic fields. Similar systems were also obtained by phase separation in electrostatically stabilized aqueous magnetic fluids [10–13]. In this case, the system contained highly concentrated microdrops of a magnetic colloid.

In a system that represents a set of microdrops, the motion of individual microdrops in a rotating magnetic field is expected to result in macroscopic hydrodynamic effects. A rotating moment acting on these microdrops is imparted to the entire system owing to viscous forces. Earlier, the effect of internal rotation was studied in as-prepared (uniform) magnetic colloids, where it was feeble [14–17]; in magnetic colloids containing quasi-solid disperse particles [18]; and in magnetic emulsions with high interfacial tension at the interface between the disperse phase and dispersive medium [19], where this effect of rotation was more pronounced.

In this paper, we report research data for the behavior of individual microdrops with a high content of a magnetic material that arise from phase separation in a magnetic colloid and offer higher magnetic properties than those studied previously. Their behavior in stationary and rotating magnetic fields is considered, and the occurrence of rotation moment acting on a macrodrop of a magnetic colloid with concentrated phase microdrops inside is discussed.

DYNAMICS OF INDIVIDUAL MICRODROPLETS OF THE CONCENTRATED PHASE

The magnetic fluid used in experiments consisted of magnetite particles dispersed in vacuum oil with oleic acid as a stabilizer. The addition of a small excess amount of stabilizer initiates phase separation in the system with formation of concentrated phase (concentrated microdrops of colloid). The dynamics of these microdrops was studied under an optical microscope. The sample was placed in a stationary magnetic field generated by Helmholtz coils. A rotating magnetic field was produced by two pairs of crossed Helmholtz coils to which quarter-phase-shifted voltages were applied. The stationary magnetic field directed horizontally along the sample’s surface deformed the microdrops: they stretched in the direction of the field. The deformation had a threshold: after the magnetic field reached some critical value, the drop considerably extended stepwise (Fig. 1). The same behavior of magnetic fluid drops was also observed previously. In the given case, however, the deformation step and the field at the onset of deformation are different. Because of much higher magnetic characteristics of our microdrops, they start deforming in very weak fields that differ from the geomagnetic one only slightly and the extension of the microdrops far exceeds that observed in previous experiments.

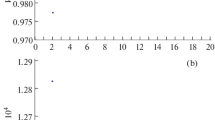

By way of example, Fig. 2 plots the ratio between the drop’s semiaxes against magnetic field strength. It is seen that the critical field is only several times higher than the geomagnetic field. Remarkably, the critical field also depends on the size of microdrops, since the process of deformation is governed by the balance between capillary and magnetic forces. Because of this, the critical field decreases for coarse microdrops and rises in the case of fine microdrops (Fig. 2). As was discovered in experiments, coarser microdrops deform only under the action of the geomagnetic field (Fig. 1). It should be noted that when taking the curves shown in Fig. 2, the magnetic field of Helmholtz coils was aligned with the horizontal component of the geomagnetic field. It is also noteworthy that magnetic fluid drops placed in a permanent magnetic field may deform in a hysteresis-like manner [10]; that is, the drop’s shape upon growing and subsequently reducing the field differ. This effect was observed in the given study as well, but its quantitative characterization was difficult to perform because of the influence of the geomagnetic field. Therefore, its consideration is omitted here.

In a magnetic field rotating in the horizontal plane coincident with the plane of observation, three drop deformation modes were revealed. When the frequency and strength of the rotating field are low (several hertz and <1 kA/m, respectively), drops rotated in the field direction, remaining extended (prolate). With an increase in the frequency and/or the strength of the rotating field, microdrops took different intermediate shapes (Fig. 3). As the field strength rises further (>5 kA/m), they took the shape of an oblate (in the field plane) ellipsoid of revolution (thin disks) irrespective of the field frequency (Fig. 3). It should be noted that if several microdrops are closely spaced, magnetic interaction between them almost instantly causes their coalescence with the formation of one large drop. As a result, their joint motion in the magnetic field (like that described elsewhere [20]) was not observed in our case.

The behavior of microdrops was also investigated under the joint action of rotating and stationary magnetic fields. First, a uniform rotating magnetic field was switched on and microdrops took the form of an oblate (in the plane of rotation) ellipsoid (disk). Then, an additional (quasi-stationary) vertical magnetic field was applied normally to the plane of rotation. In this case, wave perturbations were observed on the surface of microdrops (Fig. 4). With a further rise in the vertical field strength, the perturbations transformed into large crests propagating over the drop’s surface. Their growth caused disintegration of drops into many fine rotating droplets.

DYNAMICS OF MACRODROPS OF A MAGNETIC FLUID CONTAINING MICRODROPS OF A CONCENTRATED PHASE

To study the dynamics of a magnetic fluid macrodrop with concentrated phase microdrops inside, it was placed on a water surface and took an oblate form. The whole system was subjected to a magnetic field rotating in the horizontal plane. The apparent diameter of the drop was 3 mm. The rotation frequency of the macroscopic drop was measured as a function of the frequency and strength of the external field. The strength of the magnetic field was insufficient for changing the drop’s shape, so that the drop rotated owing to the rotation of internal concentrated phase microdroplets. To determine the rotation frequency of the drop, a number of aluminum dust particles were put on its surface. Figure 5 plots the rotation frequency of the drop versus magnetic field frequency. It is seen that when the frequency of the rotating magnetic field rises, the rotation frequency of the drop also rises. However, after the field frequency reaches a certain value, the rotation frequency of the drop starts to decline. Presumably, concentrated phase microdrops present in the magnetic fluid are first (at low frequencies) extended along the field and then, as the frequency rises, take intermediate and disk-shaped configurations. As a result, the rotation moment they impart decreases.

Figure 6 shows the experimental dependences of the rotation frequency of the magnetic fluid macrodrop against magnetic field strength. The curves are seen to be nonmonotonic, which may also be associated with microdrop morphology modification with increasing field.

RESULTS AND DISCUSSION

Consider a simplified rotation mechanism of a magnetic fluid drop containing concentrated phase microdroplets. If it is assumed that the microdroplets do not interact with each other and rotate independently, their contributions to rotation are summed in proportion to their concentrations [21]. For rotation frequency f0 of a magnetic fluid spherical drop placed in a nonmagnetic fluid, we have f0 = η1/η2 f1φ, where f1 is the rotation frequency of a single microdroplet, η1 is the viscosity of the external (nonmagnetic) fluid, and η2 is the viscosity of the medium surrounding the microdroplet. Rotation frequency f1 of a single microdroplet can be estimated by the formula [11]

where ffield is the magnetic field frequency, H is the magnetic field strength, τB is the magnetization relaxation time, χ is the magnetic susceptibility of the microdrop, and nd is the demagnetization form factor of the drop, α = 0.65. It is seen that when the frequency and strength of the rotating magnetic field rise, the rotation frequency of the drop containing concentrated phase microdroplets is expected to rise as well, which is really observed in initial portions of the experimental dependences (Figs. 5, 6). It should be noted that quantitatively the experimental data and calculation results differ markedly (Figs. 5, 6), since the latter were obtained in a rough approximation.

In addition, the above consideration disregards reconfiguration of drops and the intricate variation of their shape (see the first part of this paper). It is these processes that are responsible for the nonmonotonic run of the curves in Figs. 5 and 6. Detailed analysis of these processes is difficult and goes beyond the scope of this study.

CONCLUSIONS

In this paper, we studied a new magnetic-colloid-based composite medium representing a suspension of microdrops that contain a high concentration of a magnetic material and are capable of responding to very weak external magnetic fields. Variation of the shape of such microdrops in stationary and rotating magnetic fields was studied. Possible shapes of the microdrops were found. The occurrence of a macroscopic rotation moment that acts on a magnetic fluid macrodrop containing concentrated phase microdrops in a rotating magnetic field was demonstrated. The frequency of macroscopic drop rotation was measured as a function of magnetic field strength and frequency. The results may be helpful for solving the problem of controlling small volumes of liquid by means of external force fields.

REFERENCES

S. Afkhami, A. J. Tyler, Y. Renardy, M. Renardy, T. G. St Pierre, R. C. Woodward, and J. S. Riffle, J. Fluid. Mech. 663, 358 (2010).

A. V. Lebedev, A. Engel, K. I. Morozov, and H. Bauke, New J. Phys. 5, 57.1 (2003).

V. I. Drozdova, Yu. N. Skibin, and V. V. Chekanov, Magnetohydrodynamics 17, 320 (1981).

N. T. Nguyen, A. Beyzavi, K. M. Ng, and X. Huang, Microfluid. Nanofluid. 3, 571 (2007).

A. Zakinyan, O. Nechaeva, and Yu. Dikansky, Exp. Therm. Fluid Sci. 39, 265 (2012).

N. T. Nguyen, Microfluid. Nanofluid. 12, 1 (2012).

A. Zakinyan, E. Tkacheva, and Y. Dikansky, J. Electrost. 70, 225 (2012).

A. Zakinyan, E. Beketova, and Y. Dikansky, Microfluid. Nanofluid. 21, 88 (2017). https://doi.org/10.1007/s10404-017-1924-5

Yu. I. Dikansky and A. R. Zakinyan, Tech. Phys. 55, 1082 (2010).

J. C. Bacri and D. Salin, J. Phys. Lett. 43, L-179 (1982).

J. C. Bacri, A. Cebers, and R. Perzynski, Phys. Rev. Lett. 72, 2705 (1994).

E. Janiaud, F. Elias, J. C. Bacri, V. Cabuil, and R. Perzynski, Magnetohydrodynamics 36, 301 (2000).

O. Sandre, J. Browaeys, R. Perzynski, J. C. Bacri, V. Cabuil, and R. E. Rosensweig, Phys. Rev. E 59, 1736 (1999).

A. V. Lebedev and A. F. Pshenichnikov, Magnetohydrodynamics 27, 4 (1991).

A. Chaves, M. Zahn, and C. Rinaldi, Phys. Fluids 20, 053102 (2008).

I. Torres-Diaz, A. Cortes, Y. Cedeño-Mattei, O. Perales-Perez, and C. Rinaldi, Phys. Fluids 26, 012004 (2014).

S. Melle, O. G. Calderón, G. G. Fuller, and M. A. Rubio, J. Colloid Interface Sci. 247, 200 (2002).

M. I. Korobov, M. A. Bedzhanyan, O. V. Borisenko, and Yu. I. Dikansky, Exp. Therm. Fluid Sci. 85, 69 (2017).

A. Kolesnikova and A. Zakinyan, Magnetohydrodynamics 54, 45 (2018).

C.-Y. Chen, H.-C. Hsueh, S.-Y. Wang, and Y.-H. Li, Microfluid. Nanofluid. 18, 795 (2015). https://doi.org/10.1007/s10404-014-1472-1

N. Pannacci, E. Lemairea, and L. Lobry, Eur. Phys. J. E 28, 411 (2009). https://doi.org/10.1140/epje/i2008-10435-y

ACKNOWLEDGMENTS

This study was supported by the Ministry of Education and Science of the Russian Federation (project no. 3.5822.2017/8.9) and the Russian Foundation for Basic Research (project no. 18-03-00279a).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by V. Isaakyan

Rights and permissions

About this article

Cite this article

Dikanskii, Y.I., Bedzhanyan, M.A., Kolesnikova, A.A. et al. Dynamic Effects in a Magnetic Fluid with Microdrops of Concentrated Phase in a Rotating Magnetic Field. Tech. Phys. 64, 337–341 (2019). https://doi.org/10.1134/S1063784219030113

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1063784219030113